What Is Shotcrete | Shotcrete & Concrete | Shotcrete Technology | Types of Shotcrete Technology | Advantages of Shotcrete | Disadvantages of Shotcrete

Table of Contents

What Is Shotcrete?

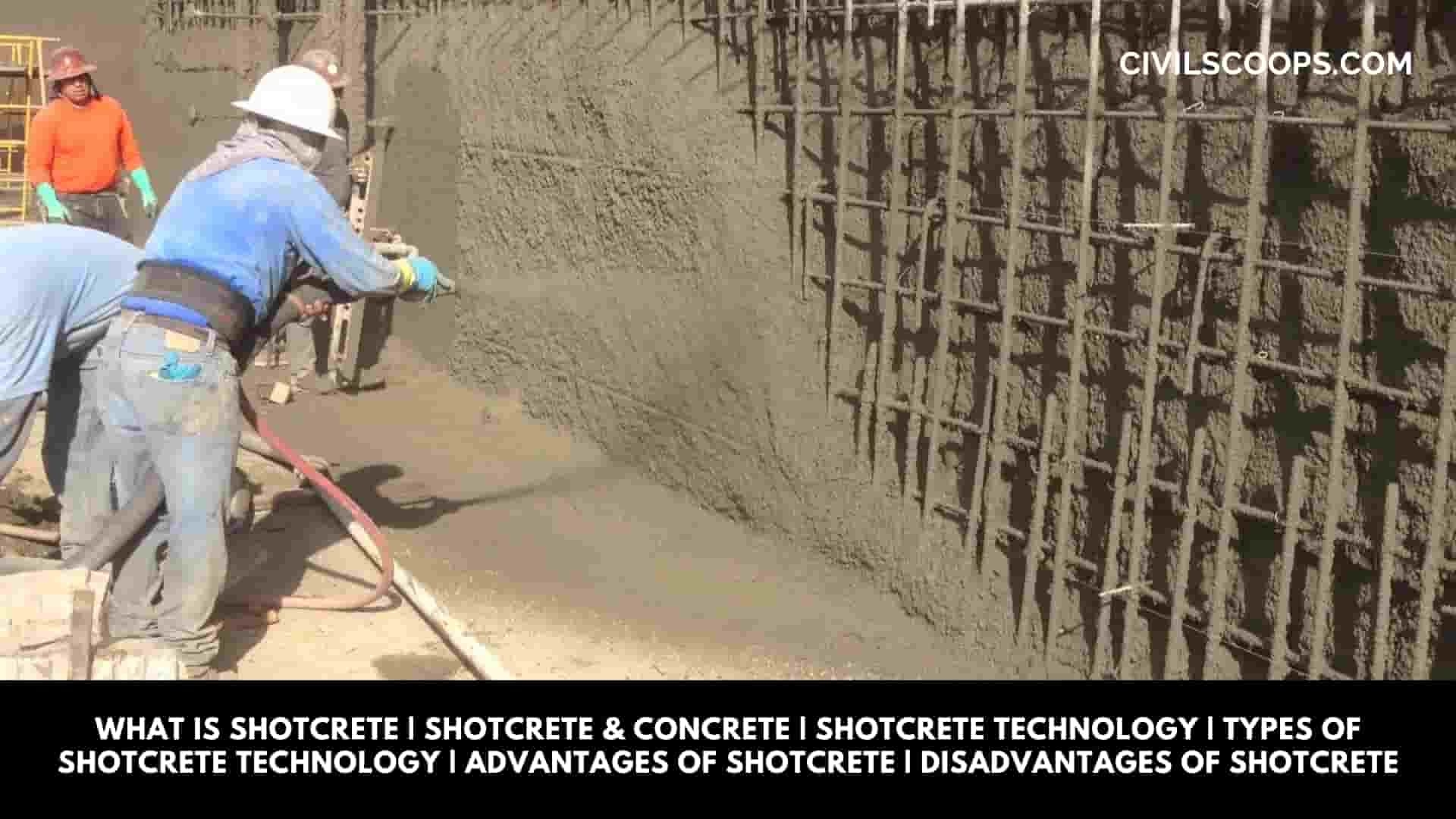

Shotcrete is a kind of refined concrete drizzled by a gas hose-pipe nozzle at high pressure & velocity on a projectile motion on a prepared wall surface. It is strengthened by conventional steel rods, steel mesh or fibres.

It is often utilised in tunnels, underground walls, retaining walls, drainage systems & swimming pools for interim support. For slope protection with wire mesh and in some confined areas wherever prosaic concreting cannot be done.

