Types of Curing | Concrete Curing Time | How to Cure a New Concrete Slab | What Is Curing of Concrete | How Long Does Concrete Take to Dry | How Long Does It Take for Cement to Dry

Table of Contents

What Is Curing of Concrete?

Too kept within the recommended temperature range and the concrete is protected against loss of moisture required for hydration the curing method is done. The curing will decrease the permeability of hardened concrete and will increase the strength of hardened concrete.

The curing is also helped in mitigating plastic cracks and thermal cracks, on the durability of structure which can severely impact. Until the hydration of concrete is complete or strength is attained a curing practice involves keeping the concrete moist or damp.

For the concrete to achieve its desired durability and strength as per the specified standards curing must continue for a reasonable period. After an initial setting time of concrete or removing the shuttering of concrete curing should be started as soon as possible.

After placing the concrete to avoid thermal shrinkage cracks the curing is the most important step in construction. By the curing to prevent plastic shrinkage cracks to control water loss from the concrete surface Protecting measures are also required.

From the body of concrete by monitoring loss of moisture and water till the end of hydration, curing concrete is a process designed generally to retain the concrete moist, in which it gains strength during the given period, In a nutshell.

There Have Many Methods to Curing of Concrete That’s Are Below

- Water Curing

- Wet Covering

- Sheet Curing

- Curing by Absorbing Heat

- Formwork Curing

- Membrane Curing

- Hot mixing method

- Electrical curing

- Natural Curing (Exposed concrete)

- Infra-Red Curing

- Cover with Sand or Sawdust, Soil, etc.

Types of Curing

There Have Many Types to Curing of Concrete That’s Are Below

- Water Curing

- Wet Covering

- Sheet Curing

- Curing by Absorbing Heat

- Formwork Curing

- Membrane Curing

- Hot mixing method

- Electrical curing

- Natural Curing (Exposed concrete)

- Infra-Red Curing

Water Curing

- This method is applying, to avoid the drying of the concrete surface, and when the concrete is thinner, and the application of the water is done.

- To curing the floor slab in building construction, this water curing method can be done.

There are two methods of water curing :

- Ponding the concrete.

- Use sprinklers to spread water continuously.

Ponding the Concrete

- Continuously wetting the concrete surface is done in this method without allowing the concrete surface to dry around the slab area, a curb is cast most of the time to make a pond in this curing method.

- This method, because of there is not required to pour the water continuously, In dry environments, so is very useful in a dry environment.

- With this method, we can easily cure footpaths, road pavements, slabs, etc.

Use of Sprinklers

- In this method, it is a must to not allow the concrete surface to get dirty, Due to evaporation.

- At a constant rate and uniformly, water must to continuously spray in a slab, fulfilling the adequate curing.

- In this sprinklers method, in the adequate space, the sprinkle is set.

- From the hand curing the sprinkle, the curing method is very easy because this method does not require lots of involvement.

Also Read: Difference Between Cement Plaster and Gypsum Plaster

Wet Curing

- To maintain the surface moisture level, wet curing is a method done by placing materials like hessian.

- After adequate hardening work to please covers, these covering shall be placed on the concrete surface.

- Due to any reason further, should not be allowed the drying of the concrete surface.

- To cure the horizontal surfaces, the title water curing can only be used.

- In this method, we can also cure the vertical structure like columns, walls, etc.

Sheet Curing

Three Types of Sheet Curing Are Below

- Polythene Sheet

- Plastic Sheet

- Curing Blankets

- Usually for the flat surfaces Both the type of the sheet issued to cure.

- To cover the concrete columns and slabs Polythene sheets are used.

- After the surface gets hardened, the sheet can be placed on the slab.

- To apply them to the concrete by using polythene, shelter areas are also created.

- This method can be used concrete not that structurally important and on special occasions less evaporation.

- To cover the concrete Plastic sheets also can be used and it is also used to cover the flat surface.

- The plastic sheets are less weight and are watertight material.

- For the newly placed concrete curing blankets are used for protection.

- As another type of sheet, it does the same thing.

Curing by Absorbing Heat

- In this absorbing heat method to absorb the heat, the Pipes are set inside the concrete.

- It absorbs the heat in the concrete when the water is circulated in the concrete.

- This method is more suitable when a higher grade of concrete and thick concrete is used for construction.

- To reduce the core temperature this method is also used.

- This method is used carefully when the temperature sudden changes in the concrete. For this, the concrete causes crack.

Formwork Curing

- In construction, the formwork is the most effective curing.

- Where the hydration temperature is high, especially in thick concretes, the formwork curing method is used.

- The formwork curing provides more safety due to the variations in the surface of the concrete when the cracking risk becomes an issue in large concrete.

- The formwork curing is used as an alternative to the thick concrete when the transmission of the heat is becoming an issue.

- The final thickness of the formwork depends on the heat, temperature gradient, peak temperature, and temperature differences.

- The heat of hydration measuring, placing temperature of concrete, its thickness, and formwork material, l, etc. are done depending on the outcome of the test.

