What Is Bond Breaker | Purpose of Providing Bond Breaker | What Is Concrete Bond Breaker | What is Bond Breaker Tape

Table of Contents

What Is Bond Breaker?

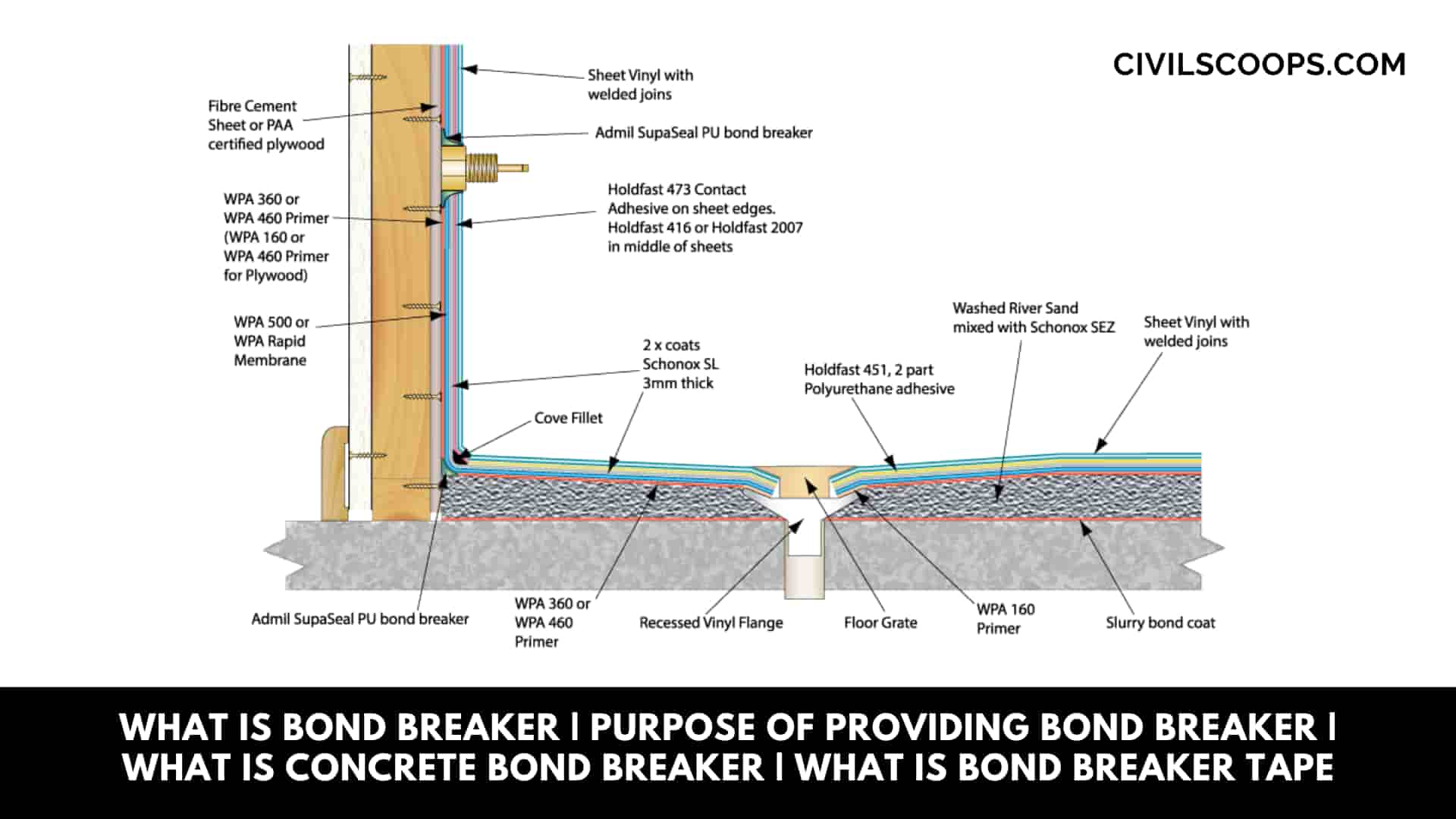

- Bond breakers are also used in breaking the bond between substrate and waterproofing membrane system, thus forming an adjustable bridge, resisting the movement of the water or moisture.

