What Is Injection Grouting | Types of Injection Grouting | Different Types of Grouting Materials

Table of Contents

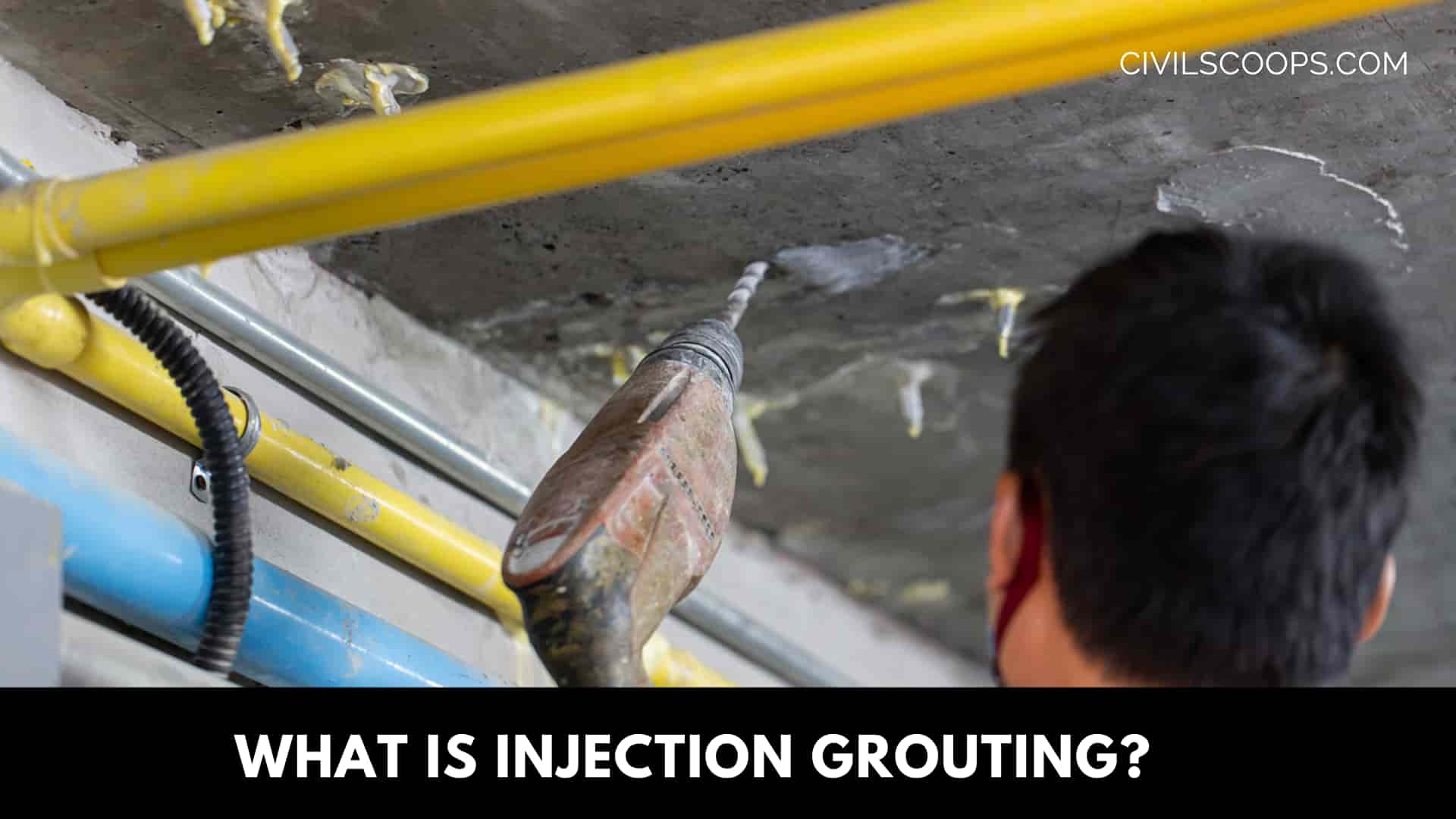

What Is Injection Grouting?

Injection Grouting is defined as the process of filling the cracks, and voids under pressure in the structural members for repairing the cracks and strengthening the damaged or deteriorated masonry structures.

In the process of grouting, the cracks and the voids are get filled with the help of grouting material which will get subsequently be hardened.

Injection grouting is a similar process to the injection of epoxy.

Grout is basically a flowable plastic material that has low shrinkage and is widely used for filling voids or gaps completely and will remain stable without cracking.

There are different types of Grounds which are used for repairing and strengthening the masonry structure members.

The selection of the types of grout for the masonry repair work depends upon the compatibility of the grout with the original material.

