What Is Lintel Beam | Lintel Beam Size | 7 Types of Lintel Beam

Table of Contents

What Is Lintel Beam?

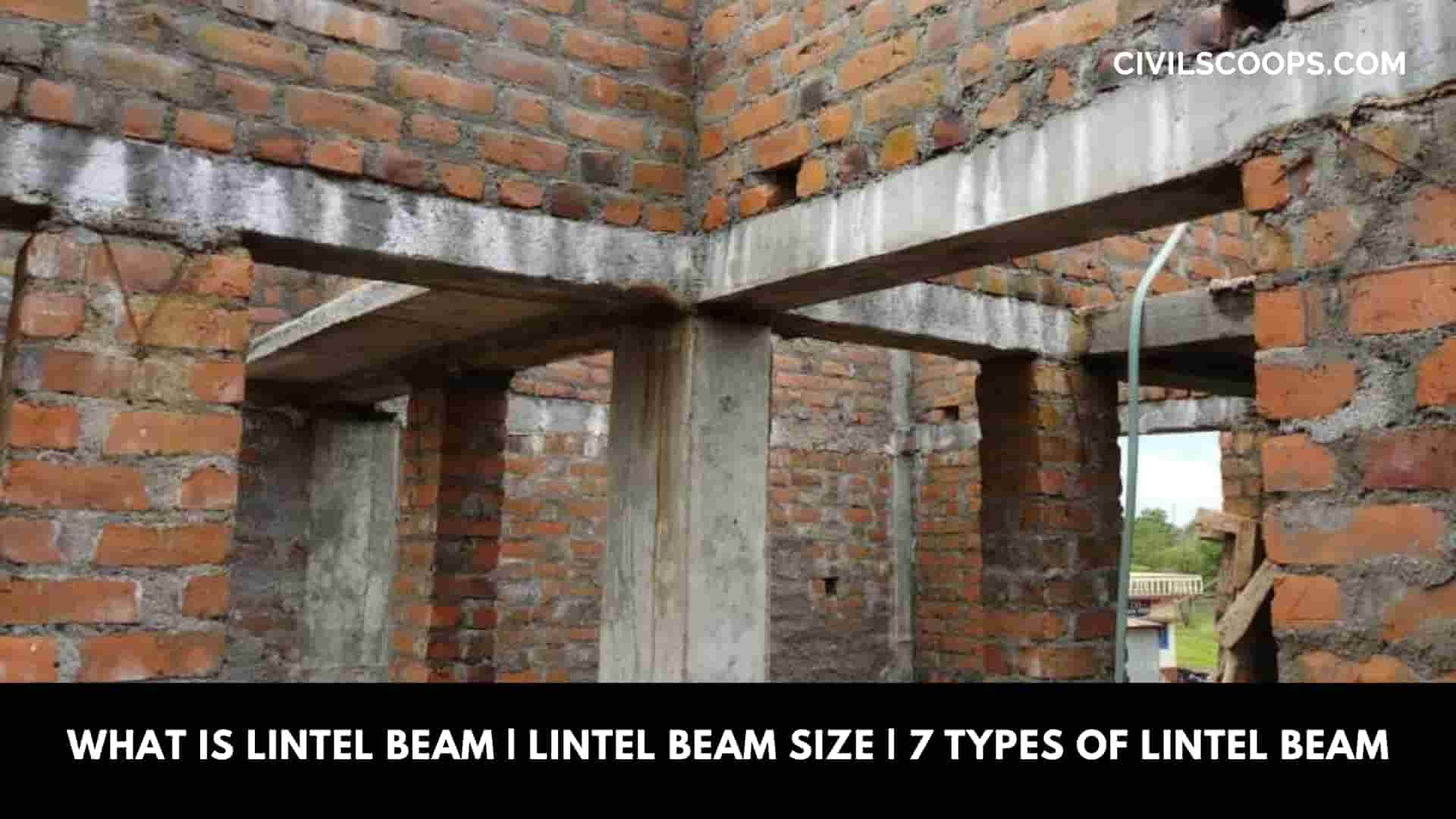

The lintel is a horizontal flexural member that spans over the openings in the walls for doors, windows, ventilators, cupboards, etc.

