Properties of Concrete | What Is the Grade of Concrete

Table of Contents

Properties of Concrete

There have many properties of concrete that are below-

- Grades of concrete (M20, M25, M30, etc.)

- The compressive strength of concrete.

- The characteristic strength of concrete.

- Tensile strength of concrete.

- The durability of concrete.

- Creep of concrete.

- Shrinkage of concrete.

- The unit weight of concrete.

- Modular Ratio of concrete.

- Poisson’s ratio of concrete.

What Is the Grade of Concrete?

By strength of the concrete and the composition, the grades of concrete are defining. For the initial construction, the minimum strength of concrete should have followed at 28 days. In the measurement MPa, the grade of concrete is expressed. Where the M stands for mix and the MPa expressed the overall strength of the concrete.

For example for the M20 grade of concrete, Where the M stands for mix and 20 means the maximum compressive strength achieves by the concrete 20N/mm2 at 28 days.

The size of the cube upon which the compressive strength test is done is 150 X 150 X 150 mm.

Also Read : Types of Wood

The different types grade of concrete is below

[su_table responsive=”yes” class=”rk”]

Group |

Designation |

Characteristic Compressive Strength Fck at 28 Days |

Ordinary Concrete |

|

|

Standard Concrete |

|

|

High Strength Concrete |

|

|

[/su_table]

Different Types of Concrete Grade with Concrete Mix Ratio and Compressive Strength

1. Normal Concrete Grade

- For the M5 grade of concrete the mix ratio (cement: sand: aggregate) is 1: 5 : 10 and the compressive strength 5 MPa ( N/mm2 ) or 725 psi.

- For the M7.5 grade of concrete the mix ratio (cement: sand: aggregate) is 1 : 4 : 8 and the compressive strength 7.5 MPa ( N/mm2 ) or 1087 psi.

- And for the M10 grade of concrete the mix ratio (cement: sand: aggregate) is 1 : 3 : 6 and the compressive strength 10 MPa ( N/mm2 ) or 1450 psi.

- For the M15 grade of concrete the mix ratio (cement: sand: aggregate) is 1 : 2 : 4 and the compressive strength 15 MPa ( N/mm2 ) or 2175 psi.

- For the M20 grade of concrete the mix ratio (cement: sand: aggregate) is 1 : 1.5 : 3 and the compressive strength 20 MPa ( N/mm2 ) or 2900 psi.

2. Standard Concrete Grade

- For the M25 grade of concrete the mix ratio (cement: sand: aggregate) is 1 : 1 : 2 and the compressive strength 25 MPa ( N/mm2 ) or 3625 psi.

- For the M30 grade of concrete the mix ratio (cement: sand: aggregate) is the design mix and the compressive strength 30 MPa ( N/mm2 ) or 4350 psi.

- And for the M35 grade of concrete the mix ratio (cement: sand: aggregate) is the design mix and the compressive strength 35 MPa ( N/mm2 ) or 5075 psi.

- For the M40 grade of concrete the mix ratio (cement: sand: aggregate) is the design mix and the compressive strength 40 MPa ( N/mm2 ) or 5800 psi.

- For the M45 grade of concrete the mix ratio (cement: sand: aggregate) is the design mix and the compressive strength 45 MPa ( N/mm2 ) or 6525 psi.

3. High Strength Concrete Grade

- For the M50 grade of concrete the mix ratio (cement: sand: aggregate) is the design mix and the compressive strength 50 MPa ( N/mm2 ) or 7250 psi.

- For the M55 grade of concrete the mix ratio (cement: sand: aggregate) is the design mix and the compressive strength 55 MPa ( N/mm2 ) or 7975 psi.

- And for the M60 grade of concrete the mix ratio (cement: sand: aggregate) is the design mix and the compressive strength 60 MPa ( N/mm2 ) or 8700 psi.

- For the M65 grade of concrete the mix ratio (cement: sand: aggregate) is the design mix and the compressive strength 65 MPa ( N/mm2 ) or 9425 psi.

- For the M70 grade of concrete the mix ratio (cement: sand: aggregate) is the design mix and the compressive strength 70 MPa ( N/mm2 ) or 10150 psi.

Also Read:What Is Plastering | What Is Pointing | Difference Between Plastering and Pointing |

4. Compressive Strength of Concrete

- A quality that varies considerably for the same concrete mix Like a load, the strength of the concrete is also.

- A single representative value, Therefore, known as characteristic strength is used.

5. Tensile Strength of Concrete

- The tensile strength of concrete, one of the basic and important properties is which greatly affect the extent and size of cracking in structures.

- The concrete is very weak due to its brittle nature in tension. Hence the direct tension is not expected to resist.

- When tensile forces exceed their tensile strength the concrete develops cracks.

- Therefore, the tensile strength of concrete to determine and it is necessary to determine the load at which the concrete members may crack.

- Furthermore, to determine the tensile strength of splitting tensile strength test on the concrete cylinder is a method concrete.

6. The Durability of Concrete

- To resist its disintegration and decay the durability of concrete is its ability.

- Influencing the durability of concrete is one of the chief characteristics. Its permeability to other potential and increase of water and deleterious materials.