Types of Injection Grouting

- Polymer Injection Grouting

- Cement Sand Grouting

- Gas-Forming Grouting

- Fibre Reinforced Injection Grouting

- Sulfo-Aluminate Grouting

1. Polymer Injection Grouting

Polymer injection grouting is mainly done with the help of polymers like polyester epoxy, vinyl ester, polyurethane, and acrylic resins.

The polymer is widely used in epoxy grout. Polyurethane and acrylic resin Polymers are generally used for repairing water-retaining structures and underground structures as well as to prevent the seepage of water.

The polymer injection grouting is available in the following grout materials

- Liquid Resin Content

- Curing Agent or Hardener

- Aggregate or Dry Filler

- This types of injection grouting are suitable for concrete repair work.

There are different types of polymer-based injection grouting are available

Types of Polymer-Based Injection Grouting

- Epoxy-Based Injection Grouting

- Acrylic Polymer Based Injection Grouting

- Lignosulfonate Based Injection Grouting

1. Epoxy-Based Injection Grouting

It is non-resistance to ultraviolet exposure and high temperatures non-shrinkable, effective in sealing cracks, and has good bonding with every construction material.

2. Acrylic Polymer Based Injection Grouting

It has improved structural as well as tensile properties and is also resistant to cracking, segregation, and imperviousness.

3. Lignosulfonate Based Injection Grouting

This type of injection grouting help to compensate for drying and plastic shrinkage.

2. Cement Sand Grouting

Cement sand grout is one of the most popular and widely used groutings for the repair of concrete and masonry structures.

This grout is used where strength enhancement of the structures is not essential. It is very easy to use and readily available in the market.

The cement and sand grouting method required a higher amount of water and cement content. The use of cement sand grouting will result in shrinkage and cracking of grouting at the hardening stage.

3. Gas-Forming Grouting

The gas-forming injection grouting basically works on the principle that the gas Bubbles expand the grout to compensate shrinkage of grout after its application.

These types of gas Bubbles will develop a reaction of some ingredients with the cement slurry.

The gas-forming grouts are very sensitive to the temperature so they cannot be used for places where the temperature is very high.

It requires proper confinement in order to develop good strength and volume stability. The reaction forming the gas bubbles is very fast and it will be complete before placing the grout.

4. Fibre Reinforced Injection Grouting

Fibre-reinforced concrete is widely used for repairing concrete structures as well as masonry structural members.

Fibres such as polypropylene, steel, or glass fibres are generally used for Portland cement to repair and strengthen the structural members. Fibre-reinforced injection grouting provides good flexural strength, resistance to impact, and ductility.

This type of injection grouting required skilled labour.

5. Sulfo-Aluminate Grouting

Sulfo-aluminate grouting is based on the principle of shrinkage compensation.

In these types of grouting, shrinkage compensating cement or anhydrous Sulfo-aluminate expansive additives are used.

This helps to produce expansion after the grout has set and it is more reliable than gas-forming grouts.

This types of grouting are not effective if it is not provided with proper moist curing.

Grouting Material

Properties of grouting material

- The material which is used for grouting should be non-shrinkable.

- The grouting material should expand when it is filled in the cracks or voids.

- The grouting material should be capable to sustain compressive loads.

- It should have good tensile strength and vibratory load resistance.

- It should richest the entry of moisture and be easy to apply.

Different Types of Grouting Materials

- Cement grout or cement-based mortars.

- Cement sand with additive grouts.

- Polymer Modified cement grout.

- Epoxy resin.

Advantages of Injection Grouting

- Injection grouting is very easy and convenient to use.

- Injection grouting is an environment-friendly process.

- It is suitable for repairing cracks and filling voids in structural members.

- It provides strength and stability to the masonry structural members.

- The injection grouting process is economical.

- There is no wastage of material in the injection grouting process.

