Fly Ash in Concrete | Advantages & Disadvantages of Fly Ash Concrete | Use of Fly Ash in Concrete | Applications for Fly Ash Concrete | Benefits of Fly Ash Concrete

Table of Contents

What Is Fly Ash?

Fly ash is a fine powder that would be a by-product of the combustion of pulverized coal in power plants. Fly ash is a pozzolan, a liquid that contains aluminous as well as siliceous material which creates cement in the presence of water.

When combined with lime and water, fly ash creates a similar composition to Portland cement. This renders fly ash ideal as a raw material for mixed cement, mosaic tiles, and hollow bricks, among many other construction materials. That is used in concrete mixtures, fly ash increases the strength and isolation of the concrete and makes pumping smoother.

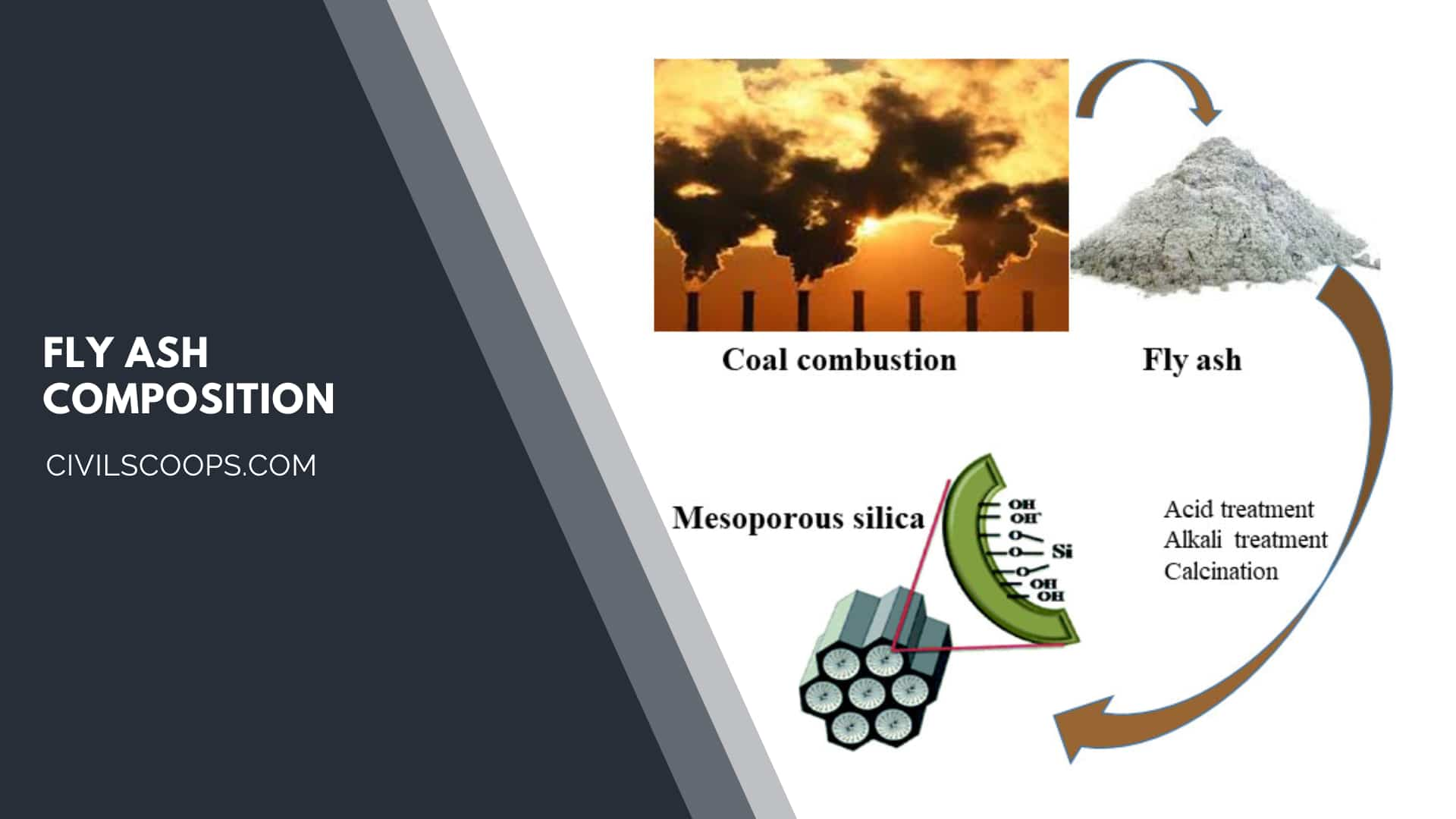

Fly Ash Composition.