It can be sprayed on any type of surface (vertical or overhead). The shotcrete method needs less formwork and is more economical and cheap (needs only a small industry to get manufactured). It forms a good chemical bonding among a variety of materials.

Shotcrete & Concrete

Concrete is a building material that comes with an exceeding diversity of choices, together with lightweight, heavyweight, porous, and fibre-reinforced, to suit a range of construction needs. It consists of refined rock dust & water paste that solidifies.

Shotcrete is a specific style of concrete that can either be dry-mix or wet-mix. It has become acclaimed for its unique application technique that is distinctive from prosaic concrete.

How Does the Application of Shotcrete Dissent from Concrete?

The main distinction between shotcrete and concrete happens during its placement. Concrete is applied by employing a mixing truck, which prepares the mixture and pours it onto the ground.

The fresh concrete is then sprayed. Conversely, shotcrete is placed using a cement gun. The gun applies the mixture at a high rate, which gives the end product high strength, high sturdiness, and low permeability.

Shotcrete Technology

Ingredients:

- Cement.

- Sand (Natural/ Crushed).

- Coarse Mixture (Below 10mm).

- Admixture.

- Water.

- Fly ash/ Microsilica.

Types of Shotcrete Technology

There are two types of Shotcrete Technology. Which is as follows.

- Dry-Mix Shotcrete.

- Wet-Mix Shotcrete.

1. Dry-Mix Shotcrete

It involves inserting the dry ingredients into a gun and then spraying them through a hose to the nozzle. The inner part of the nozzle possesses a water ring which uniformly injects water into the mixture as it is being oozed out from the nozzle and propelled on the wall surface.

The water and the dry mixture are not thoroughly mixed but are completed as the mixture hits the receiving surface. This requires a skilled nozzleman, peculiarly in heavily bolstered sections.

Advantages of Dry-Mix Shotcrete

- The dry mix process is beneficial in repair applications when it is necessary to stop & adjust frequently.

Disadvantages of Dry-Mix Shotcrete

- Dust will be higher as we are using dry ingredients. It is not applicable where the shotcrete quantity is applied more frequently.

