23 Different Types of Cement Available in India and as Per Is Standards

Table of Contents

23 Types of cement that are available and used in India.

- Ordinary Portland Cement 33 Grade

- Ordinary Portland Cement 43 Grade

- Ordinary Portland Cement 53 Grade

- Portland Slag Cement

- Portland Pozzolana Cement

- Coloured Cement/White Cement

- Sulphate Resisting Cement

- Low Heat Portland Cement

- Rapid Hardening Cement

- Hydrophobic Portland Cement

- Extra Rapid Hardening Cement

- Quick Setting Cement

- Super Sulphated Cement

- Portland Pozzolana Cement (Fly ash based)

- Portland Pozzolana Cement (Calcined based)

- Air Entraining Cement

- Masonry Cement

- Expansive Cement

- Oil Well Cement

- Rediset Cement

- Concrete Sleeper Grade Cement

- High Alumina Cement

- Very High Strength Cement

1. Ordinary Portland Cement 33 Grade

Application/Use:

- Used up to M20 Grade of Concrete

- Used in Plastering, Flooring, masonry.

Features: Low Compressive Strength Low Heat of Hydration leads to lesser cracks

Reference Indian Standard: IS:269

Remarks: The availability of higher grades of OPC in the market impacts the usage of 33 grade OPC as these days, 43/53 grade OPC is normally used for general construction work. Availability in the market is low.

Also Read: What Is Lintel Beam | Lintel Beam Size | 7 Types of Lintel Beam

2. Ordinary Portland Cement 43 Grade

Application/Use:

- Widely used in concrete grades up to M-30, precast elements.

- Used for Plastering, Flooring, etc.,

Features: 43 Grade cement attains minimum compression strength of 43 mpa (Mega pascals) at 28 days.

Reference Indian Standard: IS:8112

Remarks: Easily available in the market and largely used in the construction industry.

3. Ordinary Portland Cement 53 Grade

Application/Use:

- Widely used general-purpose cement

- For concrete grade higher than M-30, PSC works, bridge, roads, multi-storied buildings et

Features: 53 Grade cement attains minimum compression strength of 53 mpa (Mega-pascals) at 28 days.

Reference Indian Standard: IS:12269

Remarks: Easily available in the market and largely used in the construction industry.

4. Portland Slag Cement

Application/Use:

- Exposed to harsh environments, such as wastewater treatment and marine applications

- High-strength concrete, such as high-rise structures or 100-year service life bridges

Features: It works synergistically with portland cement to increase strength, reduce permeability, improve resistance to chemical attack, and inhibit rebar corrosion.

Reference Indian Standard: IS:455

Remarks: Available in the selected market place

5. Portland Pozzolana Cement

Application/Use:

- Hydraulic structures like dams, & retaining walls

- Marine structures

- Mass concrete works- like bridge footings under aggressive conditions

- Masonry mortar and plastering

Features:

- The Portland Pozzolana Cement makes concrete more impermeable and denser as compared to Ordinary Portland Cement.

- The long-term strength (90 days and above) of Pozzolana cement is better compared to OPC.

Reference Indian Standard: IS:1489 P-2

Remarks: Easily available in the market.

6. Coloured Cement/White Cement

Application/Use:

It is used for architectural beauty, interior and exterior decorations such as terrazzo tiles and floorings, ornamental concrete products such as idols

Features:

- As the name indicates, it is white in color.

- Chemical composition and physical properties meet the specification of ordinary portland cement.

Reference Indian Standard: IS:8042

Remarks: Easily available but expensive than OPC.

7. Sulphate Resisting Cement

Application/Use:

The use of Sulphate Resisting Portland Cement is recommended in places where the concrete is in contact with the soil, ground-water, exposed to the seacoast, and seawater

Features:

This Cement will get into premature hydration if kept in a wet place

Reference Indian Standard: IS:12330

Remarks: Cement is usually not available in the market on a regular basis and expensive than OPC.

8. Low Heat Portland Cement

Application/Use:

Suited for making concrete for dams and water retaining structures, bridge abutments, massive retaining walls, piers, and , etc.

Features:

Evolves less heat than OPC Avoids shrinkage cracks

Reference Indian Standard: IS:12600

Remarks: Cement is usually not available in the market on a regular basis and can be obtained on specific orders.

9. Rapid Hardening Cement

Application/Use:

- Used in Repairs

- Used where the speed of construction is required

Features:

- It’s setting time is less than ordinary portland cement

- It acquires early strength.

Reference Indian Standard: IS:8041

Remarks: Cement is usually not available in the market on, regular basis and expensive than OPC.

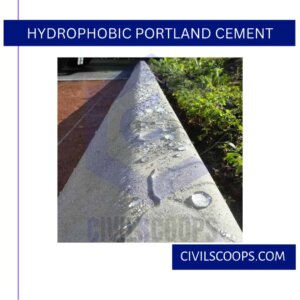

10. Hydrophobic Portland Cement

Application/Use:

These cement are used in the construction of dams, spillways, under-water constructions.

It can also be used in cold weather conditions.