Fly ash composition are as follows.

- Silicon Oxides.

- Aluminium Alloy.

- Calcium Oxides.

- Magnesium.

- Potassium.

- Magnesium.

- Titanium.

- Sulfur.

These are also found at a smaller degree. Although used it as a mineral aggregate in asphalt, fly ash is graded either as Class C or Class F ash on the basis of its chemical composition.

- Class C ash is commonly extracted from sub-bituminous coals and consists mainly of calcium aluminum sulfate glass, quartz, tricalcium aluminate, and free lime (CaO). Class C ash is often referred to since high calcium ash as it usually contains many as 20% CaO.

- Class F ash is usually extracted from bituminous which anthracite coals and consisting mainly of aluminum silicate glass, with quartz, mullite and magnetite also present. Class F or low calcium ash is less than 10% CaO.

Where Does Fly Ash Come From?

Fly ash is provided by coal-fired electrical and steam-fired power plants. Typically, coal is pulverised and blasted with air into the boiler’s combustion chamber, where it rapidly ignites, generates heat, and produces molten mineral residues.

Boiler tubes remove heat from the boiler, cool the flue gas and allow the molten mineral debris to harden and form ash. The coarse ash particles, referring to as quarry dust or slag, sink to the bottom of the combustion process, whereas the lighter fine ash particles, known as fly ash, remain stuck in the flue gas.

Fly ash is extracted by particulate pollution control systems, including such electrostatic precipitators or filter bags, previous to exhausted the flue gas.

Fly Ash in Concrete

Fly ash in concrete provides good use of portal cement hydration products. Calcium as well as alkali hydroxide solutions, that are emitted into the porous system of the paste, mix with fly ash particles, creating a cement medium, and the heat generated by hydration of portal cement is a significant factor in the initiation of a fly ash reaction.

As ash-containing concrete is fully cured, ash-containing reaction products occupy the gaps between hydrating cement particles, further reducing concrete permeability to water and offensive chemicals.

The slower response time of many fly ash relative to Portland cement limits the amount of early heat generation and the damaging early temperature increase of large structures. Properly proportioned fly ash mixtures add properties to concrete that cannot be accomplished by using portland cement alone.

Also Read: All About Green Concrete | What Is Environmentally Friendly Concrete

Benefits of Fly Ash Concrete

- Fly ash is also a cost-effective alternative to Portland cement in several countries.

- Fly ash is often known as an environmentally sustainable substance because it is a by-product that has low energy content, a measure of how much energy is used in the processing and shipment of construction materials.

- Portland cement, on the other hand, has very high incarnated energy, since its processing requires a great deal of heat.

- Fly ash has less water than Portland cement and is simpler to be used in cold weather.

- Produces different fixed times.

- Resistance to cold weather.

- High strength gains, based on the use.

- Could be used as an admixture.

- Considered a non-shrink substance.

- Produces thick concrete with a smooth surface and sharp detail.

- Great opportunity to operate.

- Reduces cracking, permeability, and bleeding issues Reduces hydration heat.

- Allows a smaller water-cement ratio with equivalent slumps relative to non-fly-ash mixtures.

- Reduces emissions of CO2

Applications for Fly Ash Concrete

- Fly ash is utilized as a raw material for many cement-based goods, including poured concrete, concrete blocks, and bricks.

- Among the most popular applications of fly ash is the PCC pavement. Road-building projects utilizing PCC will use a huge amount of asphalt, and the replacement of fly ash has major economic advantages.

- Fly ash is also used as a reservoir and mine fill,

- Usually, the rate of replacement of fly ash for Portland cement is 1 to 1 1/2 pounds of fly ash for 1 pound of cement.

- Consequently, the proportion of the fine aggregate in the concrete mixture must be decreased in order to absorb the increased content of the fly ash.

Use of Fly Ash in Concrete

- Improved workability of plastic concrete.

- Added resilience and toughness to reinforced concrete.

- An extra revenue source for coal-fired power plants.

- A drop in the cost of cement processors. When ash is applied to cement mixtures, the amount of cement used by Portland will be decreased. It also helps manufacturers to sell cement at a reduced cost with equivalent or better profit margins.