A load of masonry above the opening is transferred to the wall by flexural action of the lintel so that frames of doors, windows, etc. are not unduly loaded. The end bearings for the lintel should be at least 200 mm.

The width of lintels is the same as that of the wall.

Always provide adequate bearing at the ends of lintels. The manufacturer’s recommendations should be followed, but the usual hearing is 150mm (6″) each end. If you don’t give enough end bearing, the lintel will fail under load.

[su_box title=”Note” style=”default” box_color=”#333333″ title_color=”#FFFFFF” radius=”3″ class=”” id=””]

Lintel Construction

A lintel is a beam placed across the openings like doors, windows etc. in buildings to support the load from the structure above.

The width of the lintel beam is equal to the width of the wall, and the ends of it are built into the wall. Lintels are classified based on their material of construction.

[/su_box]

Lintel Beam Size

The width of the lintel could be equal to the thickness of opening & depth in the range between l/12 to l/8 of the span. Minimum width of 4inch (100 mm) should be provided.

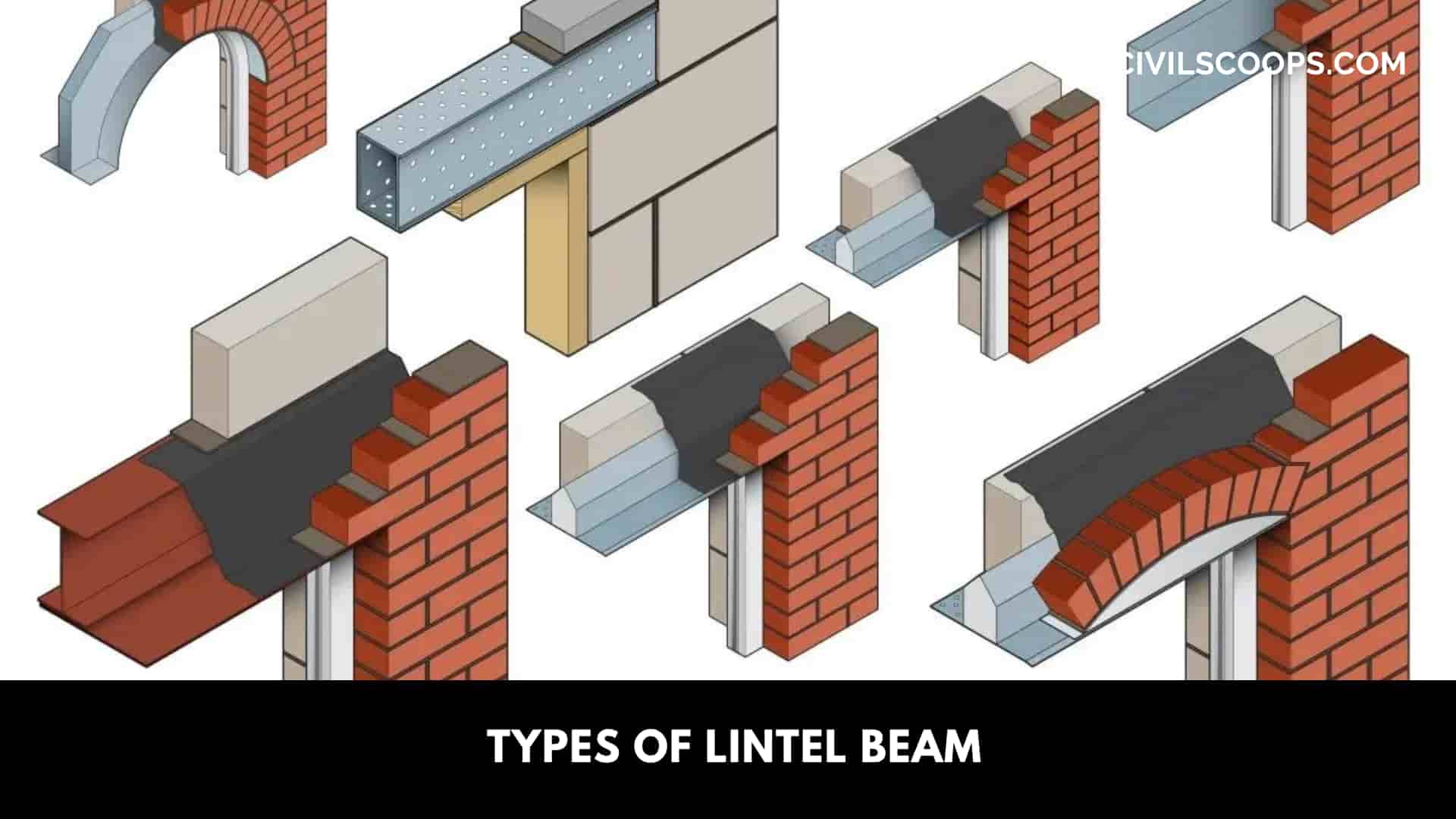

Types of Lintel Beam.

7 Different Types of lintel beam are as follows.

- Wood (Timber) Lintel Beam.

- Stone Lintel Beam.

- Brick Lintel Beam.

- R.C.C. Lintel Beam.

- Steel Lintel Beam.

- Reinforced Brick Lintel Beam.

- Precast Lintel Beam.

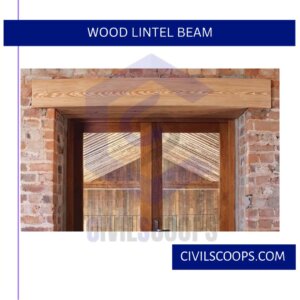

1. Wood Lintel Beam (Timber):

Timber or wooden lintels are the oldest kinds of lintels and are commonly used in hilly terrain areas.

These lintels are expensive, structurally weak, liable to decay, and vulnerable to fire. As per below fig. illustrates the application of a wooden lintel within the wall.

Timber Lintel

Often wooden lintels are used along with mild steel plates at their top and bottom in order to strengthen the timber lintels.