- Often a time, the importance of bond breaker as an inseparable part of the waterproofing system is being overlooked.

- If a bond breaker is not applied before the installation of a waterproofing membrane system, there are high chances that the membrane will wear and tear, forming holes, which would allow moisture into the substrate below, rendering the whole purpose of waterproofing system pointless.

- They are also used to resists shrinkage cracks, which may appear on the concrete during casting, due to the unexpected evaporation of water from the concrete surface.

Purpose of Providing Bond Breaker

There is numerous purpose that a bond breaker should be provided on a surface, some of which are: Dynamic, working, or lifting load is the force that will be applied to the linear actuator while it is in motion.

Static load, also called the holding load, is the force that will be applied to the linear actuator when it is not in motion.

- The primary purpose of providing bond breaker in the surface is to reduce the dynamic loads acting on when the member is lifted.

There are two types of loads which generally works in concrete member(based upon nature) Static and Dynamic loads.

Static loads are which, who’s value is constant, and the amount of the dynamic loads, continually changes. Wind loads which act on lifting a precast member, are an example of dynamic loads.

When bond breakers are applied on a surface it substantially reduces the dynamic loads’ acts on the concrete, and also enables stripping of concrete members and permits their clean separation from casting slabs or molds.

- Many a time, while casting a concrete member, in prefabricating shops, cracks may appear due to the temperature and moisture fluctuations, depending upon the atmospheric condition.

This cracks may take from as simple hair cracks, which with time, propagates, eventually leading to failure of the concrete member.

When bond breakers are applied to the concrete surface, it eventually joins together with the old concrete surface and once the concrete is poured, they become inseparable.

Thus bond breaker is used to prevent cracks, which may appear in concrete surfaces due to temperature fluctuations.

- Bond breakers are also used in breaking the bond between the substrate and waterproofing membrane system, thus forming an adjustable bridge, resisting the movement of the water or moisture.

Often a time, the importance of bond breaker as an inseparable part of the waterproofing systemise being overlooked.

If a bond breaker is not applied before the installation of a waterproofing membrane system, there are high chances that the membrane will wear and tear, forming holes, which would allow moisture into the substrate below, rendering the whole purpose of waterproofing system pointless.

- They are also used to resists shrinkage cracks, which may appear on the concrete during casting, due to the unexpected evaporation of water from the concrete surface.

Materials Used in Bond Breaker

In the modern construction industry, as technology upgraded, a wide variety of bond breaker materials have been introduced. Bonds breaker materials are generally classified into several forms, they are

- Liquid.

- Spray.

- Rods.

- Tape.

#1. Liquid-

Liquid bond breakers are widely used nowadays as significant bond breaker materials. In some countries, petroleum-based materials have been in use.

Still, these chemicals also dramatically affect the characteristics of the concrete members, so this compound is not known in all countries.

#2. Spray-

Not very much in use. Liquid bond breakers are preferred over bond breakers in spray form.

#3. Rods-

Many a time, rods with a coating of certain chemical compounds, wife mesh, have been used as a bond breaker.

Not very much in use in the modern construction industry, due to the lack of professional knowledge and lack of evaluation of side effects.

#4. Tape-

They are also used widely. I have covered this topic, under “What is bond breaker tape “portion in the following.

Wax is also a popular bond-breaker material which is being used by many countries. Although the use of it includes certain drawbacks, it is still popular as a significant bond breaker material.

What Is Concrete Bond Breaker?

- A bond breaker is a substance applied to concrete surfaces to guarantee that there is permanent bonding between the surfaces.

- Bond breakers are normally used on tilt-up walls and precast segments to ensure the right pieces are cast together.

