9 Curing of Concrete Methods | What Is Curing of Concrete | Why Curing Is Important | Minimum Curing Period for Concrete Cement | How Long Does It Take for Concrete to Dry

Table of Contents

What Is Curing of Concrete?

Curing performs a crucial role in the growth as well as the resilience of concrete strengths. Since applying water to that same concrete mixture there is an exothermic process that tends to toughen the concrete. Hardening of concrete also isn’t instantaneous yet lasts for a prolonged period of time, taking additional water to maintain hydration.

So, the concrete remained damp till the hydration process in the concrete had stopped. Such an approach is termed the curing of concrete.

Why Curing Is Important?

The activity within cement and water is referred to as hydration. That is an exothermic reaction. When applying water to just the conventional concrete, hydration occurs, which allows the concrete to dry off rapidly due to an exothermic reaction that produces heat.

In order to accomplish the hydration process, the concrete is moistened to reach the optimum workability of the material as quickly as practicable.

Also Read: What Is Concrete | 31 Different Types of Concrete

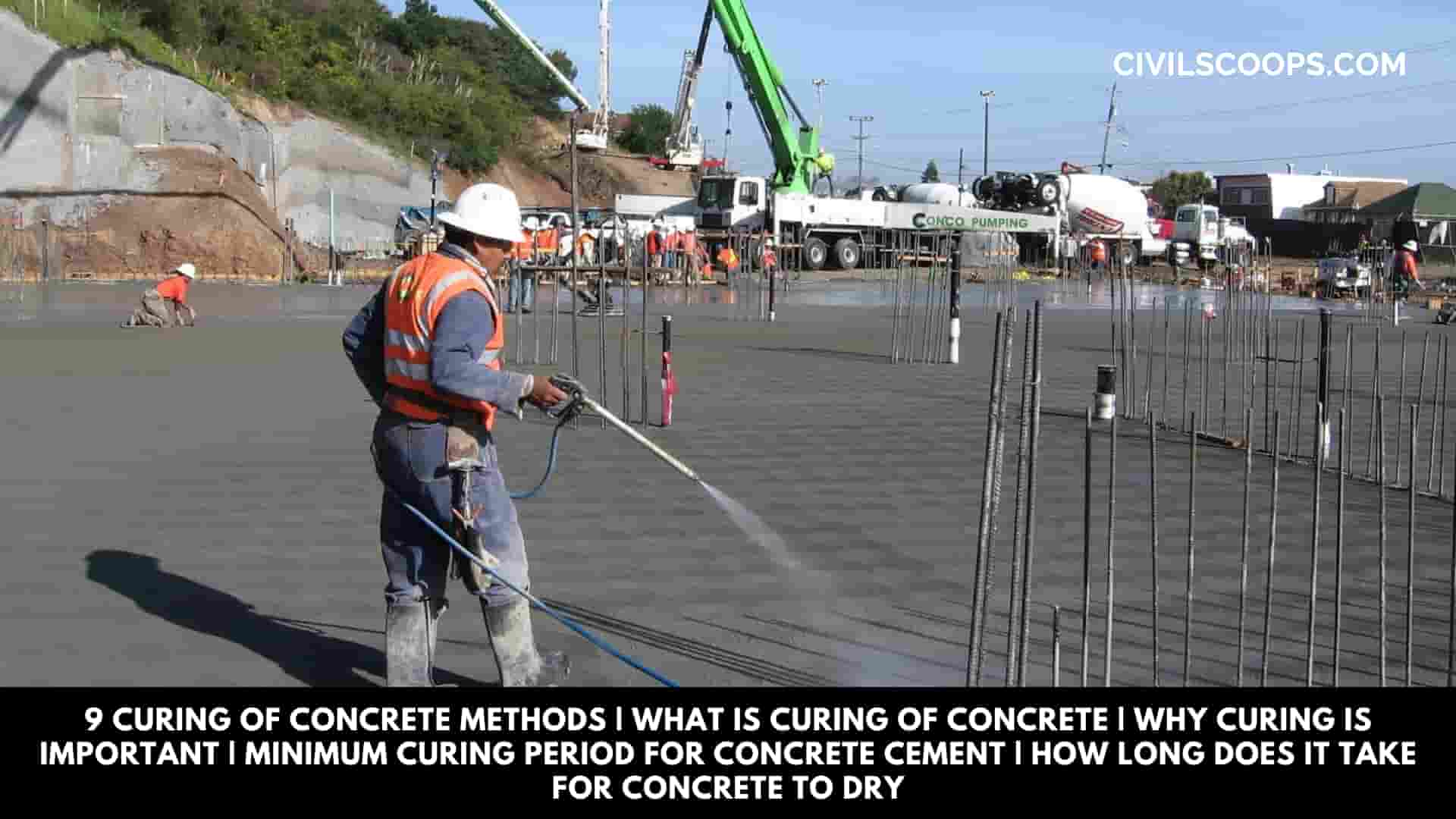

Method for the Cure of the Concrete:

The draining water mostly on the concrete surface is used to cure the concrete. Water colder than 50C isn’t really appropriate for the curing of concrete. As the hydration reaction in the concrete heats up and keeps the concrete hot, utilizing cold water only about 50 C mostly on concrete will contribute to cracking and failure.

