10 Difference Between One way and Two way Slab | What Is the Slab | What Is a One Way Slab | What Is Two Way Slab

Table of Contents

What Is the Slab?

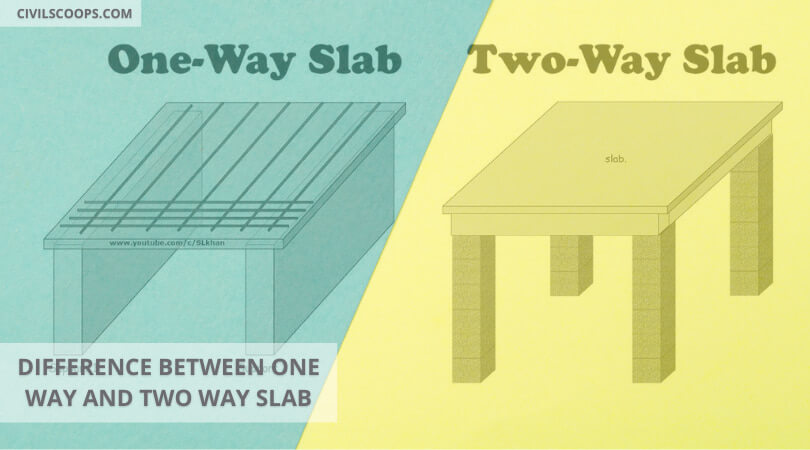

A slab is an important structural feature that provides flat surfaces in buildings. Slabs are commonly categorised as one-way or two-way based on the reinforcement offered, beam support, and span ratio. The former is endorsed on both ends, and the long-to-short time ratio is greater than two.

The above, on the other hand, is supported on four sides and has a longer to shorter time ratio that is less than two. Slabs may have a variety of shapes and support conditions. They are graded as one-way or two-way slabs based on their load-carrying action.

What Is a One Way Slab?

A one-way slab is one that is reinforced by parallel walls or beams on two opposite sides to bear the load in just one direction. Because of its geometry, a one-way slab is designed for the spanning path only, since it bends in only one direction. The shorter side of a slab from which load is passed is known as a span.

What Is Two Way Slab?

A two-way slab is one that is supported on both sides by walls or beams, has a length to width ratio just under two, as well as twists or bends throughout all directions when moving loads to the walls or beams.

Also Read: Low Income Roofing Assistance

One Way Slab Vs Two Way Slab

Differences between one-way and two-way slabs are as follows.

1. One Way Slab Vs Two Way Slab: Reinforcement

Reinforcement of one way slab: In a one-way slab, one side is wider than the other, and the entire weight is borne by the larger side, so providing main support in comparison to the load-carrying side is sufficient.

The key reinforcing bar is placed perpendicular to the greater side or parallel to the shorter direction to provide sufficient protection. Distribution bars are given in the longer direction, which would not aid in load carrying.

Reinforcement of two way slab: The steel along the shorter stretch forms the primary reinforcement, which forms the bottom layer, and the steel along the longer span forms the secondary reinforcement, which forms the top layer of the mat. It is supported only opposite the primary reinforcement, which forms the topmost layer, and the secondary reinforcement, which forms the bottom layer of the net.

2. One Way Slab Vs Two Way Slab: Loading

Loading on one way slab: Loads are transported in a single direction in a one-way slab.

Loading on two way slab: In two-way slabs, loads are transported in both directions.

3. One Way Slab Vs Two Way Slab: Support

One way slab support: A one-way slab is backed by parallel walls or beams with a length to breadth ratio of two or greater (L/B2).

Two way slab support: A two-way slab is usually protected on both sides by walls or beams, or sometimes three sides by beams, with a length to width ratio less than two (L/B2).

4. One Way Slab Vs Two Way Slab: Bending

One-way slab bending: When passing loads to the opposite supporting walls or beams, a one-way slab bends or deflects in a direction perpendicular to the supporting sides.

Two-way slab bending: Passing loads to the walls or beams, two-way slabs bend or deflect in all directions.

