Concrete Batching | Concrete Batching Plant | Types of Batching of Concrete | Various Factors Affecting the Choice of Batching System

Table of Contents

All About of Concrete Batching

Generally, concrete is a multipurpose, eco-friendly construction material that is widely used in most construction all over the world. Concrete is also an inexpensive material.

Now we need to prepare this type of material, but if you are going to prepare good quality, then you need to consider all the components with the required amount to get an accurate product; that process is called batching.

Concrete is generally made of water, aggregate (fine or coarse), and cement (powder form). Here, cement acts as a binding material. If you want to create cement batching, then you need to control the water amount and the number of aggregates & cement.

Also Read: Grey Water vs Black Water | What Is Grey Water | What Is Black Water

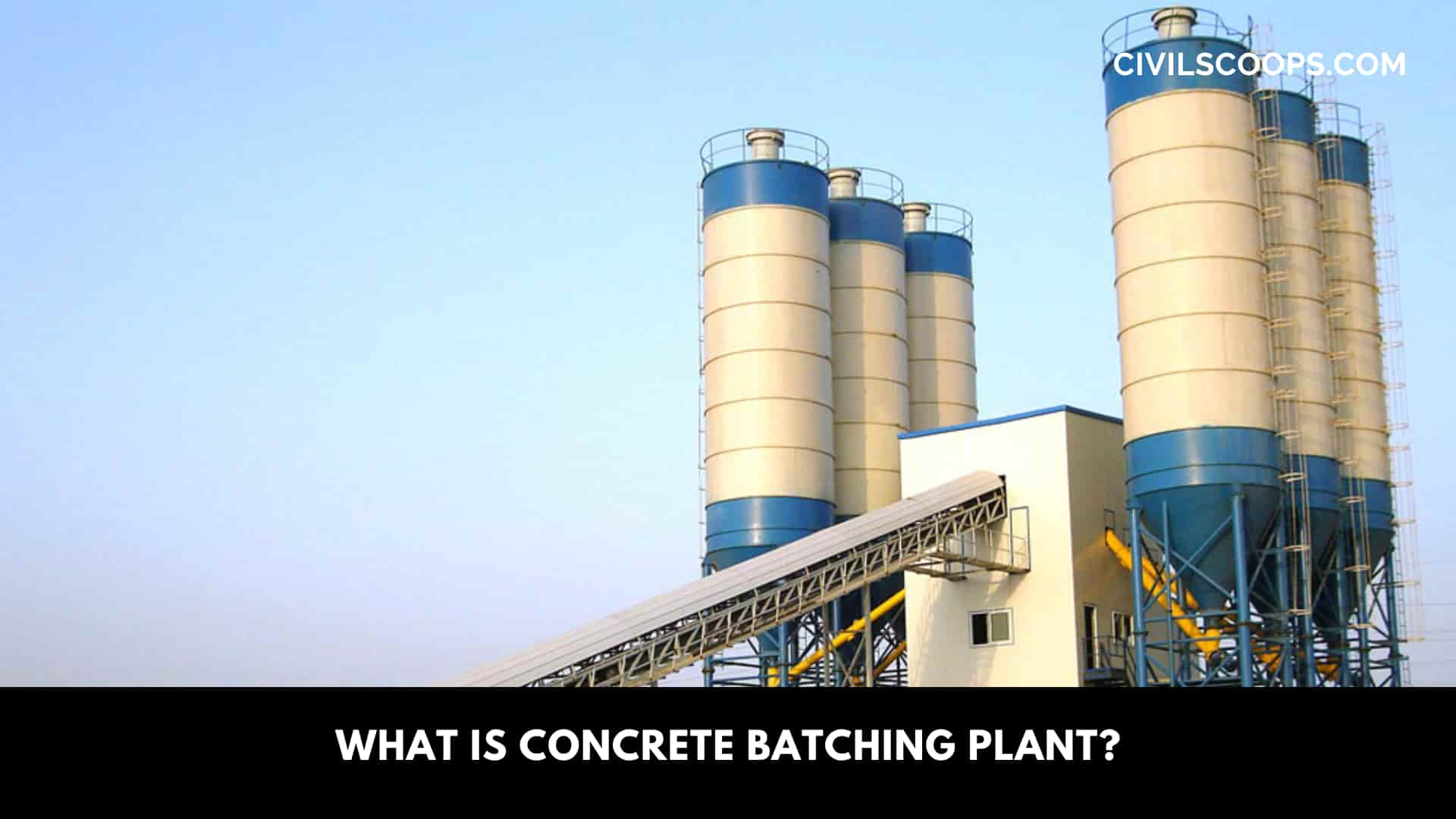

What Is Concrete Batching Plant?

A concrete batching plant is a type of plant where concrete is prepared with different ingredients. There different types of ingredients are used, those are cement, sand, aggregates, water, admixtures, silica fume, fly ash, slag, etc.

There are various types of parts of batching plants are there, those are mixer, aggregate more batch, cement more batch, aggregate bins, conveyors, cement bins, heaters, radial stackers, chillers, dust collectors, etc.

All the aggregates are collected throw screw conveyors, and they use a control system to control the overall process. After that, the mixing operation will be done, and concrete will be prepared.

What Is Batching of Concrete?

Batching of concrete refers to the process and method of estimating the number of materials and mixing them by volume and weight mix to maintain the consistent quality of the concrete.

Precision is one of the very much important parameters in concrete batching. Batching of concrete is generally done by volume because this process is better than weight batching. The aggregates and concrete materials are properly batched before mixing starts, and we get proper batched concrete, which is accurate.

