Table of Contents

What Is Consistency of Cement?

Any Cement paste requirement of minimum water in cement paste to initiate the chemical reaction. This chemical reaction calls the consistency of cement. This method calls the consistency of cement test.

What Is the Initial Setting Time of Cement?

Initial setting time of cement: Casting cement past in any mold without losing strength & Shape. This working process time calls the initial setting time of cement.

Determination of Initial Setting Time: from IS Code 4031 part 5, page no 2, cl 5.2

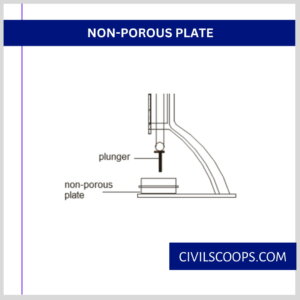

Place the test block confined in the mold and resting on the non-porous plate, under the rod bearing the needle ( C ); lower the needle gently until it comes in contact with the surface of the text block and quickly releases. From IS Code 4031 part 5

Allowing it to penetrate into the test block. In. In the beginning, the needle will completely pierce the test block.

Repeat this procedure until the needle, when brought in contact with the test block and released as described above, fails to penetrate the block beyond 5.0 ± 0.5 mm measured from the bottom of the mold.

The period elapsing between the time when water is added to the cement and the time at which the needle fails to pierce the test block to a point of 5.0 ± 0.5 mm measured from the bottom of the mold shall be the initial setting time. From IS Code 4031 part 5

Normally Initial Setting Time :

O.P.C (Ordinary Portland Cement) 30 min.Initial Setting Time of Cement

Rapid Cement 5 min Initial Setting Time of Cement

What Is the Final Setting Time of Cement?

Any cement paste stating the time of Cement paste is loose cement past to going hard shape of cement pest. All complete prosses of Cement Harding final time call final setting time of cement.

Determination of Final Setting Time: from IS Code 4031 part 5, page no 2, cl 5.3

Replace the needle ( C ) of the Vicat apparatus with the needle with an annular attachment ( F ). The cement shall be considered as finally set when from IS Code 4031 part 5

Upon applying the needle gently to the surface of the text test block, the needle makes an impression thereon, while the attachment fails to do so. From IS Code 4031 part 5

The period elapsing between the time when water is added to the cement and the time at which the needle makes an impression on the surface of the test block while the attachment fails to do so shall be the final setting time.

In the event of scum forming on the surface of the test block, use the underside of the block for the determination

Also Read: Difference Between Heartwood and Sapwood | What Is Sapwood | What Is Heartwood

Consistency Test of Cement

Aim for Consistency Test of Cement:

To determine the standard consistency of the test of Cement

Scope for Consistency Test of Cement:

This procedure covers all relative activity for the project site.

Apparatus of Consistency Test of Cement:

1. Vicat’s Apparatus

Vicat apparatus conforming from IS: 5513-1976

2. Plunger

3. Balance

4. Measuring cylinder

6. Non-Porous Plate

Sample:

1. Cement

Procedure for Consistency Test of Cement

- Take about 500 gms of cement and prepare a paste with a weight quantity of water (say 24 percent by weight of cement) for the first trial.

- The paste must be made in a conventional manner and filled into the Vicat mold within 3-5 minutes.

- After complete filling, the mold shakes the mold to expel air.

- A standard plunger 10mm in diameter, and 50mm long is attached and brought down to touch the surface of the paste in the test block & quickly released, allowing it to sink into the paste by its own weight.

- Take the reading this reading note down the depth of penetration of the plunger.

- Conduct a 2nd trial (say with 25 percent of water) and find out the depth of penetration of the plunger. Similarly,

- Conduct trials with a higher water/cement ratio till such time of plunger penetrate a depth of 33-35 mm from the top.

- That particular percentage of water maximum allows the plunger to percentage only to a depth of 33-35mm from the top is known as the %(percentage) of the water required to produce the cement paste of standard consistency.