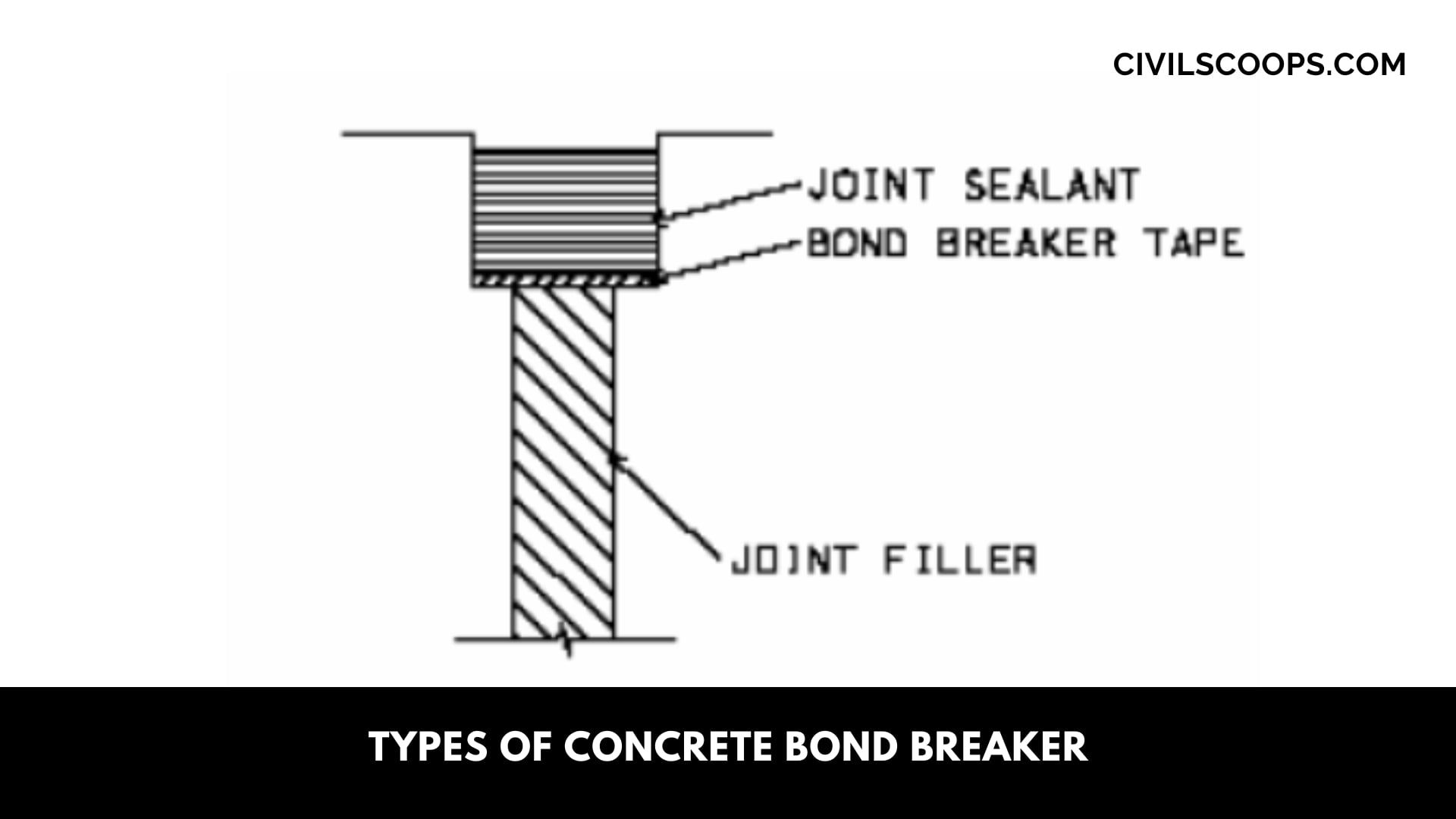

Types of Concrete Bond Breaker

The bond breakers can be broadly classified into two categories, such as

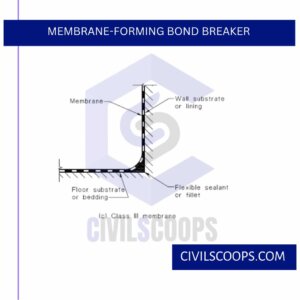

- Membrane-Forming Bond Breaker.

- Non-Membrane Forming Bond Breaker.

1. Membrane-Forming Bond Breaker

This type of bond breaker holds water into the casting slab. Whenever a casting of the slab is done, it requires an adequate quantity of water, so that the chemical reaction between cement and water can progress uninterruptedly.

Many time, due to evaporation and due to different atmospheric condition, there is a lack of water.

To prevent that for precast slabs, membrane-forming bond breakers are applied so that it can hold up the water, necessary for the chemical reaction. This type of bond breakers is made of crude resins.

