Different Types of Washers | When to Use Washers | How to Use a Washers | Shapes of Washers

Table of Contents

Introduction of Washers

A washer may be a disk formed plate (made of metal, rubber, or plastic) used to garrison the joints from ill-use through adjustment method and to disseminate the load equally below the bolt and nut (i.e., rib fasteners).

Generally, it operates as a spacer or seal. On the opposite hand, Bolt joins two surfaces. It possesses threads and a planate head.

Different Types of Washers

Here, three different types of washer are as follows.

- Plain Washers

- Spring Washers

- Locking Washers

Let’s look at more details for different types of washers.

1. Plain Washers

Plain washers which equally distribute the load through a wide area and prevent damage to the surface or provide insulation. By using it, the surface below the bolts or nuts becomes smooth.

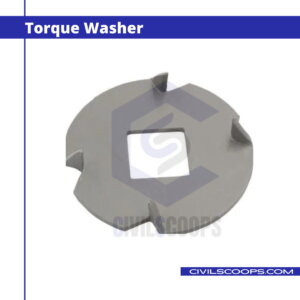

1.1. Torque Washer

These include a square shaped hole that prevents the bolt from spinning and therefore helps in the adjustment of it. They are usually utilized in carpentry.

1.2. Flat Washer

These are slender, flat, circular washer with a hole at the centre (ring-shaped). Except dividing the load equally, it conjointly provides support to little head screws. A flat washer is what the general public thinks about a standard washer. They are sensible for general use.

1.3. Fender Washer

These have a larger outer diameter (i.e., the opening at the centre is small). Except for dividing the load equally, they are conjointly used for automobile, plumbing, electrical functions, sign board flex, and banner fixing functions. It is sometimes a skinny metal. They are named for their general use of automobile fenders.

1.4. Finishing or Countersunk Washer (90°/120°)

These are used for the planate head is countersunk screws that provide a flush surface.

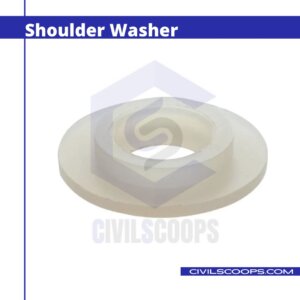

1.5. Shoulder Washer

These have a shoulder sort form. They’re in the main used for insulating electrical wires and are found in nylon, fibre-glass, PCTFE, PTFE, etc.

1.6. C-washer

These are used to slide in and out of bolt or shaft. These appear as if a flat washer, however, it’s a slot cut from the middle hole to create a “C” form.

The C-Washer used at any time may have to be adjusted or replaced while not removing the fastener.

2. Spring Washers

Spring washers that have axial flexibility and provide an axial load to fasteners to stop fastening or loosening from vibrations or shock.

There are many types of spring washers. Each has its own benefits. Single pattern spring washer, normal pattern spring washer, double pattern spring washer, grip pattern spring washer, and beam pattern spring washer are the structures of spring washer. They follow Hooke’s Law.

F=-kx

where

F= Load

x= Deflection/Displacement

k= Spring Rate/Spring Constant

2.1. Belleville or Conical Washer

These are helpful to produce strength throughout adverse thermal enlargement or contraction. They bear a little quantity of deflection, counting on height-thickness magnitude.

2.2. Dome Spring Washer

These have extreme load capability with very little deflection vary. They possess ground curves and have planate load-bearing surfaces. The dome spring washers are the same as a Belleville washer, however, with rounded sides.

2.3. Wave Spring Washer

These possess medium load capability, and deflection vary. They are usually used as cushion-springs and spacers. These kinds of washers rotate in 2 directions, forming a wave-like form.

2.4. Finger Spring Washer

These steel washers are used to handle noise, excess wear, vibrations as they decrease skidding wear. They possess a good balance between strength (well-distributed load points) and suppleness. The finger spring washers include three sickle-shaped flanges.

2.5. Crescent / Curved Spring Washer

These give support a little hundred by undergoing Brobdingnagian quantity of deflection. These have linear load-deflection options that compel them to be used for load athletics products.

These washers appear as if flat washers that are somewhat sickle-shaped to grant lighter pressure and maintain flexibility.

3. Locking Washers

Locking washers which garrison fastening or loosening by preventing unscrewing rotation of the fastening device. (Locking washers are sometimes also referred to as spring washers).

Thus, this washer garrison the nut & bolts from getting loose.

3.1. Helical/split Lock Washer

These provide further pre-load on screws, therefore leading to a shock-absorption method. Split lock washers are non-continuous rings that tilt every finish slightly outside in opposite directions.

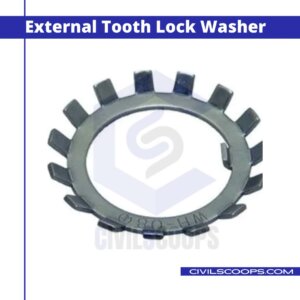

3.2. External Tooth Lock Washer

These are used to resist the loosening of wacky & bolts. They’re used in conjunction with head screws. Their teeth bite to a sexual union surface and forestall compression force.

The external tooth lock ring provides the most torsional resistance. It’s used to lock deep-headed fasteners into place.

3.3. Internal Tooth Lock Washer

These perform a similar action because of the previous one. Their teeth conjointly absorb vibration. It’s used to lock shallow-headed fasteners into place.

When to Use Washers?

