Piling for Foundation | Use of Pile Foundation | Characteristics of Pile Foundation

Table of Contents

What Is Foundation?

All engineered construction work resting on the earth must be carried by some interfacing element called a foundation. The foundation is part of an engineered system that transmits to, and into, the underlying rock and soil the loads supported by the foundation and its self-weight.

The resulting soil stresses except at the ground surface are in addition to those presently existing in geological history and the earth mass from its self-weight.

The term superstructure(all structure) is commonly used to describe the engineered part of the system bringing Tthe load to the foundation, or substructure.

The term superstructure has particular significance for buildings and bridges; however, foundations also may carry only machinery, industrial support equipment (tanks, towers, pipes ), act as sign bases, & the like. For it is better, these reasons to describe a foundation the engineered system that interfaces the load-carrying components to the ground.

It is evident based on this definition that a foundation is an essential part of the engineering system.

Type of Foundation, Use of Foundation, Application soil Conditions (piling for foundation

[su_table responsive=”yes” alternate=”no”]

| Foundation type | Applicable soil conditions | Use |

| Shallow foundations (generally D/B ≤1) | ||

| Spread footings, Wall footings | Any situations where bearing capacity is adequate for the applied load.May use on a single stratum; secure layer over a soft layer or soft layer over firm layer. Check settlements from any source. | Individual columns, walls |

| Combined footings | Same as for spread footings above | Two to four columns on the status or space are limited |

| Mat foundations | Soil bearing capacity is generally < for spread footings, over half the plan area, would be covered by spread footings. Check settlements from any source. | Heavy column loads; Several rows of parallel columns; use to reduce differential settlements |

| Deep foundations (generally Lp/B ≥ 4 +) | ||

| Pile Floating | Surface and near-surface soils with have the low competent soil and, bearing capacity is at great depth. Sufficient skin resistance can be developed by Pile to Soil perimeter to carry anticipated loads. | In groups of 2+ supporting a cap which interfaces with column(s) |

| Pile Bearing | Competent soil for point load is in a practical depth (8-20 m); Surface and near-surface soils not relied on for skin resistance | Same as for floating pile |

| Drilled piers or caissons | Same as for piles. May be floating or point-bearing (or combination). Depends on depth to competent bearing stratum | Use fewer; Same as for piles; For large column loads |

| Retaining Structures | ||

| Retaining walls, bridge abutments | Any type of soil but a specified zone in the backfill is usually of controlled fill | Permanent material retention |

| Sheeting structures (sheet pile, wood sheeting, etc.) | Retain any soil or water. Backfill for waterfront and cofferdam systems is usually granular for higher drainage | Permanent or temporary for excavations, marine cofferdams for river work |

[/su_table]

What Is Pile Foundation?

The use of piles as a foundation can be traced since olden times. The art of driving piles was well-established in Roman times, and the details of such foundations were recorded by Vitruvius in 59 AD Today, pile foundation is much more common than any other types of deep foundation.

Modem pile driving started with the first steam pile drivers, invented by Nasmyth in 1845. Piles may be classified as follows:

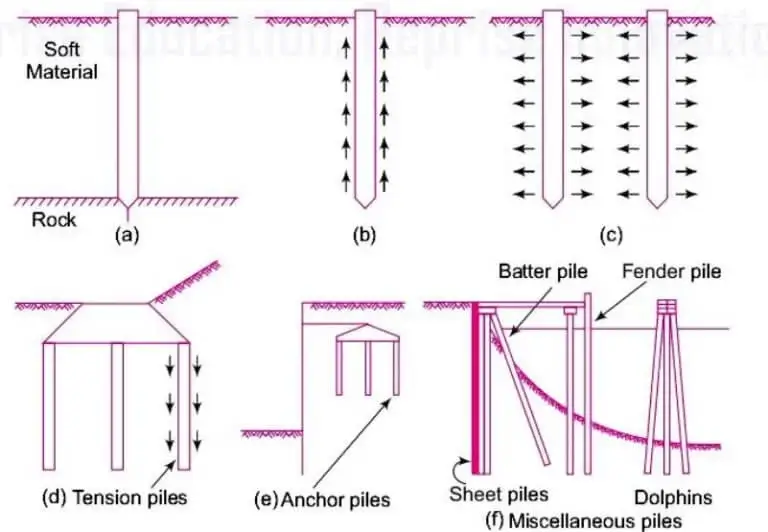

ClassificationBased on Function.