- Then the usual curing period is required to keep the formwork longer duration for the column curing.

Membrane Curing

Membrane Curing Is Usually Two Types

- Water-based.

- Oil-based.

After the curing period, it can be washed off with water, so from the oil-based curing, The water-based curing membranes are more popular.

To remove the oil-based membranes, an additional effort is required.

Hot Mixing Method

- In the hot mixing method, to enhance the strength of the concrete, an increase in the temperature of the concrete is done.

- To enhance the strength by 10% – 20%, the temperature of the concrete rises to 320 C.

- Where we required early strength of concrete in a situation this method can use because by this method the concrete gets the strength early.

In the hot mix method by the following methods, we can be sued to increase the temperature of the concrete that’s are below

- Increase the temperature of aggregate by heating.

- Heat the water.

- Inject steam into the concrete mix.

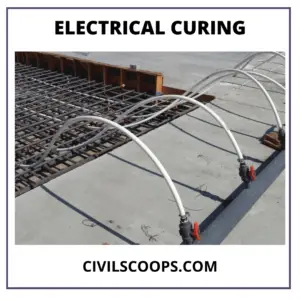

Electrical Curing

In the construction, there are three methods of curing that’s are below

- A high current is passing through the reinforcement net then it has low voltage.

- Between two external fix electrodes, the electrical current passes through the freshly laid concrete. The AC current shall be passed through the concrete.

- For the slab surfaces, large electric blankets are utilized for heating.

Natural Curing

- In this natural curing method without covering anything, concrete is allowed to cure naturally.

- We can be allowed the concrete to cure naturally where In environments due to less evaporation and no high heat to harm the concrete.

Infra-Red Curing

- The infra-red curing method is not widely used and is not a common construction method.

- In this method, inside the concrete circulating hot water or heating of the formwork is done.

Concrete Curing Time

- The curing time of concrete should be up to 28 days to develop the design strength of the concrete.

- In the curing time, the rate of development strength reduced with time with the rate of hydration.

- As per the IS:2000, the moist curing should be minimum of 7 days, and while IS:7861-1975 under hot weather conditions the curing time minimum should be 10 days.

- For the blast-furnace slag or Pozzolana cement, the curing time should be increase.

How to Cure a New Concrete Slab?

There has a simple process of cure a new concrete slab, that’s are below

- We cure the new concrete slab by the ponding curing method.

- In this method without allowing the new concrete slab surface to dry continuously wetting the concrete surface is done.

- To maintaining the newly concrete slab surface moisture level wet curing is a method is done by placing materials like hessian.

- For a new concrete floor slab, water curing is mostly used.

How Long Does Concrete Take to Dry?

So Concrete Is a Mixture of Some Materials, Then It Does Take to Dry Depends on Some Things That Are Below

Moisture

- With water, the cement’s interaction causes the curing process. Less water in the concrete will cure more quickly.

- It will take longer to cure If there is too much water.

Temperature

- The moisture evaporates faster, when it is hotter, meaning your concrete will cure faster.

Mix Design

- You should add an accelerant to the mix if you need your concrete to cure faster.

- For the high-way pavements the curing time varying from 13 to 30 days.

How Much Time Does It Take for Cement to Dry?

So the Cement Is an Intimate Mixture of Limestone, Silica, Slate Clay, Sand, or Other Things, Its Dry Does Depend on Some Things That Are Below

- Most of the sites are using Portland cement in construction as their basic element of concrete.

- The concrete and Portland cement are dries within 24 hours after pouring.

- This cement is gain enough strength after 24 hours of pouring. And after that, we can easily walk on it without leaving any impression on applying cement surface.

- It should be known that to gain the full strength of cement its takes approximately 28 days after applying it.

Also Read: What Is Estimate? | Types of Estimate | Advantage of Estimate | Disadvantage of Estimate

[note note_color=”#F2F2F2 ” text_color=”#333333″ radius=”3″ class=”” id=””]

Like this post? Share it with your friends!

Suggested Read –

- What Is Seasoning of Timber? | Methods of Seasoning of Timber | Purpose of Seasoning of Timber

- What Is Gradient of Road? | Limiting Gradient of Road | Types of Gradient of Road | Exceptional Gradient of Road | The Gradient of Road | Purpose of Providing Gradient of Road | Importance of Gradient in Roads

- What Is Lap Length? | Lap Length in Beam | Why Lapping Is Provided? | How to Calculate Lap Length? | Lap Length as Per Is Code 456 | What Are the General Rules for Lap Length? | Lapping Zone

- Hollow Block | Hollow Concrete Block | Hollow Concrete Block Size |Hollow Concrete Block Advantage | Hollow Concrete Block Disadvantage | Hollow Concrete Wall | Hollow Block Construction | Size of Hollow Blocks | How to Make Hollow Blocks

- What Is Sheepsfoot Roller? | Characteristics of Sheepsfoot Rollers | Difference Between Padfoot and Sheepsfoot Rollers

[/note]

Originally posted 2021-09-27 07:19:08.