All Abot Parts of Stairs | Stairs Parts Names & Details | Parts of Stairs Parts Names & Details

Table of Contents

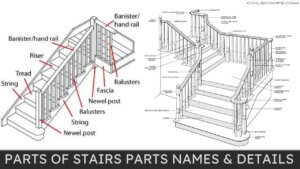

Parts of Stairs Parts Names & Details

A various part of Stair:

1. Step:

A flat surface, especially one in a series, on which to place one’s foot when moving from one level to another. all step is composed of tread and riser.

2. Tread:

Tread is a scrap of the stairway that’s stepped in. It’s the top or flat surface to press beneath the feet. It’s trodden on while climbing or descending the staircase.

It’s constructed to the same thickness as another floor. There’s always one fewer tread than risers at stairs. The general horizontal distance of the stairs is going to be the number of threads added together.

The horizontal projection of a step in a staircase is called tread. It is also known as goingIn residential buildings, the tread length provided is 250 mm while in public buildings maximum length 270 mm to 300 mm.

3. Riser:

This riser is the vertical portion between each tread on the stair. Not all stairs have risers. The rise-less steps are called the open thread.

Open riser stairs have grown in popularity Recently years. Closed tread stair has risers included. This vertical board forms the face of the step, also forms the space between one step and the next.

Rise provided could be uniform. It is normally hight at 150 mm to 175 mm in residential buildings while it is kept between hight 120 mm to 150 mm in public buildings. However, in commercial buildings, more rise is provided from the consideration of the economic floor area.

4. Nosing:

Nosing is the flat protruding edge of a stair at which most foot traffic occurs. Mostly, it’s the half curved molding fixed into the ends of those threads exposed at a half that covers where the balusters fit into the treads.

Nosing is the border of the tread projecting beyond the face of the riser and the face of a cut string. This is the place where the thread above a riser overhangs it. Sometimes, the tread may not have a nosing.

5. Base Rail or Shoe Rail

For systems in which the baluster doesn’t start at the treads, they go to a base rail. This allows for identical balusters, avoiding this second baluster problem.

6. Landing:

This is a platform provided between two flights.

How to Calculate Staircase Qty?

Here we are going to calculate the Qty of Staircase. We will divide the amount of stairs into two parts. In the first part we will calculate the concrete, then we will calculate all the steel.

- Concrete Calculation for Staircase

- Bar Bending Schedule for Staircase

Let’s go into detail about knowledge of Calculate Staircase Qty.

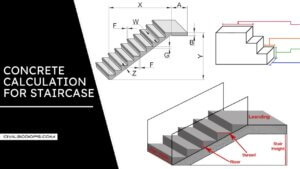

1. Concrete Calculation for Staircase

Staircase Reinforcement Details

Concrete calculation

Section 1

- Landing area concrete = L x B x H

- Landing area concrete = 1.7 M. x 3.25 M. x 0.150 M.

- Landing area concrete = 0.830 Cu.m.——–(1)

Section 2

- Wasit slab area concrete = L x B x H x N

- Wasit slab area concrete = 3.85 M. x 1.5 m. x 0.150 M. x 2 Nos.

- Wasit slab area concrete = 1.732 Cu.m. ——–(2)

Section 3

- Steps area concrete = L x Vloume of trianglar area x N x Q

- Steps area concrete = 1.5 M. x( 0.300 M. x 0.150 M x (1/2)) x 2 Nos. X 11 Qty

- Steps area concrete = 0. 75 Cu.m. ——–(3)

Section 4

- Beam area concrete = L x B x H X N

- Beam area concrete = 1.5 M. x 0.44 M. x 0.300 M. x 2 Nos.

- Landing area concrete =0.400 Cu.m.——–(4)

- Total Concrete of Staircase = (1) + (2) + (3) + (4)

- Total Concrete of Staircase = 0.830 Cu.m. + 1.732 Cu.m. + 0. 75 Cu.m. + 0.400 Cu.m.

Total Concrete of Staircase = 3.712 Cu.m.

