What Is Slump Cone Test | Principle of Slump Test | Types of Concrete Slump

Table of Contents

What Is Slump Cone Test?

A Slump cone test or concrete Slump test is to determine the workability or consistency of the concrete mixture prepared in the laboratory or at the construction site during the course of work.

A concrete Slump test is performed from batch to batch to check the uniform quality of the concrete during construction.

The Slump test is the simplest test of workability for concrete, involves low cost, and provides immediate results. Due to this fact, it has been widely used for workability tests since 1922.

The Slump is performed according to the procedures mentioned in the ASTM C143 standard in the United States, IS 1199 – 1959 in India, and EN 12350-2 in Europe.

Generally, the value of the concrete loss is used to find workability, which indicates the water-cement ratio, but there are several factors, including material properties, mixing methods, dosing, additives, etc. also affect the amount of concrete loss.

Principle of Slump Test

The result of the Slump test is a measure of the behavior of a compacted inverted concrete cone under the action of gravity.

It measures the consistency or moisture of the concrete, which gives an idea of the workability of the concrete mixture.

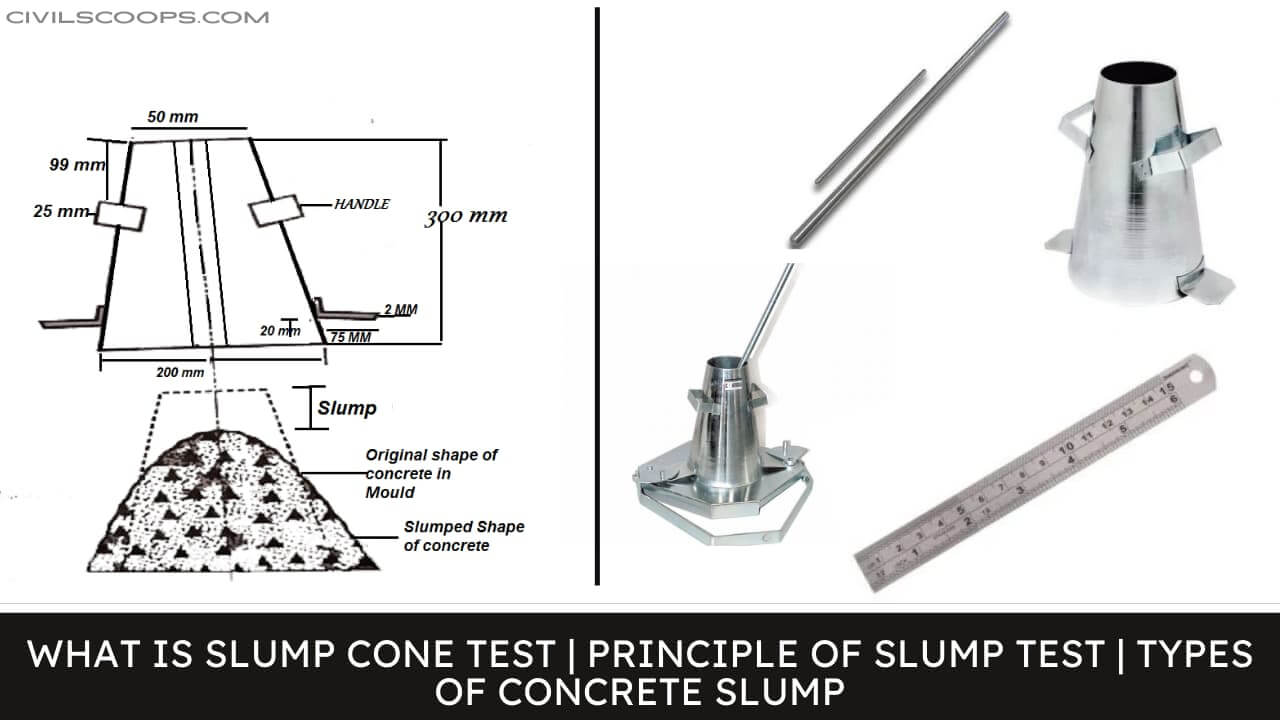

Slump Test Apparatus

- Slump Cone

- Scale for Measurement

- Temping Rod (steel)

Concrete Slump Test Procedure

- The mold for the concrete Slump test is a 300 mm high cone-shaped trunk. The base is 200 mm (8 in) in diameter and has a smaller opening at the top of 100 mm (4 in).

- The base is placed on a smooth surface, and the container is filled with concrete in three layers, whose workability must be tested.

Each layer is tempered 25 times with a standard 16 mm (5/8 in) diameter steel rod, rounded at the end. - When the mold is completely filled with concrete, the upper surface is reached (flush with the upper opening of the mold) through

the sieving and rolling motion of the quenching rod. - The mold must be held firmly against its base during the entire operation so that it cannot move due to concrete leakage, and this

- can be done through handles or footrests welded to the mold.