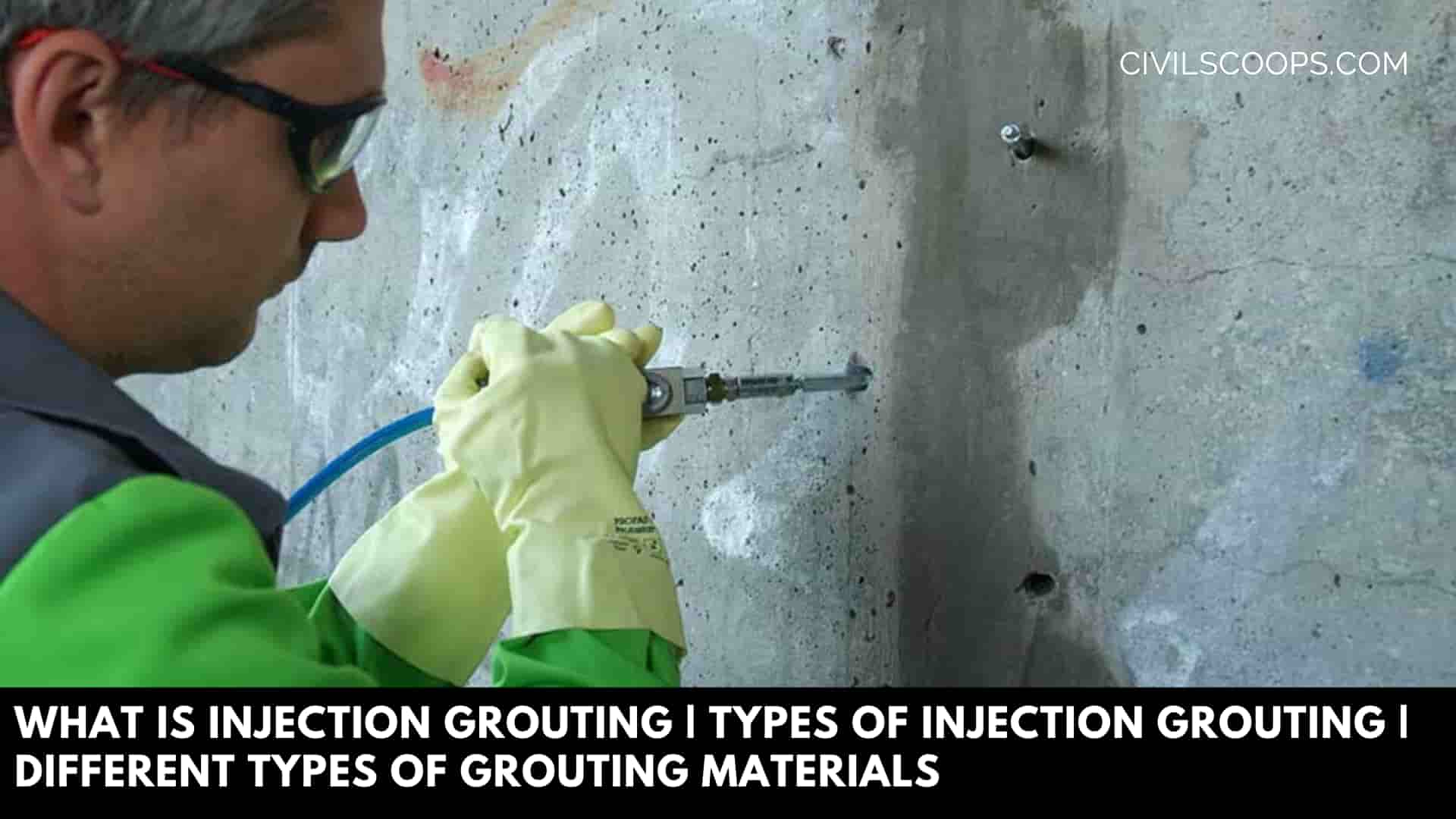

Process of Injection Grouting

As per the below processes of injection grouting

- Drilling Holes on the Surface

- Cleaning the Holes and Cracks

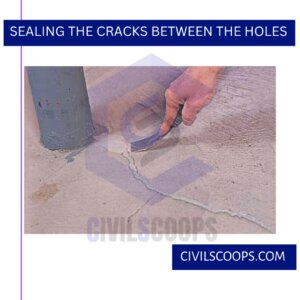

- Sealing the Cracks Between the Holes.

- Grout the Hose Connections

- Injecting Grout in the Cracks

Step – 1. Drilling Holes on the Surface

Drill the holes or ports in the cracks at regular intervals. The distance between the two ports depends upon the types of cracks.

For fined cracks, the distance between two ports ranges from 150 mm to 200 mm and the distance between ports in major cracks ranges between 300-400 mm.

Step – 2. Cleaning the Holes and Cracks

Before starting grouting it is very important to clean and flush the cracks and holes properly.

Cleaning can be done manually or by using a vacuum to clean the cracks. The cracks should besprinkle with water.

It is very essential to clean it properly to establish a strong bond and gain maximum strength.

Step – 3. Sealing the Cracks Between the Holes.

The crack between the ports should be filled with epoxy, polyester or cementitious materials.

Allow the seal to harden and then start the further process of grouting.

Step – 4. Grout the Hose Connections

Fix the nipple or pipe in the holes and seal it by applying cement paste around it such that it cannot move from its place.

Step – 5. Injecting Grout in the Cracks

Inject the grout material in the crack or voids with the help of an Injection Grouting machine. It should be filled with pressure.

