Table of Contents

What is Shoring?

Shoring is a short-term figure applied to stop settling the major incomplete work. It is necessary to maintain the building mine walls, prevent water from entering the mine, and save nearby residents. .

Shoring in the building is required to help an endless hole stop the mud from falling and afterward trouble a creation mistake. It allows essential base on the earth class and when the spot deep is 1.20m among in measure from the foundation.

Construction projects are town cities with significant construction consistency reaction needs chief analysis. Climate constructions and vehicle figures are necessary to secure and regularly need adequate shoring and drying attempts to stop the beginning formation. The essential trouble is determining the short-term count for the last construction formation. These kinds of walls can apply as everlasting walls.

What Is Shoring in Construction?

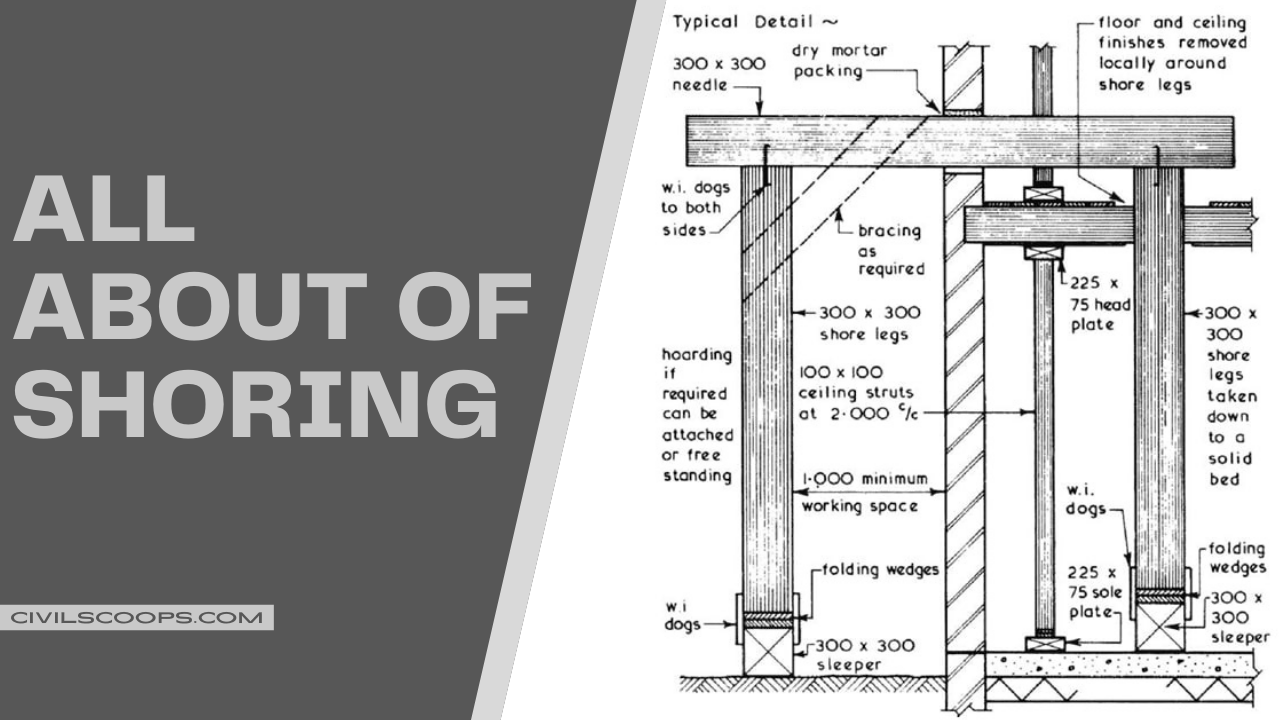

Shoring is an everlasting construction applied to stop the settlement of the significant incomplete building. The main generally shoring help is needed under the premature structure position, which is uncovering.

Shoring is known as short-term help structured to help and develop the sideward force of walls and constructs through restoration known as shoring.

Types of Shoring

1. Bored Pile Walls

These are various kinds of bored pile walls shoring,

- Single bored pile walls

- Contiguous bored pile walls

- Secant bored pile walls

Based on the aeromechanics necessary bored pile walls demand to be secured—section of the last Contiguous bored pile walls.

2. Secant Pile Shoring

Secant pile structure jointing two piles with piles interlock. A conductor kernel is a structure before taking banks’ fit in the proper position. Secant piles shoring is highly applied in endless digging up.

This method is to finish the following piles that are operating. The steel program of secondary banks is in place, and cement flows from a regular wall. Secant piles are favored when there is a good place for free digging up, which is nearest to the contiguity.

3. Diaphragm Wall

- Regular wall

- Tough shoring construction.

- It has Necessity weighty and expensive requirements.

- Maybe the section of everlasting construction.

A diaphragm wall is a copy of a rooted boost cement wall. The ditch is to stop destroying in digging up, boosting, and copying by the application of helping bentonite slurry. The technic applied for the structure of diaphragm walls are between the highly improved and effortless structure requirement using the below essential.