5. One Way Slab Vs Two Way Slab: Design

Design of One way Slab: Since the path is straightforward, one way slabs are the simplest to design. They are often constructed as a series of beam strips spanning in one direction. One-way slabs are built-in per metre strips for ease of use.

A structure consisting of only one panel sitting against a wall is studied and constructed as a clearly supported beam of 1m diameter. The depth of the slab is determined by the depth of the beam. As a continuous beam of a board, continuous slabs and continuous over supports in one direction are constructed.

Under self-weight and uniform pressure loads, the maximum moment of a simply assisted slab is at mid-span. Bottom reinforcing will be used in the design and will be delivered in a shorter direction.

Minimum shrinkage reinforcement in the opposite direction should be given. UDL’s maximum architecture moment will be WL2/8. Special considerations must be made to keep deflections under acceptable limits as specified by the design code. Deflection Limiting guarantees consumer convenience and reduces vibrations.

Design of Two way Slab: Two-way slab analysis is not as straightforward as one-way slab analysis. For analysing two-way slabs, there are numerous manual and computer analysis methods available. Due to the fact that the slab stretches in both directions, design reinforcing is given in both directions.

The following are manual research methods:

- Direct design method.

- Equivalent frame method.

- Yield-line method.

- Moment Coefficient Method.

The moment coefficient form is the most commonly used of these. This is due to the ease of review and the dependability of the data. Shear and moment tables The Reynolds handbook is mostly used in manufacturing. Moments and shear forces are determined explicitly here by multiplying load by a coefficient based on panel support conditions and period ratios.

Design strengthening in both directions is needed for two-way slabs. Bottom reinforcement is given in the direction of a maximal moment in single discontinuous panels, and second layer reinforcement is provided in the opposite direction. Hogging reinforcement is given as the top layer for slabs that are continuous over supports to ensure optimum hogging moment.

6. One Way Slab Vs Two Way Slab: Detailing

Detailing of One way Slab: Since the design of oneway slabs is similar to that of beams, the position of the design bar is also similar to that of a wall. The bottom face of the pattern is reinforced in the shorter or sweeping path. If the slab thickness exceeds 200mm, a single layer of reinforcement is sufficient. To meet reliability standards, a 50mm cover is retained. When slabs are persistent, top over supports are reinforced by hogging. The bars are extended past the plan segment by an anchorage length.

Detailing of Two way Slab: Reinforcement in both ways is structural design reinforcement in the case of two-way slabs. Maximum specification reinforcement and minimum code reinforcement criteria are given in both directions. A mesh reinforcement is provided for a simply assisted two-way slab to avoid bending in both directions. Hogging reinforcements are given at top over supports and bottom bars are curtailed in continuous slabs.

7. One Way Slab Vs Two Way Slab: Behaviour

One-Way Slab’s Behaviour: Owing to its own weight, a slab supported on both sides by masonry walls/beams is likely to bend in the shorter direction. When exposed to floor loads, the same behaviour is predicted. The slab’s self weight is shared evenly by the walls on each side.

Two-Way Slab’s Behaviour: The slab is supported over four corners, and since it is merely supported, it can curve in both directions with maximal deflection at the slab’s base.

8. One Way Slab Vs Two Way Slab: Thickness

One-way Slab Thickness: The thickness of a one-way slab ranges from 100 mm to 150 mm depending on the deflection and span.

Two-way Slab Thickness: The thickness of two-way slabs ranges from 100mm to 200mm, based on span and deflection.

9. One Way Slab Vs Two Way Slab: Span

Span of One way Slab: The one-way slab is cost-effective up to a distance of 3.6 meters.

Span of two way Slab: For panel sizes up to 6m x 6m, a two-way slab is cost-effective.

10. One Way Slab Vs Two Way Slab: Application

Application of one way slab: Slabs of Chajja and Varandha.

Application of two way slab: Slabs used in the floor structure of multi-story buildings are known as two-way slabs.

How Do We Calculate a One Way or Two-Way Slab?

Both slab design procedures are as follows.

Design Procedure of One Way Slab

- Evaluate the live load based on the slab’s feature. For example, the live load of a slab for office use is 2.4 KN/m2 according to minimum construction loads for buildings and other structures.