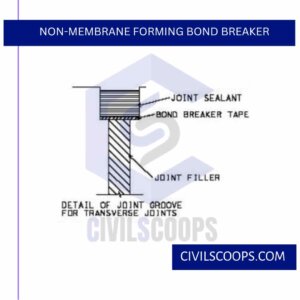

2. Non-Membrane Forming Bond Breaker

This type of bond breaker is opposite to that of the previous one. This type of bond breaker does not form a membrane which can hold up the water.

Non-membrane forming bond breakers are sub-divided into two categories

- Reactive.

- Non Reactive.

#2.1. Reactive-

- This type of bond breaker will react with water and form a crude soap

#2.2. Non-Reactive-

- This type of bond breaker will interact with the concrete surface and will create a waterproof film.

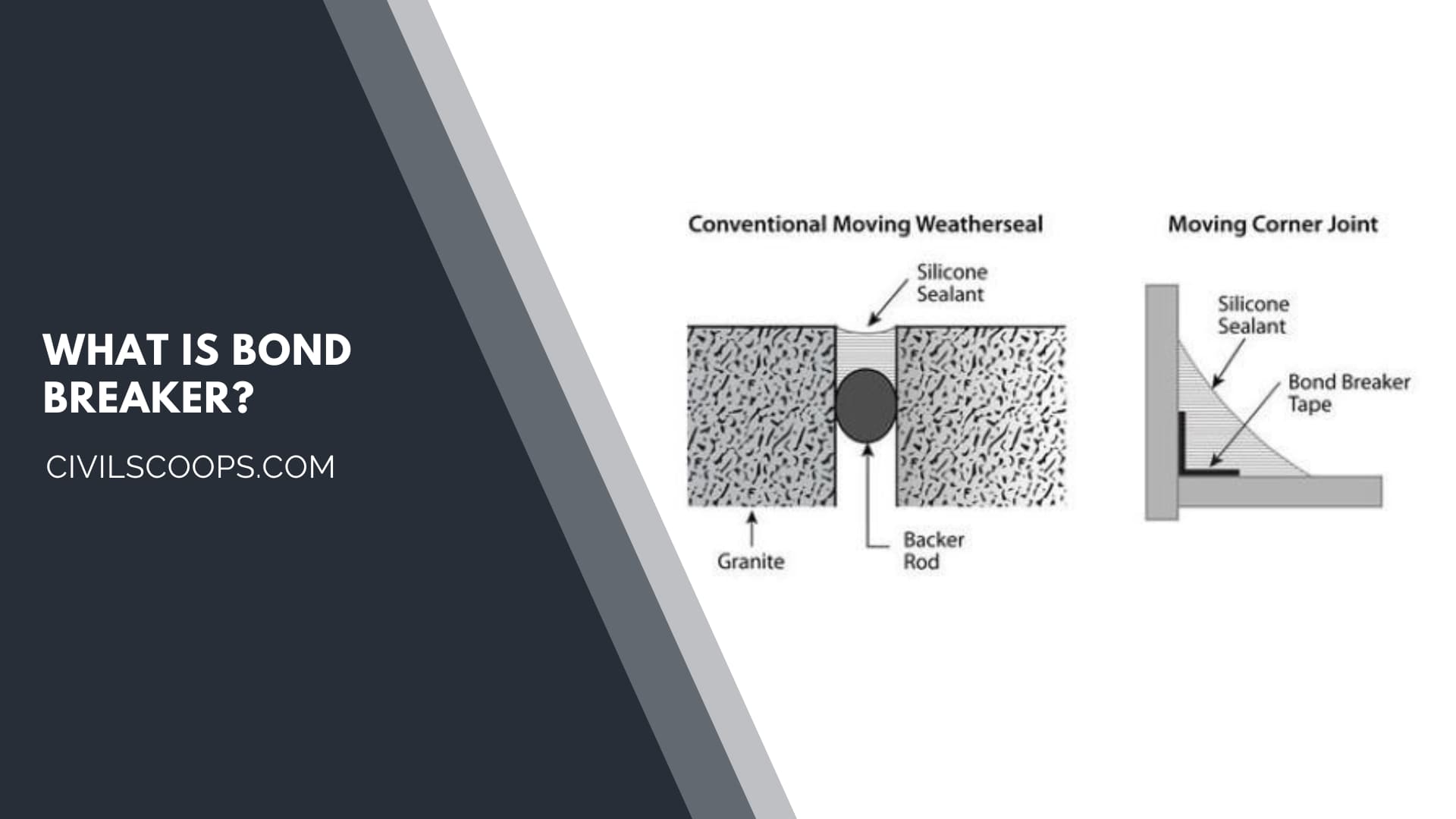

What is Bond Breaker Tape?