Features: In the initial stage, the setting of hydrophobic cement is slow because of the admixtures in cement, But the strength after 28 days when compared to that of ordinary cement is the same.

Reference Indian Standard: IS:8043

Remarks: Cement is usually not available in the market on a regular basis and expensive than OPC.

11. Extra Rapid Hardening Cement

Application/Use:

- It is used where formwork has to be removed as early as possible in order to reuse it.

- It is used where high early strength is required.

- It is generally used for constructing road pavements, where it is important to open the road to traffic quickly.

Features: The one-day strength of this cement is equal to the three-day strength of OPC with the same water-cement ratio.

Reference Indian Standard: –

Remarks: Cement is usually not available in the market on a regular basis and expensive than OPC.

12. Quick Setting Cement

Application/Use:

- It is used in under-water construction.

- It is also used in rainy & cold weather conditions.

- Where quick strength is needed in a short span of time

Features:

- This product has the unique characteristic of being able to be sculpted and molded as it sets.

- The set time for this product is 10-15 minutes.

Reference Indian Standard:

Remarks: Cement is usually not available in the market on a regular basis and expensive than OPC.

13. Super Sulphated Cement

Application/Use:

- The foundations where the chemically aggressive condition exists

- Used In marine works

- RCC pipes used in sulfate bearing soils.

Features:

- The heat of hydration is very lower

- It is resistant to sulfate attack

Reference Indian Standard: IS:6909

Remarks:

14. Portland Pozzolana Cement (Fly ash based)

Application/Use:

- Used in Plastering, Flooring, grouting of cable ducts in PSC works, etc.

- Usually, a place where low compressive strength concrete can use.

Features: Fly ash based blended cement has the properties as which required for the cement to be called blended cement.

Reference Indian Standard: IS:1489 P-1

Remarks: Cement is usually not available in the market on a regular basis and can be obtained on specific orders.

15. Portland Pozzolana Cement (Calcined based)

Application/Use:

- Used in Plastering, Flooring, grouting of cable ducts in PSC works, etc.

- Usually, a place where low compressive strength concrete can use.

Features: Calcined based blended cement has the properties as which required for the cement to be called blended cement.

Reference Indian Standard: IS:1489 P-2

Remarks: Cement is usually not available in the market on a regular basis and can be obtained on specific orders.

16. Air Entraining Cement

Application/Use: It is used for lining walls and roofs for heat and sound insulation purposes.

Features:

- It forms microscopic air bubbles during the mixture.

- It decreases the strength of concrete.

Reference Indian Standard:

Remarks: Cement is usually not available in the market on a regular basis, and it is very expensive.

17. Masonry Cement

Application/Use: The masonry mortar is often used in brick, concrete block, and stone masonry construction, also used to produce stone plaster.

Features: It creates better bonding between bricks or concrete blocks.

Reference Indian Standard: IS:3466

Remarks: Cement is usually not available in the market on a regular basis and can be obtained on specific orders.

18. Expansive Cement

Application/Use:

- Grouting anchor bolts.

- Grouting machine foundation

Features: Shrinkage of cement occurs after mixing.

Reference Indian Standard:

Remarks: Cement is usually not available in the market on a regular basis and can be obtained on specific orders.

19. Oil Well Cement

Application/Use: Oil-well cement is used for cementing work in the drilling of oil wells where they are subject to high temperatures and pressures.

Features: There is no chemical effect that occurs on cement due to oils in an oil well.

Reference Indian Standard: IS:8229

Remarks: Cement is usually not available in the market on a regular basis and expensive than OPC.

20. Rediset Cement

Application/Use:

- Very high- Early strength concrete and mortar

- Emergency Repairs.

- Construction between tides.

- Palletisation of Iron ore dust.

Features:

- The sulfate resistance of the cement is poor.

- The rate of shrinkage is fast, but the total shrinkage is similar to that of ordinary PCC.

Reference Indian Standard:

Remarks: Cement is usually not available in the market on a regular basis and can be obtained on specific orders.

21. Concrete Sleeper Grade Cement

Application/Use: In prestressed concrete railway sleepers

Features: It provides good tensile strength to concrete.

Reference Indian Standard: IRS-R 40

Remarks: Cement is usually not available in the market on a regular basis and can be obtained on specific orders. and usually used in railways for sleeper manufacture.

22. High Alumina Cement

Application/Use: It is used in cold water and under sea-water.

Features: It develops 80% ultimate strength in 24 hours.

Reference Indian Standard: IS:6452

Remarks: Cement is usually not available in the market on a regular basis and expensive than OPC.

23. Very High Strength Cement

Application/Use: It is used to construct important buildings and infrastructure.

Features: It has high compressive strength than ordinary portland cement.

Reference Indian Standard:

Remarks: Cement is usually not available in the market on a regular basis and expensive than OPC.

[su_box title=”FAQ” style=”default” box_color=”#333333″ title_color=”#FFFFFF” radius=”3″ class=”” id=””]

Types of Cement

Different Types Of Cement

- Ordinary Portland Cement (OPC)

- Portland Pozzolana Cement (PPC)

- Rapid Hardening Cement.

- Extra Rapid Hardening Cement.