2. Wet-Mix Shotcrete

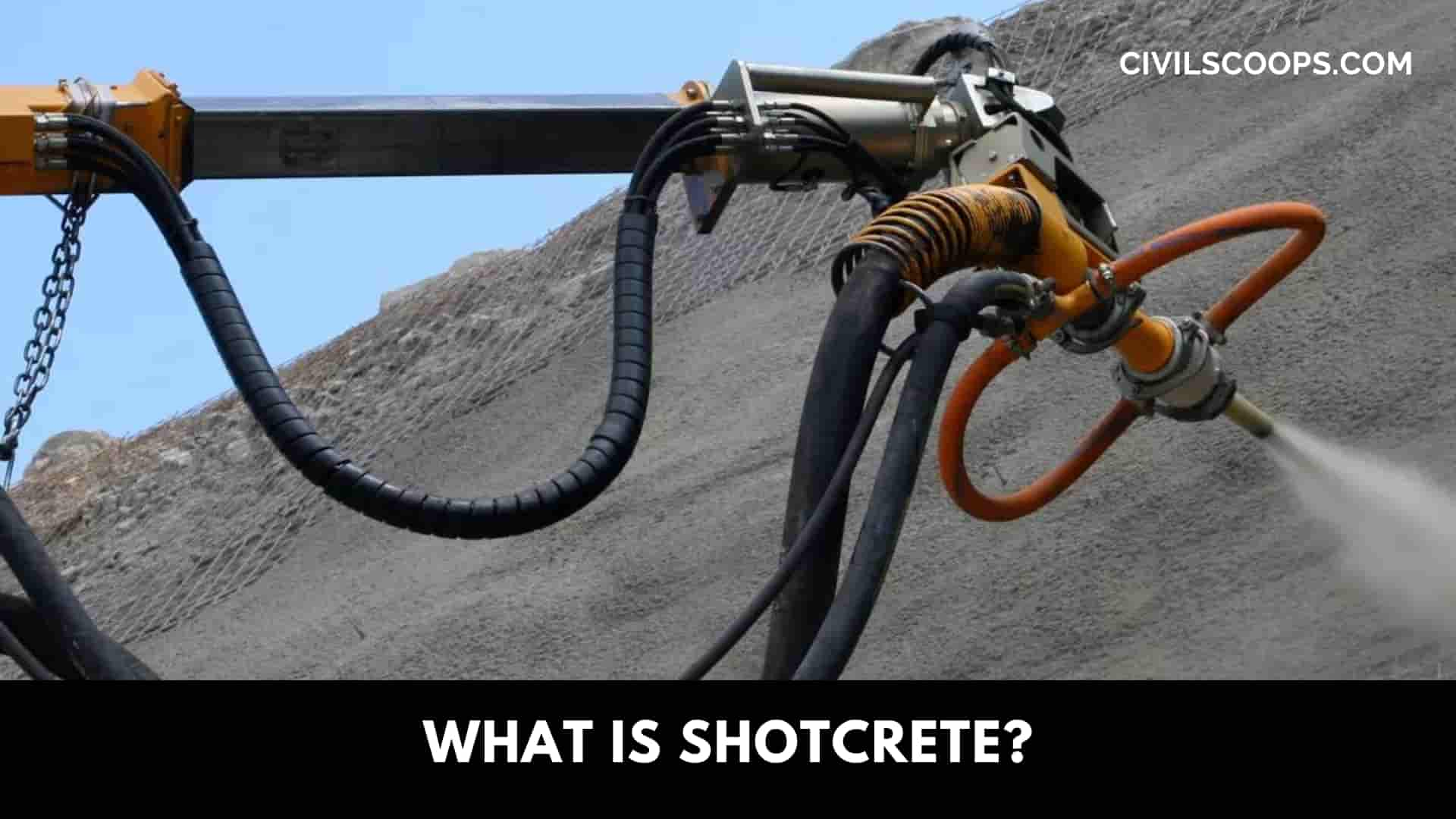

In wet-mix shotcrete, ready-mix concrete is used, which is sprayed through delivery paraphernalia such as a concrete pump which propels the mixture through the delivery hose where compressed air and accelerator is added at the nozzle point.

Advantages of Wet-Mix Shotcrete

- Less rebound (shotcrete falls down due to paucity in setting).

- Less dust compared to dry-mix shotcrete.

- A larger volume can be placed in lesser time.

Disadvantages of Wet-Mix Shotcrete

- A highly skilled operator is needed in spraying.

- W/c, pressure and accelerator dosage have to be unambiguous.

Shotcrete Wall

Shotcrete wall placement gives the subsequent benefits for quicker installation:

- Set concrete wall thickness and vertical alignment.

- Shotcrete wall at a faster rate than form-and-pour.

- Finish concrete to any specification.

Shotcrete Wall Benefits

Shotcrete Wall Benefits are as follows.

- Potentiality to place walls top-down, bottom-up or a full excavation.

- Substantially increase production compared to cast in situ concrete walls.

- ACI shotcrete specifications are readily available.

- Effortlessly incorporate shotcrete as an amendment order during construction.

- High strength, low permeability and high durability.

- Faster concrete set-up reduces labour costs.

- Better bonding to the receiving surface.

- Reduction of forming materials by up to 100%.

- No extra concrete footings are required for wall supports.

- Diminished crane time for form setting and concrete pouring.

Properties of Shotcrete

The properties of shotcrete are as follows.

- A small maximum-size mixture is used and the cement content is high.

- It is ought to enhance sturdiness in most cases.

- Whereas typical concrete is consolidated by vibration, shotcrete is consolidated by the impact of a high-velocity jet bashing on the surface.

- This method not only increases the cement content due to rebound but also brings about completely dissimilar air-void systems affecting the sturdiness of shotcrete.

- The application procedures have a greater effect on the in-place properties of shotcrete than the mix proportions.

- Shotcrete specimens are usually sawed from test panels of about one-meter square and 75 millimetres dense made by gunning out plywood.

Also Read: What Is RQD | Advantages of Rock Quality Designation | Limitations of Rock Quality Designation (RQD)

Applications of Shotcrete

Applications of shotcrete are as follows.

- Shotcrete is widely employed in different construction such as skinny overhead vertical or horizontal surfaces, notably the curved or folded sections, canals, buildings, marine structures, bridges, reservoirs, and tunnel lining.

- It is additionally employed in tunnels, canals, reservoirs, swimming pools, water retaining structures, and pre-stressed tanks.

- Shotcrete has successfully been utilised in the stabilisation of rock slopes, underground excavations and temporary protection of freshly excavated rock surfaces.

- It may be a utility for protection against long-term corrosion of pilling, coal bunker, oil tanks, steel building frames, and other structures, renovation of old buildings and fire vandalised structures as well as in encasing steel to form the structure water-resistant.

- These are developed for high-temperature applications, like the refractory lining of kilns, chimneys, furnaces, etc.

