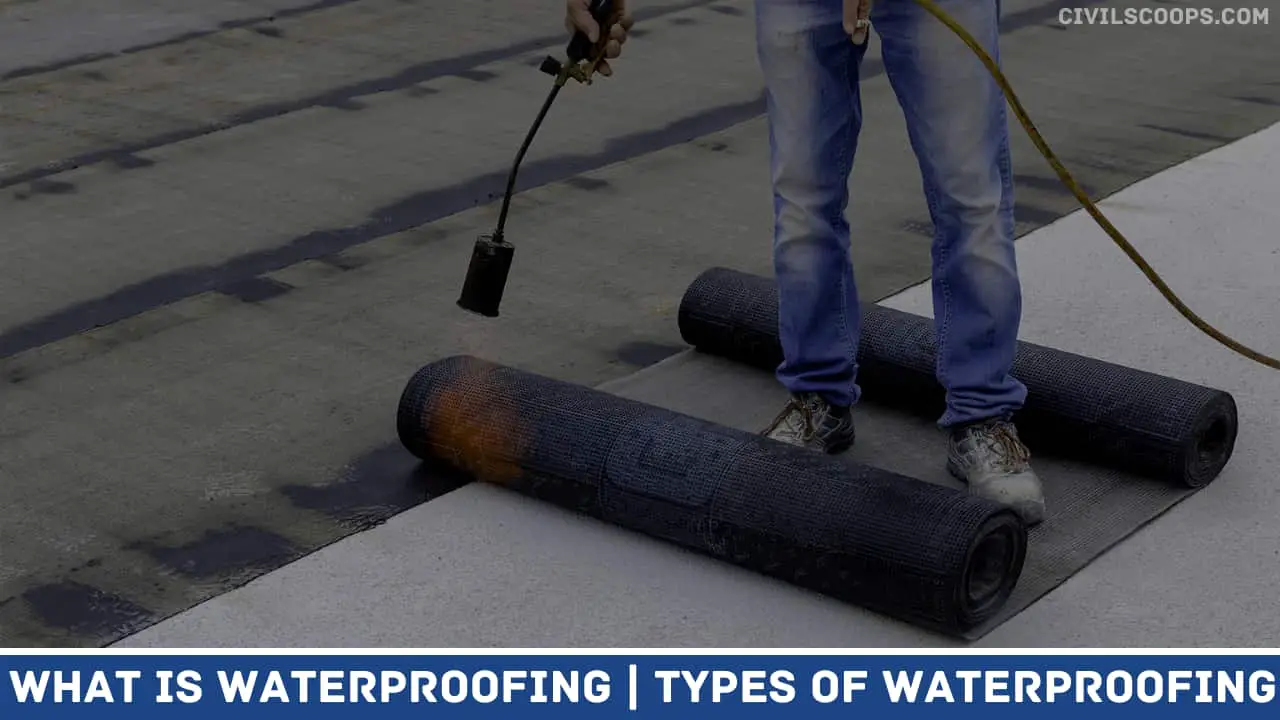

What Is Waterproofing | Types of Waterproofing

Table of Contents

What Is Waterproofing?

This is the process of making a structure water-resistant or impervious to the ingress of water. Water-Proofing is essential that prevents water from penetrating buildings and also helps to keep the inside areas dry. It helps in reducing the humidity inside the building, minimizing the damage done to furniture and alike.

In areas that experience high annual rainfall and occasional flooding events, water-Proofing is a must. It’s important for foundations and basements to be waterproof, especially in areas where the groundwater table is high.

In the case of a high water table, water from the soil is likely to exert hydrostatic pressure upon the basement walls and floor. This may force the water through the cracks, which may result in structural damages along with moisture-related problems like mildew, mold, and decay.

During monsoons, we all would have come across water seepages from the walls and ceilings or dampness in the aftermath of flooding. This is because of poor waterproofing. By waterproofing your house, you can safeguard your building from damage as well as these things inside your house from water and humidity exposure.

Types of Waterproofing Methods

The following water-proofing methods are commonly used in construction:

- Bituminous Water-Proofing

- Bituminous Membrane

- Bituminous Coating

- Polyurethane Liquid Membrane

- Cementitious Waterproofing

- Liquid Waterproofing Membrane

1. Bituminous Waterproofing

Bituminous waterproofing systems are designed to protect commercial buildings and residential. Bitumen is a mixed substance made up of organic liquids that are highly viscous,sticky,and waterproof.