Bond breaker tape is self-adhesive polyethylene tape, having black color, which has comfortability hugely to irregular surfaces. Bond breaker tapes are used for isolating sealant and eliminating sealant adhesion to concrete and metal. Bond breaker tape stops the sealant from adhering to the surfaces and prevents three-sided adhesion.

To prevent the sealant from adhering to the surfaces, bond breaker tape is applied along the whole width/length of the base of the joint.

Bond breaker tapes are available in following width:15mm, 20mm, 25mm, 50mm.

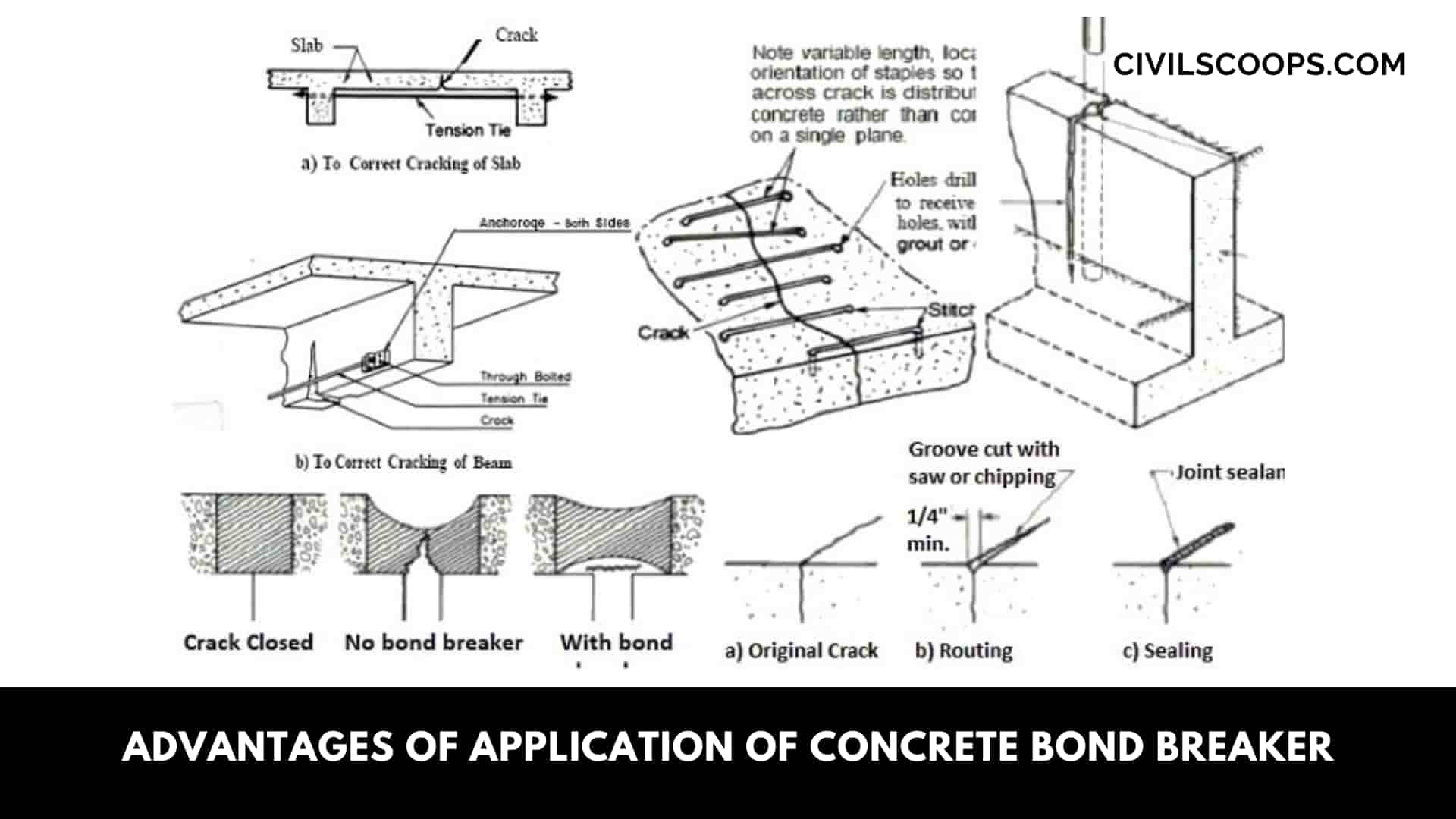

Advantages of Application of Concrete Bond Breaker

- Bond breaker tape reduces the amount of time to move loads. As the dynamic loads are substantially decreased, it takes less time and effort to carry a heavy load from one point to another.

- Bond breakers can be reused multiple times, which makes it a very cost-effective material for precast elements.

- It preserves the characteristics of the concrete surface, allowing them to be painted or modified using different architectural components, thus making the precast elects, visually appealing.

- Bond breaker does not affect the adhesion of epoxy (if applied), adhesive, and floor finishes.

Bonding Concrete to Existing Concrete

- A bond breaker literally breaks the bond between the substrate and waterproofing membrane to create an elastic ‘bridge’ that can stretch as buildings flex and move.

- The bond breaker is applied in joints where walls meet floors or two walls meet in a corner. They are also used over movement joints.

Bond Breaker Concrete

A bond breaker is a substance applied to concrete surfaces to guarantee that there is permanent bonding between the surfaces. Bond breakers are normally used on tilt-up walls and precast segments to ensure the right pieces are cast together.

What Is Bond Breaker Tape?

3M™ Bond Breaker Tape 8891 is a black polypropylene tape that provides a unique. way to break the bond of sealant between the cement joints. The tape does not allow the sealant to adhere to the tape backing allowing the sealant joint to only adhere to the two cement sides. Construction.