Alternating drying as well as wetting on the concrete surface induces volumetric variations in concrete as well as eventually contributes to cracks.

Concrete Cure Time:

The required time for curing concrete to reach full strength is 28 days.

Minimum Curing Period for Concrete Cement:

The initial strength of concrete is perhaps the most significant and seems to be ready for the final strength of the concrete. People should be doing thorough curing by taking into account the ambient factors, the form of structural elements, and the air temperature.

Maintaining an appropriate temperature often performs a crucial function in concrete, which can not be cooler than 50C. Concrete shall be maintained moist for a minimum of 28 days.

This day, due mainly to shortage of time, the treatment can be accomplished with the use of advanced therapies in 14-20 days. However, it is still good to place concrete damp with at least 14 days.

According to IS 456 – 2000, concrete for OPC should not be cured for much less than 7 days, and that it should be cure during at least 10 days for concrete of minerals mixes or cement mixtures.

In the event of hot weather as well as arid environmental conditions, the curing time ought not to be just under 10 days for Portland cement as well as 14 days for concrete of mixed cement including mineral admixtures.

Its curing period of concrete shall depend on multiple factors:

- Relevant Concrete Strength.

- The grades in concrete.

- The temperature of the atmosphere.

- Related to the chemical reaction between cement and water in concrete, heat is released that needs water to achieve hydration. In summer, 50% of the water vanishes. So, extra water is necessary on sunny days.

- Width and shape of the member of the concrete.

Method Curing of Concrete

The types of Curing are as follows.

- Ponding.

- Moist Coverings.

- Membrane Curing of Concrete.

- Synthetic Resin Curing Compound.

- Acrylic Curing Compound.

- Wax Curing Component.

- Chlorinated Rubber Curing Compound.

- Steam Curing of Concrete.

- Curing of Concrete by Infrared Radiation.

#1. Ponding:

This approach has been adopted with floor slabs. Each concrete surface was separated through small ponds, yet these ponds were continually full of water for 14 days.

#2. Moist Coverings:

The said type of system is used for columns, pillars, as well as the lower part of the slabs, in which it is not feasible to measure. Waterproof coatings such as gunny bags or hessian have been used to protect the concrete; such membranes are filled with water and keep the concrete wet.

#3. Membrane Curing of Concrete:

Ponding isn’t really necessary in areas when ambient temperatures become high. Water evaporates by intense heat. Membrane curing is used to avoid the removal of moisture content from concrete depending on the climatic temperature.

Membrane curing tends to close off by creating an impervious coating on the concrete surface that gradually prevents evaporation. This process is normally done by scraping or spraying the curing agent on the concrete floor.

There are various curing compounds available to accomplish membrane curing, beyond which four factors are important and commonly used.

#4. Synthetic Resin Curing Compound:

Synthetic resin is indeed a substance that creates an impermeable membrane on even a concrete surface to survive water evaporation from concrete. For more plastering, the plastic resin membrane may be quickly dissolved by pouring hot water onto the concrete floor. It is only sufficient in locations where subsequent maintenance has been added to the concrete.

#5. Acrylic Curing Compound:

Acrylic Curing product is a based on polymer curing product derived from acrylic acid polymers. The biggest appeal of the acrylic-based curing agent is that it does not need to be removed for plastering. Acrylic helps preserve good durability in the plastering process.

#6. Wax Curing Component:

Wax curing provides common qualities to synthetic resin. Its use of wax on surfaces to also be painting or tiled also isn’t suggested since wax hampers the conductivity between both the ground as well as the plastering.

#7. Chlorinated Rubber Curing Compound:

Once placed, chlorinated rubber creates a dense layer on the concrete floor. To use a chlorinated rubber-based curing solution, the concrete is completely cured with no small particles remaining. However the lifespan of chlorinated rubber is much older, and this can survive indefinitely.

#8. Steam Curing of Concrete:

Such practice is used at the Precast Concrete Plants in which the concrete members are mass-produced. Steam has thermal humidity in it which is poured on the concrete surface to retain concrete moisture but also to change the temperature of the concrete, which also gradually accelerates the speed of the toughening of the concrete.

