What Is a Buttress Dam | Types of Buttress Dam | Advantages & Disadvantages of Buttress Dam | Application of Buttress Dam

Table of Contents

What Is a Buttress Dam?

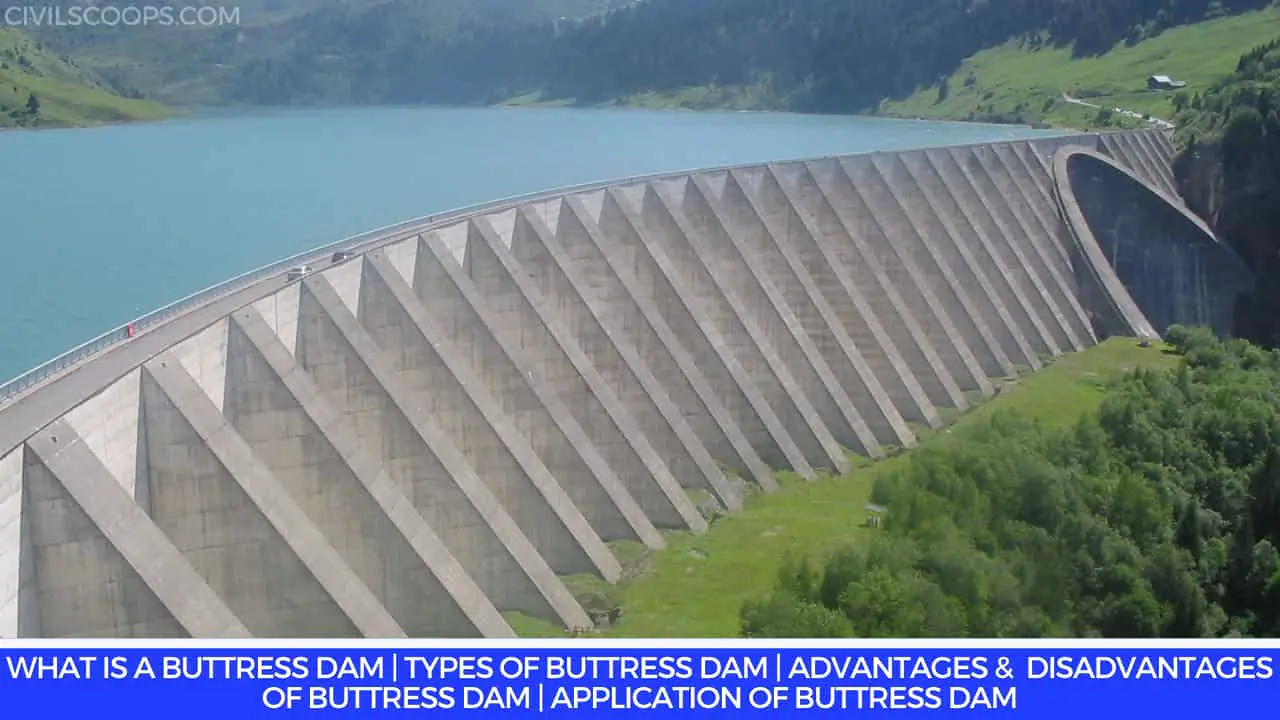

The buttress dam is a variation or improvisation of the Gravity Dam. Buttresses are just like concrete walls that are built parallel to the flow of water with such a prescribed thickness at frequent intervals. An arch slab or angled deck slab is installed on such buttresses to sustain upstream water.

Typically, the Gravity Dam needs more concrete action. To mitigate costs, the amount of concrete shall be reduced by extracting this from the unstressed section of the dam. Eventually, a vital breakthrough is taking place, that is, the buttress dam.

Types of Buttress Dams

There have been five different types of dams, from which the deck slab form and multiple arch types were often widely found. The five are as mentioned.

- Deck Slab Buttress Dam.

- Multiple Arch Buttress Dam.

- Massive Head Buttress Dam.

