What Is Floating Slab | Floating Slab Construction | How to Build a Floating Slab | Advantages & Disadvantages Floating Slabs

Table of Contents

What Is a Floating Slab?

These slabs are constructed in two stages. At the first stage, the footings are poured separately. The centre floor of this floating slab is poured only after the footings are cured.

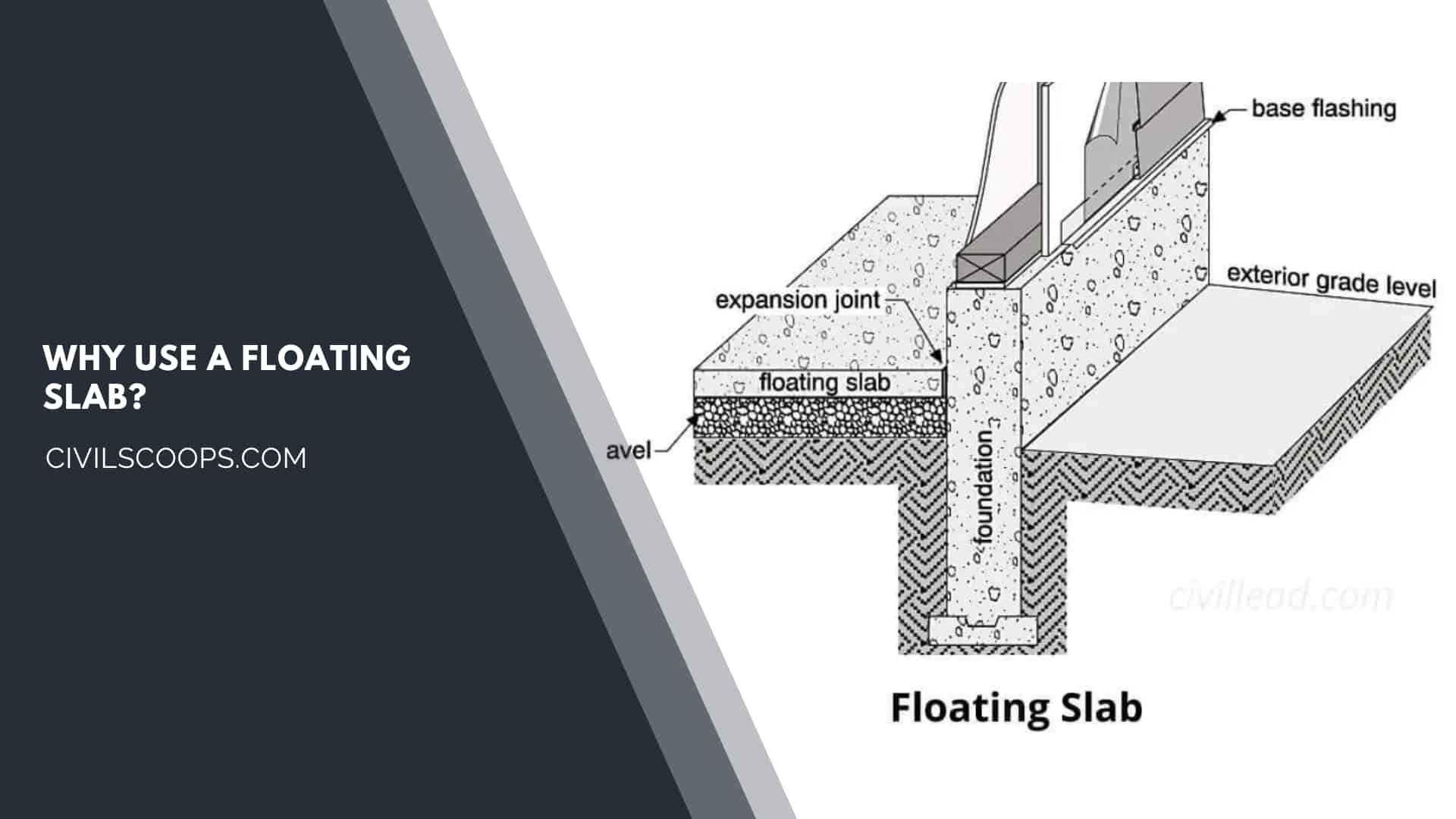

The slab isn’t anchored to the floor. This type of slab is typically used for shallow foundations such as garages, sheds, and light home extensions.

Why Use a Floating Slab?

