Shotcrete Vs Gunite | What Is Gunite | Advantage & Disadvantage of Guniting Process | What Is Shotcrete | Advantage & Disadvantage of Shotcreting

Table of Contents

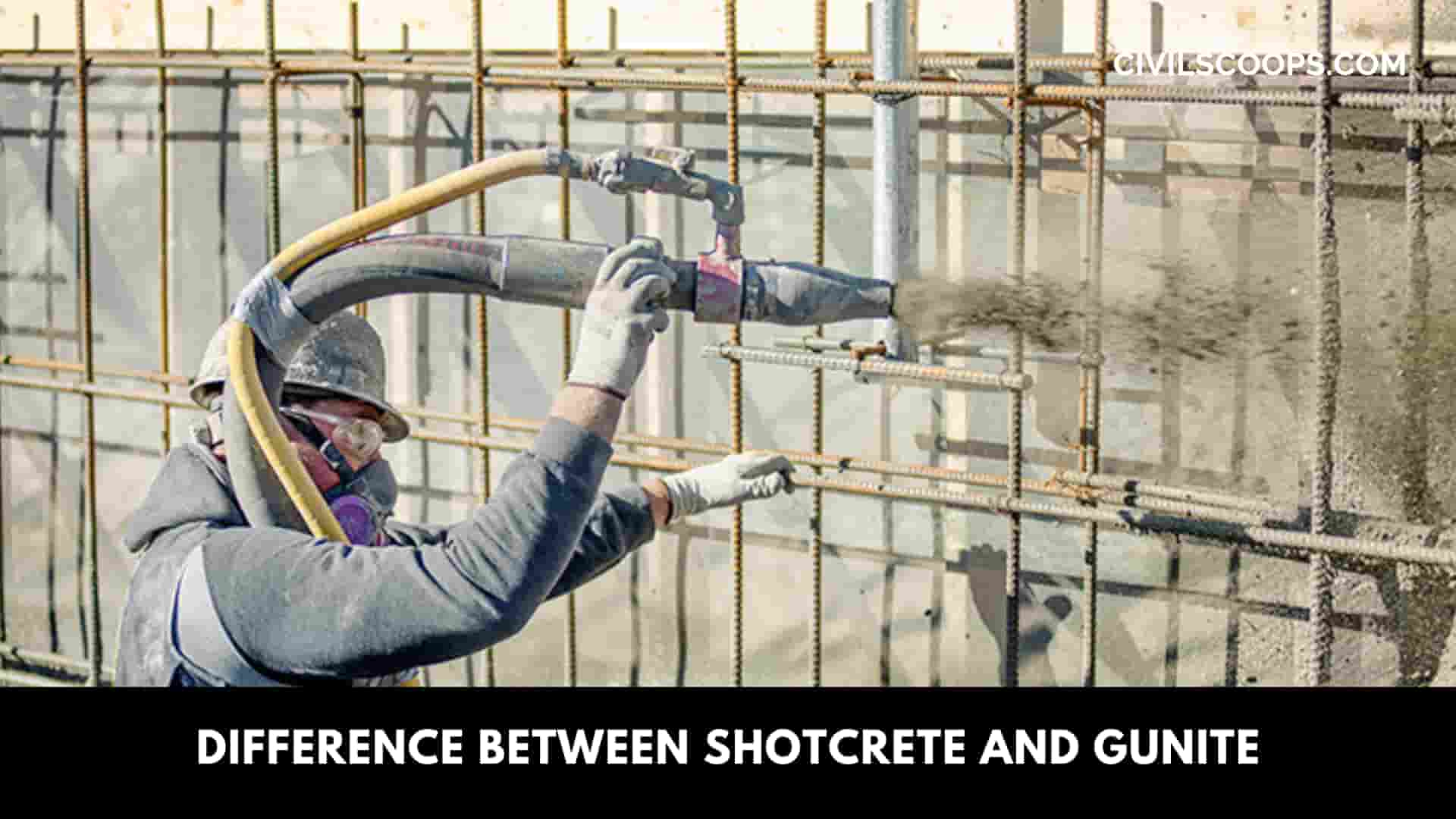

