14 Types of Plaster Finishes (List of Plaster Finishing)

Table of Contents

What is Plaster Finishes?

Having your walls up is not the end of the building construction process. If you want to decorate your walls or cover their uneven surfaces, your contractors can finish your building with plaster.

Plastering is the process wherein the coarse surfaces of your walls or ceilings are covered to achieve a smooth and aesthetic finish.

There are several types of plaster finish, and in this article, we will tell you how to achieve five different styles. Every finish gives your wall a different appearance, and it’s up to you to choose which one to use in your project.

Types of Plaster Finishes

After the application of plaster, finishing applied on the final coat of plaster following are some of the finishes.

- Smooth Coat Finish.

- Sand Face Finish.

- Rough Cast Finish or Spatter Dash Finish.

- Peddle Dash or Day Dash Finish.

- Depeter Finish.

- Scrapped Finish.

- Textured Finish.

- Special Material Used in Plastering for Finishing Coat.

- Acoustic Plaster.

- Asbestos marble Plaster.

- Barium Plaster.

- Granite Silicone Plaster.

- Plaster of Paris of Gypsum Plaster.

- Keene’s Cement Plaster.

1. Smooth Coat Finish

In this type of finish, the finishing coat is a smooth and leveled surface. The mortar used is made of cement and fine sand 1:3. Mortar is applied with the help of a wooden float.

2. Sand Faced Finish

The sand-faced finish is applied in two coats. The first coat is applied in 1:4 cement sand mortar of 12 mm thickness.

It is provided with zig-zing lines. After curing it for seven days, the second coat is applied to a thickness of 8 mm.

The mortar for a second coat is prepared from the cement sand mix ratio 1:1. The sand of uniform size is used. A sponge is used in a second coat when it is wet.

The surface of the final coat is finished by rubbing clean and washed sand of uniform size by means of a wooden float. This results in the surface having sand grains of equal and uniform density.

Also Read: What Is Plastering | What Is Pointing | Difference Between Plastering and Pointing |

3. Rough Cast Finish or Spatter Dash Finish

1:1:3 = Cement: Sand: Aggregate are used to prepare mortar for this type of finish. The coarse aggregate may vary from 3 mm to 12 mm in size.

The mortar is thrown on the prepared plaster surface then by means of a large trowel. The surface is then roughly finished using a wooden float.

This finish is water-proof, durable, and resistant to cracking and crazing. It is used for external rendering.

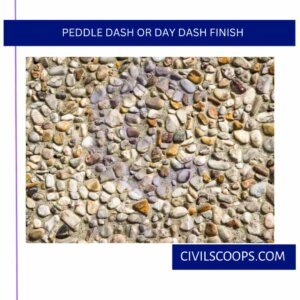

4. Peddle Dash or Day Dash Finish

In this finish, clean pebbles of size from 10 to 20 mm size are dashed against the final coat of plaster.

The pebbles may be lightly pressed into the mortar with the help of wooden float. The final coat of plaster is having Cement: sand mix proportion of 1:3 and thickens 12 mm.

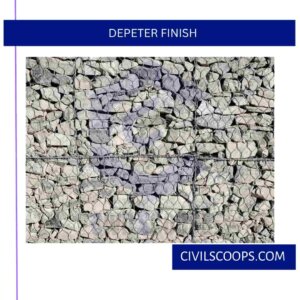

5. Depeter Finish

In this type of final finish coat of plaster is applied to have thickness 12 mm, and when it is a wet condition, the pieces of gravel flint are pressed with hand on the surface.

Flints of different colours may be used to obtain beautiful patterns.

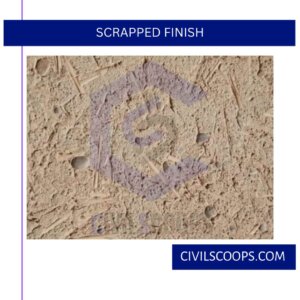

6. Scrapped Finish

The final coat of plaster of 6 to 12 mm applied. Then it is allowed to be stiffened for a few hours. The surface is scrapped in a pattern for a depth 3 mm.

Steel straight edge old saw blades or such other tools may be used for scrap. Such a scrapped surface is less liable to cracks.

7. Textured Finish

This is used with sketch plastering ornamental patterns or textured surface are made on the final coat of stucco plastering by working with suitable tools.

8. Special Material Used in Plastering for Finishing Coat

To meet with some specific requirements of finished surfaces such as durability better appearance, fireproofing, heat insulation, etc. special materials are added in mortar.

The following are the special materials to be used.

- Acoustic Plaster.

- Asbestos marble Plaster.

- Barium Plaster.

- Granite Silicone Plaster.

- Plaster of Paris of Gypsum Plaster.

- Keene’s Cement Plaster.

8.1. Acoustic Plaster

The materials like gypsum mixtures are added in mortar for a finishing coat such a coat undergoes a chemical reaction and produces gas bubbles and due to the bubbles tiny openings are formed in the coat and it appears like a honeycomb.

These honeycomb minute openings absorb sound. Such plaster is useful in interior walls of halls auditorium etc.

8.2. Asbestos Marble Plaster

For a better appearance of finishing coat, mortar is made of cement asbestos and finely crushed marble and applied as finishing coat.

8.3. Barium Plaster

To protect persons working in X-ray rooms from radioactivity, finishing coat is applied with mortar made of cement, sand, and barium soleplate.