Good quality timber with some coating using suitable preservative is only used for lintel applications, and either end of these lintels are supported by mortar base on walls.

It may be a single piece or may be assembled by joining 2 to 3 pieces. Sometimes the Tiber lintels are strengthened by steel plates at top and bottom. Such lintels are called as flitched beams

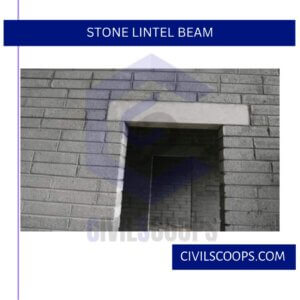

2. Stone Lintel Beam:

These lintels are a type of stone slab with good length, width, and thickness. Stone lintels can also be used over openings within brick walls (as per below fig.).

Stone Lintel Beam

Generally, stone lintels are used in areas for construction, where the stone is easily available. As a stone is weak in tension they can be used only for small spans.

Their depth is kept about 1/10 th span. Stones are cut to the width of the wall and dressed before using as lintels.

Sometimes dressed stone lintels used in the buildings, which give a very good architectural appearance.

Stone lintels are weak in tension and cracks easily when subjected to vibration loads. Thus the application of these lintels should be avoided in the seismically active areas.

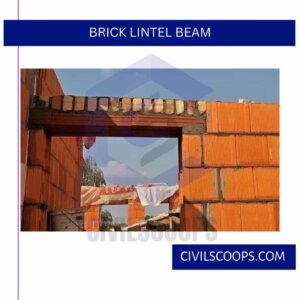

3. Brick Lintel Beam:

Brick lintels are used to provide small openings with lighter loads. These lintels are not structurally very strong and consist of bricks placed on end or edges of piers or abutment or walls (as per below fig.).

Brick Lintel Beam

The depth of brick lintel depends on the span and is constructed over temporary wooden centering.

The bricks along with frogs are suitable for lintel construction because the frogs when filled with mortar form joggles, increase the shear resistance of end joints.

Brick lintels are built up with hard, well burnt, crack-free, sharp, and straight edges bricks.

