Why Hairline Cracks in Concrete | Types of Cracks in Concrete

Table of Contents

Why Hairline Cracks in Concrete?

Hairline Cracks in concrete are extremely common but often misunderstood. Once an owner sees a crack in his slab or wall, especially if the concrete is relatively new, he automatically assumes there is something wrong.

This isn’t always this case. Some types of cracks are inevitable. Best that a contractor can do is try to control the hairline cracking. This is done by properly preparing this subase, assuring that the concrete isn’t too wet, utilizing reinforcement where needed, and by properly spacing and placing crack control joints and expansion joints.

But, sometimes cracks happen in spite of any precautions taken. In this ACI (American Concrete Institute) addresses this issue in ACI 302.1-04. “Even with the ideal floor designs and proper construction, it’s unrealistic to expect crack-free and curl-free floors.

Consequently, every owner Ought to Be advised by both the designer and contractor that It’s normal to expect some amount of curling ans cracking on every project, which such occurrence doesn’t necessarily reflect adversely on either the adequacy of the floor design or the quality of its construction.”

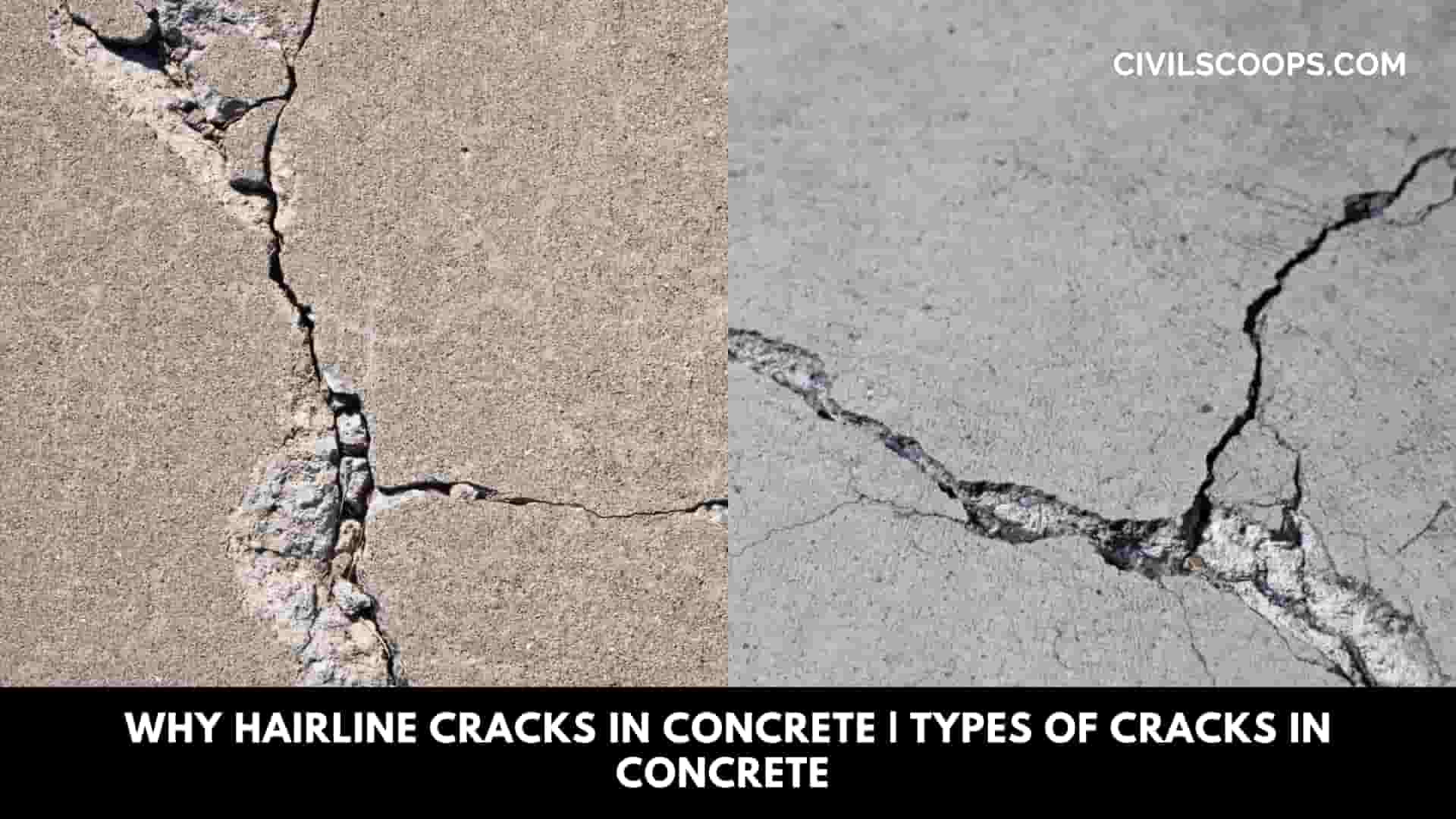

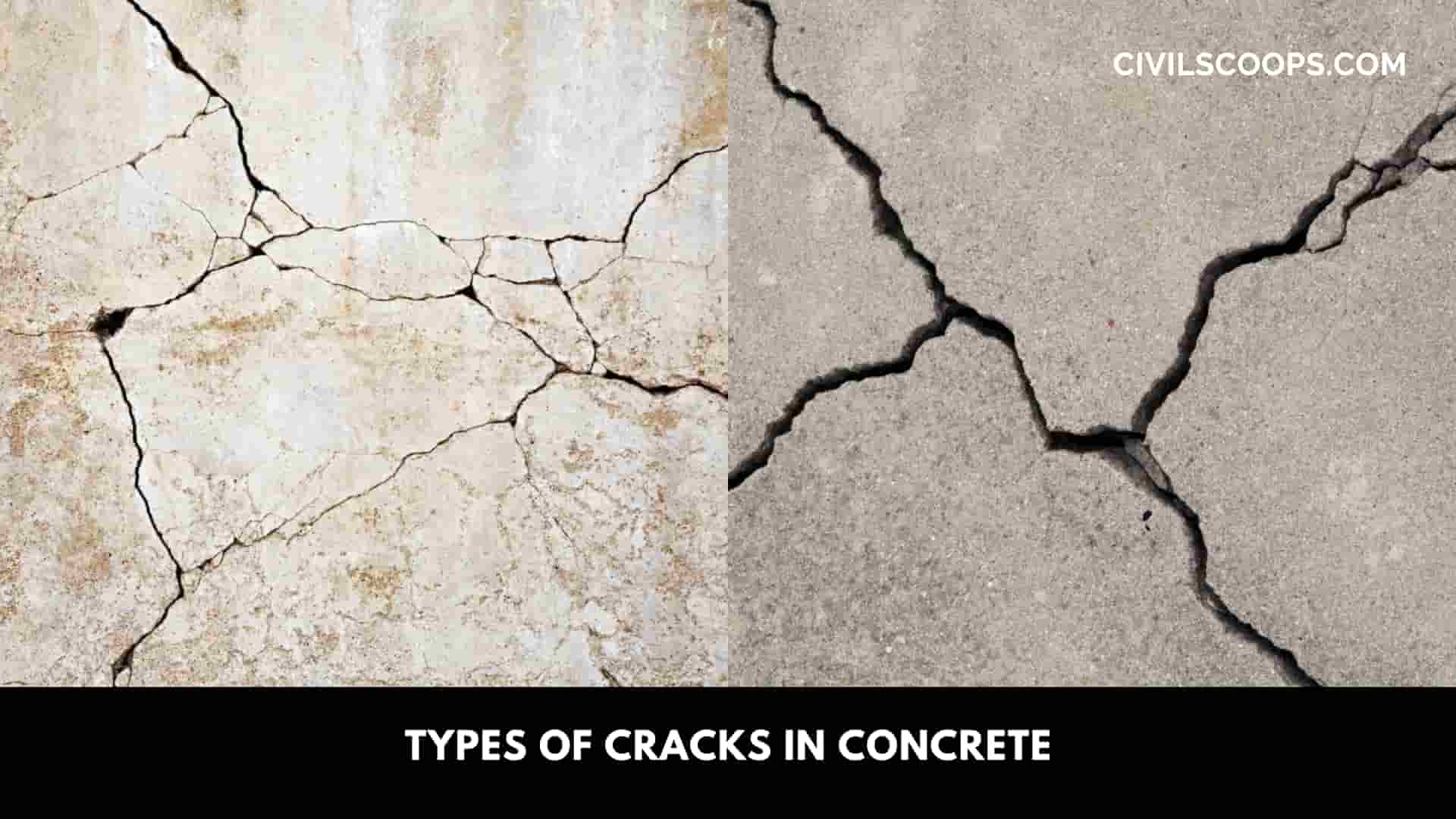

Types of Cracks in Concrete

- Shrinkage Cracks in Concrete.

