What Is Seasoning of Timber? | Methods of Seasoning of Timber | Purpose of Seasoning of Timber

Table of Contents

What Is Seasoning of Timber?

Seasoning of timber is a process that is applied on the wood piece to reduce the moisture content, which was absorbed by that timber, to a certain level.

A properly well-seasoned timber wood contains only 15% moisture content.

Reducing the moisture content by the seasoning method helps to regain the strength, durability, and elasticity property of that timber.

The seasoning process is done after cutting down the tree to reduce the moisture content in a certain level, it increases the durability of that timber.

Methods of Seasoning of Timber:

There are mainly two methods are followed in the timber industry, those are-

- Natural Seasoning

- Artificial Seasoning

1. Natural Seasoning:

Natural seasoning are classified are classified into two categories, those are-

1.1. Air Seasoning:

- Air seasoning is a common and natural seasoning process that is widely used all over the world.

- This process is done under the shade with a platform. The platforms are also made of wood sheets which are 300mm high from the ground level.

- Proper air circulation is needed for each wooded chair for this process.

- After a certain period, the moisture content is slowly decreased by this natural process.

- The air seasoning process is a very slow process but it is the most effective process, the well-seasoned wood contains only 15% moisture.

- In the seasoning process, the thick end of the wood piece rests in the upward direction and after 2 to 4 weeks the wood is prepared.

- In that period wood, the sap is washed out from the wood and then staled under the shed for free air circulation.

1.2. Water Seasoning:

- In water seasoning, the timber is immersed into the water and flows to remove the sap of the timber.

- Water seasoning required 2 to 4 weeks time and then timber is going to dry, then it is fully prepared and well seasoned to use.

2. Artificial Seasoning:

In the artificial seasoning method, the wood is kept in the chamber and then the heat is used to control the humidity, it only takes 4 to 5 days to complete. There are mainly four types of artificial seasoning is used, those are-

2.1. Boiling Seasoning:

- In the boiling seasoning, the timber is immersed into the water and then it allows to boil for 3 to 4 hours.

- After this process, the wood is slowly dried and then hot steam is circulated to the timber.

- This process is very effective but quite expensive.

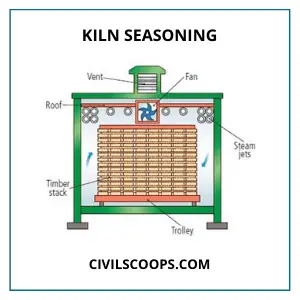

2.2. Kiln Seasoning:

- In the kiln seasoning, the timbers are placed into the kiln, basically, the kiln is an airtight chamber.

- In this process, the wood is forced with fully saturated air with a temperature of 35 to 38°C, and heated slowly.

- From the discharging of the kiln the hot air is supplied, for this reason, the temperature will gradually increase in the charging end.

- This method is very useful to make spices that’s why another name of this process is the Kiln Masala Process.

2.3. Chemical Seasoning:

- In this type of seasoning, the timber is immersed in a chemical solution.

- Then the drying process of wood is done in the kiln.

- Finally, the timber is treated by chemical agents.

2.4. Electrical Seasoning:

- Naturally, the resistance of electric current is very low but the moisture content is present in the wood then it is very high.

- In this method of seasoning, the high-frequency alternating current is passing through the wood.

- A low amount of moisture content decreases the resistance.

- This electrical seasoning technique is not used for types of plywood industries and it is also a very expensive process.

Purpose of Seasoning Timber:

- Wood seasoning is mainly done to get some special features of the wood.

- Wood seasoning is done to determine the wood shrinkage percentage.

- It is done to improve the qualities of wood.

- It is done to ensure the massive use of forests.

- It is done to reduce the adverse behavior of the wood.

Ability Improves After Seasoning Operation of Timber:

After doing the seasoning operation some properties are improved in the wood, those are-

- Hardness of timber

- Strength of timber

- Weight of timber

- Durability of timber

- Gluing property

- Painting and finishing property

- Electrical resistance property

- Insect attack resistance power of timber

- Heat resistant property

Benefits of Seasoning of Timber:

- A large amount is suitable for this process.

- We get a good quality product wood.

- It requires less time, naturally 3-4 hours.

- It develops strength and elasticity properties in the wood.

- We get durable and suitable wooden structures for this seasoning method.

[note note_color=”#F2F2F2 ” text_color=”#333333″ radius=”3″ class=”” id=””]

Like this post? Share it with your friends!

Suggested Read –

- What Is Gradient of Road? | Limiting Gradient of Road | Types of Gradient of Road | Exceptional Gradient of Road | The Gradient of Road | Purpose of Providing Gradient of Road | Importance of Gradient in Roads

- What Is Lap Length? | Lap Length in Beam | Why Lapping Is Provided? | How to Calculate Lap Length? | Lap Length as Per Is Code 456 | What Are the General Rules for Lap Length? | Lapping Zone

- Hollow Block | Hollow Concrete Block | Hollow Concrete Block Size |Hollow Concrete Block Advantage | Hollow Concrete Block Disadvantage | Hollow Concrete Wall | Hollow Block Construction | Size of Hollow Blocks | How to Make Hollow Blocks

- Hand Level Surveying | What Is Site Level? | What Is Hand Level? | How to Use a Hand Sight Level | Estimating Distances with a Sight Level

- Types of Cement Grades | Difference Between 33, 43 &53 Grade Cement

[/note]

Originally posted 2021-09-15 11:49:01.