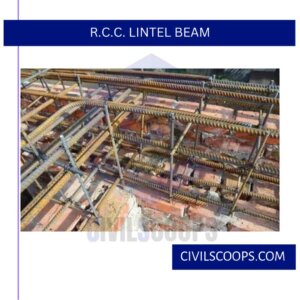

4. R.C.C. Lintel Beam:

RCC has replaced practically all other materials for the lintel. RCC lintels are fire-proof, durable, strong, and easy to construct.

The usual concrete mix used for lintel is 1:2:4. Plain concrete lintels can be used up to a span of 800 mm. The amount of reinforcement depends upon the span.

RCC lintels can be cast-in-situ.RCC lintels are convenient for spans up to 2 m. Also, they increase the speed of construction and allow sufficient time for curing before fixing.

The top of the lintel should be properly marked with tar or paint so that the lintel can be placed correctly.

For cast-in-situ RCC lintels, centering is prepared, reinforcement is placed, and concreting is done. Sunshades can be easily projected from the lintels.

Where appearance is not important, the surface of the RCC lintel is left exposed. As per below fig. shows a lintel over a wall.

Reinforced Cement Concrete Lintel Beam

Flexible DPC must be provided, and the toe of the lintel should be strong enough to bear the load of the wall above it.

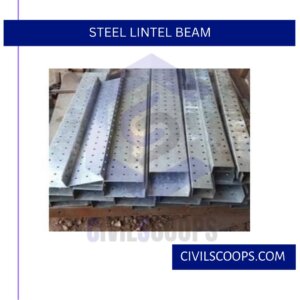

5. Steel Lintel Beam:

One of the most common types of lintels in use today is the structural steel lintel or angle iron. The steel angle iron, which is shaped like the letter L, should have a thickness not less than 1/4″ and a width not less than 3W’ to support the standard 4″ masonry unit.

Angle irons such as this one may be installed back to back when building an 8″ wall. Three angle irons are required to build a wall 12″ in thickness, as per below fig.

Steel Lintel Beam

There are some important items to remember when installing steel lintels over openings. The mason should consult the specifications on the job to determine the lintel bearing (the load which the lintel must bear).

The lintel should bear a minimum of 4″ on each side of the opening on houses or small commercial buildings. Most angle irons have been cut from a larger piece of iron with a burning torch.

This burning causes small beads of steel to form on the surface of the bottom and top portions of the angle iron. The beads should be removed from the irons with the brick hammer before installing them.

The masonry units will not lay level over these rough welds. This is especially important if flashing is to be installed over the lintel, as the rough deads of steel may puncture the flashing.

The lintel must be set plumb and level so that the unit which is laid on it is also in the proper position. It is also important that a steel lintel has rust protected paint.

The steel lintel must be set back 3/8″ to1/2″ from the face of the wall so that a mortar joint may be formed in front of the steel without cracking, as per below fig.

Never set the angle iron on the wall until the masonry unit under it has set sufficiently to avoid sinking.

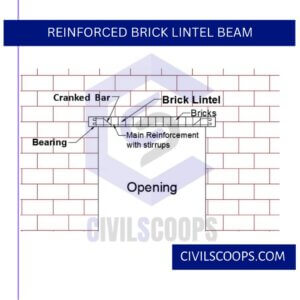

6. Reinforced Brick Lintel Beam:

When bricks lintel are required to be used over large spans, they are reinforced with steel bars. These lintels are constructed on the same principle as R.C.C lintels the only difference being good quality bricks are used instead of concrete.

The bricks are so arranged in parallel rows that at a 2 cm to 4 cm wide space is left lengthwise of inserting the reinforcement, i.e., steel bar or rods.

These spaces with reinforcement are then filed or embedded with rich cement motor or cement concrete.

Reinforced Brick Lintel Beam

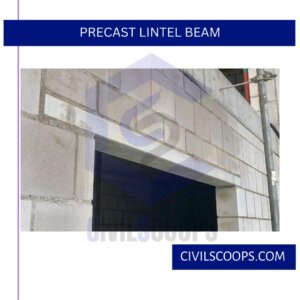

7. Precast Lintel Beam:

Precast concrete lintels are affordable and supply strong support for structures like masonry over door and window openings.

