All About Waffle Slab | What is Waffle Slab | Waffle Slab Details | Advantages & Disadvantages Waffle Slab | Waffle Slab Design | Construction of Waffle Slab

Table of Contents

What is Waffle Slab?

Slabs required supports which is given in the form of columns so that the load coming on the slab can be transmitted through it at the foundation. But sometimes the columns act as an obstruction where longer space is required. In the Construction of auditorium, Large seminar halls and Airports required slabs with the longer spans. Conventional slabs cannot be constructed for the longer spans.

Whenever longer area has to be covered without any hindrance, engineers recommend the Construction of waffle slab. Waffle slabs are the best option which is used when the structures are required with the longer spans. Waffle slab is also known as the Ribbed slab. Nowadays many Builders and Engineers are also recommended to use the waffle slab in the projects rather than conventional slabs.

The thickness of the waffle slab is very less as compared to a conventional slab. The Beam which is used in the waffle slab has more depth. The upper portion of the waffle slab is very thin which rests on the grid lines and laid perpendicular to each other.

The Waffle slab is generally used in the Cinema Halls, Railway Station, Auditorium, Airports and in the structures where a large number of columns cannot be construed.

The waffle slab is used where we have to design the structures for the longer spans. Waffle slabs are best suitable for slabs where high vibration Control is required.

Waffle Slab Design

- The design of the waffle slab depends upon the total area on which the waffle slab is required.

- The thickness of the waffle slab is generally range from 80 mm to 100 mm.

- The overall depth of the waffle slab is limited to 300 mm to 600 mm.

- The width of the beam in the waffle slab ranges from 100 mm to 200 mm.

- The spacing between two consecutive ribs ranges from 600 mm to 1500 mm.

- Waffle slabs can be reinforced with the rebar for additional strength.

- The Reinforcement is provided in the waffle slab is provided in the form of a mesh or individual bars.

- The reinforcement in the waffle slab is two-directional.

- The main horizontal beams are connected by the small beams which form the grid-like pattern.

Construction of Waffle Slab

- The Construction of the waffle slab is done in three ways. First is the In situ construction of the waffle slab, precast Construction and the prefabricated construction.

- In situ construction of waffle, the slab is done by casting the waffle slab on-site as per the design and the size required.

- In the precast Construction of waffle slab, the slab panels are cast at another place and joined together with the reinforcement.

- In the prefabricated construction of waffle slab, the reinforcement is provided in the slab panels while casting.

- The construction cost of the prefabricated slab is higher as compared to the other two slabs.

- Construction of the waffle slab is generally preferred for spans longer than 12 m.

- Waffle Slab Construction required about 30% less concrete and 20% less reinforcement.

Waffle Slab Details

- The construction of a waffle slab is generally suitable for flat areas.

- The Volume of concrete which is used in the waffle slab is less as compared to other types of slabs.

- Waffle slabs have good shrinkage resistance.

- Waffle slab required very less amount of steel and concrete as compared to other types of slabs.

- Waffle slabs are the Structural component which is plain from the top and has a grid-like pattern at the bottom side.

- Waffle slabs can be used for both constructions of the floor slab as well as ceiling slabs.

- A flat slab cannot be constructed for a longer span and also get cracked.

- Waffle slabs are the special type of slab which is mainly constructed for the longer span and has a crack and sagging resistance.

Advantages of Waffle Slab

The Advantages of the waffle slab are as follows

- Load bearing the capacity of waffle slab is higher than other types of the slab.

- Waffle slabs have good structural stability.

- The construction of a waffle slab is very speedy and fast.

- Waffle slab can be used for larger span with less number of columns.

- Waffle slab can bear a larger amount of load as compared to the conventional slabs.

- Waffle slabs are lightweight as compared to other types of slabs because of the less dead load of the slab.

- Waffle Slab has high vibration Control capacity.

- Waffle Slabs are attractive and have good Aesthetical appearance when exposed.

- All the services like lighting, plumbing, electrical and air conditioning are easily provided in the waffle slab without any difficulty.

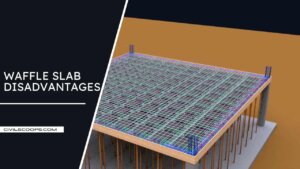

Disadvantages of Waffle Slab

The disadvantages of a waffle slab are as follows

- The Formwork which is required for the construction of the waffle slab is very costly.

- The Construction of the waffle slab required skilled workmanship.

- Waffle slab Construction cannot suitable to bear high wind loads.

- The floor height in the waffle slab is high as compared to the conventional slab due to which the number of floors in the structures is

get reduced. - The waffle slabs cannot be constructed on the slope areas.

- The Maintenance of waffle slabs is expensive and difficult.

[su_box title=”FAQ” style=”default” box_color=”#333333″ title_color=”#FFFFFF” radius=”3″ class=”” id=””]

Waffle Slab

A waffle slab or two-way joist slab is a concrete slab made of reinforced concrete with concrete ribs running in two directions on its underside. The name waffle comes from the grid pattern created by the reinforcing ribs.

Waffle Slab Foundation

The Wafflemat foundation system, also called a waffle slab foundation, is an above-ground mat foundation used to provide load-bearing capacity on expansive, rocky, compressible, or hydro collapsible soils.

Concrete Waffle Slab

A waffle slab or two-way joist slab is a concrete slab made of reinforced concrete with concrete ribs running in two directions on its underside. The name waffle comes from the grid pattern created by the reinforcing ribs.

[/su_box]

[su_note note_color=”#F2F2F2 ” text_color=”#333333″ radius=”3″ class=”” id=””]

- Different Types of Pavers for Driveways

- Septic Tanks Are Back In! Here’s What You Need to Know About How They Work

- What Is Granolithic Floors | Construction Method | Advantages аnd Disadvantage

- Mivan Shuttering | Merit & Demerit Mivan Technology | Mivan Formwork Assembly Process

- Room Soundproofing | What Is Room Soundproofing | Cost to Soundproof a House | Fully Soundproof Room

[/su_note]

Originally posted 2022-06-25 16:41:49.