What Is Epoxy? | What Is Epoxy Flooring? | Types of Epoxy Flooring | Advantages of Epoxy Flooring | Disadvantages of Epoxy Flooring | Uses of Epoxy Flooring | Application Process of Epoxy Flooring

Table of Contents

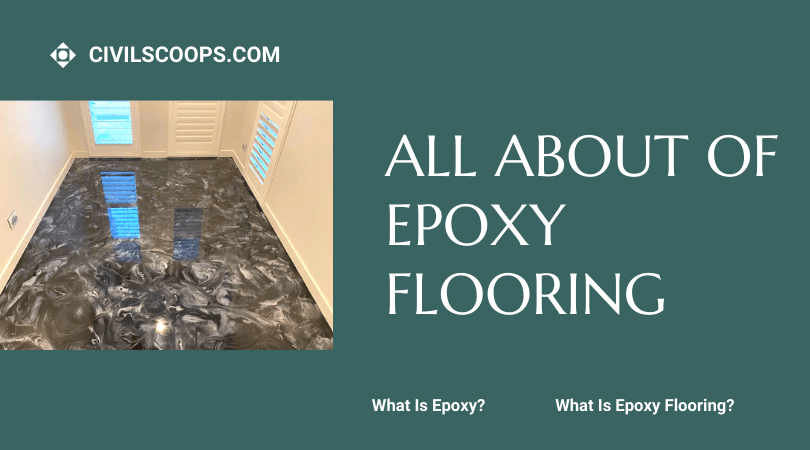

Introduction of Epoxy Flooring

- Usually, chemical resins are a group of short-chain polymers that contains epoxide groups at their ends.

- Epoxy was 1st discovered by curing the polymer with a phthalic acid anhydride by Swiss Scientist Pierre Castan in 1936. In 1946 Industrial & commercial usage of the compound started.

- During the middle of the 20th Century, in the United States of America, Dr Sylvan Greenlee was also successful to manufacture resins by preparing a blend of epichlorohydrin & bisphenol-A. This compound is additionally called BADGE & is widely utilized nowadays.

- Epoxy resins can be cured at any temperature ranging from 5-150° C.

What Is Epoxy?

- Epoxy is a rigid & durable thermoset plastic resin prepared by covalent bonding of two or more chemical compounds. Epoxy is a copolymer.

- They are effortlessly obtainable in a range of variety of color & designs due to which it is used as a decorative substance.

What Is Epoxy Flooring?

- Epoxy bulk is less than 2 millimetres = Epoxy coating.

- Epoxy bulk is greater than 2 millimetres = Epoxy floor.

- It is actually a blend of polymers, resins & solidifies, which ultimately becomes hard like plastic & is often applied as the base material of concrete, steel or wood. Hence, it is also referred to as resinous flooring.

- They are applied to provide a smooth, shiny & tidy finish to floors which can hold up a significant quantity of load for a lengthy time period.

- Additives such as accelerators, flow control, UV inhibitors, adhesion promoters can be included to create a canopy that acts as a positive catalyst to a vast range of flooring.

Applications by increasing abrasion resistance, providing rapid cure & higher chemical resistance.

- Epoxy floors require 30 days for complete curing & 18-24 hours after curing to become ideal for walking.

- Aesthetic appearance can be ameliorated by the inclusion of colored quartz aggregate, vinyl flakes, glitter & so on. Aggregate sand mixtures such as slurry, trowel & broadcast can be added to generate non-slippery flooring.

Types of Epoxy Flooring

1. Epoxy Mortar Floor

This is a blend of 100% solid epoxies & quartz sand & is required in places or areas where there is a continuation application of ponderous loads.

Generally used in-

Restaurants, Garages, Warehouses, Plants where high load & Chemical impacts occur.

2. Self Levelling Epoxy Floor

This is usually applied on old, cracked & damaged concrete floors to make smooth, durable, leveled texture.

Generally used in-

Aesthetic facilities, Showrooms, Garages, Kitchens.

3. Quartz Filled Epoxy Floor

This is a blend of heavy-duty epoxy polymer resin & stained quartz grains. This is applied where sanitary & slip-resistant features are required.

Generally used in-

Offices, Lobbies, Locker Rooms, Schools, Cafeterias.

4. Epoxy Flake Floor

This gives a vibrant look & reduces the possibility of slipping & the probability of falling. They contain tinted flake materials, which additionally diminishes slip properties.

Generally used in-

Showrooms, Sports Venues, Bars, Locker Rooms, Churches, Laboratories, Hospitals, Temples, Masjids, Clinics.

5. Anti Static Epoxy Floor

It diffuses any potential electrical charge. It is also ideal for areas where inflammable liquids or gases are utilized frequently.

Generally used in-

Chemical, Electronics & Healthcare Units

Pharmaceutical Manufacturing Units.

Also Read: Difference Between Cement Plaster and Gypsum Plaster

Advantages of Epoxy Flooring

1. Appearance

- Epoxy floors, in comparison to garage floors, are shiny & professional.

- It offers a smooth, even & glossy surface which provides an outstanding interior & also it is effortless to clean & maintain.

- Some instances of epoxy flooring are Terrazzo flooring, Chip flooring, Colored-aggregate flooring & so on.

2. Variety

- Epoxy floors are obtainable in a wide range of variety of designs & patterns with different color shades, which gives a modish look to the floors.

3. Durability & Longevity

- Epoxy flooring aids concrete to become more durable, which can again withstand ponderous & continuous load & can last for several years without cracks & peels.