#9. Curing of Concrete by Infrared Radiation:

This approach is used in cold climate areas. Throughout this process, infrared radiation is introduced to the concrete, raising the original temperature and increasing the intensity of the concrete. This has been the most efficient method than steam curing, as increasing the initial temperature in concrete may not lower the final workability of concrete.

That methodology is used for hollow concrete components where even the heating systems are located in concrete components that produce a temperature of 900°C.

How Long Does It Take for Concrete to Dry?

The whole curing process of concrete may last only a month, concrete would be prepared to be used earlier. Every other design can vary a bit due to the variations in environmental conditions, concrete mixing, and positioning and finishing strategies.

Keep such timeframes in mind when awaiting for concrete to dry:

- 24 to 48 hours – following initial setting, forms could be eliminated and people could walk on the floor.

- 7 days- after limited healing, traffic between cars and machinery is perfect.

- 28 days – during that stage, the concrete must be completely healed.

Also Read: Difference Between Fat Lime and Hydraulic Lime | What Is Fat Lime | What Is Hydraulic Lime

How Long Does Cement Take to Dry?

The cement will dry in phases that will take around 30 days to finish. It requires 1 or 2 days for cement through dry for the person to cross, but 5 to 7 days until people can ride upon this.

- The temperature has a big influence on how easily cement finishes the healing process. Considerations along with rainfall, sunshine, wind as well as humidity are all determining significantly.

- Processing of freshly poured cement relies heavily on climatic conditions, as humidity fluctuations can trigger cracking when cement drying stage.

- Concrete can recover more and more if it has been fully dried gradually. Unless the circumstances are mild, it covers the cement with plastic.

- When temperatures are 80 degrees or higher, watering the garden hose also holds it damp and avoids cracking. Approximately 90% curing phase can be completed inside a right set of circumstances.

- Accelerator technologies seem to be on the market that can speeding up the processing. Accelerators are additives applied to a concrete mix which minimize the fixed process and increases the hydration factor.

- There is already Portland cement, which is formed and hardened by chemical reactions with water. The curing method is perhaps the most critical step towards the achievement of solid and sometimes even cement.

How to Cure a New Concrete Slab?

Allow time to completely cure the slab for at minimum 7 days following completion to achieve the best appearance on the new concrete slab as 28 days is ideal). Curing seems to be the method of regulating the frequency and degree of degradation of concrete moisture throughout cement hydration.

Curing plays a very important role in the production of strength and the longevity of concrete. This is achieved by constantly wetting the exterior surfaces while avoiding the lack of moisture. Unless the water evaporates so soon, the final product may be weakened by stress as well as cracking.

Sprinkle the slab with water as much as possible for the first 7 days following completion. When the asphalt has been poured, the healing process starts immediately.

Correctly curing the concrete increases strength, longevity, moisture resistance as well as resistance for several decades.

[su_box title=”FAQ” style=”default” box_color=”#333333″ title_color=”#FFFFFF” radius=”3″ class=”” id=””]

Curing of Concrete

Curing is the process of maintaining satisfactory temperature and moisture conditions in concrete long enough for hydration to develop the desired concrete properties. The potential strength and durability of concrete will be fully developed only if concrete is properly cured.

What Is Curing and Types of Curing?

Curing is the process to control moisture loss during hydration of cement. Hydration takes time – days, or even weeks rather than hours. To achieve its potential strength and durability, curing needs to be done for an ideal period of time. The reaction between cement and water is called hydration.

How Many Days Is the Curing of Concrete?

Concrete typically takes 24 to 48 hours to dry enough for you to walk or drive on it. However, concrete drying is a continuous and fluid event, and usually reaches its full effective strength after about 28 days. Here are some of the basic facts regarding the question of concrete drying and curing time.

What Is the Process of Curing Concrete?

Concrete curing is the process of maintaining adequate moisture in concrete within a proper temperature range in order to aid cement hydration at early ages. Hydration is the chemical reaction between cement and water that results in the formation of various chemicals contributing to setting and hardening.

Types of Curing

Methods of Curing Concrete

- Water Curing.

- Wet Covering.

- Formwork Curing.

- Membrane Curing.

- Sheet Curing.

- Curing by Absorbing Heat.

- Hot mixing method.

- Electrical curing.

Concrete Cure Time

It’s always recommended to follow the guidelines provided by the concrete manufacturer or consult with a structural engineer to determine the appropriate cure time for your specific project. Environmental conditions such as temperature, humidity, and air circulation can also impact the cure time, so it’s essential to consider these factors as well.

What Is Curing of Concrete?

