Monolithic Slab I Monolithic Definition I Monolithicfooting I Monolithic Slab Foundationl Monolithic Slab Foundation Design L What Is a Monolithic Slab L How to Form a Monolithic Slab

Table of Contents

Monolithic Slab

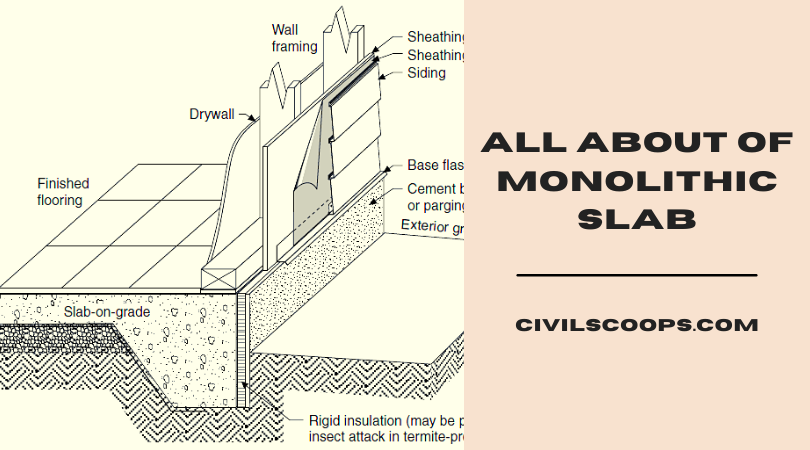

Monolithic means “all single pouring,” so the foundation is made of a single layer of a concrete slide with thick surfaces under load-bearing walls and all the edges of the perimeter to replace the footer. Because this Slab is applied simultaneously, it is very fast and keeps labor costs low.

Monolithic Definition

In simple terms, the term “Monolithic ” means a slab and a beam both work as a single body. This monolithic beam action is achieved by both the slab and the beam at the same time.

In concrete slide construction, the monolithic slab is a term used to describe concrete structures such as footings, slabs, foundations, grade beams, piers, and columns applied simultaneously.

Also Read: Types of Cement Grades | Difference Between 33, 43 & 53 Grade Cement

Monolithic Footing

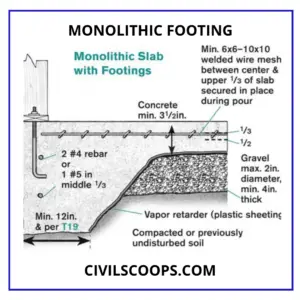

- In addition to the single-step pouring, the monolithic Footing is also much smaller than the traditional footings. They are only about two inches (4 cm) in diameter and can be up to 12 inches [12 cm] high. This means that you will only have to dig about six inches, and all the work is done by your hand.

- The slab usually rests on a stone bed for water development and is reinforced with wire or rebar wire to gain more strength and reduce the chance of cracking. In colder climates like the one we are facing here in Colorado, you can combine indoor heating with an additional coating around the base border that pushes the ice line out and down, keeping it safe in cycles of cold and melting.

- There are so many significant problems that arise if many conditions do not conflict with the Monolithic Slab. They cannot be used when more filling is required because concrete has a higher chance of if the soil is not compacted sufficiently.

- The major problem is to build homes above the flood plain which is provided by your engineer (as most builders in Florida should). In this case, Monoslabs tend to surround the perimeter walls and other large load-bearing areas. This cracking can cause structural problems affecting other household items to proceed with the construction process, such as drywall and floor if the framed walls are not stable.

Monolithic Slab Foundation

- The foundation is made by pouring a single layer of concrete to form a slab and foot. Contractors prefer the monolithic concept because it keeps labor costs low, and the construction process is faster than other foundations.

- The base of a typical monolithic slab is 12-18 inches thick at the feet and 4 to 6 inches thick. Proper site preparation and concrete reinforcement using rebar and wire are required to build a monolithic foundation.

- Construction is quick and easy: Once a circular ditch has been installed and the gravel spreads, concrete pouring can begin.

- This foundation dries faster than any other foundation.

- Solid foundation: This foundation is strong as long as the anchor bolts and bolts are correctly installed.

- Low Storage: Monolithic foundation needs to be tested only at regular intervals to ensure no cracks in the foundation.

- Energy-saving: Less energy is wasted because there is no space between home and soil. The air does not move under the ground floor.

- It is a good way for climates where the soil is not cold, and the temperature is not too hot, and it is not like a desert. If there is no need for a basement or crawlspace, you can use a monolithic slab to increase energy efficiency.

- Medium base costs can vary between $ 4,600 to $ 20,000, depending on certain factors. Some factors which mainly determine the price of a foundation include where you live, the size of your home, the reinforcement used in concrete, the size, and the soil you build on.

Also Read: What Is Estimate? | Types of Estimate | Advantage of Estimate | Disadvantage of Estimate

Monolithic Slab Foundation Design

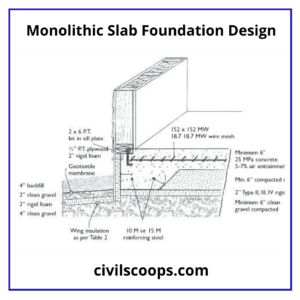

- The major elements of a Monolithic slab foundation design are the floor itself and can be distance beams or foundation walls with feet on the slab’s edges. In some cases, additional feet (usually a thick slab) are required under the walls or columns in the middle of the slab. Molded concrete floors are generally designed to be strong enough to support ground loads without reinforcement when poured into uninterrupted or compacted soil. Proper use of hot-rolled steel fabric and low-grade concrete/cement scale can reduce shrinkage cracking, which is very important in appearance and can also help with radon penetration control techniques.