- They are also used for waterproofing walls.

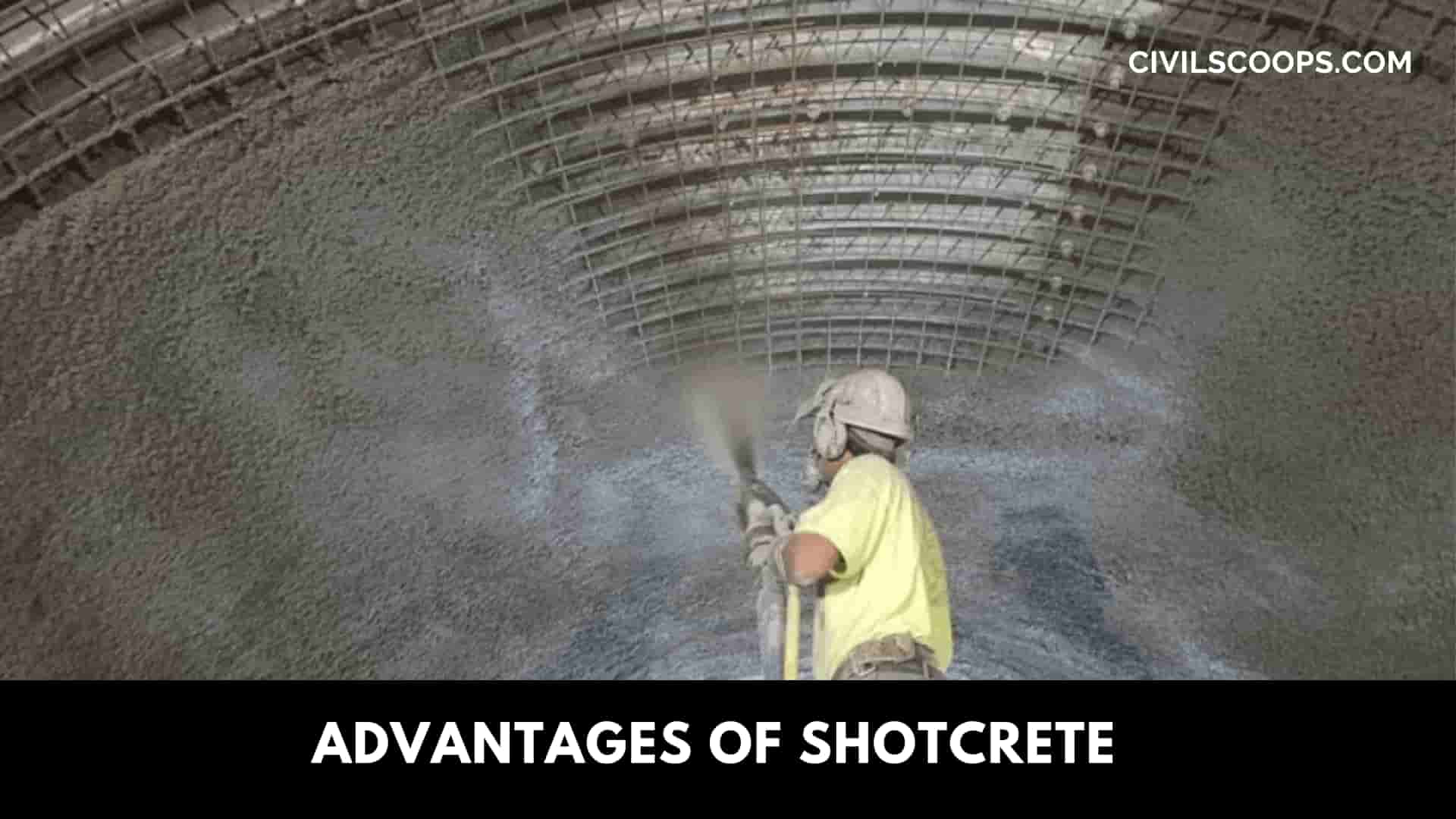

Advantages of Shotcrete

The advantages of shotcrete are as follows.

- The shotcrete can be applied by a nozzle from a secured haughtiness. It requires no vibration or compaction after placement since it is blown into place under pressure.

- More economical than prosaic concrete and requires less formwork. It is reasonable thanks to build concrete in curves and serpentine shapes that are arduous or unfeasible with traditional concrete forming, such as those required in tanks, domes, swimming pools, and skate parks.

- Eximious bonding in nature makes the concrete layers terribly robust.