Based on the use or the function, piles may be classified as:

- End bearing pile (See Figure a)

- Friction pile (See Figure b)

- Compaction pile (See Figure c)

- Tension pile or uplift pile Anchor pile (See Figured)

- Fender pile and dolphins (See Figure a)

- Batter pile (See Figure f)

- Sheet pile (See Figure g)

1. End bearing piles

This type of piles is used to transfer load through water or soft soil to a suitable bearing stratum.

2. Friction piles

This type of piles is used to transfer loads to a depth of a friction load-carrying material using skin friction along the length of the piles.

Friction pile is a kind of pile foundation. This type of pile utilizes the frictional resistance force between the pile surface and adjacent soil to transfer the superstructure load.

Depending on the subsoil strata condition, resistance force due to friction can develop in a definite pile length of on the full length.

3. Compaction piles

Compaction is used to compact loose granular soil, thus increasing their bearing capacity. The compaction piles themselves don’t carry any load. Hence they may be of weaker material-sometimes of sand only.

Driven to compact the soil, the pile tube, is gradually taken out and sand is filled in its place, thus forming a ‘sandpile.’

4. Tension or uplift piles

This type of piles anchor down the structures subjected to uplift due to hydrostatic pressure or due to overturning moment.

5. Anchor piles

This type of piles provides anchorage against horizontal pull from sheet piling or other pulling forces.

6. Fender piles and dolphins

This type of piles is being used to protect waterfront structures against the impact of ships or other floating objects.

7. Sheet piles

These piles are commonly used as bulkheads, or as an impervious cutoff to reduce seepage and uplift under hydraulic structures.

8. Batter piles

This type of piles is used to resist large horizontal or inclined forces.

Classification based on the function./(Piling Foundation Types)

Classification of Piles Based on Materials

Concrete piles:

- Precast

- Cast-in-situ

- Driven piles: Cased or uncased

- Bored piles: Pressure piles and under-reamed piles.

Timber piles:

Steel piles:

- H-piles.

- Pipe pile.

- Sheet pile.

Classification of Piles Based on Composition.

Composite piles:

- Concrete and timber.

- Steel and Concrete.

1. Precast concrete piles

The precast concrete piles are commonly used for a maximum design load of near about 80 tonnes, except for large pre-stressed piles.

They need to be reinforced to withstand handling stresses. They require space for storage and casting, more time to set and cure before installation and heavy equipment for driving and manging.

They also incur a high cost in cutting off the extra length or adding more distance.

2. Cast-in-situ piles

The cast-in-situ piles are commonly used to get a maximum design load of 75 tonnes, except for compacted, pedestal piles. They’re installed by pre-excavation, therefore eliminating vibration because of driving and the handling stresses.

The Cast-in-place piles may be classified into two classes:

- Driven piles (cased or uncased)

- Bored piles (Pedestal piles, pressure piles, and under-reamed piles).

A variety of cast-in-situ piles are in use, each bearing the name of the manufacturer.

The common types are as follows:

- Raymond standard pile,

- Raymond step-taper pile,

- Union metal pile of monotube,

- MacArthur compressed uncased pile,

- MacArthur cased pile,

- Franki standard pile,

- Western button bottom pile.

3. Under-reamed

The under-reamed pile is a particular type of bored pile having an increased bulb or diameter at some point in this length, to anchor the expansive foundation soil subjected to alternate contraction

4. Timber piles

Timber piles have a small bearing capacity and aren’t permanent unless treated. They’re prone to damage from hard-driving, and shouldn’t be driven through hard stratum or boulders.