Washers are units which are typically used once the bolt and nut fabrication isn’t tight enough. Washers will be used to increase the gap between the aluminium nut and also the item that’s placed along. This provides additional leverage to create it holds

additional tightly.

Apart from that, washers also can be used to create the fastening supplementary waterproof. For example, if you’re protecting the outpouring through the area between the merchandise and also the fastener, you may utilize a washer to seal it. However, this may only work if you utilize a top quality washer properly.

Threaded fasteners do a reliable ancillary job once assembled with washers. Most notably, washers defend the surface from injury throughout the installation. They distribute the pressure and forestall the fastener from moving or chemical processes.

Decreased application of washers might lead to a short life of your product once place along. Ultimately, that ends up in the holocaust for the merchandise itself.

How to Use a Washers?

- If you have decided to use washers when fastening a product, you should first make sure that it is of the right thickness.

- This often depends on what the washer needs to be done. For example, if you want to make sure that the assembly is as tight as

possible, you could use a thick washer. - In some cases, it may be necessary to use more than one washer to achieve this state.

- You can also apply some grease to the washer. This serves for multifarious purposes, including reducing the risk of corrosion as

well as making it easier to put the fastener in place. - Apart from that, putting some grease on the washer will also make it more water-resistant, which is important if you are interested

in using it to reduce leakage. - Measuring the correct washer size is also critical. Using one that is too small or too big may result in less than perfect results.

- For example, if you want to reduce leakage and use a very big washer, this could result in even more leakage as the space

between the fastener and the washer will be large.

Shapes of Washers

- Structural Washer– spherical or square with a high bearing surface cut at an associate degree angle.

- Conical/Spring Washer– spherical with concave edges parallel to the centerline

- Countersunk Washer– Spherical with a flat or oval head

- Fender Washer– Spherical with a giant outside diameter

- Flat Washer– Spherical or Square with a pair of flat surfaces

- Sealing Washer– Round & soft

- Slotted Washer– Spherical with a slot

- Spherical Washer– Spherical (2 Pieces- one flat & one disk-shaped)

- Split Lock Washer– Spherical and split with one finish point bent slightly

- Tooth Lock Washer/Star Washer– Spherical with teeth or serrated edges

- Wave Washer– Round(Wavy)

Purpose of Washers

The principal aim of using washers are:

- To disseminate the pressure of the nut or bolt equally over the part being secured, reducing the prospect of harm.

- To offer an even surface for the nut or bolt to be turned on, making it less likely to loosen as a result of an uneven fastening

surface. - To offer vibration absorption.

- To give liquid safeguard (Often utilized to create a water-resistant seal).

The two most ordinary improper uses of washers are:

- To enable the use of a bolt or nut too little for the opening in part being secured, or

- To build, it attainable to tighten a bolt or nut that’s too long.

- Using washers improperly may result in damage or injury, so it’s value understanding how they’re alleged to be used.

[su_box title=”FAQ” style=”default” box_color=”#333333″ title_color=”#FFFFFF” radius=”3″ class=”” id=””]

What Are Washers Used for

Washer, machine component that is used in conjunction with a screw fastener such as a bolt and nut and that usually serves either to keep the screw from loosening or to distribute the load from the nut or bolt head over a larger area. For load distribution, thin flat rings of soft steel are usual.

Different Types of Lock Washers

- Split lock washers are helical-shaped split rings.

- Internal use lock washers have teeth made to bite into the nut/screw head and surface it contacts.

Spring Washer Types

- Shaft Lock Nuts.

- Shaft Lock Washers.

- Curved Spring Washers.

- Finger Spring Washers.

How to Use a Washers

To use your washer and bolt properly, first insert the bolt into the washer. Next, slide the bolt and washer into the mounting hole.

Once the bolt is threaded into the hole, begin turning the head of the bolt using the appropriately sized wrench. Tighten the bolt down to the washer until the head contacts the washer.

Fender Washer Vs Flat Washer

Fender Washers have a larger outside diameter as compared to the inside diameter. Therefore fender washers distribute the load to a relatively larger area compared to flat washers.

Fender Washers have applications in automobile, plumbing, sheet metal and electrical applications, attaching sign boards, panels and drywall.

When to Use Washers?

The primary purpose of most washers is to evenly distribute the load of the threaded fastener with which they are used.

Threaded fasteners stress the material in which they are driven. Driving a screw into wood, for example, may cause the wood to crack around the surface

Washer Shape

A washer is a thin plate (typically disk-shaped, but sometimes square) with a hole (typically in the middle) that is normally used to distribute the load of a threaded fastener, such as a bolt or nut.

Purpose of Washers

Washer, machine component that is used in conjunction with a screw fastener such as a bolt and nut and that usually serves either to keep the screw from loosening or to distribute the load from the nut or bolt head over a larger area. For load distribution, thin flat rings of soft steel are usual.

[/su_box]

[su_note note_color=”#F2F2F2 ” text_color=”#333333″ radius=”3″ class=”” id=””]

Like this post? Share it with your friends!

Suggested Read –

- Steel Is Stronger Than Concrete?

- Steel Is Stronger Than Concrete | Steel Vs Concrete

- Skeleton Frame | Building Skeleton | Steel Structural Building

- What Is Veneer | What Is Laminate | Veneer VS Laminate | Difference Between Veneer and Laminate

- All About of Underwater Concrete | What Is Underwater Concrete | Advantages & Disadvantages of Underwater Concrete

[/su_note]

Originally posted 2022-07-12 16:52:42.