8.4. Granite Silicon Plaster

Granite and silicon are mixed with mortar. This finish is used for a superior type of construction. It is a quick setting and elastic in nature. This eliminates cracks.

8.5. Plaster of Paris of Gypsum Plaster

Ground gypsum is heated at 160o to 170o C to obtain plaster of parish. Plaster of Paris hardens with 3 to 4 minutes of adding water.

Suitable retarders are added to increase setting time. Plater of a parish is generally used in combination with lime for ornamental work and reporting carks.

Gypsum plaster has fire resistance, light weight. It does not shrink while setting. It has a sound-insulating properly. It is very useful for ornamental work.

However, gypsum plaster is soluble in water.

8.6. Keene’s Cement Plaster

Kenees’s cement is obtained by calcination of plaster of Paris with alum. This is very hard and sets in a few days taking a white glass-like polish. It is useful for decorative work.

[su_box title=”FAQ” style=”default” box_color=”#333333″ title_color=”#FFFFFF” radius=”3″ class=”” id=””]

What Is Finishing Plaster Made of?

The most common types of plaster mainly contain either gypsum, lime, or cement, but all work in a similar way. The plaster is manufactured as a dry powder and is mixed with water to form a stiff but workable paste immediately before it is applied to the surface.

What Is Finishing Plaster Used for?

Finishing plaster is used to create the final surfacing on any wall or ceiling. There are various types available and they will be applied over either a base coat or plasterboard. Coats of finishing plaster will need to be smooth to crate the ideal facing.

Types of Plastering

- Clay plaster.

- Gypsum plaster (plaster of Paris)

- Lime plaster.

- Cement plaster.

- Heat-resistant plaster.

Plaster Finishes for Exterior Walls

- Smooth cast finish.

- Rough cast finish.

- Sand faced finish.

- Pebble dash finish.

- Scrapped finish.

- Depeter finish.

- Textured finish.

What Are the Three Types of Plaster?

- Lime Plaster.

- Cement Plaster.

- Gypsum Plaster.

What Is the Difference Between Drywall and Plaster?

Drywall is made out of softer material called gypsum which doesn’t crack. Sheets of it are nailed into the wooden studs when finishing the interior of a house. Plaster, on the other hand, dries much harder than drywall, and is more labor-intensive and expensive.

How Thick Can You Apply Plaster?

Plaster over concrete or masonry is referred to as a maximum thickness. Without lath, the maximum is 5/8-inch for walls and 1/8-inch for ceilings. Plaster may be applied thicker, if lath is used.

Plaster Finishes

Types of Plaster Finishes used in Building Construction are: Smooth Cast Plaster Finish. Rough Cast Plaster Finish. Sand Faced Plaster Finish. Pebble Dash Plaster Finish.

Skim Coat Walls

A skim coat is a thin layer of drywall joint compound (also known as mud) that gives walls a glass-smooth finish. It’s also called plastering a wall though you are using drywall joint compound, not plaster. The purpose of skim coating is to repair damaged walls and smooth down intentionally applied wall texture.

Is Plasterboard Waterproof?

Not all plasterboard is waterproof but those that are (after treatment against water and humidity) have certain advantages. The term waterproof simply refers to high resistance to humidity and water in general.

Types of Rendering Finishes

- Rendering your walls is a great way to achieve a smooth finish and provide additional protection for the brickwork underneath. But did you know there are different types of render?

- Cement.

- Lime.

- Pebble dash.

- Acrylic Render.

- Silicone Render.

- SprayCork.

What Causes Hairline Cracks in Plaster?

Hairline cracks are thin cosmetic cracks that are caused by temperature or humidity fluctuation. These fluctuations can result in plaster shrinkage or swelling, creating small fissures. Hairline cracks are simply an eyesore and can be easily fixed with a new coat of paint.

What Causes Plaster to Crack?

Over time the plaster separates from the lath, creating structural cracks. Plaster is also prone to thinner spider-web cracks, which occur when the topcoat of the plaster degrades. It’s common to have both kinds of cracking — and both types can be repaired.

Does Plaster Have Asbestos in It?

Asbestos was commonly added to plaster until the late 1980s, as it was seen as an inexpensive way to add to the plaster’s insulation and fire-retardant properties.

Does Horsehair Plaster Have Asbestos in It?

Horsehair plaster and dust can be potentially dangerous because they may contain asbestos and anthrax spores. If you brush the plaster, you risk exposing yourself to the plaster dust and these spores.

[/su_box]

[su_note note_color=”#F2F2F2 ” text_color=”#333333″ radius=”3″ class=”” id=””]

Like this post? Share it with your friends!

Suggested Read –

- 20 Types of Construction Beam & Their Uses

- What Is RQD | Advantages of Rock Quality Designation | Limitations of Rock Quality Designation (RQD)

- What Is Pneumatic Structures | Types of Pneumatic Structures | Advantages & Disadvantages of Pneumatic Structures | Uses of the Pneumatic Structures

- Extra Rapid Hardening Cement | Advantages & Disadvantages of Extra Rapid Hardening cement | Applications, Properties & Uses of Extra Rapid Hardening cement

- What Is a Concrete Vibrator | 6 Types of Concrete Vibrator | Concrete Vibrator Alternatives | Advantages of Concrete Vibrator | Disadvantage of Concrete Vibrator

[/su_note]

Originally posted 2023-03-21 12:05:42.