Composite piles are suitable which in the upper part of a pile is to project above the water table. This type of pile consists of a lower portion of untreated timber and an upper portion of concrete.

5. Steel piles

5.1. H-piles

- Steel H piles (designated as HP) are suitable for penetrating rock as well as for driving through hard and resistant materials.

- These piles displace a minimum of soil mass when driven through it and, therefore, can be easily driven through dense material

without causing soil heave. - These piles can carry loads in the range of 80 kips (356 kN) to 240 kips (1068 kN) and have lengths in the range of 40ft (12m) to 100 ft (30m).

- The maximum stresses in the pile section should not be more than 12,000 psi (82.7 M Pa) or as per the allowable code or specification for the job.

- Steel H piles are generally driven through soft soils to hard-bearing strata. The classic case of danger for these piles driven through loose materials to hard, uneven rock is that these piles generally get demolished at their ends, resulting in questionable end-bearing capacity.

- These piles should, therefore, be protected by attaching hard steel points at their ends. Associated Pile Fitting Corp. (1985) cites a Federal Highway Administration Ohio test case where HP 10 x 42 piles were driven to hard limestone. None of the piles that had APF cast steel points experienced damage despite hard-driving with up to 50,000 ft-lb hammer energy. In contrast, all piles driven without point protection got damaged even by driving energy of an 8700 ft-lb hammer.

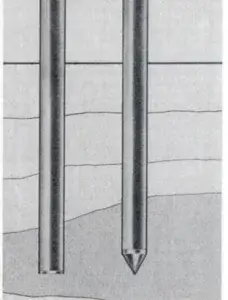

5.2. Pie Piles

- Pipe piles have two main advantages: (l) the soil within the pipe can be easily taken out since there are no obstructions for cleaning out tools (e.g., no corners), and (2) the circular shape minimizes drag from waves and current forces in deep waters.

- Pipe piles can also be inspected for any damage and/or deviation from plumb by lowering a light source within the hollow section.

- As shown in Figure 2.7, pipe piles can also be fitted with end caps in areas of hard-driving.

A typical type of pie foundation with tip fitting

- Where the hard-bearing strata are inclined or sloping, the flat plate at the end of the pipe may cause uneven stresses on the pipe pile resulting in stress concentration and crippling of the pile.

- In such situations, conical points, as shown on the pile on the right in Figure 2.7, arc used to distribute the stress around the

pipe. - Pipe piles are always filled with concrete after driving in the U.S.A. This gives the piles a higher section modulus and rigidity.

- The pile’s arc generally economical in the range of 40 to 80 ft (12 to 24 m) and can carry loads as high as about 250 kips (1115

kN). - Pipe piles are most suited where the overburden is soft clays, silts, and loose-to-medium dense sand and is underlain by dense-

bearing granular material. They also have successfully been installed in layered soils. - For example, Lee et al. (1984) describe a foundation system for the Shangri-La Hotel on the bank of Chao Phraya River in

Bangkok, Thailand, which, among other facilities, also consists of a 27-story tower block. - The foundation soils consist of the soft Bangkok clay from the surface down to about 43 ft (13 m) underlain by alternating layers

of stiff clay and sand. - Pumping of water from the sand layers has reduced piezometric head in the stiff clay and sand layers causing ground

subsidence as much as 4 in./yr (10 cm (yr) in Bangkok. - Pile foundations designed to rest on dense sand layers will, therefore, be subjected to negative (downward) skin friction due to

subsidence of surrounding clay layers that are undergoing consolidation. - The foundation system consisted of installing 24-in. (600 mm) diameter open-ended steel pipe piles.

- The installation procedure consisted of auger-pressing the pile through clay layers and through the near-surface sand layer.