Building a floating slab is one of the most economical ways of constructing a foundation. Traditional foundations include a strip foundation using a frost wall above.

The strip footing is installed below the frost level, typically 4′-0″ below grade. The cost of a strip footing and frost wall is a lot higher because there are more excavation, concrete, and labour required.

Also Read: All About Slab Construction | What Is Slab Construction | Types of Slab Design

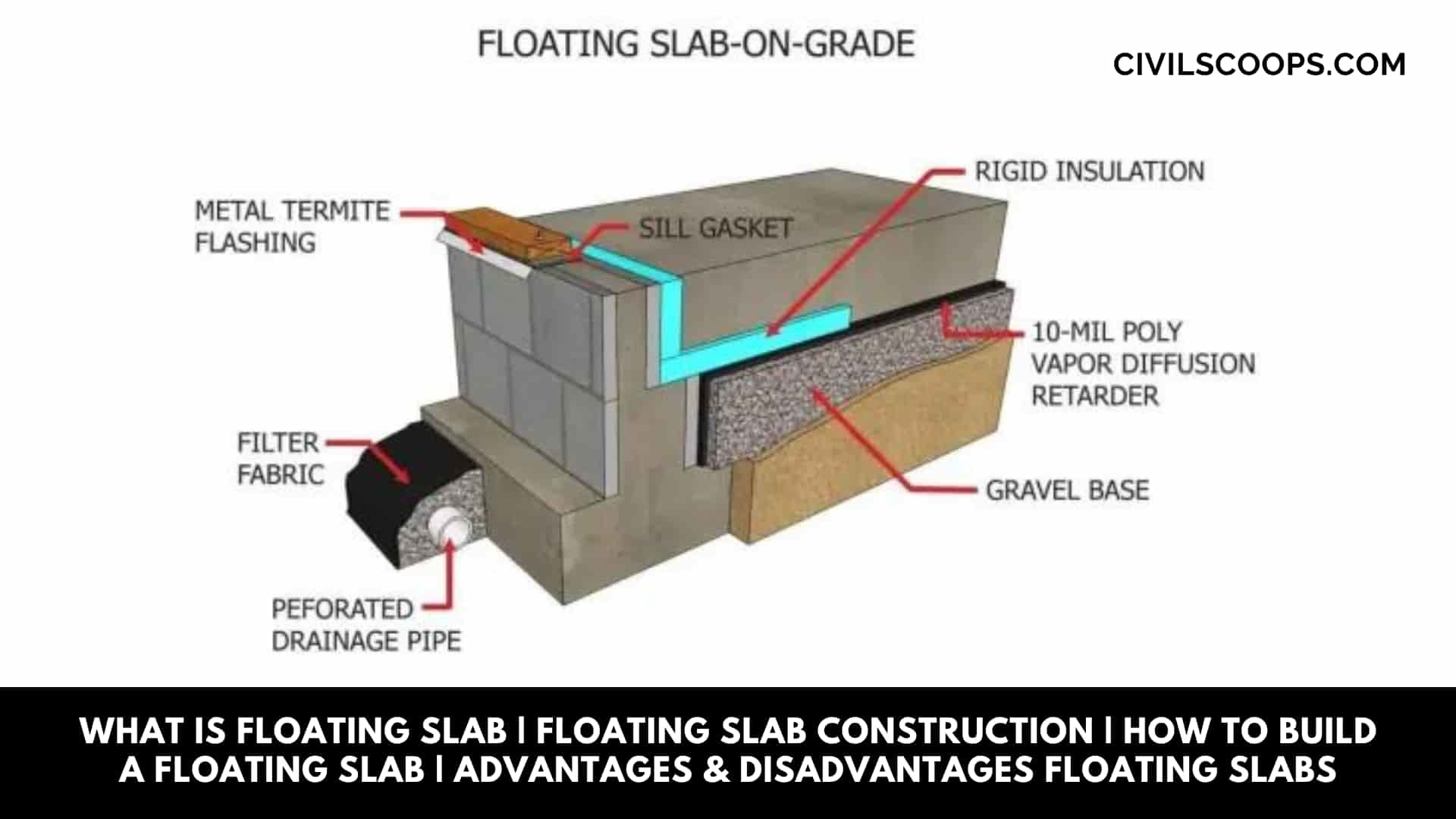

Floating Slab Construction

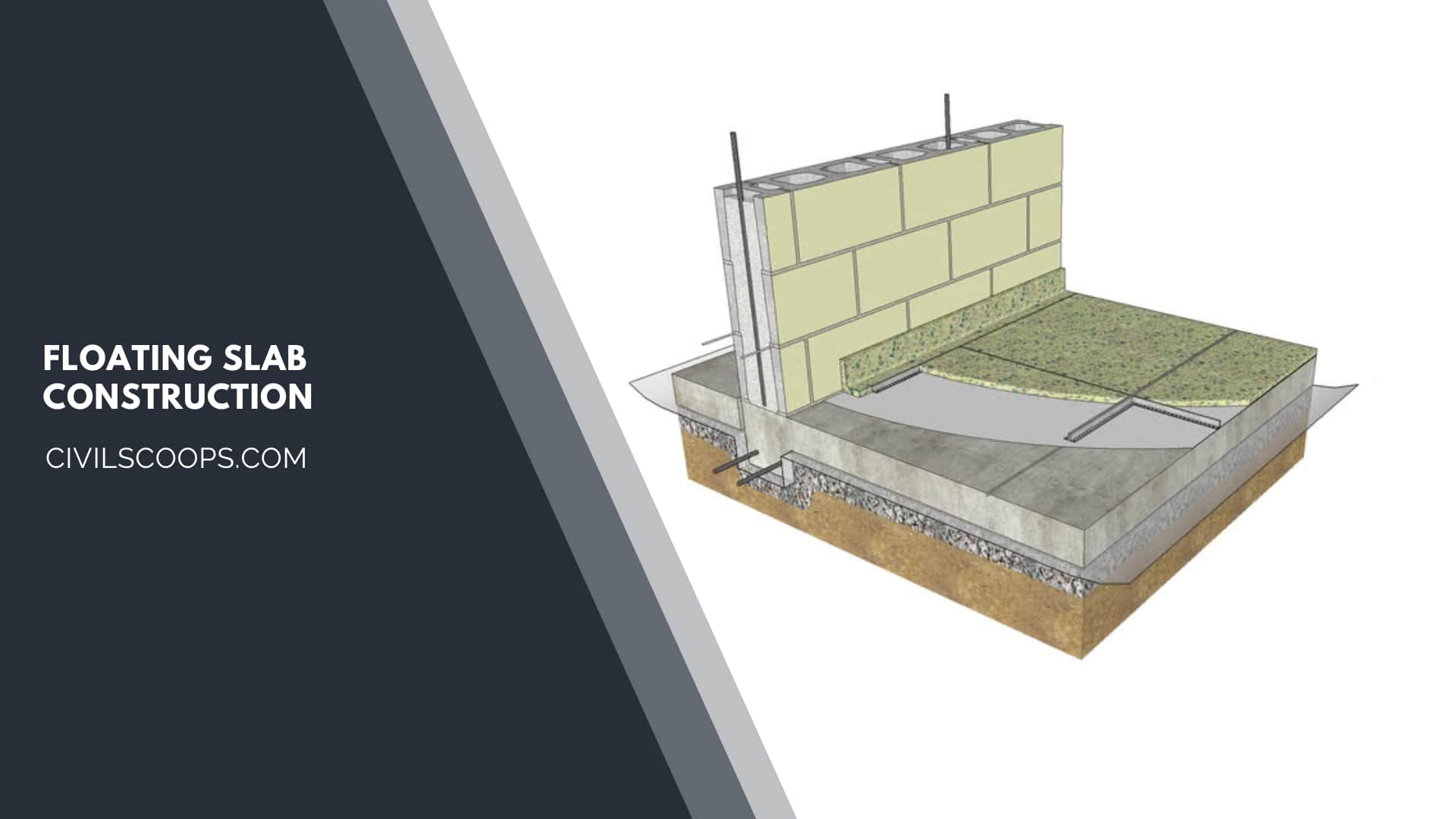

A building construction typically needs a solid foundation where it could bear the weight of the entire structure, including the roof, floor, and other loads it could contain.

But, small structures such as sheds, garages, backyard extensions don’t need elaborate and extra strong foundations as they’re generally light in structure.

The floating slab is an ideal solution for such basic foundation structures. This type of slab foundation is mostly used in northern climates as the slab doesn’t require concrete footing with deep extensions below the frost line.

The floating slab is sometimes called a raft foundation, and they’re generally constructed on soil with high proportions of sand, clay, or water.

