Tests on Stones | Crushing Strength Test, Water Absorption Test, Abrasion Test, Impact Test, Acid Test

Table of Contents

Tests on Stones

To determine the required properties of stones, the following tests Could be conducted:

- Crushing Strength Test

- Water Absorption Test

- Abrasion Test

- Impact Test

- Acid Test

Crushing Strength Test of Stone

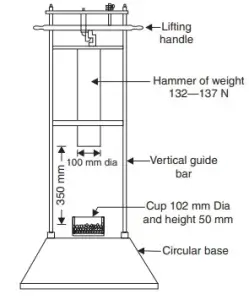

- For conducting this test, a specimen of size 40 × 40 × 40 mm is prepared from parent stone.

- Afterward, the sides are finely dressed and placed in water for three days.

- The saturated specimen is provided with a layer of plaster of paris on its top also bottom surfaces to get even surface so that load applied is distributed uniformly.

- Uniform load distribution could be obtained satisfactorily by providing a pair of 5 mm thick plywood instead of using plaster of paris layer also.

- The specimen so placed in the compression testing machine is loaded in the rate of 14 N/mm2 per minute. The crushing load is noted.

- Then crushing strength is equal to this crushing load divided by the area where the load is applied.

- At least three specimens must be tested, and the average ought to be taken as crushing strength.

Water Absorption Test of Stone

With this test cube specimen weighing about 50 grams are Ready, and the test is carried out at the steps given below:

- Note the weight of dry specimens as W1.

- Place the specimen in water for 24 hours.

- Take out the specimen, wipe out the surface with a piece of cloth, and weigh the specimen. Let its weight be W2.

- Suspend the specimen freely in weight and water it. Let its weight be W3.

- Place the specimen in boiling water for 5 hours. Then take it out, wipe the surface with a cloth, and weigh it. Let this weight be W4. Then,

Percentage absorption by weight = (W2 – W1) / W1 x 100 ……….(1)

Percentage absorption by volume = (W2 – W1) / (W2 – W3) x 100 ……….(2)

Percentage porosity by volume = (W4 – W1) / (W2 – W3) x 100 ……….(3)

Density = W1 / (W2 – W1) x 100 ……….(4)

Specific Gravity = W1 / (W2 – W3) x 100 ……….(5)

Saturation Coefficient = Water Absorption / Total Porosity = (W2 – W1) / (W4 – W1)

Abrasion Test of Stone

This test is carried out on stones that are used as aggregates for road construction. The test result indicates the suitability of

stones against the grinding action under traffic.

Anyone of the following tests could be conducted to find out the suitability of aggregates:

- Los Angeles Abrasion Test

- Deval Abrasion Test

- Dorry’s Abrasion Test.

However, the Los Angeles abrasion test is preferred since these test results have a good correlation with the performance of the pavements.