- Low Heat Cement.

- Sulfates Resisting Cement.

- Quick Setting Cement.

- Blast Furnace Slag Cement.

Psc Cement

PSC consists of 25-70% granulated slag, 3% gypsum and the rest is clinker. Granulated slag is, essentially, a non-metallic product comprising more than 90% glass content with silicates and alumino-silicates of lime.

Pozzolana Cement

Pozzolanic cements are mixtures of portland cement and a pozzolanic material that may be either natural or artificial. The natural pozzolanas are mainly materials of volcanic origin but include some diatomaceous earths. Artificial materials include fly ash, burned clays, and shales

Difference Between Opc and Ppc

OPC is the most commonly used cement in construction. PPC is highly resistant to sulphate attacks hence its prime use is in construction of dams ,foundations , buildings near the sea shore , reservoirs , marine construction to name a few. PPC is cheaper than OPC.

Pozzolana Meaning

A type of volcanic ash used for mortar or for cement that sets under water.

Sulphate Resisting Cement

Sulphate Resisting Cement is a type of Portland Cement in which the amount of tricalcium aluminate (C3A) is restricted to lower than 5% and (2C 3A +C4AF) lower than 25%, which reduces the formation of sulphate salts. The reduction of sulphate salts lowers the possibility of sulphate attack on the concrete.

Sulphate Resisting Cement Uses

Applications

- Foundations and piling works.

- Basements and underground structures.

- Sewage and water treatment plants.

- Chemical, fertiliser and sugar factories.

- Food-processing industries and petrochemical projects.

- Coastal works.

Sulfate Resisting Portland Cement

Sulfate-resisting Portland Cement (SRPC) is a special purpose cement used where sulfates are present in concentrations that would damage concrete made using CEM I or CEM II cements. Sulfate resistance is achieved by adjustments to chemical composition to limit the level of C3A in the SRPC.

Low Heat Portland Cement

Low heat cement is a special tailored cement which generates low heat of hydration during setting. It is manufactured by modifying the chemical composition of normal Portland cement.

Rapid Hardening Cement Uses

Uses of Rapid Hardening Cement

It is used where high early strength is required. It is generally used for constructing road pavements, where it is important to open the road to traffic quickly. It is used in industries which manufacture concrete products like slabs, posts, electric poles, block fence, etc.

Properties of Rapid Hardening Cement

Properties of Rapid Hardening Cement

- It gains strength faster than OPC.

- Its final setting times is 30 mins and final setting time is 600mins which is same as OPC.

- It emits more heat during setting, therefore this cement is unsuitable for mass concreting.

Rapid Hardening Cement Initial Setting Time

Initial setting time = not less than 30 mins. Within this period, solidification begins. Final setting time = not more than 600 mins. During this time, the mixture attains sufficient hardness.

Super Sulphated Cement

Super Sulphated cement is made from well-granulated blast furnace slag (80- 85%), calcium sulphate(10- 15%), and Portland cement (1 – 2 %) and is ground finer than the Portland cement.

Portland Pozzolana Cement Fly Ash Based

Portland Pozzolana Cement (BIS CERTIFICATION AS PER IS:1489 Part-I) is a fly-ash based blended cement. High-quality Portland cement clinker, gypsum and pozzolanic materials are thoroughly inter-ground or blended in certain proportions for producing PPC.

Entrained Air in Concrete

Entrained air refers to microscopic air bubbles intentionally incorporated into concrete during mixing, usually by use of a surface-active agent. These bubbles are spherical with diameters between 0.0004 and 0.04 in. (0.01 and 1 mm).

Air Entraining Cement Uses

The primary use of air-entraining concrete is for freeze-thaw resistance. The air voids provide pressure relief sites during a freeze event, allowing the water inside the concrete to freeze without inducing large internal stresses. Another related use is for deicer-scaling resistance.

Expansion for Concrete

Expansion joints are full-depth gaps between individual poured-concrete slabs and are sometimes called isolation joints. The gaps allow the slabs to move with normal expansion, contraction or settling that occurs due to temperature changes or moisture conditions.

Oil Well Cement

Oil-well cementing is the process of pumping cement slurry down the annulus between the casing and wellbore. This is known as the primary cementing. The objective is to form a cement sheath that will ensure zonal isolation, support, and protect the casing (Vuk et al., 2000).

High Alumina Cement Uses

Generally, this refractory product is widely used in sewer infrastructure and marine construction. Besides, it is also used in refractory concretes for furnaces, boilers, kilns, and chimneys. This is due to its strength to withstand very high temperatures with proven durability.

[/su_box]

[su_note note_color=”#F2F2F2 ” text_color=”#333333″ radius=”3″ class=”” id=””]

Like this post? Share it with your friends!

Suggested Read –

- 23 Different Types of Doors

- How to Get Rid of Paint Smell

- Best Concrete Mix for Driveway Repair

- What Is an Arch | 21 Different Parts of an Arch

- What Is Building Construction | Steps & Processes of Building Construction | Application of Building Construction | How to Do Planning of Building Construction

[/su_note]

Originally posted 2023-04-10 06:54:09.