A floating slab spreads the structure weight over the entire base instead of at strategic supporting columns. As they are shallow in-depth, they could ideally be used in specific construction locations.

How to Build a Floating Slab?

A floating slab is the basic foundation structure used for buildings that don’t have basements (garages, sheds, barns, and even some homes in the high water table or coastal areas).

Concrete floating slabs may and, in areas that experience freezing temperatures, must be insulated.

Because there are no footings on this type of foundation, the insulation is either built directly in the concrete by sandwiching it between layers of concrete or by laying it directly on top of the concrete.

These additions are far cheaper than building a full foundation with footings and frost barrier as an excavation, and extra concrete costs far outweigh the cost of insulation.

Follows Steps To Build Floating Slab

- Determine the area to your floating slab and then mark the four corners with 3-feet metal stakes.

- Determine the height of the top surface of the concrete slab. Once you’ve made this determination, use string to mark the height by wrapping it around the metal stakes. Use a level to ensure the string is straight, and the height is consistent.

- Measure out two feet in the perimeter (laterally) and mark off this area for drainage.

- Measure down 2 feet and 11 inches in the perimeter strings. Here is the starting point of the foundation for the slab. Excavate this entire interior area of the foundation to this depth. Also, excavate the 2-feet drainage section.

- Fill the excavated area 3″ deep with crushed stone to form a drainage area to the foundation.

- Cover the 3 inches of rockfill with 2 feet of sand.

- Compact the sand using a tamp (sand compactor) until it is 8 inches below the perimeter lines. Check the area in many locations to make sure the entire area is level.

- Place 2″-by-10″ (inch) lumber around the perimeter of the proposed slab to create the slab molds. Connect the corners with joints and secure them with framing nails. Make sure the forms are level.

- Insert support stakes [2-feet metal stakes with nail holes] each foot along the outside of the slab form. Secure these with framing nails as well.

- Remove the initial guideposts and perimeter string. At this point, it’s time to install any drainage lines or electrical conduit that must run through the foundation.

- Dig a 16-by-18-inch trench just within the slab form to provide extra support on the exterior of the slab to support walls.

- Install the 2″ (inch) foam insulation over the sand. Cut pieces to fill in the sides and base of this trench as well.

- Install a vapor barrier over all of the foam. Overlap pieces by 2″ to 4″ and secure with tape.

- Place the three-eighths-inch rebar at a criss-cross pattern within the vapor barrier. Be sure to use the 2″ rebar supports to lift the rebar off the ground so liquid concrete may flow around it.

- Add the five-eighths-inch rebar into the trench area. Make a cage formation with the bars to add extra support.Mix and pour your cement. If you’re working with a cement delivery service, they will determine the amount of concrete necessary for the pour. Otherwise, you’ll have to follow the calculations on your cement bag to determine how much to pour.

Also Read: Difference Between Footing and Foundation | What is Footing and Foundation

Advantages of Floating Slabs

- The floating slab has the property of spreading the vertical loads or pressures coming over it to be distributed over a larger area.

- The floating slab construction can be employed in site areas with lower load-carrying capacity and where investing large money on soil treatment is futile. This system lets us utilize over loose soil or from the soil using varying compressibility.

Floating slabs behave as a barrier for the entrance of the moisture coming out of the floor. It acts as a barrier between the superstructure and the floor.

This avoids seepage of water and frosting. For this purpose, the slab could be insulated for moisture or freeze. This was made their widespread usage in cold region construction.

Floating slab foundations are a good solution when it comes to the extension of houses. There’s a situation once we require a building extension without affecting the already existing foundation. This will not interfere with the building structures already built.

The floating slabs do not require the use of footer trenches. They may be poured with the help of trenching or digging, which can be economical.

In areas where there are possibilities of shifting in the earth layer, mainly because of high moisture content, the floating slabs are best suited.

The floating slab doesn’t cause any disturbance to the earth layer lying beneath. Neither will interfere with the quality.

Also Read: How Cement is Made | Cement Ingredients | History of Cement

Disadvantages of Floating Slabs

- Some limitations associated with floating slab would be its comparatively primitive technology, entrapped air within sealed floating foundation systems and lower layout resonance.

- Floating slab foundations have the distinct disadvantage of lack of underground access for utility lines.

[su_box title=”FAQ” style=”default” box_color=”#333333″ title_color=”#FFFFFF” radius=”3″ class=”” id=””]

What Is a Floating Slab?