Introduction of Shotcrete Vs Gunite

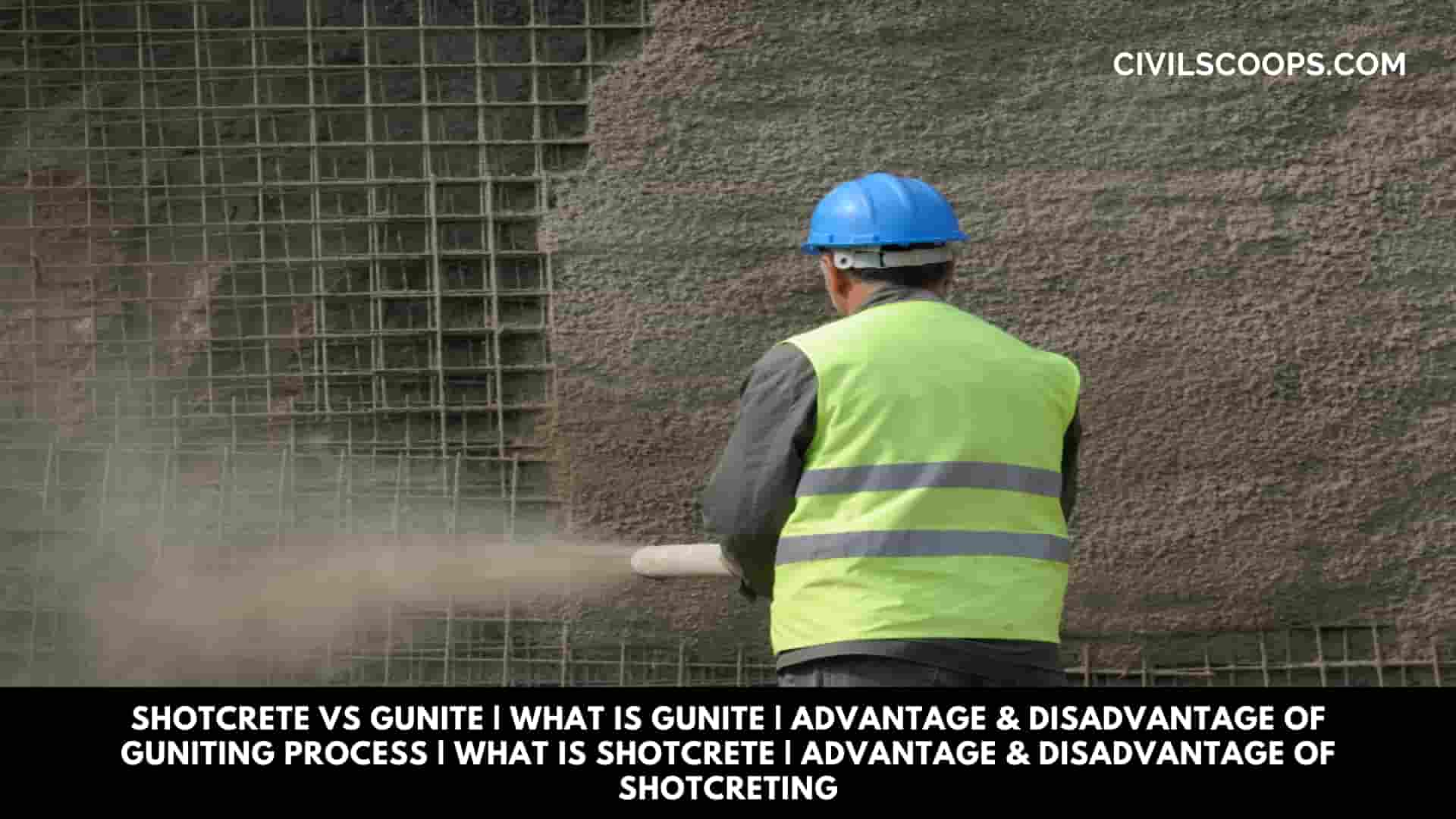

- Shotcreting and Guniting are one of the most important and widely used techniques in construction.