- Multiple Dome Buttress Dam.

- Columnar Buttress Dam.

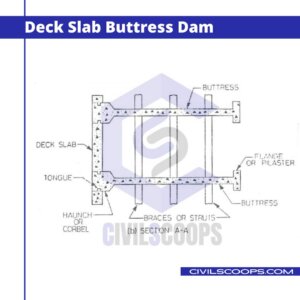

1. Deck Slab Buttress Dam

There is a deck slab for this form of a dam that is protected by the corbels of the buttresses. Some of these dams is usually built between 20 to 50 meters in lower levels.

The slab given is angled to the horizontal position by approximately 40 to 55 degrees. This inclination is necessary to strengthen the dam and to sustain the dead weight of the deposited reservoir water, but also to keep the dam from slipping.

Throughout this case, every other deck slab system on two adjacent buttresses functions as a single independent unit. Therefore, whether one unit is affected or destroyed, there is no need to think about the other units.

The design of the Deck Slab Buttress Dam is the same as the Gravity Dam factors. Perhaps, throughout this situation, we’ve got three forms and they’re.

- Fixed Deck Slab.

- Free Deck Slab.

- Cantilever Type.

1.1. Fixed Deck Slab Buttress Dams

In the case of a fixed deck slab form dam, the deck slab, as well as the buttresses, are built monolithically.

1.2. Free Deck Slab Buttress Dams

This is often named the simple deck slab buttress dam. These are built where the base soil is really thin. Throughout this scenario, reinforcing is given on the downstream side of the deck slab.

1.3. Cantilever Type Buttress Dams

Throughout this scenario, the deck slab is cantilevered across both ends as well as the upstream face is reinforced.

2. Multiple Arch Buttress Dam

Multiple arch dam contains an arrangement of arches, and for this situation, arch slabs are given at the upstream substance of the dam. These slabs are upheld by buttresses. The buttress divider is developed as a single hardened divider or a twofold empty divider.

This kind of dam can be liked for bigger statures about in excess of 50 meters. When contrasted with deck slab-type buttress dams, multiple arch buttress dams are more adaptable and stable.

The primary burden of this situation is the nearby buttress units rely upon one another. In this way, in the event that one unit gets influenced, it causes extreme issues for the entire arrangement of arches. To conquer this great establishment for every one of buttresses divider ought to be given.

The thickness of the arc given differs in the case of high stretch and is consistent in the situation of short length. The central angle of the arch will be between 180 degrees and 150 degrees.

The distance between the buttresses will be between 15 and 21 meters. That being said, some attention can also be given to greater spacing.

3. Massive Head Buttress Dam

In the same kind of buttress dam, there is no slab or arch on the upstream face, rather than the buttress head, which is widened and joined to the corresponding buttress head. Such as this one, all buttress heads make the area solid, promoting water.

The expansion of the buttress heads may be achieved in various forms, such as rounded and diamond shapes, respectively. Thus, such forms can withstand water pressure very well. The linking of the heads is enhanced by the provision of copper strips.

Construction of a large head buttress dam is simpler compared to other methods, but no strengthening is needed; only bulk concrete is spread all over the dam body. Because of a very massive concrete body, it’s indeed thicker and avoids slipping.

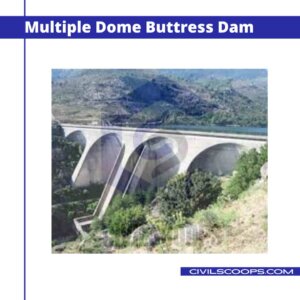

4. Multiple Dome Buttress Dam

This is quite identical to the multiple arch type buttress dam, except in this scenario, the domes are built in the places of the arches. Besides, nearly all the functions are the same.

The requirement of these kinds of domes influences the establishment of a greater spacing between all the buttresses. It is also possible to have a longer span and, therefore, to reduce the number of buttresses.