These systems are sometimes used to construct roofs, in the form of roof felt or roll roofing products.

as per below type bituminous waterproofing

- Bituminous Membrane

- Bituminous Coating

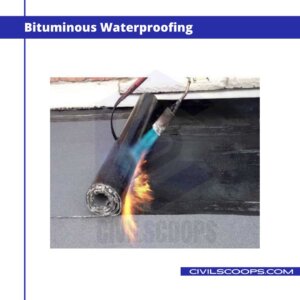

1.1. Bituminous Membrane

Bituminous membrane waterproofing is a popular method used for low-sloped roofs because of their proven performance.

The bituminous waterproofing membrane has a torch on the membrane along with a self-adhesive membrane. Self-adhesive compounds include asphalt, polymers, and filler; additionally, certain resins and oils could be added to improve adhesion characteristics.

The self-adhesive type has a low shelf life as bonding properties of this membrane reduces with time. Torch on membrane has covered and exposed types.

The exposed membrane frequently has granular mineral aggregate to withstand the wear and tear of this weathering and the other types of membrane. The contractor needs to apply one protective screed to prevent the puncture of the membrane.

1.2. Bituminous Coating

Bituminous coating is a type of coating used for waterproofing and a flexible protective coat in accordance with its formulation and polymerization grade.

Its flexibility and protection against water could be influenced by the polymer grade as well as reinforcement of fiber. Bituminous coating is also called an asphalt coating. The most common applications of bituminous coatings include areas that are beneath screed wet.

It’s an excellent protective coating and waterproofing agent, especially on surfaces like concrete foundations. Bituminous coating is made from bitumen-based materials, and it isn’t suitable for exposure to sunlight.

It becomes very brittle and fragile when long exposure to the sunlight unless it’s modified using a more flexible material like polyurethane or acrylic-based polymers. The flexibility of these finished products always depends on the solid content of this polymer added to the bitumen.

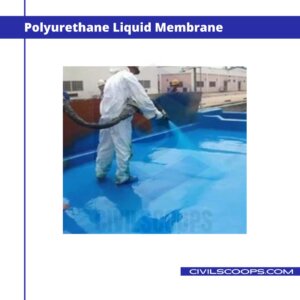

2. Polyurethane Liquid Membrane

Polyurethane is made up of two elements, reactor, and base. Polyol acts as the base, while isocyanide is your reactor component.

The combination of these two in a specific design ratio creates a liquid coating for waterproofing applications. Polyurethane is a rather popular choice because of its ease of installation. Unlike other waterproofing systems such as sheet membranes and liquid applied membranes, this polyurethane application requires comparatively less skill and supervision.

Application is fast, and this type of treatment may be used for post-construction applications as well. It’s easy to install, provides a seamless finish, and has long term durability and wear resistance. It’s UV and weather-resistant alkaline cleaners, battery acid, and fuels.

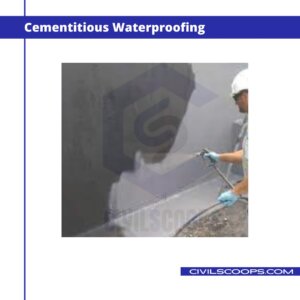

3. Cementitious Waterproofing

Cementitious products are probably the easiest waterproofing materials to use. They are readily available from suppliers of masonry products, and they are easy to mix and apply. When you plan to use this material, a long-handled brush will make your life easier.

Also, spend the extra money to buy an acrylic additive to mix in with the cement product. You will get a more solid, better bonding, and durable coating.

The chief disadvantage is that cementitious products have no given to them, probably because cement just does not stretch to any degree worth mentioning. They’ll stand up fine to a head of water, however, will tolerate almost no joint or crack movement.

Cementitious waterproofing is used in the following type of structures:

- Railway & Subway Systems

- Marine Cargo Ports & Docks

- River Locks/Channels & Concrete Dykes

- Parking Structures & Lots

- Tunnels

- Water Treatment Plants

- Sewage Treatment Plants

- Bridges

- Dams

- Toilet in Flats

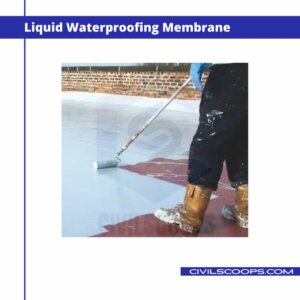

4. Liquid Waterproofing Membrane

Liquid Roofing is this process of waterproofing a roof from the application of a specialist liquid roof coating. It’s suited to all types of roofs, including flat, domed, and pitched.