- Hairline Cracks in Concrete.

- Settlement Cracks in Concrete.

- Temperature and Shrinkage Cracks in Concrete.

- Vertical Cracks in Concrete.

- Diagonal Cracks in Concrete.

- Horizontal Cracks in Concrete.

- Structural Cracks in Concrete.

- Floor Cracks in Concrete.

1. Shrinkage Cracks in Concrete

There are basically Nine types of everyday cracking. A first, and most common, is shrinkage cracking. When concrete is placed, it’s a liquid. You must keep it a liquid to get it to form the shape you want.

With the right water-cement ratio, you may get a liquid that flows. This makes it easier to push out of a pump or truck to an intended spot.

The amount of water added is tightly controlled. There’s a constant battle between the supplier that has promised the concrete will get into a certain hardness or strength, and the placement contractor whose job it is to get the wet gray material out to the middle of the slab and get it flat.

The supplier wants it drier because that helps achieve strength also placement contractor wants that mud wetter because it makes it much easier to get it into place.

The key point to understand in relation to cracking is that water is a certain percentage of the concrete mix. Any material which contains water will shrink as it dries and the water evaporates.

Concrete is no different. A typical 4″ (10 cm) slab will shrink at least 1/4 inch for every 100 square feet of surface space.

This shrinkage causes several issues. The two main ones are curling and breaking. In this article, we will only focus on cracking. As the shrinkage begins, the concrete will crack at which it is the weakest.

Cracking typically starts within 12 hours of this finishing process, but it may be slowed or accelerated by weather conditions. Shrinkage cracking is typically planned for and handled with control joints.

Control joints are designed cuts that go at least half-way through the thickness of the concrete slab.

All these are intended to cause weakness so that the concrete cracks along the bottom of this control joint, which releases the stress from the evaporating moisture. These joints are typically spaced evenly through a project.

I typically see control joint placement across a slab with the cuts forming squares, which are 10 x 10 or 15 x 15-feet wide.

If the spacing between these control joints is larger, even when the concrete follows the joint control pattern, you end up with extremely wide joints, which become harder to fill and maintain.

Over time with traffic, the edges of wide joints break easier, creating safety issues. Larger sections also have a greater chance to crack in unintended locations.

2. Hairline Cracks in Concrete

Hairline cracks can develop in concrete foundations as the concrete cures. Hairline cracks don’t cause problems with the stability of this foundation but do cause leakage problems.

If the cracks appear shortly after pouring a concrete foundation, concrete might have been mixed poorly or poured too quickly.

In poured concrete foundations, hairline crack frequently appears in the center of the walls because the wall corners have greater stability.

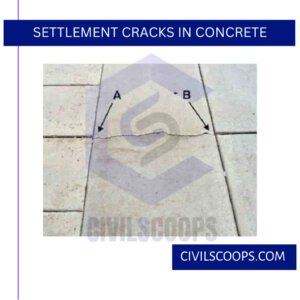

3. Settlement Cracks in Concrete

Settlement cracks might appear if the underlying ground hasn’t been compacted or appropriately prepared or when the subsoil wasn’t of the proper consistency.

A settlement crack could also appear as a random crack above areas where the soil of the subgrade was uneven after this concrete was poured.

Settlement cracks are generally more extensive in the top of the crack than the bottom as the foundation “bends” over a single point, allowing differential settlement.

This types of crack is usually continuous and might occur multiple times at a wall.

4. Temperature and Shrinkage Cracks in Concrete

Horizontal cracks found in the center of this wall are most likely due to an applied load like backfill around foundation compacted improperly or too soon, earth compacting as it settles, hydrostatic pressure against foundation due to the high water table and poor drainage against the foundation wall, or heavy equipment operated too close or too soon to the foundation wall.

Horizontal cracks found high up on the wall is most likely due to frost damage. Sometimes these fine cracks aren’t noticed for years. In a case such as this, a structural engineer should be consulted.