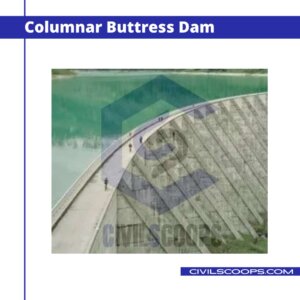

5. Columnar Buttress Dam

Throughout the situation of the columnar buttress dam, the inclination columns protect the floor of the dam. It’s a variation of the deck slab-style buttress dam. It needs a very solid and secure base. It also needs qualified individuals to develop underpinnings. Therefore, the dam is not commonly used.

Advantages of Buttress Dam

- The buttress dam would be less huge than the Gravity Dam. The buttress dam may well be built on even a comparatively thin

basis over which the Gravity Dam could not be built. - A wide vertical water pressure feature, which adds to the improvement stabilization of the dam which preserves concrete, is built

on the upstream face of the buttress dam. - The safety factor in the situation of the buttress dams is considerably greater than that of the gravity dams.

- Because ice continues to slip across the inclined U/S surface, there is little importance to the ice strain.

- The height of the buttress dams can be raised by stretching both the buttresses and the deck slab.

- Powerhouses or even other plants may be situated in the open space in between buttresses.

- The expense is not minimized by the very same ratios as the additional cost of formwork and strengthening is necessary.

- According to the gap between the buttresses, the backspace of the deck slab can be reached.

- Periodic examination of foundations, respectively. It may be taken out by approaching this stage.

- Although the exposed surface of the concrete is more, the amount of concrete is less than the gravity dam, and the excess heat

throughout construction is best accomplished. - The speed of the building can also be improved as thinner parts do not pose any problems with cooling.

- The dispersing of the buttresses might be changed in accordance with the use zones of good foundations

- Buttress dams can be intended to oblige moderate measures of establishment development without genuine harm; along these

lines, it tends to be underlying the dirt with differential settlements. - The measure of concrete needed for a buttress dam is around 1/3 to ½ of the concrete needed for a gravity dam of similar

stature. - Access is conceivable to the rear of the upstream essence of the dam and to the establishment between buttresses for

occasional investigation and for resulting grouting and boring pressing factor depended on openings, whenever required. - The uplifting strain at the buttress dam is significantly lower, which adds to the economy of the concrete and overall stabilization

of the dam. - Powerhouse, and switchyard, respectively, may be situated between the buttresses, reducing some building costs.

Disadvantages of Buttress Dam

- This is since the thickness of the slab is quite limited, although there is access to the end of the slab via the gap between the

buttresses. - Skilled labor standards and a shutter to concrete proportion are higher for the buttress dam than with the Gravity dam. This will

contribute to a higher unit cost of concrete. - The decline of the upstream surface of the comparatively thin reinforced deck slab or arch of the buttress dam has much more

drastic effects on the integrity of the dam; - The volume of water sealing to be established and preserved for the buttress dam is normally higher than for other dams.

- The stress of the foundation is greater, indeed a sound rock foundation is appropriate or a spread base or a continuous mat

might be needed, which would increase the cost of building. - The savings due to a decrease in the quantity of concrete would also, to some degree, be compensated by the need for strong

reinforcing for comparatively thin members of the buttress dam. - The buttress dams are more vulnerable to intentional destruction than the strong gravity dams.

Application of Buttress Dam

To have an ‘enhanced dam structure using the buttress walls as well as the buttress heads in which the front face of the buttress head is covered by a waterproofing material. Also, provide an enhanced dam of the buttress kind in which the buttress head is a longitudinal direction and separated by a joint, allowing contraction across defined lines.

To have a river that’s headed. Buttress walls in which the heads are separated by a bridging construction that bridges the gap between the heads and provides that very link between both the bridging construction as well as the buttress heads that perhaps the forces transmitted by the bridging constructions to the heads are distributed by direct compression so that at least, if any, bending moments in the heads are created.