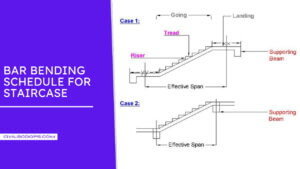

2. Bar Bending Schedule for Staircase

Staircase Reinforcement Details

Section 1

- Landing Area Bar Bending Schedule

- Distribution bar 8 mm C/C 120 mm Length 3.25 in Y-axis Distribution area 1.5m

- So No, of 8 mm Steel bar = 1.5 M. / 0.120 M. = 12.5 Nos

- Consider 13 Nos. steel bar use Top Side +13 Nos Steel use Bottom Side

- Weight of distribution of 8 mm dia steel bar = L x Nos of steel x Weight of Steel

- Weight of distribution of 8 mm dia steel bar = 3.25 x 13 x 2 x 0.395 (0.395 kg/m is 8mm dia steel bar weight)

- Weight of distribution of 8 mm dia steel bar = 33.34 kg ——– (1)

- Section 1 Total = 33.34 kg

Section 2-1

- Wasit slab Bar Bending Schedule

- Distribution bar 8 mm C/C 140 mm Length 1.5 in Y-axis Distribution area 3.89m

- So No, of 8 mm Steel bar = 3.89 M. / 0.140 M. = 27.75 Nos

- Consider 28 Nos. steel bar use Top Side +28 Nos Steel use Bottom Side

- Weight of distribution of 8 mm dia steel bar = L x Nos of steel x Weight of Steel

- Weight of distribution of 8 mm dia steel bar = 1.5 x 28 x 2 x 0.395 (0.395 kg/m is 8mm dia steel bar weight)

- Weight of distribution of 8 mm dia steel bar = 33.1 kg ——– (2-1-1)

- Main bar Bottom Area 10mm dia C/c 80 mm distance

- Length of main bar bottom area = 1.5 M. – 0.180 M. + 0.150 M. + 3.89 M. + 0.450 M.

- Length of main bar bottom area = 5.81 m

- Nos of bar 10 mm dia C/c 80 mm distance = 1.5 M. / 0.080 M. = 18.75 Nos.

- Consider 19 Nos. steel bar use Bottom bar Side

- Main bar Bottom Area 10mm dia steel bar = 5.81 M. X 19 Nos. X 0.617 kg/m (0.617 kg/m is 10mm dia steel bar weight)

- Main bar Bottom Area 10mm dia steel bar = 68.11 kg ——– (2-1-2)

- Main bar Top Area 10mm dia C/c 80 mm distance

- Length of main bar top area = 1.7 M. – 0.180 M. + 3.89 M. + 0.450 M. +0.250 M.

- Length of main bar top area = 6.11 m

- Nos of bar 10 mm dia C/c 80 mm distance = 1.5 M. / 0.080 M. = 18.75 Nos.

- Consider 19 Nos. steel bar use Bottom bar Side

- Main bar Top Area 10mm dia steel bar = 6.11 M. X 19 Nos. X 0.617 kg/m (0.617 kg/m is 10mm dia steel bar weight)

- Main bar Bottom Area 10mm dia steel bar = 71.63 kg ——– (2-1-3)

- Section 2-1 total = 33.1 kg + 68.11 kg + 71.63 kg = 172.84 kg

Section 2-2

- Wasit slab Bar Bending Schedule

- Distribution bar 8 mm C/C 140 mm Length 1.5 in Y-axis Distribution area 3.83m

- So No, of 8 mm Steel bar = 3.83 M. / 0.140 M. = 27.75 Nos

- Consider 28 Nos. steel bar use Top Side +28 Nos Steel use Bottom Side

- Weight of distribution of 8 mm dia steel bar = L x Nos of steel x Weight of Steel

- Weight of distribution of 8 mm dia steel bar = 1.5 x 28 x 2 x 0.395 (0.395 kg/m is 8mm dia steel bar weight)

- Weight of distribution of 8 mm dia steel bar = 33.1 kg ——– (2-2-1)

- Main bar Bottom Area 10mm dia C/c 80 mm distance

- Length of main bar bottom area = 1.5 M. – 0.180 M. + 0.150 M. + 3.83 M. + 0.450 M.

- Length of main bar bottom area = 5.78 m

- Nos of bar 10 mm dia C/c 80 mm distance = 1.5 M. / 0.080 M. = 18.75 Nos.

- Consider 19 Nos. steel bar use Bottom bar Side

- Main bar Bottom Area 10mm dia steel bar = 5.78 M. X 19 Nos. X 0.617 kg/m (0.617 kg/m is 10mm dia steel bar weight)

- Main bar Bottom Area 10mm dia steel bar = 67.75 kg ——– (2-2-2)

- Main bar Top Area 10mm dia C/c 80 mm distance

- Length of main bar top area = 1.7 M. – 0.180 M. + 3.83 M. + 0.450 M. +0.250 M.