- Then the piles were driven with a K45 hammer with a drop height of about 8 ft (2.5 m) until a set of about 0.04 in. (1 mm) per

blow was achieved. - At this time, the piles were at about 180 ft (55 m) to 190 ft (58 m) depth below ground surface. To reduce negative skin friction,

some pipe pile sections that were to him in the settling clay layer depths were coated with a bitumen slip layer that was protected

by a polyethylene layer. - Remaining pile lengths (sections) were left uncoated to mobilize the skin friction. These piles thus supported the imposed loads

by mobilizing skin friction and end bearing in lower stiff clay and dense sand. - Pipe piles can be used as friction piles, end-bearing piles, and a combination of friction and end-bearing or even rock-socketed

piles. - They are also useful for marine structures where large diameter pipes can resist lateral forces in deep waters.

5.3. Any other type of composite

In the other type of composite piles, steel piles are attached to the lower end of the cast-in-place concrete pile. This type is used in a case where the required length of piles is greater than that available for the cast-in-place type.

Another type of steel piles that have been used to support light loads arc called screw piles. These piles consist of installing by screwing the helix steel sections down into the ground by applying the torque without digging into the ground.

The main advantage of this type of piles is that the structure or the equipment can be placed on the foundation immediately after the piles have been installed without having to return to the job site after the concrete has cured.

- These piles can be installed in all soil types and have been used in several countries for mast and tower foundations.

- As per the above figure gives examples of some typical application of these pile types that have been used in the past. These

piles are mostly used to support lightly loaded foundations. - All the above type of foundation (Piling Foundation Types)

Characteristics of Different Types of Foundation

In this section, the mechanisms of resistance of an individual foundation and a pile group are discussed.

The function of different types of foundations is also addressed.

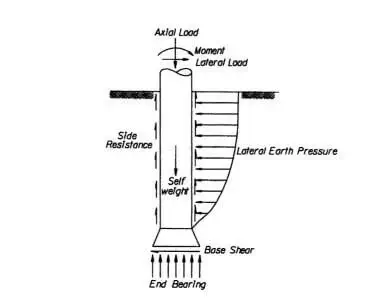

Complex loadings on top of a foundation from the bridge structures above can be simplified into forces and moments in the longitudinal, transverse, and vertical directions, respectively (As per below figure).

Resistances of an individual foundation

Longitudinal and transverse loads are also called horizontal loads; longitudinal and transverse moments are called overturning moments; a moment about the vertical axis is called torsional moment.

The resistance provided by an individual foundation is categorized in the following (also see above figure).

- End-bearing. Vertical compressive resistance at the base of a foundation; distributed end-bearing pressures can provide resistance to overturning moments;

- Base shear. Horizontal resistance of friction and cohesion at the base of a foundation;

- Side resistance Shear resistance from friction and cohesion along the side of a foundation;

- Earth pressure: Mainly horizontal resistance from lateral Earth pressures perpendicular to the side of the foundation;

- Self-weight Effective weight of the foundation.

Both base shear and lateral earth pressures provide lateral resistance of a foundation, and the contribution of lateral earth pressures decreases as the embedment of a pile increases.

For long piles, lateral earth pressures are the main source of lateral resistance. For short piles, base shear and end-bearing pressures can also contribute part of the lateral resistance.

As per below table lists various types of resistance of an individual pile.

For a pile group, through the action of the pile cap, the coupled axial compressive and uplift resistance of individual piles provides the majority of the resistance to the overturning moment loading.

Horizontal (or lateral) resistance can at the same time provide torsional moment resistance.