Concrete batching generally helps to increase the practicality because it helps to create a smooth surface and increase the construction speed because the volume of concrete is reduced for properly batching. Batching of concrete is an essential process for concrete making.

Also Read: What Is Concrete | 31 Different Types of Concrete

Types of Batching of Concrete

There are generally three types of concrete batching available and followed by the engineers; those are the following

- Random Volume Batching

- Volumetric Batching

- Weigh Batching of Concrete

1. Random Volume Batching

In random volume batching, there is no proportion of cement, aggregates, water, etc. It creates an error in the concrete, and that concrete can not get its desired strength.

The number of materials can not be controlled because of the random use of different containers by the workers, and the number of containers is not taken into account.

It is an unscientific process, and it is not allowed even in medium-type construction.

2. Volume Batching of Concrete

Volume batching is another type of concrete batching where we use measurement boxes which are usually known as ‘gauge boxes’ or ‘farms.’

Generally, the volume of ‘farma’ is equal to the volume of one bag of cement, which is 35 litter. After that, all the coarse aggregates and fine aggregates are also measured by farmers, and then all the materials are properly mixed with each other.

Then water is mixed with that, and the cement batching process is done by volume batching.

3. Weigh Batching of Concrete

Weight batching of concrete is another method of concrete batching, and it is widely used on construction sites. Here, all the aggregates and cement is measured by weighing, and it is done by the instrument named weight more batch. Weight batching is a very much accurate, easy, and simple process. That’s why everyone tries to adopt this.

According to the types of construction work, different types of weights and more batches are required. There are three types of weight watchers available, those are manual more batch, semi-automatic more batch, and fully automatic more batch. After all these operations, water is added to the mixture, and the batching of concrete by weight batching is done.