- It also has the least effect when a ponderous substance is dropped on the floor from a considerable height.

4. Protective

- Epoxy flooring shields concrete from cracks, dampness, grease & stains, which again diminishes expense & thereby offers effortless maintenance.

5. Safety

- Epoxy aids to reflect the light on the floor, which is vital to keep room/ area illuminated & thus helps in safety, security, workability & other benefits.

- Often anti-slip additives are applied in epoxy flooring.

6. Affordability

- Installation & cost per feet2 is comparatively lower than other kinds of floorings.

7. Resistance

- Epoxy flooring offers a fine resistance to.

8. Chemicals, Oils, Gasoline, Bleach-

- They are resistant to oil & grease, which aids in their increased application in garages & automobile factories where greases & turpentine oils are in the vast application.

9. Heat & Water-

- Except being oil & grease resistant, they are also non-porous & possesses a fine thermal resistance capacity & water resistance ability.

10. Bacteria & germs-

- They are also employed in hospitals or nursing homes since they are also resistant to germs & bacteria, which aids to check infection spread. They are hygienic & free from allergens & prevents yeast & fungus growth thriving of nooks & crannies.

11. Maintenance

- Epoxy flooring is monolithic & jointless.

- They possess negligible maintenance costs.

- Moreover, cleaning is effortless because any greasy liquid slips off the surface of the floor quite always without leaving any stains or blotches.

12. Price

- Epoxy flooring expense ranges approximately 120-550 Rupees/feet2.

- Unlike hardwood or vinyl flooring, they can be extremely economical & cheap.

13. Slip-resistant & accident-free

- Despite being smooth & glossy, epoxy floors are slip-resistance, i.e., nobody is going to slip & fall, which is totally accident-free.

14. Regulatory standards & safety

- They are well-trusted by various bonafide industries.

Disadvantages of Epoxy Flooring

1. Temporary solution

Ultimately it is required to replace, which can be a costly process.

2. Strenuous & Time-consuming process

The process is tiresome & on the other hand, it is additionally time-consuming since it is required to be tidy & thoroughly washed. Moreover, 1st coat must dry fully before the application of 2nd coat.

3. Costly renovation process

Once finished, it is expensive to modify color & designs & repair or renovate the floor again.

4. Requires attentive installation

The coating must be applied at low-humidity conditions since sogginess affects durability.

5. Noise produced while walking

A little noise may be produced while walking over the floor surface.

6. Cold during winter

On account of being excessively smooth, shiny & hard, their temperatures diminish & may get cooled down significantly during the winter season, which makes it difficult to walk without sandals.

Uses of Epoxy Flooring

- Employed in commercial & industrial buildings & warehouse floors where regular wiping & cleaning is tedious.

- Utilized to make wonderful entrance floors for office, hotel lobby floors, fire-proof warehouse floor & also to manufacture floor paints. Epoxy floors often have a high-gloss surface, which can increase the brightness in space by up to 200 percent.

- Applied as powder coating for white products such as dryers & washers.

- Utilized in automobiles & boats as a primer that prevents corrosion by aiding the strong adhesion of paints.

- Fusion bonded epoxy canopy is employed in steel pipes, oil & gas industries, water pipes & concrete reinforcement rebars.

- Applied on metal cans & containers to resist rusting when acidic foods are packaged.

- It is also utilized to produce carbon fiber, fibreglass.

- It also has a vast range of marine applications.

- Additionally employed in aeroplane hangars, building garages, manufacturing & distribution units & factories, retail stores, hospitals, showrooms, shopping malls, cinema halls, laboratories, pharmaceutical plants, personal houses, living rooms, bedrooms, kitchen & so on.

Application Process of Epoxy Flooring

1. Surface Preparation

To provide strong adhesion, the base must be ground by a diamond grinding machine. Any paint, sealer, topping, moisture, the grease must be removed totally.

2. Sweeping & Wiping the floor

The floor must be cleaned by an electronic vacuum cleaner if possible.

3. Epoxy primer

Application of primer aids to seal the base, thereby eliminating any risk of bubbling in the presence of gas & air molecules in it. It prolongs the life of the floor.

4. Epoxy grout

If any hair cracks are still present, these cracks must be widened by a diamond cutter & then epoxy grout is applied to supply a solid seal.

5. Epoxy paint

After mixing the paint for 2 minutes, it can be applied with a roller.

6. 1st coating

After application of 1st coating, the floor must be checked again for cracks; if cracks still persist, grouting must be performed again.

7. Final coating

After thorough scanning for the presence of any cracks & dust, the final coating of paint can be applied within 45 minutes after mixing.

[note note_color=”#F2F2F2 ” text_color=”#333333″ radius=”3″ class=”” id=””]

Like this post? Share it with your friends!

Suggested Read –

- Difference Between Short Column and Long Column

- What Is Plastering | What Is Pointing | Difference Between Plastering and Pointing |

- What Is Timber ? | What Is Lumber ? | What Is Lumber Used for ? | Lumber Vs Wood | Difference Between Lumber and Timber | Standard Wood Size | What Is Timber Used for ?

- Concrete Slump Test | Principle of Slump Test | What Is Slump Test ? | How to Measure Concrete Slump? | Slump Test Results | Concrete Slump Test Procedures |

- Difference Between Coarse Aggregate and Fine Aggregate | What Is Coarse Aggregate? | What Is Fine Aggregate? | Advantage of coarse aggregates | Advantage of Fine Aggregate

[/note]

Originally posted 2021-08-24 07:24:55.