- The purpose of using the shotcrete and Guniting method is the same but the process of application is different.

- Guniting and shotcreting are both different techniques. Many people do not know the difference between Guniting and shotcreting.

- Sprayed concrete is widely used in the construction of tunnels, underground structures, slope stabilization, structural repairs, and swimming pools.

- In this article, you will get to know about the guniting and shotcreting process and the difference between Shotcrete and Gunite.

What Is Guniting?

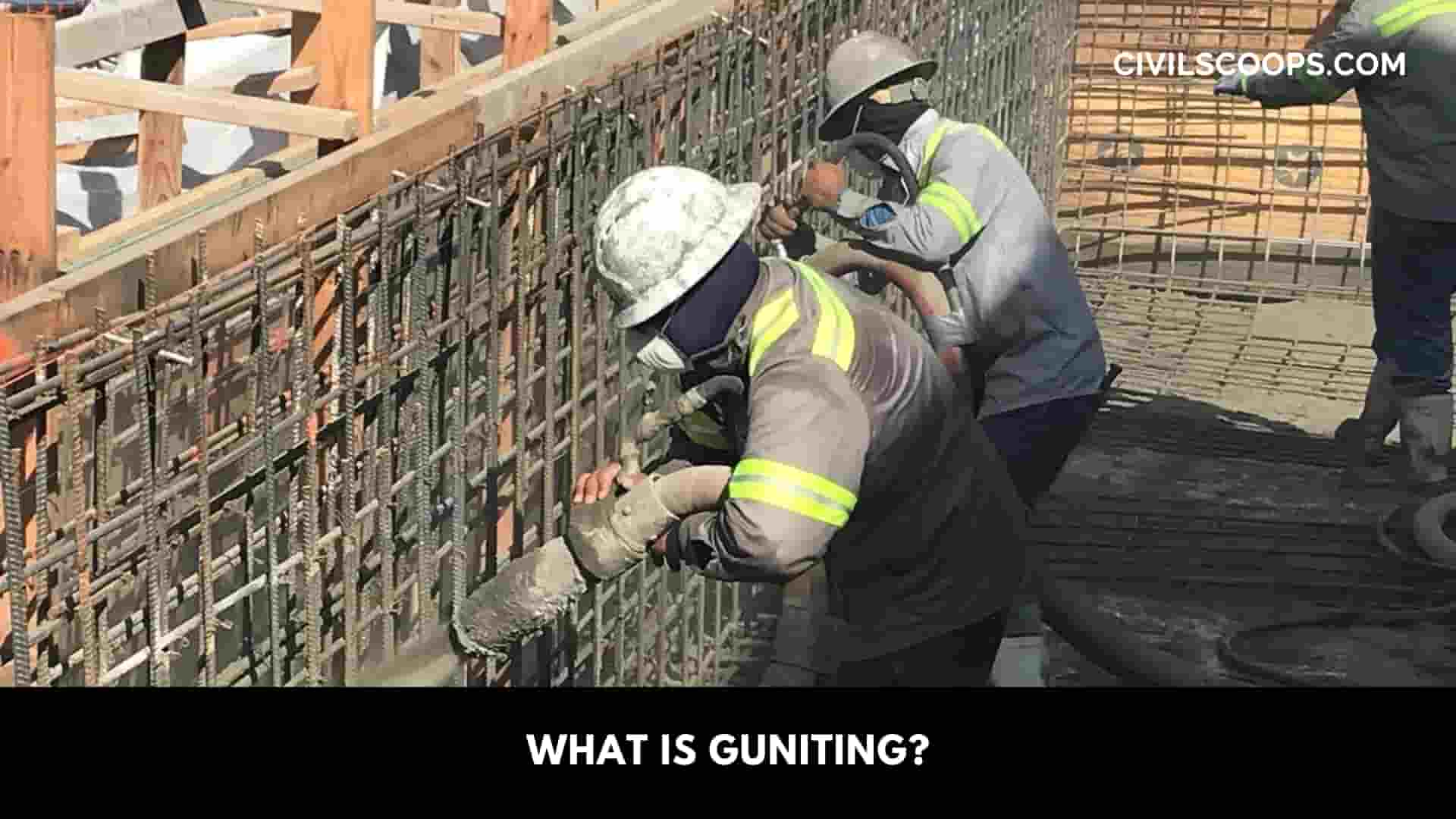

- Guniting is a technique that consists of the pumping of mortar or concrete at a high velocity through a hose or spray gun to apply on the surface.

- The Guniting process is also known as Dry Shotcreting. It is a process of spraying a mix of mortar or concrete at high pressure to the surface with the help of spray gun.

- Guniting is one of the most effective techniques which is widely used for the repairing of the concrete which is damaged.

- Guniting process is used in the slope stabilization dome construction of retention walls water tanks and pools etc.

- The process of converting has wide applications such as the strengthening of old structures, lining of the reservoir and canal, and waterproofing of the surface which come directly with the contact of water.

Advantage of Guniting Process:

The various advantages of guniting process are as follows

- The Guniting process is economical as compared to other types of method.

- The dry mix can be prepared quickly as compared to the wet shotcreting mix.

- The guniting process is used in swimming pools and artificial caves to provide special shapes and features.

- The High compressive strength of the concrete can be obtained with guniting process.

Disadvantage of Guniting Process:

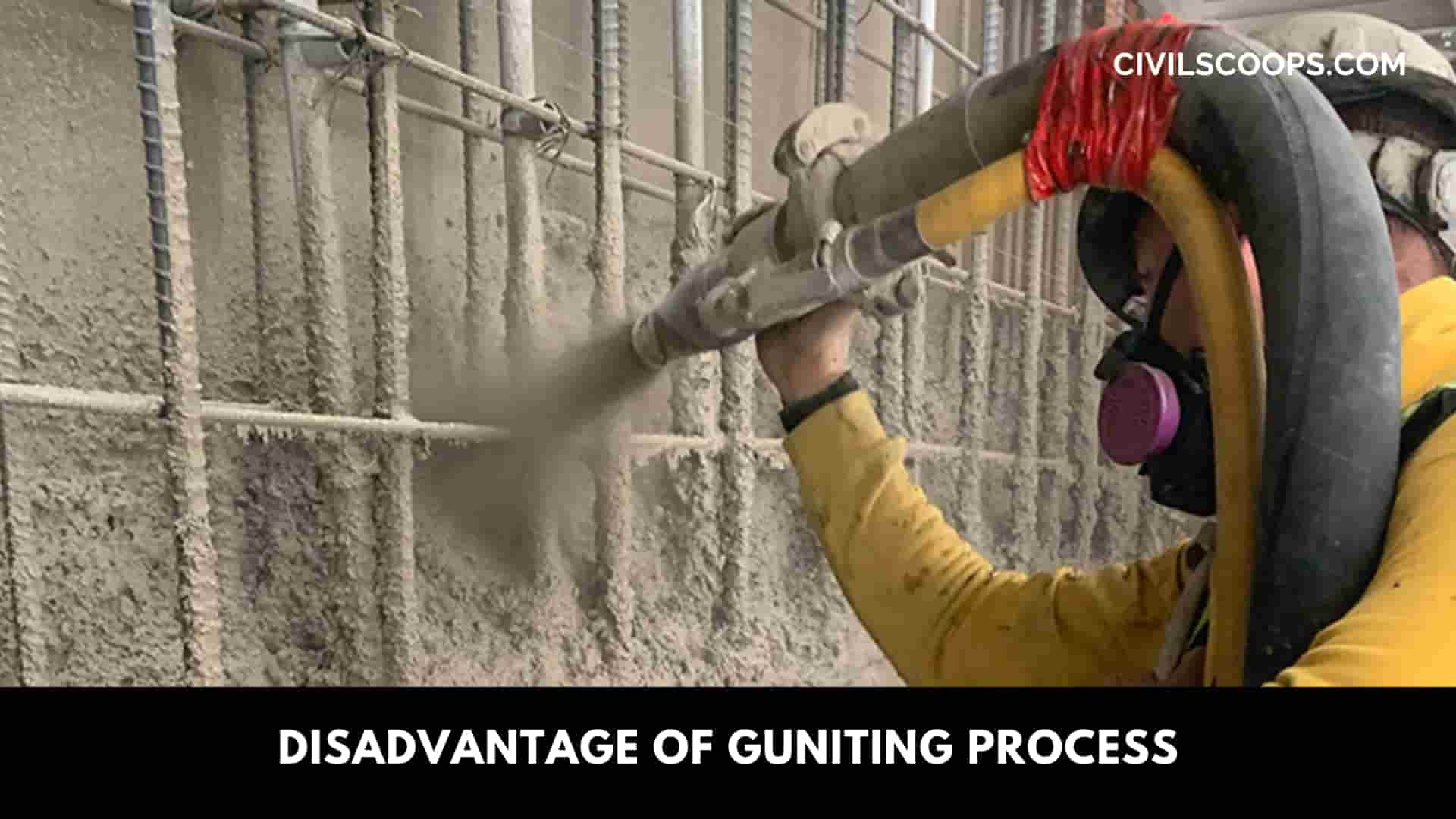

The various disadvantages of Guniting process are as follows

- The dry mix of concrete can clog or block the hose pipe during the application of concrete.

- The process of Guniting required a skilled operator.

- The quality of the work depends upon the operator.

- In this method, there may be chances of wastage of concrete.

Also Read: What Is Concrete | 31 Different Types of Concrete

What Is Shotcrete?

- The term Shotcrete itself says that it is a technique in which the concrete is shot out through the hose is known as Shotcrete.

- Shotcrete is sprayed on the surface through a hose at a high velocity. Shotcrete is used with both wet mix as well as dry–mix

- Shotcrete can be done with both dry mix or wet mix. Shotcrete is placed and compacted properly.

- Dry mix process for shotcreting, in which water is added to the concrete mix at the nozzle.

- Wet mix process involves the mixing of all the ingredients required for concrete. In the case of wet-mix shotcrete process, the water content is controlled more accurately as compared to the dry-mix method.

- Shotcreting is the best method in which the concrete mix is applied in layers under the pressure of compressed air.

- The water cement ratio for shotcrete normally ranges within 35 to 0.50 by mass which is somewhat lower than for most conventional concrete mixes.

- Shotcreting process is done with the special unit which consists of a mortar gun. The dry mix of cement sand and aggregate is prepared in the appropriate proportion for the process of shotcreting.

- There are different types of shotcreting machines are available which help to control the complete process and make it easy.

- The Shortcrete is widely used for the repairing of the structure and earthquake damage. Shotcreting method is very helpful in underground mining.

Advantage of Shotcreting:

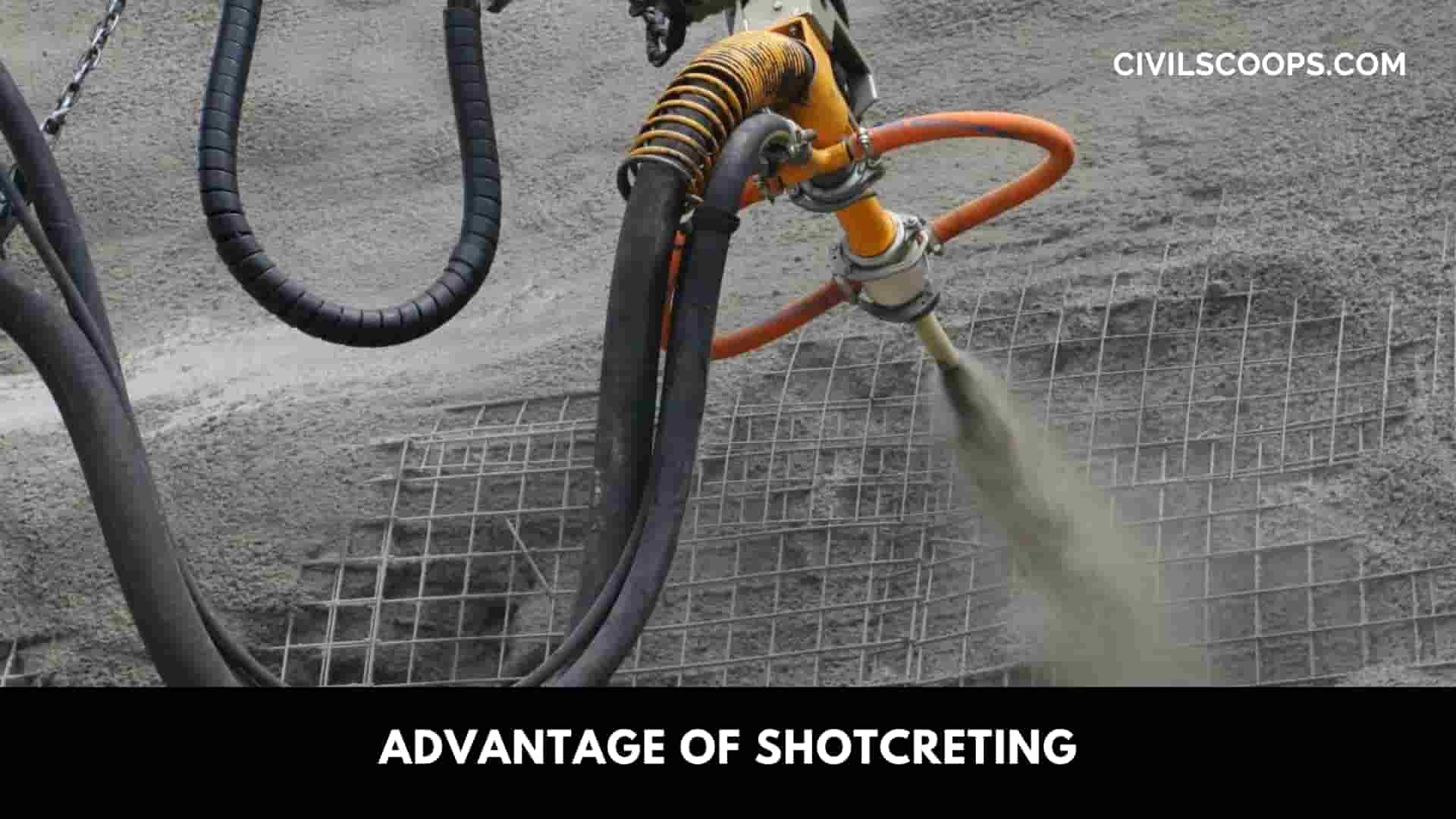

The various advantages of shotcreting process are as follows

- The process of shotcreting forms a strong and uniform layer of concrete on the surface.

- The shotcreting process is more economical as compared to conventional concrete which required formwork.

- Shotcreting is suitable for the construction where the formwork cannot be installed.

- The concrete can be applied to one nozzle from a safe distance.

Disadvantage of Shotcreting:

The various disadvantages of shotcreting process are as follows

- The concrete in the process of shotcreting is premix so that it is necessary that it has to be applied quickly.

- There may be chances of developing crack if more water is added in the premix concrete.