Injection grouting required skilled labour. The temperature on the site is also considered while the process of grouting.

Also Read: 14 Difference Between CPM and PERT | What Is CPM | What Is PERT

Applications of Injection Grouting

- It is used to reduce or fill the cracks or voids in the structural members.

- It is generally used for repairing cracks in walls columns and other structural members.

- It is also used for providing finishing to the wall.

- Injection grouting is used to repair damage in the structural or masonry members.

- Injection grouting is best suitable for honeycombing.

- Injection grouting is used to repair and strengthen the damaged areas.

- It is also used for making walls waterproof.

[su_box title=”FAQ” style=”default” box_color=”#333333″ title_color=”#FFFFFF” radius=”3″ class=”” id=””]

What Is Injection Grouting?

Grout injection, otherwise referred to as injection grouting, is an effective method for repairing or strengthening masonry walls. This technique involves low-pressure injection of fine hydraulic lime grout into cracks, voids, and cavities within the masonry.

What Are the Three Types of Grout?

The most common types of grout are epoxy, sanded and unsanded. Epoxy grout is made of resins, silica fillers, pigments and hardener. Sanded and unsanded grouts are cementitious grouts. This means their main component is cement.

How Long Does Epoxy Injection Last?

You should expect a quality epoxy crack repair to last at least 5 years. You can find more information about cracks and their causes here, and why Acculevel recommends epoxy fill in this blog.

Can You Jb Weld a Cracked Block?

If a engine block develops a crack, JB Weld can be used to seal up the crack and prevent the crack from sucking in air or leaking coolant. JB Weld is a type of epoxy that seals and hardens to close cracks and holes.

Injection Grouting Price

Grouting cost is varies between 25 to 45 Rs per sq. ft.

Is Epoxy Grout Better Than Cement Grout?

Epoxy grouts are stronger than cementitious grouts and are highly resistant to chemicals, making them ideal for applications like petrochemical.

Grouting Material

Grout is a composite material generally consisting of water, cement, and sand. It is typically used for filling voids under machines or other structural elements, sealing joints and openings in surfaces and reinforcing existing structures.

Cement Grouting

Cementitious grouting is a process in which a fluid cementitious grout is pumped under pressure to fill forms, voids, and cracks. It can be used in several settings including bridges, marine applications, dams, and rock anchors. The grouted mass has an increased strength, stiffness, and reduced permeability.

What Is the Best Grout to Use in a Shower?

Acrylic Grout: Acrylic grout is a great option for wet areas like decks and showers. It’s intended to be mildew-resistant and retains its color well. Epoxy Grout: Epoxy grout is less do-it-yourself-friendly than other types.

How Long Do You Leave Grout Before Wiping Off?

Let the grout set for 15 to 30 minutes, and wipe up the excess grout with a dense grout sponge soaked in water. (If you think it’s going to take you longer than 30 minutes to grout all of the tiles and be ready to move onto cleanup, you may have to work in smaller sections.)

Types of Grouting in Dams

Dam grouting can be performed from the bottom up, termed upstage grouting, or from the top down, termed downstage grouting. Each of these techniques has advantages and disadvantages with specific soil conditions necessitating the use of one or the other.

Foundation Grouting Methods

The most usual form of grouting method is referred to as permeation grouting, which in simple terms, involves filling open voids. Although all varieties of grouting contain some measure of permeation grouting, there are four distinctive approaches: permeation, compaction, fractural and jet grouting.

Is Epoxy Grout Better Than Regular Grout?

Epoxy grout won’t crack, shrink, or discolour, making it ideal for applying in wet areas, such as showers. It’s also highly resistant to the harsh chemicals found in cleaning products. As an added bonus, unlike traditional cement grout, epoxy grout does not need to be sealed, due to its non-porous nature.

Pressure Grouting Method Statement

Pressure grouting involves the injec- tion under pressure of a liquid or suspension into the voids of a soil or rock mass or into voids between these materials and an existing structure.

[/su_box]

[su_note note_color=”#F2F2F2 ” text_color=”#333333″ radius=”3″ class=”” id=””]

Like this post? Share it with your friends!

Suggested Read –

- 22 Types of Beams | Standard Size of Beams

- What Is Bridge | Components of Bridge and Their Function

- Plasticizer Vs Superplasticizer | What Is Plasticizer In Civil | What Is Superplasticizer In Civil

- What Is Honeycomb in Concrete | Cause of Honeycomb in Concrete| Cure of Honeycomb in Concrete | Types of Grouting

- Skeleton Frame | What Is Building Skeleton | What Is Steel Structure Building | Use of Steel Frame Structures| Advantages & Disadvantage of Steel Frame

[/su_note]

Originally posted 2023-02-25 12:02:01.