- Reduction of garbage at the dumpsite, thereby enhancing the environment.

Advantages of Fly Ash Concrete

- It’s really economical.

- The use of Fly Ash is environmentally sustainable since waste materials from industry are successfully used to manufacture high-quality construction materials.

- Fly Ash contains very small particles that make the concrete very thick and decreases the permeability of concrete. It could bring more power to the house.

- The concrete mixture produces a very low hydration heat, which avoids thermal cracking.

- Fly Ash concrete is immune to acid and sulfate attacks.

- The shrinkage of fly ash concrete is even smaller.

- The use of fly ash gives concrete a strong ability to perform, toughness, and finish.

Disadvantages of Fly Ash Concrete

- Smaller manufacturers and housing contractors may not be familiar with fly ash materials, which may have different properties based on where and how they have been made.

- Fly ash applications can face opposition from conventional builders due to its propensity to bloom along with concerns about freeze/thaw efficiency.

- Slower power gain.

- Seasonal Restriction.

- Increased need for air-conducting mixtures.

- Increase in salt scaling provided by higher proportions of fly ash.

- The consistency of fly ash is significant, but it can vary. Poor-quality fly ash can have a harmful impact on concrete.

- The key benefit of fly ash is decreased permeability at a low cost, but low-quality fly ash can also improve permeability. Some fly ash, such as that generated at a power plant, is consistent with concrete.

- Other varieties of fly ash must be used, and other forms could be adequately changed for use in concrete.

- Any asphalt can eventually set as the ash is used. While this could be seen as a drawback, it may also be a gain by minimising thermal tension.

- As cement sets, it produces 100 calories per gramme such that the temperature of the structure will climb to 135 degrees. Any fly ash should be used to prevent the temperature from growing too high (less than 45 degrees).

- Even so, concrete with fly ash can be set up normally or even quickly, as many other factors affect the production of the set and power.

- Freeze-thaw stability in the use of fly ash in concrete will not be acceptable. The amount of air released in the concrete determines the freeze-thaw longevity and the high carbon content of certain fly ash materials absorbs certain air-conducting agents, reduces the amount of air produced in the concrete and makes the concrete vulnerable to frost damage.

- High-carbon fly ash materials prefer to use more water and even darken asphalt. It is not advised to use a high-carbon (greater than 5%) content of fly ash, but if it is to be used, the correct air content can be obtained by increasing the concentration of the air-training agent.

- Low setup and weak early intensity do not have to be the results that use fly ash. That most of the time, higher fineness as well as reduced fly ash can lead to high early intensity.

- Fly ash may also be blended with a limited volume of condensed silica smoke to boost fixed or initial properties. Definitely, close consideration to mixing design including water content is often needed to ensure proper set-up and early production of power.

- Precasters must aim to achieve as high silica content as practicable from fly ash. Silica reacts with cement lime to create capacity and decrease permeability.

[su_box title=”FAQ” style=”default” box_color=”#333333″ title_color=”#FFFFFF” radius=”3″ class=”” id=””]

What Is Fly Ash?

Fly ash, flue ash, coal ash, or pulverised fuel ash – plurale tantum: coal combustion residuals – is a coal combustion product that is composed of the particulates that are driven out of coal-fired boilers together with the flue gases.

What Is Fly Ash in Concrete?

Fly ash is a byproduct obtained from the combustion of pulverized coal in coal-fired power plants. It is a fine, powdery material that is collected from the flue gas through electrostatic precipitators or other emission control systems. Fly ash is often used as a supplementary cementitious material in concrete production due to its pozzolanic properties.

What Is Fly Ash Used For?

Among other applications, fly ash is used as material to make bricks, ceramic tiles, and plaster; as filler in metal and plastic composites and in paints and adhesives; and as structural fill for road construction. Flue gas desulfurization products rank as the second most abundant type of coal ash.

What Does Fly Ash Do in Concrete?

Fly ash use in concrete improves the workability of plastic concrete, and the strength and durability of hardened concrete. Fly ash use is also cost effective. When fly ash is added to concrete, the amount of portland cement may be reduced. Benefits to Fresh Concrete.

What Is Fly Ash Made Of?

Fly ash consists primarily of oxides of silicon, aluminum iron and calcium. Magnesium, potassium, sodium, titanium, and sulfur are also present to a lesser degree. When used as a mineral admixture in concrete, fly ash is classified as either Class C or Class F ash based on its chemical composition.