What Is Bond Breaker Tape Used For?

Used in joint sealing applications, Bond Breaker Tape stops joint sealants from adhering to surfaces and preventing “3-sided adhesion” which limits the ability of the sealant to accommodate movement. Bond breaker Tape is black self-adhesive polyethylene tape that has excellent conformability to irregular surfaces.

What Is a Bond Breaker in Waterproofing?

Bond Breaker Between Concrete Pours

Bond Breaker Tape for Sealant

Bond Breaker Tape is a polyethylene tape used to prevent 3-point adhesion in shallow caulk joints or joints where the backer rod cannot be used. This ensures the correct and uniform sealant depth along the whole length of the joint.

Concrete Bond Breaker Material

A geotextile bond breaker is a nonwoven, needle-punched fabric used between new concrete and an existing cementitious pavement layer. German engineers have been successfully using non-woven geotextiles as bond breakers for decades.

Types of Concrete Bond Breakers

Types of bond breakers can be flexible sealants like silicone or polyurethane, bond breaker tapes, fabric mesh, or foam rods.

What Is a Bond Breaker for Concrete?

Concrete bond breaker is a chemical which is used to stop concrete panels from sticking or bonding together when poured on top of each other. The bond breaker chemical forms a smooth membrane that allows concrete to be poured directly on top of another slab, without sticking.

[/su_box]

[su_note note_color=”#F2F2F2 ” text_color=”#333333″ radius=”3″ class=”” id=””]

Like this post? Share it with your friends!

Suggested Read –

- What Color Helps You Fall Asleep | Best Bedroom Colors for Sleep 2022

- What Is Superstructures | Difference Between Load-Bearing and Framed Structures

- Difference Between Fat Lime and Hydraulic Lime | What Is Fat Lime | What Is Hydraulic Lime

- Concrete Batching | Concrete Batching Plant | Types of Batching of Concrete | Various Factors Affecting the Choice of Batching System

- All About Waffle Slab Foundation | What is Waffle Slab Foundation | Waffle Slab Foundation Pros and Cons | Features of Waffle Slab Foundation

[/su_note]

Originally posted 2023-05-18 09:29:48.