Curing of concrete is a process that involves maintaining favorable conditions to promote hydration and proper hardening of the concrete. It is a critical step in the construction process and plays a vital role in achieving the desired strength, durability, and overall quality of the concrete.

How Long Does Concrete Take to Dry?

In general, concrete takes about 24 to 48 hours to dry to the touch. During this initial drying period, the concrete may still contain a significant amount of moisture within its interior, even though the surface appears dry. It is crucial to avoid applying any loads or subjecting the concrete to stress during this early drying stage.

How Long Does Cement Take to Dry?

The general rule of thumb is that concrete takes about 28 days to dry for every inch of slab thickness. Within 24 to 48 hours, the concrete will be ready for foot traffic.

Concrete Curing Time

The typical curing time for concrete is around 28 days. During this period, the concrete undergoes a series of chemical reactions known as hydration, where the cement particles react with water to form strong crystalline structures. As the hydration process progresses, the concrete gains strength and durability.

Fast Curing Concrete

How to Speed Up Concrete Drying

- Weather is a factor. If your concrete is exposed to the elements, you won’t be surprised to learn that the concrete will dry faster in warmer, sunnier conditions.

- Using a heater.

- Using warm water.

- Reducing the amount of water.

- Avoid hard trowelling.

Curing Process of Concrete

Concrete sets and hardens as a result of a chemical reaction between cementitious materials and water. This process is called hydration. Curing is the process of maintaining satisfactory temperature and moisture conditions in concrete long enough for hydration to develop the desired concrete properties.

Fast Setting Concrete Cure Time

As the name suggests, rapid-set concrete is a concrete mix which hardens faster than standard mixes. Whereas traditional concrete will harden within 48 hours, rapid-set concrete will harden within an hour.

Why Curing Is Important?

Curing helps to develop the concrete’s full strength and durability, which is critical for its longevity. Without curing, the abrasion resistance of the concrete surface may be compromised, leading to dusting and poor durability.

Cement Curing Period

The curing period for cement generally spans several days to weeks. During this time, the cement particles react with water in a chemical process called hydration. This reaction forms bonds that bind the aggregates together, resulting in the solidification and hardening of the concrete.

When Is Concrete Fully Cured?

By seven days, your concrete should be cured to at least 70 percent of its full strength. You will probably be able to drive on it without damaging it, although you may want to hold off on rolling heavy equipment over it. In 28 days, you can treat your concrete as fully hardened.

What Happens If Concrete Is Not Cured?

Poor curing of concrete leads to reduced durability, strength and abrasive resistance. When it comes to your dream home, the last thing you will want is to end up with a weak structure after putting in so much money, hard work, and time.

Why Curing Is Required for Concrete?

Curing plays a vital role in developing the dense microstructure and pore structure of concrete from the proper chemical reactions between cement compounds and water. It is crucial to prevent or control the moisture loss of concrete during cement hydration to ensure it attains the desired properties.

What Is the Minimum Curing Time for Concrete?

It is also recommended that the curing duration should not be less than 10 days for concrete exposed to dry and hot conditions and 14 days for concrete with mineral admixture.

What Is the Process of Concrete Curing Called?

This process is called hydration. Curing is the process of maintaining satisfactory temperature and moisture conditions in concrete long enough for hydration to develop the desired concrete properties. The potential strength and durability of concrete will be fully developed only if concrete is properly cured.

Why Is It Necessary to Cure Concrete?

Curing promotes the hydration process, allowing cement to chemically react with water and form strong bonds. Adequate curing enables concrete to reach its full design strength, enhancing its load-bearing capacity and structural integrity.

What Is the Best Way to Cure Concrete?

It involves wetting the concrete slab often with water (5-7 times per day) for the first 7 days. This method ensures your concrete slab will be extremely strong and durable, because it allows the moisture to evaporate slowly, preventing cracks and shrinks.

[/su_box]

[su_note note_color=”#F2F2F2 ” text_color=”#333333″ radius=”3″ class=”” id=””]

Like this post? Share it with your friends!

Suggested Read –

- Why Hairline Cracks in Concrete | Types of Cracks in Concrete

- What Is Brutalist Architecture | Brutalist Design | Brutalism Architects Buildings & Houses | What Is Neo-Brutalism

- Difference Between Marble and Granite | What Is Marble and How Is It Made | What Is Granite and How Is It Made

- Functions of Foundation | Requirements of Good Foundation | Types of Foundation | Types of Shallow Foundations | Types of Deep Foundations

- Introduction of Bamboo | Advantages & Disadvantages of Bamboo | Bamboo Uses in Construction | Properties of Bamboo as a Construction Material | Bamboo Architecture

[/su_note]

Originally posted 2023-05-24 13:35:00.