Floating slabs are concrete slabs that are laying over the ground, without any kind of anchoring, as if it simply sits on it and floats. Floating slab, as the name tells it resembles a plate that is simply laid over water, with no kind of connection between them.

Floating Slab Construction

Floating slabs are used as the foundations for a variety of structures, including sheds, car garages, additions, cottages and much more. The slabs have a thickened reinforced perimeter but no frost footings. They are called “floating” because they are allowed to move above the frost line as a monolithic unit.

How to Build a Floating Slab?

The construction involves the following steps:

- Floating Slab Layers.

- Preparation of land by removing the upper layer.

- Excavated drainage and the prepared drainage.

- Laying Gravel base layer over the area for drainage of unwanted water.

- Compaction of Poured Concrete.

Floating Concrete Slabs

Floating slabs are a form of foundation that provides an economical solution compared to traditional slab foundations. Floating slabs do not require excessive excavation but are constructed to “float” on the ground without direct supports like beams, footings or thickened edges.

Floating Concrete Floor

A floating concrete floor is formed of floating concrete slabs that are laid on the ground without any type of anchoring. Floating concrete floors are idea for small structures that do not require solid, strong foundations (like garden sheds or garages).

Floated Concrete Floor

A concrete finish is accomplished through a power float to smooth and level a hardened concrete floor once water has evaporated from the ground. A power float machine utilises its rotating circular pans to achieve a smooth and polished finish.

How to Make a Floating Concrete Slab?

To create a floating concrete slab:

- Prepare the site and mark the area.

- Excavate the area and add a layer of compacted gravel.

- Place forms and optional reinforcement.

- Pour and level a layer of crushed stone or sand.

- Pour the concrete mix, level with a screed, and smooth with a trowel.

- Cure the concrete using plastic sheeting or a curing compound.