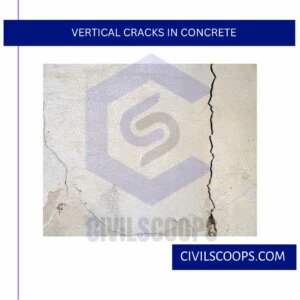

5. Vertical Cracks in Concrete

Vertical cracks often appear in multiples (multiple cracks in one or more areas). Vertical foundation cracks in poured concrete foundations that tend to appear nearly straight or to wander, normally even in width, intermittent, or more often straight is caused by shrinkage/thermal and are usually low risk.

When there’s significant vertical dislocation or signs of ongoing movement, you should consult a structural engineer. If the cause is shrinkage, it’s probably less of a concern than if because of settlement.

A vertical foundation cracks because of earth loading, or frost could be unusual. A more massive vertical crack may occur when the construction contractors incorrectly prepare a concrete footing, and when the wall had poor steel reinforcement as the workers poured the concrete to the wall. Cracks may also occur during the footing settlement.

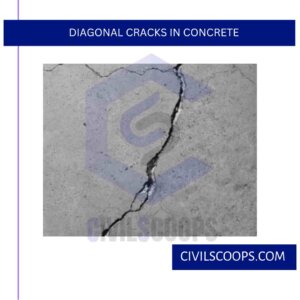

6. Diagonal Cracks in Concrete

Settlement generally causes diagonal cracks, which are almost the full height of the foundation wall. Whenever there’s a settlement problem with footing on one side of the wall, this settlement may also cause a diagonal crack. In a case such as this, a structural engineer ought to be consulted.

If the diagonal crack is wider at a top than at a bottom, then it can be caused by expansion clay soil or frost damage. If the crack is wider in the bottom than the top, there’s likely a problem with the settlement beneath.

Some uniform diagonal cracks are merely caused by shrinkage and will only cause water leakage problems. Diagonal cracks that emanate out of a corner of a window and other openings are known as reentrant cracks and are normally the result of stress built-up in the corner.

7. Horizontal Cracks in Concrete

Horizontal cracks found in the center of this wall are most likely due to an applied load like backfill around foundation compacted improperly or too soon, earth compacting as it settles, hydrostatic pressure against foundation because of the high water table and poor drainage against the foundation wall, or heavy equipment operated too close or too soon to the foundation wall.

Horizontal cracks found high up on this wall is most likely due to frost damage. Sometimes these fine cracks aren’t noticed for years. In a case such as this, a structural engineer should be consulted.

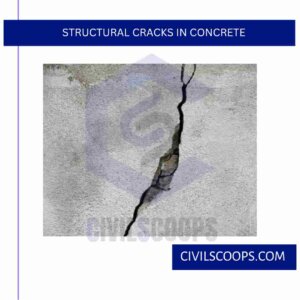

8. Structural Cracks in Concrete

Structural cracks in residential foundations normally result from horizontal loading or settlement.

Many (but not all) structural cracks caused by an applied load ( heavy equipment or hydrostatic pressure around foundation wall) are nearly horizontal and appear 16″ to 48″ in the top of the wall. They’re more common in block foundation walls.

Also Read: What Is Paint Finishes for Walls | Types of Paint Finishes | Types of Paint Finishing

9. Floor Cracks in Concrete

Floor cracks in concrete slabs are relatively usually and common, not worrisome on a structural level. They ought to be repaired to prevent common issues like moisture, insects, and damage from seeping through.

When floor cracks leak, it’s usually caused by hydrostatic pressure or a high water table. Thus, sealing the crack will redirect those issues elsewhere, so fixing the source of those problems beforehand is recommended.

[su_box title=”FAQ” style=”default” box_color=”#333333″ title_color=”#FFFFFF” radius=”3″ class=”” id=””]

Hairline Cracks in Concrete

Hairline cracks may develop in concrete foundations as the concrete cures. Hairline cracks do not cause problems with the stability of the foundation but do cause leakage problems. If the cracks appear shortly after pouring the concrete foundation, concrete may have been mixed poorly or poured too quickly.

Hairline Crack in Concrete Slab Foundation

A hairline crack in a concrete slab foundation is a common issue that many homeowners encounter. While hairline cracks are generally not a cause for immediate alarm, it is essential to monitor them and take appropriate action if necessary.