The resistance of an Individual Foundation

[su_table responsive=”yes” alternate=”no”]

| Types of Foundation | Types of Resistance | ||||

| Vertical Compressive Load (Axial) | Vertical Uplift Load (Axial) | Horizontal Load (Lateral) | Overturning Moment (Lateral) | Torsional Moment (Torsional) | |

| Spread footing (also see Chapter 31) | End bearing | – | Base shear, lateral earth pressure | End bearing, lateral earth pressure | Base shear, lateral earth pressure |

| Individual short pile foundation | End bearing; side friction |

Side friction | Lateral earth pressure, base shear | Lateral earth pressure, end bearing | Side friction, lateral earth pressure, base shear |

| Individual end-bearing long pile foundation | End bearing | – | Lateral earth pressure | Lateral earth pressure | – |

| Individual frictional long pile foundation | Side friction | Side friction | Lateral earth pressure | Lateral earth pressure | Side friction |

| Individual long pile foundation | End bearing; side friction |

Side friction | Lateral earth pressure | Lateral earth pressure | Side friction |

| Anchor | – | Side friction | – | – | – |

[/su_table]

A pile group is more efficient in resisting overturning and torsional moments than an individual foundation. As per the above table summarizes functions of a pile group in addition to those of individual piles.

Additional Foundation of pile Group Foundations

[su_table responsive=”yes” alternate=”no”]

| Type of Foundation | Type of Resistance | |

| Overturning moment (Lateral) | Torsional moment (Torsional) | |

| Grouped spread footings | Vertical compressive resistance | Horizontal resistance |

| Grouped piles, foundations | Vertical compressive and uplift resistance | Horizontal resistance |

| Grouped anchors | Vertical uplift resistance | – |

[/su_table]

A pile group is more efficient in resisting overturning and torsional moments than an individual foundation. As per the above table summarizes functions of a pile group in addition to those of individual piles.

[su_box title=”FAQ” style=”default” box_color=”#333333″ title_color=”#FFFFFF” radius=”3″ class=”” id=””]

Tension Pile

Tension piles, also known as uplift piles or anchor piles, are a type of pile foundation that is used to resist uplift forces that might otherwise cause it to be extracted from the ground. Uplift forces can develop as a result of hydrostatic pressure, seismic activity or overturning moments.

Pile Foundation Details

A pile foundation is defined as a series of columns constructed or inserted into the ground to transmit loads to a lower level of subsoil. A pile is a long cylinder made up of strong material, such as concrete. Piles transfer the loads from structures to hard strata, rocks, or soil with high bearing capacity.

Pile Foundation Types

Depending on their function, piles are classified as bearing piles, friction piles, friction-cum-bearing piles, batter piles, guide piles, and sheet piles. Based on the composition of materials, piles are classified as timber piles, concrete piles, sand piles, or steel piles.

Macarthur Pile

A patented pile is formed by driving a steel shell into the ground to the required depth, putting in small quantities of concrete, and hammering them down so as to force the concrete into the earth beyond the point of the shell; thus enlarging the end and greatly increasing the bearing area.

Uses of Pile Foundation

Pile foundations are principally used to transfer the loads from superstructures, through weak, compressible strata or water onto stronger, more compact, less compressible, and stiffer soil or rock at depth, increasing the effective size of a foundation and resisting horizontal loads.

Pile Foundation Types

5 Types of Pile Foundation

- Bored Piling.

- Driven Piling.

- Screw Piling.

- Mini Piling.

- Sheet Piling.

Types of Deep Foundation

There are two main types of Deep foundations; Driven Piles and Drilled Piers. A driven pile is driven into the ground, as you would imagine a nail being driven into a wall with a hammer. In essence, the pile is driven into the earth with a strong hammer.

Concrete Pile Foundation

A pile foundation is defined as a series of columns constructed or inserted into the ground to transmit loads to a lower level of subsoil. A pile is a long cylinder made up of strong material, such as concrete. Piles are pushed into the ground to act as steady support for structures built on top of them.

Micro Pile Foundation

Micropiles, also known as mini piles, pin piles, needle piles, and root piles, are deep foundation elements constructed using high-strength, small-diameter steel casing and/or threaded bars.

Different Types of Pile Foundation

There are three types of pile foundations according to their construction methods which are driven piles, cast-in-situ piles, and driven and cast-in-situ piles.