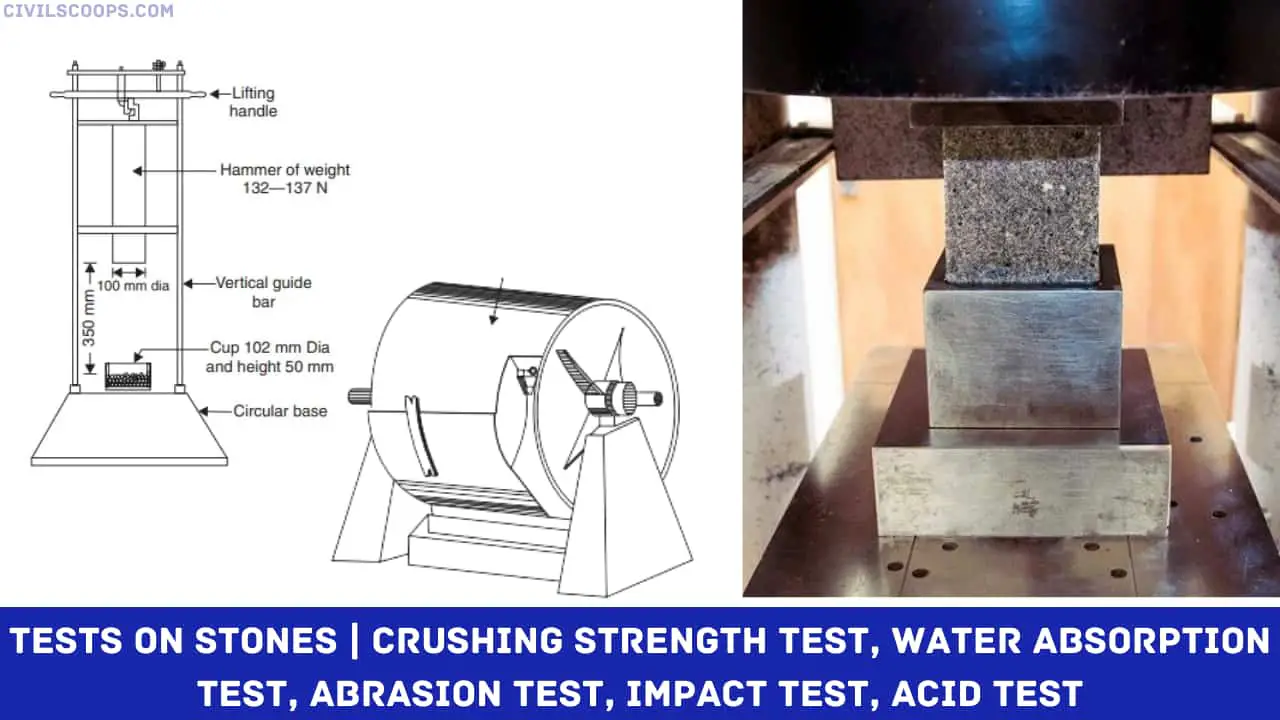

The Los Angeles apparatus [Below Figure] consists of a hollow cylinder 0.7 m inside diameter and 0.5 m long with both ends closed.

It is mounted onto a frame so that it could be rotated about a horizontal axis. IS code has standardized the test procedure for different gradations of specimens.

Together with the specified weight of the specimen, a specified number of cast iron balls of 48 mm diameter are placed in the cylinder.

Los Angeles testing machine

Then the cylinder is rotated at a speed of 30 to 33 rpm for a specified number of times (500 to 1000). Then the aggregate is removed along with sieved on 1.7 mm. IS sieve. The weight of aggregate passing is found.

Then Los Angeles value is found as = (Weight of aggregate passing through sieve / Original weight ) x 100

The following values are recommended for road works:

[su_table responsive=”yes” alternate=”no”]

| For bituminous mixes | 30% |

| For base course | 50% |

[/su_table]

Impact Test of Stone

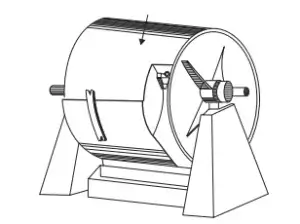

The resistance of stones to impact is found by conducting tests in impacting the testing machine [Below Figure].

It consists of a frame with guides where a metal hammer weighing 13.5 to 15 kg can freely fall from a height of 380 mm.

Aggregates of size 10 mm to 12.5 mm are filled in a cylinder in 3 equal layers, every layer being tamped 25 times.

The same is then transferred into the cup and again tamped 25 times. The hammer is then allowed to fall freely onto the specimen 15 times.

The specimen is then sieved through a 2.36 mm sieve.

Then, Impact value = W2 / W1

where,

W2 = Weight of Fines.

W1 = Original Weight.

The recommended impact values for various works are:

- for wearing course ≯ 30%

- for bituminous macadam ≯ 35%

- for water-bound macadam ≯ 40%

Acid Test of Stone

- This test is normally carried out on sandstones to check the presence of calcium carbonate, which weakens the weather resisting quality.

- In this test, a sample of stone weighing about 50 to 100 gm is taken and kept in a solution of one percent hydrochloric acid for seven days.

- The solution is agitated at intervals. A good building stone maintains its sharp edges and keeps its surface intact.

- If edges are broken, and powder is formed on the surface, it indicates the presence of calcium carbonate.

- Such stones will have poor weather resistance.

[su_box title=”FAQ” style=”default” box_color=”#333333″ title_color=”#FFFFFF” radius=”3″ class=”” id=””]

Characteristics of Good Building Stone

Strength and durability are essential properties of building stone. The compressive strength of a stone determines its ability to withstand the weight of stacking on top of each other. A building stone’s compressive strength should be 60 to 200 N/mm2

Properties of Stone

Stone is a heterogeneous substance characterized by wide ranges of mineral com- position, texture, and structure. Consequently, the physical and chemical pro- perties, i.e., the durability, are extremely variable.

Tests on Stones

Following are different tests on building stones:

- Acid test.

- Attrition test.

- Crushing test.

- Crystalline test.

- Freezing and thawing test.

- Hardness Test.

- Impact test.

- Water absorption test.

[/su_box]

[su_note note_color=”#F2F2F2 ” text_color=”#333333″ radius=”3″ class=”” id=””]

Like this post? Share it with your friends!

Suggested Read –

- Procedure for RCC Concrete

- What Is Bleeding In Concrete | What Is Segregation In Concrete

- What Is Sand Blasting | Concrete Sand-blasting Equipment | Key Benefits of Sand Blasting

- What Is Passometer & Pedometer | Advantage of Passometer & Pedometer | Passometer Vs Pedometer

- What Is Pedestal | Functions of Pedestal | Methods of Construction: Pedestals | Advantages and Disadvantages of Pedestal

[/su_note]

Originally posted 2022-07-09 12:17:20.