- Length of main bar top area = 6.05m

- Nos of bar 10 mm dia C/c 80 mm distance = 1.5 M. / 0.080 M. = 18.75 Nos.

- Consider 19 Nos. steel bar use Bottom bar Side

- Main bar Top Area 10mm dia steel bar = 6.05 M. X 19 Nos. X 0.617 kg/m (0.617 kg/m is 10mm dia steel bar weight)

- Main bar Bottom Area 10mm dia steel bar = 70.92 kg ——– (2-2-3)

- Stection 2-2 Total = 31.1 kg + 68.09 kg +70.92 kg = 170.11 kg

- Total Secction 2 weight = 172.84 kg + 170.11 kg = 342.95 kg

Section 3

- Beam area bar bending schedule

- 8mm dia Ring Size for lenth of column ring = Column Size – Cover

- Ring Size for lenth of column ring = ( L of Column – cover – cover + B of Coumn – cover – cover + Hook ) x 2

- Ring Size for lenth of column ring = (600 -25 -25 + 300 – 25 -25 +8 ) x 2

- 8mm dia Ring Size for lenth of column ring = 1.616 M.

Staircase Reinforcement Details

- No ring requirement = Length / Spacing

- No ring requirement = 1.5 /0.140 = 11 Nos

- Weight of ring = 1.616 x 11 x 0.395 = 7.02 kg ——–(3-1)

- Length of Bar = Length of bar +( wall bering + wall bering ) + ( End side L Bend x No of Qty )

- 12 mm dia Length of Bar = 1.5 + (0.200 + 0. 200 ) + (0. 300 X 4)

- Length of Bar = 3.1 M.

- Weight of ring Main bar = 3.1 x 6 x 0.89 = 16.554 kg ——–(3-2) (0.89 kg/m is 12mm dia steel bar weight)

- Section 3 total = 7.02 kg + 16.554 kg = 23.57 kg x 2 ( Beacuse of same two beam ) = 47.51 kg

- Total Weight of Staircase Bar Bending secdule

Section = Section 1 + Section 2 + Section 3

Section = 33.34 kg + 342.95 kg + 47.51 kg

Total Weight of Staircase Bar Bending secdule = 423.79 kg.

Which Type of Stairs Is Best?

Great for tight spaces and small residences, ladder stairs are one of the most space-efficient types of staircases. Of course, it’s a good idea to check building codes in the local area because often they are not permitted as the main staircase.

What Is the Size of Staircase?

The stair’s width usually varies depending on the type of building the staircase is in, but for a normal residence, the standard tends to be 3 feet, 6 inches (106.7 cm). The minimum, in most places, is 2 feet 8 inches (81.3 cm). If a staircase exceeds 44 inches (111.8 cm), handrails are required for both sides.

What Is Staircase and Its Types?

There are more than 14 types of staircases namely the L-shaped-shaped, Winder stairs, Spiral, Spiral case with landing, Circular, Curved, Ladder, Split, Space-saving, Floating stairs, I-Shaped staircase, Stairs with storage, Sculptural floating staircase, Bent metal, Floating stand-alone staircase, Stairs with bookshelves, Concrete, Marble, Carpeted, Organic, Graphical iron, Two-tone spiral, enclosed two-wall, partially open-one wall, Granite, Bifurcated, and Three-quarter turn.

What Is Two Flights of Stairs?

A flight of stairs is a set of steps between two floors or two landings. Flight of stairs is also called as a stairway or stairwell.

What Is RCC Staircase?

RCC stairs may be the most common stairs widely used than any other types of stair. These stairs can be easily moulded to any desired shape and are better wear and fire resistant. The steps of RCC stairs are made by using ordinary cement concrete.

Like this post? Share it with your friends!

Suggested Read –

- Important Factors to Consider When Building a New Home

- All About Plywood | What Is Plywood | What Is Plywood Used For | What is Plywood Made From

- All About Soil Compaction | What Is Soil Compaction | Different Types of Soil Compaction Equipment

- All About Consider | When Building a New Home | Important Factors to Consider When Building a New Home

- All About Painting | What Is Painting | Painting Area Calculation for Evan Surface & Uneven Surface |How Much Paint Do I Need

[/su_note]

Originally posted 2022-06-15 14:50:04.