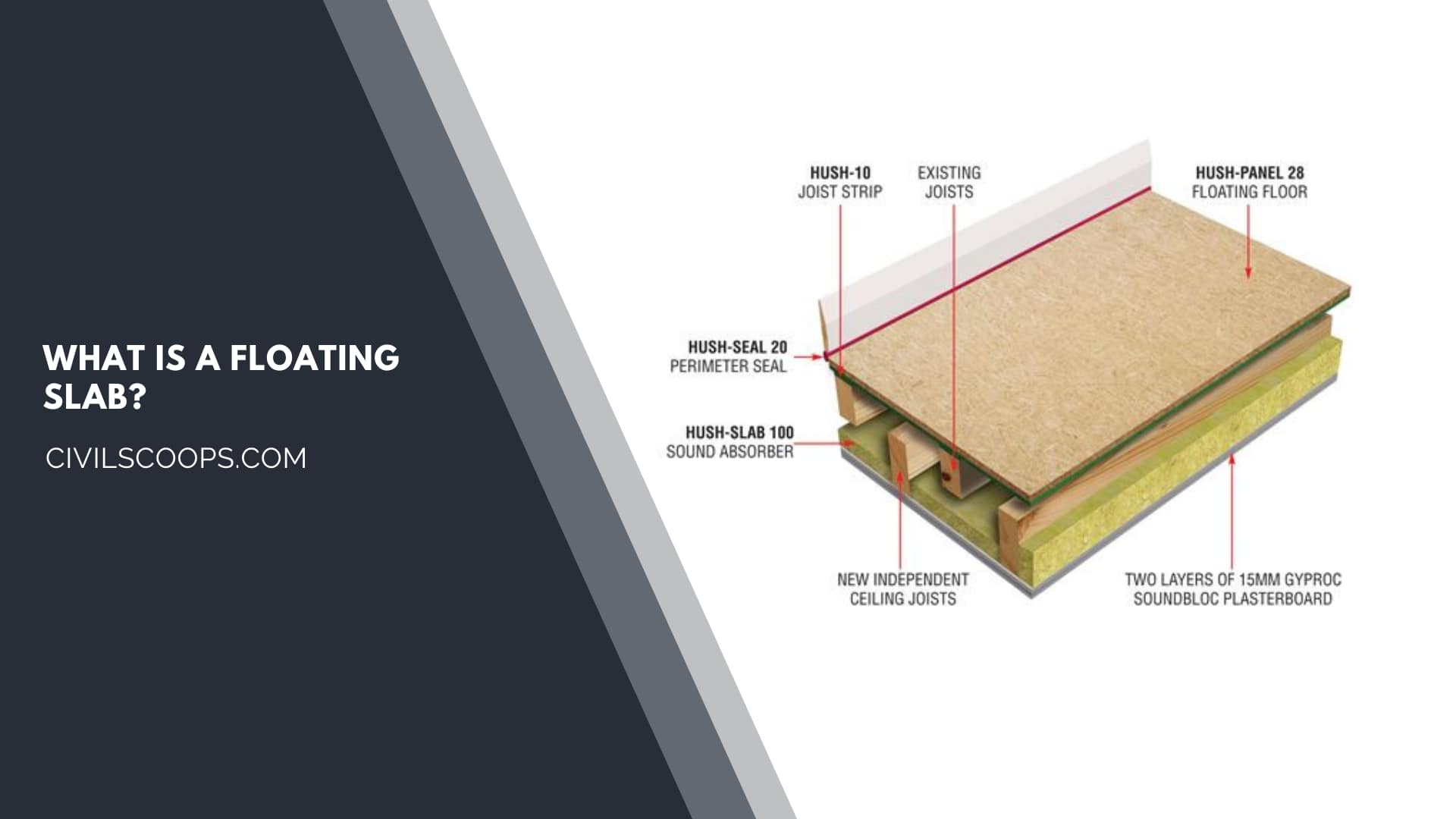

Floating Garage Floor

It is typically taken to mean a lightweight construction where chipboard, gypsum or cement fibre board floor panels are ‘floated’ across the top of the rigid insulation layer. Floating floors are used most often in domestic buildings especially when retrofitting or refurbishing an existing building.

How to Float a Concrete Floor?

Guide to Floating Concrete

Step 1 – Prepare Form. Make a form, or frame, out of pieces of softwood.

Step 2 – Pour Concrete.

Step 3 – Screed Concrete.

Step 4 – Smooth Concrete.

Step 5 – Wait for Surface to Dry.

Step 6 – Float Concrete.

Floating Slab Foundation

A floating slab foundation, also known as a slab-on-grade foundation, is a type of concrete foundation that is used to support a structure, such as a building or a small shed, directly on the ground without the use of a traditional footing or basement. Unlike traditional foundations that are deeply anchored in the ground, a floating slab is poured directly onto a leveled and compacted surface. It “floats” on the ground rather than being anchored deep into it.

How Thick Should a Floating Slab Be?

The slab’s thickness varies between 4 and 6 inches. When Floating Slabs are installed in a building, radiant floor heat can be used to provide comfort and even heating.

Floating Slab Vs Monolithic Slab

Floating slabs are idle for house addition and garages on the soil with low bearing capacity. In comparison, the monolithic slabs are suitable for the level and well-compacted ground with a low slope.

Explain What Is Floating Slab Foundation?

Floating slab foundations are a type of foundation constructed to support the structures in a similar manner as other foundations. As the name implies, it is a floating slab constructed on the ground, not on the direct support such as a beam or wall. A floating slab is separated from the main structures.

What Is Difference Between Floating and Monolithic Slab?

The quicker, more efficient way to pour a concrete foundation utilizes what is known as a monolithic slab. Instead of three separate sections to pour, the foundation walls and slab are combined and poured at one time, and the footings do not need to be dug as deep as with the traditional method.

Floating Slab Design Example

As the name implies, it is a floating slab constructed on the ground, not on the direct support such as a beam or wall. A floating slab is separated from the main structures. The main example of the floating slab is the slab on grade. In addition, slab foundations are also can be considered floating slab foundations.

[/su_box]

[su_note note_color=”#F2F2F2 ” text_color=”#333333″ radius=”3″ class=”” id=””]

Like this post? Share it with your friends!

Suggested Read –

- Types of Wooden Beams

- Introduction to Stair Landing | What Is Stair Landing | Stair Landing Dimensions

- What Is Skillion Roof | Types of Skillion Roof | Uses of Skillion Roof | How to Build a Skillion Roof

- What Is Cedar Wood | Is Cedar a Hardwood | Uses of Cedar Wood | Types of Cedar | Red Cedar Wood | Facts About the Cedar Tree

- What Is Gypsum Boards? | Properties of Gypsum Board | Types of Gypsum Board | Advantages & Disadvantages of Gypsum Board

[/su_note]

Originally posted 2023-08-24 09:47:52.