Definition of Design Period | Why Design Period is Provided | Factors Affecting Design Period | Design Period Values

Table of Contents

Definition of Design Period:

The design period could be defined as the number of years in the near future in which the supply will surpass the demand. Or, It is the number of years in the near future in which the given facility is obtainable to satisfy the demand.

Why Design Period Is Provided?

The main reasons behind providing Design Periods are:

- It is prodigiously strenuous or unfeasible to produce frequently.

- It is affordable to supply one mammoth unit in lieu of constructing a variety of bijou ingredients.

Also Read: 19 Different Types of Slabs in Construction | What Is a Slab | Types of Slabs

Factors Affecting Design Period:

Factors affecting the Design Period are given below. Following are some aspects that act on the Design Period of the structure:

- Availability of Funds.

- Life of the structure.

- Ease or Difficulty in Extension.

- Rate of Increment.

- Lead Time.

- The economy of Scale.

- Interest Rates.

- Quality of Material.

- First Cost.

1. Availability of Funds:

If funds are obtainable, one must hold on to a smaller design period.

2. Life of Structure:

Life of structure is the number of years in the near future in which the design period is physically & practically suitable to bestow the intended amenity.

So it always ought to be less than a lifetime of the structure.

- Pumps.

- Conduits(Type of Pipes).

[su_table responsive=”yes” alternate=”no”]

| Factors Affecting Design Period Type of Pipe |

Average Service Life

|

| Steel Pipes | 25 – 50 Years |

| Cast Iron Pipes | 100 Years |

|

Concrete Pipes

|

75 Years |

[/su_table]

3. Ease or Difficulty in Extension:

For projects whose augmentation is unquestionably feasible, it’s generally kept low. For instance, we are capable of inaugurating new tube wells at any time since we don’t require to install all tube wells which might be required after 20

- Tubewell: Easy to drill.

- Treatment Plant: Easy to enlarge.

But for the projects whose augmentation is strenuous, their design period is kept sizeable. For instance, dams and reservoirs cannot be augmented

Adroitness and difficulty that’s likely to be faced in expansions, if undertaken at future dates. For instance, vigorous expansions mean choosing a finer value of the design period.

4. Rate of Increment:

If the speed of growth is lofty, then for that region dwarf design period is required. Anticipated rate of population growth, including feasible shifts in communities, industries, and commercial inceptions.

For instance, if the speed of increase of population is comparatively sloth, a better figure for the design period could also be chosen.

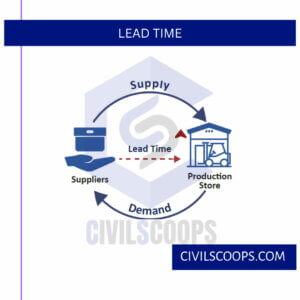

5. Lead Time:

It is the time from the outset of a project to its completion. The design period should be greater than the interval.

Lead Time = Time for Design of Project + Construction Time

6. Economy of Scale:

- The decrease in monetary value parallel to the increase in a facility is thought of as an Economy of Scale.

- If the economy of scale is little, smaller design periods are used.

- It’s economical to make an oversized structure, for an extended design period.

7. Interest Rates:

- If the charge per unit is bijou, the lofty value of the design period is also economically possible.

- The rate of interest depends on the borrowings and also the ancillary money which needs to be invested.

- Amount and availability of ancillary investment likely to be incurred for extra arrangements. For instance, if the funds aren’t available, one should keep a bijou design period.

8. Performance Time:

Structures are checked under working conditions in due course, which mustn’t be considered in the design period. During this point, it’s not providing facilities to the community.

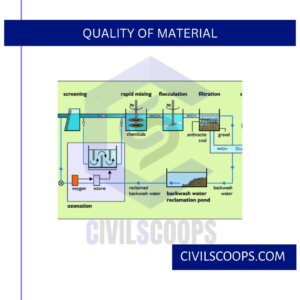

9. Quality of Material:

- The design period mustn’t be longer than the lifetime period of the material utilized in the installation project.

- The quantity of years in which a provision is formed in designing the capacities of the varied modules of the water system scheme is recognized as the design period.

10. First Cost:

In case of High first cost and High Rate of interest, the design period should be brief, so that the aggregate cost of the project should not be disseminated to the present population e.g. Houses.