Buttress Dam in India

Meer Alum Dam is the only dam in India, which is Buttress Dam. The remarkable multi-arch Mir Alam dam was constructed for the water system of Hyderabad in 1804. This dam became undoubtedly the work of Henry Russel, a participant of the British Royal Engineers.

The frame, which reached a maximum of 12 m, consisted of 21 semicircular vertical arches of constant thickness and varying span. It was 100 years before a dam with a similar design was completed. The Mir Alam Dam should therefore be regarded as one of the exceptional, genuine strokes of genius!

[su_box title=”FAQ” style=”default” box_color=”#333333″ title_color=”#FFFFFF” radius=”3″ class=”” id=””]

Buttress Dam

A buttress dam or hollow dam is a dam with a solid, water-tight upstream side that is supported at intervals on the downstream side by a series of buttresses or supports. The dam wall may be straight or curved. Most buttress dams are made of reinforced concrete and are heavy, pushing the dam into the ground.

Buttress Dam in India

Buttress dams in India are of three types: (i) Deck type, (ii) Multiple-arch type, and (iii) Massive-head type. A deck type of buttress dam has a sloping deck supported by buttresses. Buttresses‘ walls are the ones that are triangular in shape. They transmit the water pressure from the deck slab to the foundation.

Types of Buttress Dams

- Deck Slab Buttress Dam.

- Multiple Arch Buttress Dam.

- Massive Head Buttress Dam.

- Multiple Dome Buttress Dam.

- Columnar Buttress Dam.

Advantages of Buttress Dam

The uplift pressure acting on a buttress dam is considerably less, which leads to the economy of the concrete and the overall stability of the dam. The powerhouse, switchyard, etc., can be located between the buttresses, thus saving some cost of construction.

Disadvantages of Buttress Dam

- Buttress dam requires more work than solid concrete dams.

- As the thickness of the upstream concrete surface is less, it is more liable to get deteriorated.

- It requires constant maintenance and supervision.

- The life of the dam is less compared to other dams.

Application of Buttress Dam

Buttress or hollow gravity dams were originally built to retain water for irrigation or mining in areas of scarce or expensive resources but cheap labor. A buttress dam is a good choice in wide valleys where solid rock is rare.

Concrete Buttress

A buttress dam or hollow dam is a dam with a solid, water-tight upstream side that is supported at intervals on the downstream side by a series of buttresses or supports. The dam wall may be straight or curved. Most buttress dams are made of reinforced concrete and are heavy, pushing the dam into the ground.

Which Is the Oldest Dam in the World?

The Quatinah Barrage, or Lake Homs Dam, located in Syria, is the oldest operational dam in the world. The dam was constructed during the reign of the Egyptian Pharaoh Sethi between 1319-1304 BC and was expanded during the Roman period and between 1934 and 1938.

Which Is the Highest Dam in the World?

Currently, the tallest dam in the world is the Nurek Dam on the Vakhsh River in Tajikistan. It is 984 feet (300 meters) tall. Hoover Dam is 726.4 feet (221.3 meters) tall.

Which Is the Oldest Dam in India?

Kallanai Dam, built across the Kaveri river of Tamil Nadu, is the oldest dam (first dam) in India. It is also known as the Grand Anicut.

What Is Saddle Dam?

Saddle dam is the term given to a water barrier built in a topographic depression or gap on the rim of a reservoir. It is typically an auxiliary feature to increase water storage capability. Most saddle dams are relatively small embankments, but some are of substantial size.

Advantages and Disadvantages of Arch Dam

Advantages of Arch Dam.

- Arch dams are particularly adapted to the gorges where the length is small in proportion to the height.

- For a given height, the section of an arch dam is much lesser than a corresponding gravity dam.

- Because of much less base width, the problems of uplift pressure are minor.

What Is a Cofferdam Used For?

A cofferdam is a structure that retains water and allows a work area to be dewatered so that crews can pour concrete, excavate, repair, weld, etc.

What Type of Dam Is Embankment?