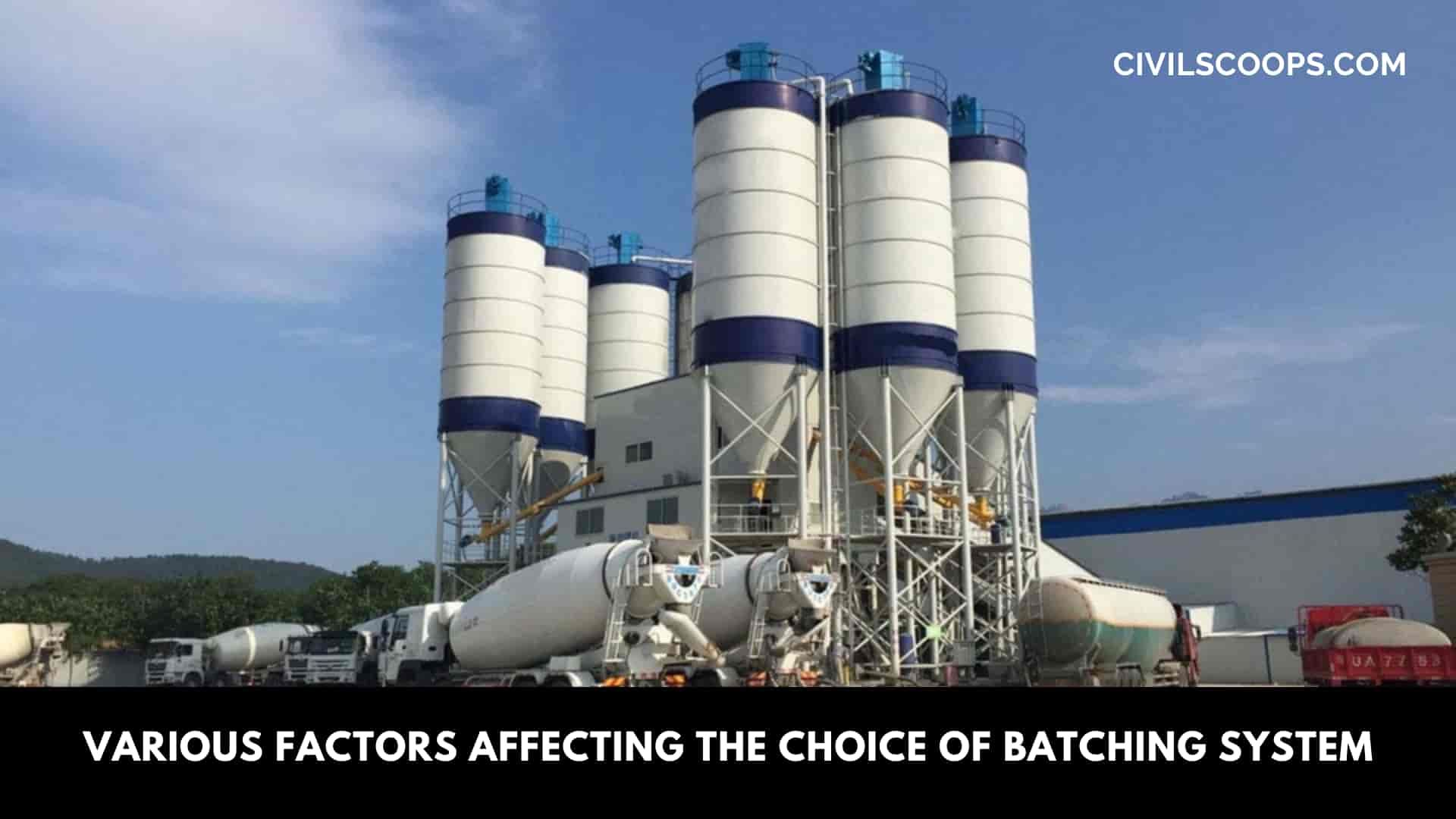

Various Factors Affecting the Choice of Batching System

There are various types of factors are there for the batching system; those are the following.

The choice of batching is one of the most important parameters where you need to need to choose the batching method according to your job site.

Concrete production rate is another important parameter where you need to choose the batching system according to the production rate of concrete. A weight measurement of aggregates and batching is the standard batching procedure.

Weight Watchers are generally controlled manually or electronically. Electronic weight watchers are more efficient and widely used in industry nowadays than manual batches but still now some places, manual weight batches are used to save electricity.

Mechanical weight watchers have a circular scale, and the weight of the aggregates is measured by spring, but in the electronic weight more batch, there is an electronic scale, and the weight is measured by the suspended load. The electronic scale measures more preciously than the manual scale.

There are various types of weight watchers available, and according to the type of job, different types of weight watchers are used, those are- low profile, high silo, underground batching plant, etc.

The batches are generally stationary systems,s but there are also some moving batches that they consider transport vehicles.