Design Period Values:

Water system projects, under a standard state of affairs, could also be designed for a design period of 30 years. This 30-year period may, however, be amended in relevance to specific units of the project, depending upon.

- The useful lifetime of the component facility.

- Ease in polishing off extensions when required.

- The rate of interest is in order that expenditure, far ahead of utility, is avoided.

The design period for designing the assorted components of a facility project is provided in the ensuing table:

[su_table responsive=”yes” alternate=”no”]

| Item |

Design Period in Year

|

| Storage by Dams | 50 year |

| Intake Works | 30 year |

| Pumping

1. Pump House |

30 year 15 year |

| Water treatment units | 15 year |

| Pipe connection to the sundry treatment units and other small paraphernalia. | 0 year |

| Raw water and clear water transporting units | 30 year |

| Clearwater reservoirs at the head works, balancing tanks, and service reservoirs | 15 year |

| Distribution system | 30 year |

[/su_table]

What Are Design Period and Return Period for Design Conditions?

- Design life means the rock bottom span of a structure that is predicted to last.

- The longer the design life; the further the cost of a project.

- Therefore, in choosing the design life for a structure, engineers ought to inspect the design life which spawns an economical project without relinquishing the desired function.

- In a selection of return periods of particular design conditions, winds, waves, etc., one ought to consider the connotations of over-expenditure.

- In fact, there are ordinarily no paramount or maximum values of those design conditions, and its selection is anticipated on the probability of expenditure which is set forth to the return period.

- Hence, design life might not be indistinguishable from the return period of design conditions because their selections are succored on different considerations.

[su_box title=”FAQ” style=”default” box_color=”#333333″ title_color=”#FFFFFF” radius=”3″ class=”” id=””]

What Is Per Capita Demand

Per capita demand. Total consumption of water for a water supply system in a year divided by the population and the number of days in the year is called per capita demand. It can be expressed in liters per capita per day.

Design of Grit Chamber

Transition law: The design of grit chamber is based on removal of grit particles with minimum size of 0.15 mm and therefore Stoke’s law is not applicable to determine the settling velocity of grit particles for design purposes.

Per Capita Demand of Water

Per capita water demand: It is the ratio of the annual average water consumption of a community to the total population for 365 days. Hence, Per Capita Demand is the annual average amount of daily water required by one person.

Return Period Formula

Thus the return period of an event of a given magnitude may be defined as the average recurrence interval between events equal or exceeding a specified magnitude. The probability p = P(X >= xT) of occurrence of the event X >= x in any observation may be related to the return period in the following way.

Flood Return Period Formula

The theoretical return period between occurrences is the inverse of the average frequency of occurrence. For example, a 10-year flood has a 1/10 = 0.1 or 10% chance of being exceeded in any one year and a 50-year flood has a 0.02 or 2% chance of being exceeded in any one year.

Exceedance Probability and Return Period

The exceedance probability may be formulated simply as the inverse of the return period. For example, for a two-year return period the exceedance probability in any given year is one over two = 0.5, or 50 percent. 1- (1-p)n .

Return Period in Hydrology

The return period is a probabilistic concept used to measure and communicate the random occurrence of geophysical events such as floods, droughts, storm surges, tsunamis, earthquakes, landslides that may produce huge economic, social and envi- ronmental damages.

What Is Return Period of Flood

Commonly referenced return periods when assessing flood risk include: 1 in 30 year (3.3% annual exceedance probability)- High risk; 1 in 100 year (1% annual exceedance probability)- Medium risk; and. 1 in 1000 year (0.1% annual exceedance probability) Low risk.

[/su_box]

[su_note note_color=”#F2F2F2 ” text_color=”#333333″ radius=”3″ class=”” id=””]

Like this post? Share it with your friends!

Suggested Read –

- Properties of Stones | Requirements of Good Building Stones

- What Is Falsework | Types of Falsework | Causes of Falsework Failures

- Standard Height of Window from Floor Level | Window Sill Height from Floor

- What Is Azimuths Surveying | What Is Bearings Surveying | Difference Between Azimuths and Bearings in Surveying

- How Much Does It Cost to Pump a Septic Tank | Why Septic Tanks Required Pumping | Typical Problems Leading to Septic Tank Pumping

[/su_note]

Originally posted 2023-03-03 13:31:28.