Pile and Beam Foundation

What are the pier and beam framing concepts? Pier and beam design features deep concrete footings to which piers are attached or, in some cases, piles drilled deep into the ground. Beams are connected to the top of the piers so they are above the ground. The floor joists then sit directly on the beams.

Pile and Pier Foundation

In pile foundations, the loads are transferred by means of vertical timber, concrete, or steel. The Pier foundation consists of cylindrical columns to support and transfer large superimposed loads to firm strata. 2. Piles are driven through the overburdened soils into the load-bearing strata.

Pile Foundation for House

Pilings are timber, metal, or concrete columns driven many feet into the ground to support the house on bedrock, while piers sit above the ground. Building a house on pilings requires the assistance of an engineer to calculate the load and the type, length, and diameter of the pilings.

Pin Pile Foundation

Pin Pile Technology combines the best features of both types of foundations. By grouping short stiff piles (bearing pins), which can easily be driven into intact penetrable soils, and setting them at angles to work more like a shallow spread footing, a sound foundation can be constructed that requires no excavation.

Screw Pile Foundation Detail

Screw pile foundations are a type of pile foundation with a helix near the pile toe so that the piles can be screwed into the ground. The process and concept are similar to screwing into wood. A screw pile may have more than one helix (also called a screw), depending on the usage and the ground conditions.

Caisson Pile Foundation

Pile Foundation

Caissons are watertight structures made up of wood, steel or reinforced concrete built above the ground level and then sunken into the ground. Pile foundation is a type of deep foundation, in which the loads are taken to a low level by means of vertical timber, concrete or steel.

Detail Pile Foundation

Pile foundation detail

A pile foundation is defined as a series of columns constructed or inserted into the ground to transmit loads to a lower level of subsoil. A pile is a long cylinder made up of strong material, such as concrete. Piles are pushed into the ground to act as steady support for structures built on top of them.

Deep Foundation Drilling

In short, foundation drilling is a process that involves using a drill rig to bore a large hole deep into the ground in order to insert structures—such as piles—that are used to build a foundation for a construction project.

Screw Piles for House Foundations

A Screw Pile Foundation Is Versatile

Most house plans feature a slab, crawlspace, or basement foundation, but the options go beyond that. Generally referred to as “helical,” a screw pile foundation consists of several large metal poles driven securely into the ground. These poles form the support and base for the home.

Deepest Pile Foundation in the World

The twin Towers of Malaysia have the world’s deepest foundations. Which is situated in Kaula— Lampur Malaysia. The depth of its foundations is 120m ( i.e. 400ft approx ). On the purposed site of the Twin Towers of Malaysia, the available on top was black cotton soil.

Helical Piles for House Foundation Cost

What is the Cost of a Helical Pier Underpinning Project? The average helical pier underpinning cost comes out to be $24,000 to $60,000.

Design Pile Foundation

The design of a pile foundation involves providing adequate pile type, size, depth, and number to support the superstructure load without excessive settlement and bearing capacity failure. Deep foundations are more expensive and technical than shallow foundations.

Pier and Pile Foundation

Pile foundations are of great depth. Pier foundations are of shallow depth. Pier foundation is used where top strata consist of decomposed rock, stiff clays. The types of pile foundations are end-bearing piles, friction piles, compaction piles, anchor piles, tension or uplift piles, sheet and batter piles, etc.

[/su_box]

[su_note note_color=”#F2F2F2 ” text_color=”#333333″ radius=”3″ class=”” id=””]

Like this post? Share it with your friends!

Suggested Read –

- 15 Different Types of Cement and Their Uses

- What Are the Components of Stairs | 19 Different Types of Stairs Components

- What Is Sealing Brick Work| Advantages of Brick Sealer | Types of Brick Sealer

- 10 Different Between Mortar And Concrete | What Is Mortar & Concrete | Types of Mortar & Concrete

- Types of Bearing Capacity Failures of Foundation | Bearing Capacity Definitions | Theory of Terzaghi’s Bearing Capacity

[/su_note]

Originally posted 2022-09-07 12:21:57.