- Diaphragm wall grab

- Trench cutters

4. Contiguous Pile Shoring

Contiguous pile shoring is nearby places with the front of every pile which holds the following bundles. Kinds of bundles shoring are commonly applied where water is not great. Contiguous pile shoring is highly potent in brick soils and can use to keep simple powder elements. It can choose to fill this space to form a leak-proof detain wall.

This shoring is not good to apply on a tall pore water bench except for drying duty. Contiguous pile shoring structure is the same as secant piles as earlier in the design, and an escort stream must structure to deliver as a conductor for the adjacent wall to design in space.

5. Sheet Piles Shoring

The sheet pile wall formula is based on the dynamic of steel parts that will help from bright soils. It is usually used with admiration for the honesty of the piles. The look of pore water can learn by the complex bond and the long attachment among the parts.

- Bonding of sheet pile

- Design and straining of pullback.

- Design of sheet piles by shaking

- They are digging up a structure hole.

Also, Read: All About of Plumbing Fittings | What Are Plumbing Fittings | Types of Plumbing Fittings

Types of Shoring in Construction

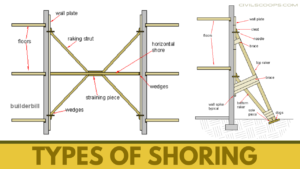

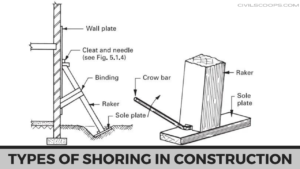

1. Raking Shoring

Raking shores are structured by situating extra wood supports on the front of the construction to be helped and the floor. Ranking shoring is highly productive if the raker connects the wall at an edge of 60 to 70 degrees? The wall dish is applied to grow the zone of the beam.

2. Beam and Plate Shoring

Beam and plate are essential guides into the floor, and the steel plates move between them. The exact process used to be soon and freely, and the second process is applying for permanent statements.

3. Soil Nailing Shoring

Soil nailing is a process of shoring in by digging up, and thin soil walls build by guiding boost materials in them. The pit in the mud is a hammer pit and then filled at once. These materials are put at a light down tendency, providing good cover opposite each expend work.

4. Hydraulic Shoring

Hydraulic shoring is commonly applied hydraulic diesel, which drives outside till they force opposite the ditch walls. This drive is widely joint with plywood 1-1/8” wide.

Like this post? Share it with your friends!

Suggested Read –

- All About of Parking Space | What Is a Parking Space | Standard Parking Space Dimension

- All About of Standard Door | What Is the Standard Door Size | Standard Size of the Door Frame

- All About of Wall Texture | What Is Wall Texture | Uses of Texture Paint | Types of Wall Texture Paint

- All About of Drapes Vs. Curtains | Difference Between Drapes and Curtains | What Are Drapes | What Is Certain

- All About of Tort and Contract | What is tort | What Is Contract | Difference between Tort and Contract | Tort law definiti on

Frequently Asked Questions (FAQ)

Shoring System

Shoring is commonly used when installing the foundation of a building. A shoring system such as piles and lagging or shotcrete will support the surrounding loads until the underground levels of the building are constructed. Commonly used shoring equipment includes post shores, shoring beams, and timber jacks.

Trench Box

A trench box is a safety device used to protect workers in trenches. It is a square structure made up of pre-constructed side sheets and adjustable cross members. It is usually made of steel or aluminum. Trench boxes are critical to the safety of workers working below ground as a trench collapse can be fatal.

Trench boxes may also be referred to as sewer boxes, manhole boxes, trench shields, trench sheets, or tap boxes.

Trench Shield

Trench shields (also called trench boxes or trench sheets) are steel or aluminum structures used for protecting utility workers while performing their duties within a trench and avoid cave-ins. They are customarily constructed with sidewalls of varying thicknesses held apart by steel or aluminum spreaders.

Spreaders can be interchanged to match the width of the trench. The different materials and building designs lead to a variety of depth ratings, i.e. the depth of a trench that the shield can withstand a collapse without buckling. Depth ratings are determined by registered professional engineers.

Trench Box For Sale

If you’re looking for the most durable, lightweight, and long-lasting aluminum trench boxes for sale on the market, you’re in the right place. For over twenty years, the staff at Aluminum Trench Box has supplied workers with the equipment they need to get their jobs done quickly, efficiently, and – most importantly – safely.

From portable trench shoring and aluminum trench shields to modular trench shoring systems, we offer all the solutions you need to ensure a safe environment for your workers. To learn more about who we are and the equipment we offer, we encourage you to browse our products by clicking the button below.

Sheeting And Shoring

Sheeting and shoring are typically used at construction sites in order to provide temporary support of soil and existing structures. A variety of materials and methods are available depending upon the space available, magnitude of forces, and the criticality of the area being shored.