Where Does Fly Ash Come From?

Fly ash is produced by coal-fired electric and steam generating plants. Typically, coal is pulverized and blown with air into the boiler’s combustion chamber where it immediately ignites, generating heat and producing a molten mineral residue.

What Is Fly Ash Concrete?

Fly ash is the fine ash produced at coal-fired power plants that develops cementitious properties when mixed with cement and water. Fly ash in concrete is widely used across the U.S. to the strength of concrete.

Fly Ash in Concrete

Fly ash is a byproduct of burning coal in power plants, and it can be used as a supplementary cementitious material (SCM) in concrete production. When coal is burned, the inorganic mineral impurities in the coal, known as fly ash, are released as fine particles and carried away in the flue gas.

Fly Ash Concrete Disadvantage

Disadvantages of Fly Ash

- The quality of fly ash can affect the quality and strength of Cement concrete.

- Poor-quality fly ash can increase the permeability of the concrete and cause damage to the building.

Purpose of Fly Ash in Concrete

Fly ash is used in concrete to improve workability, increase strength and durability, reduce heat of hydration, enhance long-term performance, and provide environmental benefits.

Advantages of Fly Ash Concrete

The advantages of fly ash concrete include increased strength, improved durability, reduced heat of hydration, enhanced workability, environmental sustainability, and potential cost savings.

Is Fly Ash Cheaper Than Cement?

With cement being the costliest ingredient, substituting fly ash or slag can help maintain a stronger mix at a lower cost. Fly ash and Slag will typically be 18% cheaper than Portland cement. When a mix includes 20% fly ash, this will provide savings of 3.5% in cost.

Is Fly Ash Good for Cement?

The use of fly ash in portland cement concrete (PCC) has many benefits and improves concrete performance in both the fresh and hardened state. Fly ash use in concrete improves the workability of plastic concrete, and the strength and durability of hardened concrete. Fly ash use is also cost effective.

What Is Fly Ash Cement?

Fly ash cement, also known as fly ash concrete or fly ash blended cement, is a type of cementitious material that incorporates fly ash as a partial replacement for Portland cement in concrete mixtures. It is produced by combining fly ash, which is a byproduct of coal combustion in power plants, with Portland cement.

What Is the Use of Fly Ash in Concrete?

The use of fly ash in concrete provides benefits such as improved workability, increased strength, enhanced durability, reduced heat of hydration, and environmental sustainability.

How Much Fly Ash Is Used in Concrete?

Typically, 15 percent to 30 percent of the portland cement is replaced with fly ash, with even higher percentages used for mass concrete placements. An equivalent or greater weight of fly ash is substituted for the cement removed. The substitution ratio for fly ash to portland cement is typically 1:1 to 1.5:1.

Why Is Fly Ash Used in Concrete?

Fly ash is used in concrete to enhance strength, improve workability, reduce heat of hydration, and promote environmental sustainability.

What Is Flyash in Concrete?

Fly ash in concrete refers to the utilization of a byproduct called fly ash as a supplementary cementitious material (SCM) in the production of concrete. Fly ash is a fine, powdery substance that is generated during the combustion of pulverized coal in coal-fired power plants. It consists mainly of silicon dioxide (SiO2), aluminum oxide (Al2O3), and calcium oxide (CaO), along with other minor constituents.

What Is the Effect of Fly Ash in Concrete?

The effects of fly ash in concrete include improved workability, increased strength, enhanced durability, reduced heat of hydration, and environmental sustainability.

[/su_box]

[su_note note_color=”#F2F2F2 ” text_color=”#333333″ radius=”3″ class=”” id=””]

Like this post? Share it with your friends!

Suggested Read –

- Water Damage from Water Heater | How to Repair Water Damage from a Leaking Water Heater

- What Is Hail Damage | How to Inspect a Wooden Roof for Hail Damage | Roof Types and Hail Affects on Roof

- Roof Leak Detection | What Can a Leaking Roof Due to My Home | What Are the Symptoms of a Leaking Roof | What Causes a Roof to Leak

- Built Up Roof with Gravel | Why Do They Put Gravel on Flat Roofs | Purpose of Gravel on a Flat Roof | Added Benefits of Bur Flat-Roof Gravel

- Hail Damage to Asphalt Shingles | Introduction of Hail Damage to Asphalt Shingles | What Is Hail and How Does It Damage the Asphalt Shingles

[/su_note]

Originally posted 2023-07-11 11:49:39.