- Among the benefits, it does not need a tortuous system of forms just like the more amicable poured-in-place concrete, since it is applied as a stiff paste and is solely a one-sided type, or none the last bit if it is applied over compacted soil.

- It can be used with steel reinforcing bars, welded wire reinforcing mesh, fibre reinforcement mixed with the concrete, or with no reinforcement.

- It has identical non-combustible and fire-resistant qualities as concrete that has been formed and poured in a prosaic manner.

- It minimises manpower.

- Helps to manage cement-water ratio.

Disadvantages of Shotcrete

The Disadvantages of shotcrete are as follows.

- The primary pitfall of shotcrete compared to slooshed concrete is the bulk of the time that it takes when utilised for Brobdingnagian foundations, structural piers, and other structures with giant cross-sections, in juxtaposition to using prosaic forms for these giant structures.

- Another disadvantage is the dusting drawback.

- Two common issues when applying shotcrete are gravel within the concrete concoction that is too colossal, which hinders the spraying of the concrete; and ready-mixed concrete that is too wet so that it does not adhere well to vertical and overhead surfaces.

- Production cost is incredibly high.

- Much concrete is squandered in comparison to prosaic concrete.

- High-skilled manpower is needed to perform the work.

- The procedure is sophisticated to some extent.

[su_box title=”FAQ” style=”default” box_color=”#333333″ title_color=”#FFFFFF” radius=”3″ class=”” id=””]

What Is Shotcrete Used For?

Because it can take any shape, is easily coloured, and can be sculptured after application, shotcrete is used for a variety of fancy concrete structures, including artificial rock walls, zoo enclosures, canopy roofs, refractory linings, pools, and dams.

Shotcrete

Shotcrete is a method of applying concrete projected at high velocity primarily on to a vertical or overhead surface. The impact created by the application consolidates the concrete.

Shotcrete Concrete

Shotcrete, also called (trademark) gunite, concrete applied by spraying. Shotcrete is a mixture of aggregate and portland cement, conveyed by compressed air to the nozzle of a spray gun, where water is added. The wet mixture is then sprayed in place and may be carved or troweled almost immediately.

Shotcrete Wall

Frequently used in underground applications, shotcrete is a wet- or dry-mix concrete that is pneumatically propelled at high velocity through a hose and nozzle. It does not require conventional forming and is an economical solution for the time and related costs it saves.

Application of Shotcrete

In building repairs, shotcrete is commonly used for repair of fire and earthquake damage and deterioration, strengthening walls, and encasing structural steel for fireproofing. The repair of structural members such as beams, columns, and connections is common for structures damaged by an earthquake.

Difference Between Shotcrete and Concrete

Shotcrete is pretty much the same thing as concrete (i.e. it is used ready mixed), but its name derives from the way it is applied. Instead of being poured, it is fired out of a hose at high speed

Shotcrete Technology

Shotcrete is a mortar or high performance concrete conveyed through a hose and pneumatically projected at high velocity onto a backing surface. It is the force of this spraying action that leads to compaction of the concrete or mortar which then forms layers of concrete to the required thickness .

Types of Shotcrete

The two types of shotcrete processes, dry shotcrete (also known as gunite), and wet shotcrete, have grown steadily in popularity in both concrete repair and new construction.

Dry Shotcrete

Dry process is defined by the ACI as “shotcrete in which most of the mixing water is added at the nozzle.” Dry ingredients are placed in a hopper and then are pneumatically propelled through a hose to the nozzle. The nozzleman then controls the addition of water manually at the nozzle.

Advantages of Shotcrete

Shotcrete has all of the advantages of standard concrete materials, such as its high tensile strength, durability, fire retardation, low permeability, and thermal efficiency.

[/su_box]

[su_note note_color=”#F2F2F2 ” text_color=”#333333″ radius=”3″ class=”” id=””]

Like this post? Share it with your friends!

Suggested Read –

- What Is DLC (Dry Lean Concrete) | Advantage of DLC (Dry Lean Concrete)

- Carbon Steel vs. Stainless Steel | What Is Carbon Steel | What Is Stainless Steel

- What Is Linear Measurement Surveying | Types of Linear Measurement Surveying

- All About Soffit | What Is Soffit | Different Types of Soffit | What Is Fascia | Advantages & Disadvantages of Fascia and Soffits |

- All About Brick Bat Coba | What Is a Brick Bat Coba | Procedure of Brick Bat Coba Waterproofing | Advantages & Disadvantage of Brick Bat Coba Waterproofing

[/su_note]

Originally posted 2023-03-27 11:33:27.