Liquid roofing involves the application of a monolithic, fully bonded, liquid-based coating into a roof. The coat cures to form a rubber-like elastomeric waterproof membrane, capable of extending and returning to its original shape without damage.

Such coating systems are usually reinforced with secondary materials like glass-reinforced plastic to provide additional tensile strength. The coatings may be applied over most traditional roofing materials, including felt, asphalt, concrete, and bitumen.

The process of liquid roof provides a cost-effective way of making a new or existing roof waterproof. It can deliver up to 25 years’ performance depending on the coating system employed. It’s estimated that liquid roofing is 70% less expensive than overall roof replacement in refurbishment situations.

Types of Waterproofing PDF: Click Here

[su_box title=”FAQ” style=”default” box_color=”#333333″ title_color=”#FFFFFF” radius=”3″ class=”” id=””]

Waterproofing

Waterproofing is the process of making an object or structure waterproof or water-resistant so that it remains relatively unaffected by water or resists the ingress of water under specified conditions. Such items may be used in wet environments or underwater to specified depths.

Cementitious Waterproofing

Cementitious waterproof coatings are typically two-component blends used behind tile, over masonry patching, and over concrete surfaces. These above and below-grade waterproofing coatings have a good affinity to concrete and masonry substrates due to their cementitious nature, and thus strong bonding strength.

Bituminous Waterproofing

Bituminous waterproofing systems are designed to protect residential and commercial buildings. Bitumen (asphalt or coal-tar pitch) is a mixed substance made up of organic liquids that are highly sticky, viscous, and waterproof.[1] These systems are sometimes used to construct roofs, in the form of roofing felt or roll roofing products.

Bitumen Waterproofing

Bituminous waterproofing systems are designed to protect residential and commercial buildings. Bitumen (asphalt or coal-tar pitch) is a mixed substance made up of organic liquids that are highly sticky, viscous, and waterproof.

Bituminous Sheet Waterproofing

Bitumen, also known as asphalt, is a sticky, black and highly viscous liquid or semi-solid form of petroleum. Thanks to its waterproofing qualities, it is widely used in construction. Bituminous membranes are perfect for waterproofing roofs, basements, below-ground structures, bridges, and other structures.

Types of Waterproofing Materials

Here, list of types of waterproofing materials are as follows.

- Polyurethane.

- Cementitious Coating.

- EPDM Rubber.

- Rubberized Asphalt.

- Thermoplastic.

- Bituminous Membrane.

- PVC Waterproofing Membrane.

Waterproofing Methods

List of waterproofing methods are as follows.

- Cementitious Waterproofing.

- Liquid Waterproofing Membrane.

- Bituminous Coating Waterproofing.

- Bituminous Membrane Waterproofing.

- Polyurethane Liquid Membrane Waterproofing.

Latest Waterproofing Techniques

Given below are few of the waterproofing innovations occurring across the globe.

- Nano technology in waterproofing.

- Crystalline waterproofing.

- Waterproofing membranes.

- Self-healing, water-repellent, spray-on coating.

- New coatings make natural fabrics waterproof.

- Ultra-Water Resistant Surface.

- Torch on waterproofing.

Types of Waterproofing Membrane

List of Waterproofing products are as follows.

- Polyurethane.

- Cementitious Coating.

- EPDM Rubber.

- Rubberized Asphalt.

- Thermoplastic.

- Bituminous Membrane.

- PVC Waterproofing Membrane.

Polyurethane Waterproofing

Polyurethane-based waterproofing membranes is a liquid applied system that offers decisive advantages particularly where seamless systems are desired; either structurally or aesthetically, and for geometrically complicated connections with ventilation outlets or upturns.

[/su_box]

[su_note note_color=”#F2F2F2 ” text_color=”#333333″ radius=”3″ class=”” id=””]

Like this post? Share it with your friends!

- Suggested Read –

- 21 Different Types of Arches Construction

- Difference Between Carpet Area and Built-up Area

- What Is Fresh Concrete | 8 Properties of Fresh Concrete

- Difference Between Veneer and Laminate | What Is Veneer | What Is Laminate

- What Is Foundation Repair | Foundation Techniques | Effects of Foundation Damage | What Foundation Repair Techniques Are Available

[/su_note]

Originally posted 2022-07-08 06:35:10.