- The test is expected required to be conducted at a constant temperature (27°± 2°) C & constant humidity (90%)

Also Read: Civil Engineering Basic Knowledge

Results of Consistency Test of Cement:

Express the amount of water as a % by weight of the dry cement

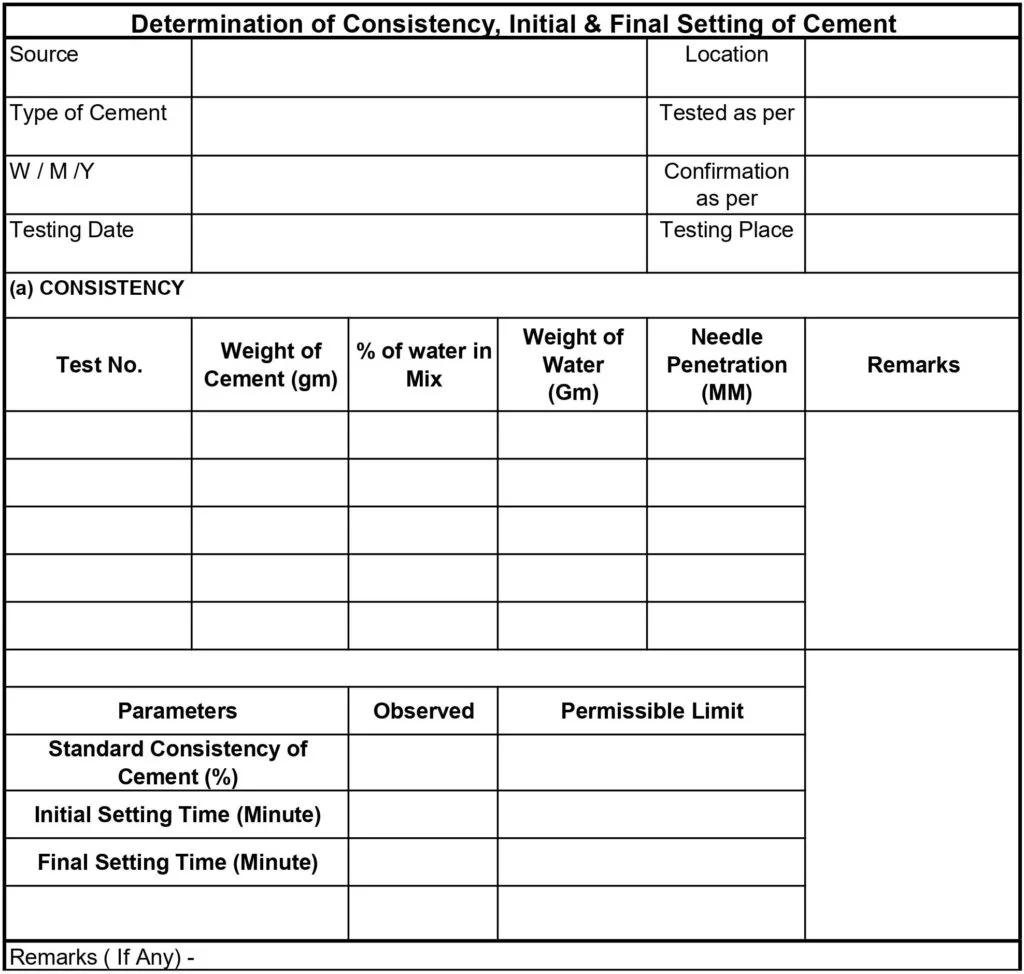

Sample Excel File Consistency, initial & Final setting of cement

The calculation for the Consistency Test of Cement:

Express the amount of water as a percentage by mass of the dry cement to the first place of decimal.

Consistency of Cement

The standard consistency of cement is that consistency, which permits the Vicat plunger to penetrate to a point 5 to 7mm from the bottom of the Vicat mold when tested. The procedure to determine the quantity of water required to produce a cement paste of standard consistency is described below.

What Is Consistency of Cement?

The consistency of cement paste is defined as the percentage of water requirement of cement paste at which the viscosity of paste in such a way that it determines the amount of water needed to make a paste. It is necessary to determine consistency because the amount of water affects the setting time of the cement.