- The walls of the foundation are usually made of stone or concrete for concrete construction. The foundation walls must withstand vertical loads from the upper structure and pass these angles to the feet. The spreading foundations of the concrete should provide support under the walls and pillars. Similarly, the distance beams at the edges of the foundation support the upper structure above. Footings should be designed to a size sufficient to distribute the load on the ground. Coldwater under the feet may rise, causing cracks and other structural problems. For this reason, footings should be placed under high snow unless established on rock or ground that has been proven non-frozen or frozen to prevent frost.

- Where there is widespread soil or in areas with high seismic activity, special foundations may be needed. In that case, local building official consultation is required, and a building engineer is recommended.

What is a Monolithic Slab?

The term Monolithic means “all in one demolition,” so, in the construction where the Monolithic Slab is used, the foundation is made of a single layer of a concrete slide with thick areas under the load-bearing walls and all the edges around the foot support.

Construction of Monolithic Slab is very fast, and labor costs are low as in this Slab concrete is poured simultaneously. Not only is concrete used with a single layer of concrete for the concrete floor, but it is also accompanied by a fixed slab.

The use of expensive materials makes the pouring of concrete stones monolithically with concrete pillars and pillars, while the fixed concrete slate is above ground level. Monolithic slabs are basic structures made of a single layer of concrete, usually consisting of a 4-inch thick concrete tube with thick inner layers under load-bearing walls and usually hardened at the perimeter of the perimeter.

Advantages of monolithic slabs are:

- Fast time to build.

- It is very strong, especially with the addition of reinforcing steel and fiber mesh.

- It can also be improved by adding pressure to the weak soil.

How to form a Monolithic Slab?

Monolithic means “all single pouring,” so the foundation is made of a single layer of a concrete slide with thick surfaces under load-bearing walls and all the edges of the perimeter to replace the footer. Because this Slab is applied simultaneously, it is very fast and keeps labor costs low.

When used under ideal conditions, Monoslabs may sound like Stem-Wall slabs. In most sub-category communities, it builds up, the soil is evenly distributed throughout the property and is very compacted with the minimal filtration required. In this case, if all the floor height is the same from a lot to a lot and a lot less, Monoslabs could be the best option.

Proper site layout and concrete reinforcement are important methods for the construction of a monolithic slab.

1. Soil:

It is necessary to cover the soil below the sulfur and not to contain any living things. If the topsoil is eroded, it tends to set up the soil that is not disturbed below the surface enough.

It is important to remove the soil well. It is important to respond with water flow, and proper redirection should be prepared not to overwhelm the lab.

Perimeter Trenches: The thick edge of a monolithic slide is formed by a trench corresponding to the slope rotation. The trench may only need foot depth and foot width in warm conditions.

The trench depth is a minimum of 2 meters required in areas that receive frost that penetrate and can be prevented to prevent snow from moving under the lab.

2. Gravel:

Combined gravel is scattered under slides and trenches to a depth of 3-1 / 2 to 4 inches or more. Gravel that emits well with aggregates from 3/8 to 3/4 inches is a popular method.

3. Reinforcement:

6-inch by 6-inch (6 ″ x 6 ″) wire mesh is used in a standard installation, which is placed on the rebar seats to be located near the center of the completed slide.

To tighten the thick edge, the # 4 rebar is often defined. In the lower part of the canal, 2 consecutive bars can be placed next to each other, from one bar at the top. Rebars should be placed in a trench and kept tied up.

4. Concrete:

Typically, concrete is defined as 3,000 psi and a minimum of 4 inches in diameter. At least a height of six inches above the ground should be at the end of the slide. The soil you cover should be away from the lab.

5. Anchor Bolts:

With 1/2-inch anchor bolts, the bottom plates of the construction walls are attached to the ear. At the edges inserted into the concrete when it is already wet, these bolts have a J or L shape.

Other sides of the anchor bolts are installed so that the upper side of the wall plate is fastened to the nuts. Typically, the anchor bolts are separated by six feet from the center.

[note note_color=”#F2F2F2 ” text_color=”#333333″ radius=”3″ class=”” id=””]

Like this post? Share it with your friends!

Suggested Read –

- What Is a Spillway | Types of Spillway | Definition Spillway | Spillway Design

- What Is Workability | What Is Workability of Concrete | Types of Workability of Concrete | Factors Affecting Workability of Concrete

- What Is Sewerage System? | Types of Sewerage System | Why We Need a Partially Separate System? | How Does a Sewer System Work? | How Does a Sewage Treatment Plant Work?

- What Is Seasoning of Timber? | Methods of Seasoning of Timber | Purpose of Seasoning of Timber

- What Is Gradient of Road? | Limiting Gradient of Road | Types of Gradient of Road | Exceptional Gradient of Road | The Gradient of Road | Purpose of Providing Gradient of Road | Importance of Gradient in Roads

[/note]

Originally posted 2021-09-20 12:43:01.