Hairline Crack in Foundation

Hairline cracks are common in new construction foundations across the country. They usually appear within one year and caused by the settling and drying of the new foundation. The good news is these cracks are usually cosmetic and can be repaired by DIY homeowners for ~$200 or professionals for $400-$600.

Hairline Foundation Crack Repair

- Clean the crack

- Prepare the crack for repair

- Choose a suitable repair material

- Apply the repair material

- Smooth and finish the repair

- Allow curing and drying time

What Is a Hairline Crack in Concrete?

Hairline cracks are commonly observed in freshly placed concrete and their occurrence is owed to the phenomenon of plastic shrinkage. As the name implies, these cracks are very small- about 0.003 inches (0.08mm) in width and can be very shallow.

Is It Normal to Have Hairline Cracks in Concrete?

Hairline cracks in a concrete slab are rarely a cause for concern. They can be controlled, but not eliminated. A crack in a slab of 1/8 inch or less is typically a normal shrinkage crack and not a cause for concern.

Types of Cracks in Concrete

Six Common Types of Cracks in your Concrete

- Plastic shrinkage concrete cracks.

- Expansion concrete cracks.

- Heaving concrete cracks.

- Settling concrete cracks.

- Concrete cracks caused by overloading the slab.

- Concrete cracks caused by premature drying.

How to Fix Hairline Cracks in Concrete?

How to Fill Cracks

- Chisel out the crack to create a backward-angled cut.

- Clean out any loose material from the crack.

- Apply a thin layer of bonding adhesive.

- Mix and trowel reinforced patching compound into the crack.

How to Fix Shrinkage Cracks in Concrete?

The Plastic shrinkage/Plastic Settlement may be repaired in plastic state by reworking the concrete surface using surface vibrators to close the cracks over their full depth and then completed by surface finishing.

How to Repair Settlement Cracks in Concrete?

Wide cracks in concrete are best patched and sealed with a concrete patching compound. Smaller cracks, less than 1/4 inch wide, can be repaired with a concrete caulk or liquid filler. Patching compounds typically are mixed with water and applied with a trowel.

How to Repair Horizontal Cracks in Concrete Foundation Walls?

Repairing horizontal cracks in concrete foundation walls requires careful attention, as they can indicate more serious structural issues.

- Assess the crack

- Stabilize the Foundation

- Prepare the crack for repair

- Inject epoxy or polyurethane

How to Fill Vertical Cracks in Concrete?

- Clean the crack

- Prepare the crack for repair

- Choose a suitable repair material

- Apply the repair material

- Smooth and finish the repair

Diagonal Foundation Cracks

It can be caused by the earth pushing against the basement wall and an inadequate connection (i.e. missing anchor bolts) between the basement wall and the first floor framing. Another type of diagonal crack can appear anywhere in the wall and is usually wider at the top and tighter at the bottom.

How to Fix Cracks in Concrete Walls?

Cracks in concrete walls can be repaired with a liquid or paste elastomeric compound. The compound is squirted into the crack with a bottle or forced into the crack with a putty knife. Cracks up to 1/2-inch wide and 1/4-inch deep, either interior or exterior, can be repaired this way.

How to Repair Cracks in Concrete Floor?

The best way to repair cracked concrete is to use an epoxy resin crack filler. Repairing cracks in concrete can be a key part of extending the life of the concrete and preventing further damage from occurring.

[/su_box]

[su_note note_color=”#F2F2F2 ” text_color=”#333333″ radius=”3″ class=”” id=””]

Like this post? Share it with your friends!

Suggested Read –

- What Is Paint Finishes for Walls | Types of Paint Finishes | Types of Paint Finishing

- What Is Brutalist Architecture | Brutalist Design | Brutalism Architects Buildings & Houses | What Is Neo-Brutalism

- 10 Principles of Architecture | What Is Architecture | Why Need Design Principles in Architecture

- Difference Between Marble and Granite | What Is Marble and How Is It Made | What Is Granite and How Is It Made

- What Is Bond Breaker | Purpose of Providing Bond Breaker | What Is Concrete Bond Breaker | What is Bond Breaker Tape

[/su_note]

Originally posted 2023-05-20 12:40:01.