Prestressed Precast Lintels are used for the construction of Residential & Commercial Buildings. apartments are available in more size

Precast Lintel Beam

[su_box title=”FAQ” style=”default” box_color=”#333333″ title_color=”#FFFFFF” radius=”3″ class=”” id=””]

What Is the Purpose of Lintel Beam?

A lintel beam serves a very specific purpose providing structure for openings in walls like windows and doors. The opening means there is nothing to hold up everything above it. A lintel carries the load of the wall above the opening and shifts it to the columns along the sides of the opening.

Is Lintel Beam Necessary?

A lintel is one type of beam which used to support the above wall when openings like doors, windows etc. are necessary to provide a building structure. The main function of the lintel is to take loads coming from above wall and transfer its load to the side walls.

What Is a Masonry Lintel?

A lintel is a structural member placed over an opening in a wall. In the case of a brick masonry wall, lintels may consist of reinforced brick masonry, brick masonry arches, precast concrete or structural steel shapes.

What Is a Steel Lintel?

Steel lintels are structural components installed over an opening in a wall, like a window or a doorway, to support the loads above the gap and prevent the structure from collapsing.

Lintel Construction

Simply put a lintel is a beam that is usually placed above windows and doors. The lintel’s main job is to support the load from the structure above it. Both doors and windows are not constructed to structurally withstand massive loads by themselves. Lintels are mainly found in masonry or brick structures.

Lintel Beam

A lintel or lintol is a type of beam (a horizontal structural element) that spans openings such as portals, doors, windows and fireplaces. It can be a decorative architectural element, or a combined ornamented/structural item.

Difference Between Lintel and Beam

The beam carries the load from slab and transfers it to the column from, column it is transferred to the footing and from footing finally to the soil. Whereas lintel carries the load of the wall above the openings and transfers it to walls only.

Lintel Beam for Windows

A lintel is a beam placed across openings like doors, windows etc. in buildings to support the load from the structure above. Windows and doors are not made to be structural members of the home. When an opening is made in a home, there is a concentrated load above the doorway or window opening that must be supported.

Lintel Beam Size

Specification. A bearing of 150mm to 200mm should be provided, and it should be placed on the mortar. The width of the lintel could be equal to the thickness of opening & depth in the range between l/12 to l/8 of the span. Minimum width of 80mm should be provided.

Lintel Beam Thickness

Steel angle lintels should be at least 1/4 in. (6 mm) thick with a horizontal leg of at least 3 1/2 in. (90 mm) for use with nominal 4 in. (100 mm) thick brick, and 3 in.

Lintel Structure

A lintel is a structural horizontal support used to span an opening in a wall or between two vertical supports. It is frequently used over windows and doors, both of which represent vulnerable points in a building’s structure. Lintels are generally used for load-bearing purposes, but they can also be decorative.

RCC Lintel

RCC lintel is a type of lintel reinforced with steel rods. RCC lintels are suitable in any type of loads and spanning. They are widely used due to their strength, rigidity, economy, fire resistance, and ease of construction.

Precast Concrete Lintel Sizes

Lintels sizes range from 100 x 65mm through to 214 x 140mm.

[/su_box]

[su_note note_color=”#F2F2F2 ” text_color=”#333333″ radius=”3″ class=”” id=””]

Like this post? Share it with your friends!

Suggested Read –

- What Is Plaster | Methods of Plastering

- All About Grillage Foundation | Types of Grillage Foundation | Features of Grillage Foundation

- What Is Pier Foundation | Types of Drilled Piers | Advantages and Disadvantages of Drilled Pier Foundations

- What Is Bracing | Types of Bracing | What Does Brace Mean | Advantages & Disadvantages of Bracing Systems

- What Is Caisson Foundation | Types of Caisson Foundation | Advantage, Disadvantage, Application, & Construction of Caisson

[/su_note]

Originally posted 2023-04-06 07:01:16.