- By having adequate cement, the desired low permeability in concrete is achieved, by ensuring full compaction of concrete and by adequate curing sufficient low water/cement ratio.

7. Creep of Concrete

- Under sustained load, creep is defined as tic deformation. On the duration of sustained loading, the creep strain depends primarily.

- According to the code, 1.6 at 28 days of loading the value of the ultimate creep coefficient is taken.

8. Shrinkage of Concrete

- During the process of drying and hardening, the property of diminishing me is termed Shrinkage. The duration of exposure depends mainly.

- If this strain is prevented, hence concrete develops cracks and produces tensile stress in the concrete.

Also Read: Difference Between Cement Plaster and Gypsum Plaster

9. The Unit Weight of Concrete

- On the percentage of reinforcement, the unit weight of concrete depends, type of aggregate, varies from 23 to 26 kN/m2 the number of voids.

- The unit weight of reinforced concrete and plain concrete as specified by IS:456 are 24 and 25 KN/m3

10. Modular Ratio of Concrete

- The short-term modular ratio is the modulus of elasticity to the modulus of elasticity of steel of concrete.

- The effects of creep and shrinkage are taking into account partially IS code gives the following expression for the long-term modular ratio.

- Where, fcbc = permissible compressive stress due to bending in concrete in N/mm2 Long term modular ratio (m) = 280/ (3fcbc).

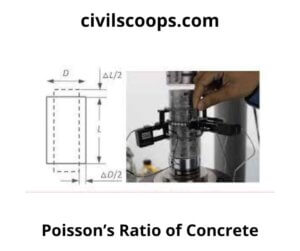

11. Poisson’s Ratio of Concrete

- For high-strength concrete Poisson’s ratio varies between 0.1 and 0.2 for weak mixes.

- For strength design, It is normally taken as 0.15 and 0.2 for serviceability criteria.

[su_box title=”FAQ” style=”default” box_color=”#333333″ title_color=”#FFFFFF” radius=”3″ class=”” id=””]

Properties of Concrete

- Mechanical strength, in particular compressive strength. The strength of normal concrete varies between 25 and 40 mpa.

- Durability.

- Porosity and density.

- Fire resistance.

- Thermal and acoustic insulation properties.

- Impact resistance.

Cinder Block Houses

While the price can be as low as 90 cents per cinder block, the average price range is $1 to $3 per block. Additionally, you need to factor in the cost of mortar, rebar, and concrete fill involved in the construction process.

High Density Concrete Mix

High-density concrete can only be manufactured by using various high-density natural or man-made aggregates. High-density concrete can be used for structural and/or specialized construction purposes. The main use of hdc is in the nuclear industry as radiation shielding.

Low-Density Concrete

Structural low-density (lightweight) concrete is structural concrete made with low-density aggregate having an air-dried density of not more than 115 lb/ft3 (1850 kg/m3) and a 28-day compressive strength of more than 2500 lb/in2 (17 mpa).

High Strength Concrete Mix

What is high strength concrete? It is a type of high performance concrete generally with a specified compressive strength of 6,000 psi (40 mpa) or greater.

Thermal Conductivity Test for Concrete

Thermal conductivity is determined through the heat flow and the difference in mean temperature between the specimen surfaces [29]. Gandage et al. [20] measured the thermal conductivity of specimens in five temperature ranges (from 30°c to 80°c) with this method.

High Density Concrete

High-density concrete or heavyweight concrete is produced using special heavy aggregates (with specific gravities higher than 3000 kg/m3). En 206:2013+a1:2016 (2016) defines heavyweight concrete as having an oven dry density greater than 2600 kg/m3. The density achieved will depend on the type of aggregate used.

Water Absorption of Concrete

The maximum absorption was observed at w/c ratio of 0.55. As the w/c ratio becomes larger than 0.55, water absorption decreases. This decrease could be due to excess amount of water available for hydration and therefore more pores near to the surface of the specimens being blocked by the hydration products of opc.

[/su_box]

[su_note note_color=”#F2F2F2 ” text_color=”#333333″ radius=”3″ class=”” id=””]

Like this post? Share it with your friends!

Suggested Read –

- What Is Fresh Concrete? | Properties of Fresh Concrete | Factors Affecting Workability

- What Is Heat Resistance Concrete? | Reinforcement in Heat Resisting Concrete | Properties of Heat Resisting Concrete | Application of Heat Resisting Concrete | Advantages & Disadvantages of Heat Resisting Concrete

- What Is Traffic Rotaries? | Rotary Intersection | What Is Rotary Island? | Advantages & Disadvantages of Traffic Rotary

- What Is Development Length | Why We Provide Development Length | How to Calculate Development Length | Development Length for Single Bars

- What Is Tie Beam? | Tie Beam Details | Ties in Column | Tie Beam Design | Concrete Tie Beam | Tie Beam Reinforcement Details

- Types of Curing | Concrete Curing Time | How to Cure a New Concrete Slab | What Is Curing of Concrete | How Long Does Concrete Take to Dry | How Long Does It Take for Cement to Dry

[/su_note]

Originally posted 2024-04-05 05:14:01.