- Immediately after completing the filling and leveling the concrete, the cone is slowly and carefully lifted vertically. An unsupported

concrete will now Slump. - The decrease in the height of the center of the Slumped concrete is called a Slump.

- The Slump is measured by placing the cone just beside the Slumped concrete, and the quenching rod is placed over the cone so

that it also exceeds the area of the Slumped - The decrease in the height of the concrete in relation to that of the mold is observed in (usually measured up to the nearest 5 mm

(1/4 inch).

Precautions in the Slump Test

Concrete Slump Test To reduce the influence of Slumping variation in surface friction, the interior of the mold and its base must be moistened at the beginning of each test and, before lifting the mold, the area immediately around the base The cone must be cleaned of concrete that may have Slumped accidentally.

Types of Concrete Slump

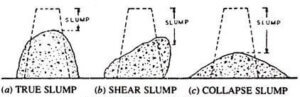

Slumped concrete takes various forms and, according to the profile of Slump concrete, the Slump is termed as;

- True Slump

- Shear Slump

- Collapse Slump

1. True Slump

In a real Slump, the concrete simply disappears, maintaining more or less the shape. This is the only Slump that is used in several tests.

Mixtures of rigid consistency show a Zero Slump, so that, in the very dry range, no variation can be detected between mixtures of different workability.

However, in a lean mixture with a tendency to roughness, a real Slump can easily change to the type of shear Slump or even collapse, and widely different Slump values can be obtained from different samples of the same mixture; therefore, the Slump test is not reliable for lean mixtures.

2. Collapse Slump

In a collapse Slump, the concrete Slumps completely. A collapse Slump generally means that the mixture is too moist or is a highly workable mixture, for which the Slump test is not appropriate.

This means that the water-cement ratio is very high, that is, the concrete mixture is very wet or is a highly workable mixture, for which a Slump test is not appropriate.

3. Shear Slump

In a sheer Slump, the top of the concrete cuts and slides to the side. Or

If half of the cone slides downward on an inclined plane, the Slump is considered a sheer Slump.

The sheer Slump indicates that the result is incomplete, and the concrete needs to be tested again to obtain valid results. If a shear Slump or collapse is achieved, a new sample must be collected, and the test is repeated.

If the shear Slump persists, as can happen with aggressive mixtures, this is an indication of a lack of cohesion of the mix.

Applications of Slump Test

The Slump test is used to ensure uniformity for different batches of similar concrete under field conditions and to verify the effects of plasticizers on their introduction.

This test is very useful on the spot, as checking the variation from day to day or hourly in the materials being fed into the mixer. An increase in a Slump may mean, for example, that the moisture content of the aggregate has increased unexpectedly.

Another cause would be a change in the classification of the aggregate, such as a sand deficiency. A very high or very low Slump gives an immediate warning and allows the mixer operator to resolve the situation.

This application of Slump tests, as well as its simplicity, is responsible for its widespread use.

[su_box title=”FAQ” style=”default” box_color=”#333333″ title_color=”#FFFFFF” radius=”3″ class=”” id=””]

Slump Test

The Slump Test is a neural tension test used to detect altered neurodynamics or neural tissue sensitivity.

Slump Test of Concrete

Concrete slump testing is a quick and easy procedure that can be performed in real-time and on-site that is used to determine the workability as well as the consistency of fresh concrete. Concrete with slump values that are too low or too high can be identified and corrected prior to use.

Slump Value

In case of a shear slump, the slump value is measured as the difference in height between the height of the mould and the average value of the subsidence.

Slump Cone Size

The American standards explicitly state that the slump cone should have a height of 12-in (300 mm), a bottom diameter of 8-in (200 mm) and an upper diameter of 4-in (100 mm).

Slump Test Apparatus

The Slump Cone apparatus for conducting the slump test essentially consists of a metallic mould in the form of a frustum of a cone having the internal dimensions as Bottom diameter: 20 cm, Top diameter: 10 cm, Height: 30 cm and the thickness of the metallic sheet for the mould should not be thinner than 1.6 mm.

[/su_box]

[su_note note_color=”#F2F2F2 ” text_color=”#333333″ radius=”3″ class=”” id=””]

Like this post? Share it with your friends!

Suggested Read –

- History of Remote Sensing | Application of Remote Sensing

- What Is Fresh Concrete? | Properties of Fresh Concrete | Factors Affecting Workability

- What Is Self Compacting Concrete | What Is U Box Test | Equipment U-Box Text | Procedure U-Box Text

- What Is Self Compact Concrete | What Is J-Ring Test | Equipment of J-ring Test | Procedure of the J-Ring Test

- Concrete Slump Test | Principle of Slump Test | What Is Slump Test ? | How to Measure Concrete Slump? | Slump Test Results | Concrete Slump Test Procedures |

[/su_note]

Originally posted 2022-07-03 07:40:05.