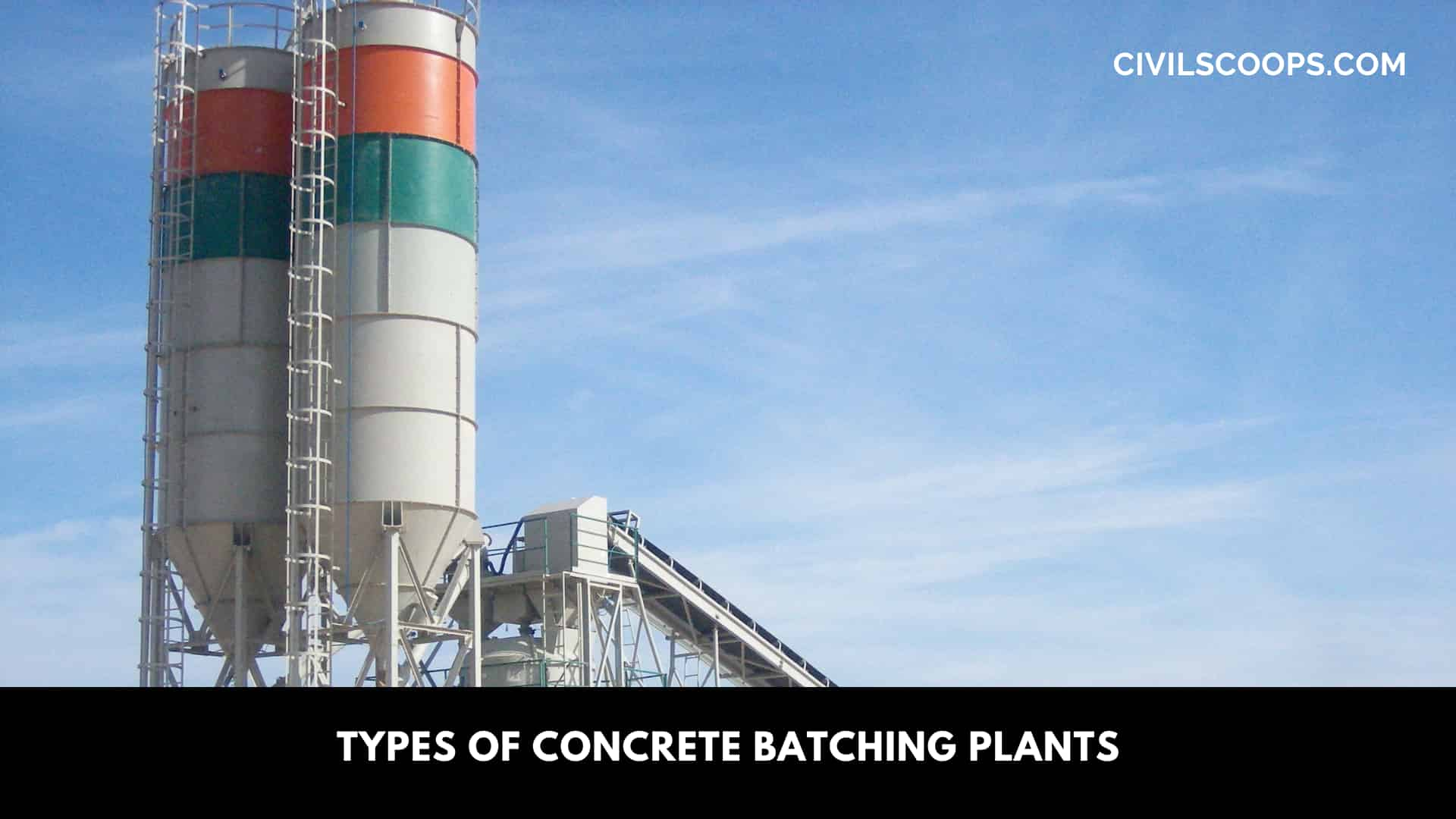

Types of Concrete Batching Plants

There are generally three types of batching plants are there, those are in the following

- Manual Weigh Batching Plant

- Semi-automatic Weigh Batching Plant

- Fully Automatic Weigh Batching Plant

1. Manual Weigh Batching Plant

The manual weight batching plant is the first type of batching plant which is used in the previous time. This type of plant is very time-consuming, and the proportion is not well maintained.