- Determine the slab’s self-weight and apply it to the superimposed dead load, if available. The self-weight is proportional to the concrete unit weight multiplied by the thickness of the slab (h), which is calculated using Table-1 and the span volume.

- Determine the ultimate distributed load on the slab using the ACI 318-19 load combination equation.

- Determine the ultimate moment/applied moment (Mu) using appropriate structural analysis techniques such as the ACI coefficient process or calculations for situations such as cantilever or strictly supported slabs.

- Determine the effective depth (d), which is equal to the slab thickness (h), as well as the minimum (25 mm).

- calculate the maximum reinforcing ratio.

- Assume that there is a reinforcing ratio. It is advised to use 30% of the full reinforcing ratio.

- calculate effective depth from the assumed reinforcement ratio to determine if the minimum depth computed in Step-2 is sufficient.

- Assume a value for the rectangular tension block and then calculate the reinforcing field.

- Finally, insert the reinforcing area from Step 9 to quantify the rectangular tension block.

- Perform three experiments to determine the appropriate reinforcement ratio.

- calculate shrinkage and temperature reinforcing.

- predict spacing for both primary and secondary reinforcing calculated in Steps 9 and 10.

- Examine the slab’s shear ability.

d2 = (Mu)/(∅ρƒyb {1-[(0.59ρƒy) /ƒc]})

As = (Mu)/(∅ρƒy {d-[a/2]})

a = (Asƒy)/(0.85ƒcb)

Mu= Applied or ultimate moment

ρ = Reinforcement ratio

b= Width of slab strip which is 1m.

As= Area of reinforcement, mm2

a = Depth of rectangular stress block, mm

Design Procedure of Two Way Slab

- Determine the form and layout of the slab.

- Select a slab thickness that is sufficient to prevent undue deflections and accommodate shear at internal and exterior columns.

- Select a design process

- Determine the positive and negative moments in the slab.

- Distribute moments across the breadth of the slab.

- If beams are present, specify a portion of their moments.

- Compute reinforcements for moments discovered in the preceding two stages.

- Examine shear power

[box title=”FAQ” style=”default” box_color=”#f2f2f2f2″ title_color=”#4c64c9″ radius=”3″]

What Is the Slab?

A concrete slab is a common structural element of modern buildings, consisting of a flat, horizontal surface made of cast concrete. Steel-reinforced slabs, typically between 100 and 500 mm thick, are most often used to construct floors and ceilings, while thinner mud slabs may be used for exterior paving.

What Is a One-Way Slab?

One way slab is a slab which is supported by beams on the two opposite sides to carry the load along one direction. The ratio of longer span (l) to shorter span (b) is equal or greater than 2, considered as One way slab because this slab will bend in one direction i.e in the direction along its shorter span.

What Is Two-Way Slab?

Two–way slabs are slabs that are supported on four sides. In two–way slabs, the load will be carried in both directions, thus main reinforcement is provided in both directions for two–way slabs. The slabs are considered as spanning two–way when the longer to shorter span length is less than a ratio of two.

How Do We Calculate a One Way or Two-Way Slab?

If L/b ratio is greater than or equal 2 or then it is considered a one–way slab. If L/b ratio is less than 2 then it is considered a two–way slab.

One Way Slab and Two Way Slab

The one–way slab is supported by a beam on two opposite side only. The two–way slab is supported by the beam on all four sides. In one–way slab, the load is carried in one direction perpendicular to the supporting beam. In two–way slab, the load is carried in both directions.

One Way Slab Vs Two Way Slab

The one–way slab is supported by a beam on two opposite side only. The two–way slab is supported by the beam on all four sides. In one–way slab, the load is carried in one direction perpendicular to the supporting beam. In two–way slab, the load is carried in both directions.

One Way Concrete Slab

One way slab is a slab which is supported by beams on the two opposite sides to carry the load along one direction. The ratio of longer span (l) to shorter span (b) is equal or greater than 2, considered as One way slab because this slab will bend in one direction i.e in the direction along its shorter span.

[/box]

Originally posted 2021-03-30 09:08:48.