What is an Embankment Dam? An Embankment Dam is a freshwater-retaining structure comprising excavated rock, soil, or a combination of rock and soil from nearby geological formations. In fact, Embankment Dams are known as “Earthfill Dam” when filled with soil and a “Rockfill Dam” when filled with rocks.

What Is Gravity Dam?

A gravity dam is a dam constructed from concrete or stone masonry and designed to hold back water by using only the weight of the material and its resistance against the foundation to oppose the horizontal pressure of water pushing against it.

On Which River Tehri Dam Built?

Bhagirathi River

The Tehri dam, a 260.5 m-high earth and rockfill dam, impounds water 44 km along Bhagirathi River and 25 km along Bhilangana River, creating dead storage of 925 Mm3 and live storage of 2,615 Mm3, making a total storage capacity of 3,540 Mm3. Impoundment commenced in 2005.

Sardar Sarovar Dam Is Built on Which River

river Narmada

A concrete gravity dam, 1210 meters (3970 feet) in length and with a maximum height of 163 meters above the deepest foundation level, is under construction across the river Narmada.

Which Is the Oldest Dam in India?

Kallanai Dam

Kallanai Dam, built across the Kaveri river of Tamil Nadu, is the oldest dam (first dam) in India. It is also known as the Grand Anicut.

Oldest Dam in the World

Quanah Barrage / Lake Homs Dam

The Quatinah Barrage, or Lake Homs Dam, located in Syria, is the oldest operational dam in the world. The dam was constructed during the reign of the Egyptian Pharaoh Sethi between 1319-1304 BC and was expanded during the Roman period and between 1934 and 1938.

Kallanai Dam Age

around 2,000 years ago

Built around 2,000 years ago across the Cauveri River in Tiruchirapalli District of Tamil Nadu, the Kallanai Dam is still in excellent condition and is used as a major irrigation dam even now. The dam has been an inspiration to many modern-day dams, too, due to its amazing engineering.

Top 10 Oldest Dam in the World

Image courtesy of Bernard Gagnon.

- Quanah Barrage / Lake Homs Dam, Syria.

- Proserpina Dam, Spain.

- Cornelio Dam, Spain.

- Kaerumataike Dam, Japan.

- Kallanai Dam / Grand Anicut, India.

- Sayamaike Dam, Japan.

- Manlike Dam, Japan.

- Sadd-e Kobar Dam, Iran.

Oldest Dams in India

Kallanai Dam, built across the Kaveri river of Tamil Nadu, is the oldest dam (first dam) in India. It is also known as the Grand Anicut.

Kallanai Dam Built Year

The dam was originally built by King Karikalan of the Chola Dynasty in c. 150 AD – c. 100 AD. It is located on the River in Thanjavur district, exactly 14km from the city of Tiruchirappalli and 45km from the city of Tanjavur.

Kallanai Dam History in English

Located at a distance of 15 km from Tiruchirapalli and 45 km from Tanjavur, the dam was originally constructed during the reign of Chola king Karikalan in c. 150 AD.

Kallanai Dam Capacity

The dam currently holds more than 15.4 million cubic meters of water.

[/su_box]

[su_note note_color=”#F2F2F2 ” text_color=”#333333″ radius=”3″ class=”” id=””]

Like this post? Share it with your friends!

Suggested Read –

- 11 Difference Between Silt and Clay

- What Is Stone | Classification of Stones | Application of Stone | Advantages of Stone | Disadvantages of Stone

- What Is Plate Load Test | Method of Plate Load Test | Limitations of Plate Load Test | Advantages & Disadvantages of Plate Load Test

- What Are Frost Wall | Types of Frost Wall | Requirements for Frost Wall Construction | Application of Frost Wall | Advantages of Frost Wall | Uses of Frost Wall

- What Is Isolated Foundation | Types of Isolated Foundations | Shape of Isolated Foundations | Design of Isolated Foundation | Advantage & Disadvantage of Isolated Foundation

[/su_note]

Originally posted 2022-09-07 11:32:23.