In the manual weight batching plant, all the aggregates are mixed with the manual process. A manual-weight batching plant is used for small-type construction purposes.

2. Semi-Automatic Weigh Batching Plant

Semi-automated weight batching plant is another type of batching plant where the aggregate bin gates are controlled manually. The mixing process is done automatically, and after finishing the delivery process, the gates are automatically closed.

3. Fully Automatic Weigh Batching Plant

A fully automated weigh batching plant is the modern type of batching plant that is highly used in recent times. It is an automated system where you need to deploy experienced and trained engineers.

A fully automated weigh batching plant has an automated microprocessor for controlling the batching system. In this system, the moisture content of aggregates is also measured automatically, and if there are some changes in moisture content, then relative measurements will be taken to get the desired strength of the concrete.

[su_box title=”FAQ” style=”default” box_color=”#333333″ title_color=”#FFFFFF” radius=”3″ class=”” id=””]

What Is Concrete Batching?

The process of measuring ingredients or materials to prepare concrete mix is known as batching of concrete. Batching can be done by two methods, volume batching and weight batching. Batching should be done properly to get quality concrete mix.

What Is Batching Concrete?

Batching is the process in which the quantity or proportion of materials like cement, aggregates, water, etc. are measured on the basis of either weigh or volume to prepare the concrete mix. Proper Batching improves the workability of concrete by reducing the segregation or bleeding in concrete.

How Does a Concrete Batch Plant Work?

A concrete batching plant is a machine that mixes concrete by using a rotating drum. The machine creates the right mix of cement and water. The drum rotates at high speeds, which allows the cement to be mixed with air and water at different rates, creating a homogeneous mixture.

How Do You Make Concrete Planters?

Step-By-Step For A DIY Cement Planter

- Mix Cement and Water.

- Form the Milk Carton, Yogurt Container, or Plastic Food Container Planter.

- Let the Cement Planters Dry Overnight.

- Remove the Layers.

- Sand Your Planter.

- Fill Your DIY Cement Planters With Your Plants and Succulents!

What Is a Concrete Batch Plant?

Concrete batching plants use equipment to produce concrete and concrete products by batching or mixing cements and other materials. Equipment used at a concrete batching plant includes silos, weigh hoppers (batchers), conveyors, mixer engines and auxiliary generators.

Types of Concrete Batching Plant

Concrete batching plants can be divided as transit mix plant and central mix plant depending upon the mixers.

- Transit Mix Plant/ Dry Concrete Batching Plant.

- Central Mix Plant/Wet Concrete Batching Plant.

- Stationary Concrete Batching Plant.

- Mobile Concrete Batching Plant.

Batching of Concrete

Batching of concrete is the process in which the elements or ingredients required for producing the concrete mix such as cement, sand, aggregate and water are measured in quantity for correct mixing according to the mix ratio. Accurate quantity of all the ingredients should be used to produce high-quality concrete.

Types of Batching Plant

Wet mix concrete batching plants can be classified into two knis: stationary type wet concrete plant and mobile type wet mix concrete batch plant.

[/su_box]

[su_note note_color=”#F2F2F2 ” text_color=”#333333″ radius=”3″ class=”” id=””]

Like this post? Share it with your friends!

Suggested Read –

- What Color Helps You Fall Asleep | Best Bedroom Colors for Sleep 2022

- What Is Superstructures | Difference Between Load-Bearing and Framed Structures

- Difference Between Fat Lime and Hydraulic Lime | What Is Fat Lime | What Is Hydraulic Lime

- What Is Transportation Engineering | Major Disciplines of Transportation Engineering | What Do Transportation Engineers Do

- All About Waffle Slab Foundation | What is Waffle Slab Foundation | Waffle Slab Foundation Pros and Cons | Features of Waffle Slab Foundation

[/su_note]

Originally posted 2023-05-15 12:40:11.