- The process of shotcreting is a little bit expensive as compared to guniting process.

Also Read: Load-Bearing Vs Partition Walls | What Are Walls | Classified of Walls

Difference Between Shotcrete and Gunite

The difference between shotcreting and Guniting are as follows

[su_table responsive=”yes” alternate=”no”]

| Sr.No. | Shotcreting | Guniting |

| 1 | Shotcreting is a technique of spraying of concrete on the surface at high pressure. |

Guniting process is a technique of spray mix of mortar and concrete at high velocity.

|

| 2 | The Shotcrete process can be done with both dry mix as well as wet mix. |

The guniting process is carried out with only dry mix. It is also known as dry shotcreting.

|

| 3 | In the shotcreting process large size of aggregates can be also used. |

In the guniting process small size of aggregates are used.

|

| 4 | Shotcreting process is used for or large quantity of work. |

Guniting or dry shotcreting process is used for the small quantity of work

|

| 5 | Formal operating labours can be also work ok in the shotcreting process. |

High skilled labour is required for the greeting process.

|

| 6 | The waste created by the sprayed concrete in case of shotcreting process is less. |

The waste created by the spread concrete in case of guniting process is more.

|

[/su_table]

[su_box title=”FAQ” style=”default” box_color=”#333333″ title_color=”#FFFFFF” radius=”3″ class=”” id=””]

Shotcrete Vs Gunite

The major difference between the two is that shotcrete is applied pre-mixed with water, so it simply hardens where it falls. On the other hand, gunite is applied as a dry plaster which mixes with water as it leaves the hose.

What Is Gunite?

a mixture of cement, sand, and water applied through a pressure hose, producing a dense hard layer of concrete used in building for lining tunnels and structural repairs.

Is Gunite Stronger Than Concrete?

Regarding strength, gunite is typically the strongest. Shotcrete is made from a pre-mixed concrete that is delivered to the job site, while gunite is made from dry ingredients that are mixed on site.

Is Shotcrete Waterproof?

Shotcrete applications have erroneously been described as more difficult to waterproof. This is simply not true.

Is Gunite the Same as Concrete?

You could refer to gunite as concrete’s cousin because they are both in the same family, but have their differences. Gunite is the dry mixed form of sprayed concrete. Gunite typically only contains fine particles in its mix while concrete contains both large and small particles.

What Is Gunite Used For?

The trade terms for sprayed concrete are gunite and shotcrete. Gunite and shotcrete are alternative forms of concrete, distributed by a hose at a high velocity, which enables us to reach awkward surfaces such as tunnels, bridges, swimming pools and train stations.

Which Is Better Shotcrete or Gunite?

Gunite generally lasts longer and maintains a higher quality than shotcrete. For instance, gunite tends to dry faster than shotcrete, leading to a much smoother surface and avoiding significant cracks from shrinking. Gunite can also withstand up to 9500 psi, a much higher psi than shotcrete.

Is Shotcrete Stronger Than Gunite?

Durability. Gunite generally lasts longer and maintains a higher quality than shotcrete. For instance, gunite tends to dry faster than shotcrete, leading to a much smoother surface and avoiding significant cracks from shrinking. Gunite can also withstand up to 9500 psi, a much higher psi than shotcrete.

[/su_box]

[su_note note_color=”#F2F2F2 ” text_color=”#333333″ radius=”3″ class=”” id=””]

Like this post? Share it with your friends!

Suggested Read –

- Top 20 AAC Block Company in India

- All About Transom Window | What Is a Transom Window | Types of Transom Window

- All About Sandbag Cofferdam | What Is Sandbag Cofferdam | Advantages of Sandbag Cofferdam

- What Is Plumbing Joint | 11 Types of Plumber Joint | Different Types of Pipe Joints and Where Are Use

- Detail of Beam Connection | Simple Framing Connection | Semi-Rigid Framing Connection | Rigid Frame Connection

[/su_note]

Originally posted 2023-05-04 11:52:06.