Standard Consistency of Cement

The Standard or Normal consistency for Ordinary Portland cement varies between 25-35%. To prepare a mix of cement paste of Standard consistency 25-35% of water is added to the cement. To explain in detail Let us assume a standard consistency is 30%. Take 400g of Cement for this quantity, and Add 30% of Water.

Setting Time of Cement

The time at which cement completely loses its plasticity and became hard is the final setting time of cement. The time taken by cement to gain its entire strength is the Final setting time of cement. For Ordinary Portland Cement, The Final Setting Time is 600 minutes (10hrs).

Final Setting Time of Cement

The time at which cement completely loses its plasticity and became hard is the final setting time of cement. The time taken by cement to gain its entire strength is the Final setting time of cement. For Ordinary Portland Cement, The Final Setting Time is 600 minutes (10hrs).

Setting Time Test of Cement

Record the period elapsed between the time of adding water to the cement to the time when the needle fails to pierce the mold by 5 + 0.5mm as the initial setting time. Final Setting Time

- Replace the needle of the Vicat apparatus by needle with an annular ring

- Lower the needle and quickly release.

Initial and Final Setting Time of Cement Test

The initial setting time is the exact moment when the concrete starts to harden. In theory, this time starts as soon as the water is added to the cement. The final setting time is the moment the concrete has hardened enough so that a five-millimeter square needle no longer penetrates the surface.

Consistency of Cement Meaning

The consistency of cement paste is defined as the percentage of water requirement of cement paste at which the viscosity of paste in such a way that it determines the amount of water needed to make a paste. It is necessary to determine consistency because the amount of water affects the setting time of the cement.

Consistency of Cement

The standard consistency of cement is that consistency, which permit the vicat plunger to penetrate to a point 5 to 7mm from the bottom of the vicat mould when tested. Procedure to determine the quantity of water required to produce a cement paste of standard consistency is described below.

Normal Consistency of Cement

The Standard or Normal consistency for Ordinary Portland cement varies between 25-35%. To prepare a mix of cement paste of Standard consistency 25-35% of water is added to cement. To explain in detail Let us assume a standard consistency is 30%. Take 400g of Cement for this quantity, Add 30% of Water.

Consistency Test of Cement

- The standard consistency of any cement is achieved when cement permits the Vicat plunger to penetrate to a point 33 to 35 mm from the bottom of the Vicat mold.

- First of all, take about 300 gm of cement into a tray and is mixed with a known percentage of water by weight of cement.

Normal Consistency of Portland Cement

Normal consistency is also known as standard consistency of cement. Normal consistency for ordinary Portland cement generally varies between 26-33%.

What Is Standard Consistency?

Explanation: Standard consistency of cement paste may be defined as the consistency which permits the Vicat’s plunger (10 mm, 40 to 50 mm in length) to penetrate to a point 5 mm to 7 mm from the bottom ( or 35 mm to 33 mm from top) of Vicat mould.

What Is the Initial Setting Time of Cement?

The time available for mixing the cement and placing it in position is an Initial setting time of cement. If delayed further, cement loses its strength. For Ordinary Portland Cement, The initial Setting Time is 30 minutes.

What Is Initial Setting Time?

The initial time refers to the time that cement turns into paste by mixing with water and begins to lose its plasticity. And the time that cement completely loses its plasticity by mixing with water and begins to have a certain structural strength is known as the final setting time.

Initial and Final Setting Time of Opc Cement

The national standards prescribe that the initial setting time of Portland cement should not be earlier than 45 min and the final setting time should not be later than 6.5 h.

Setting Time Test of Cement

Once cement mortar/cement concrete is placed, it should completely lose its plasticity. So that external agencies may not harm it. This time should not be more than 10 hours (600 minutes) which called final setting time of cement.

Setting Time of Concrete

In most cases, standard concrete (or full strength concrete) has a setting time of around one day, sometimes two days depending on the environment in which it is set. However, concrete reaches its full strength after approximately 25-28 days.

Initial Setting Time of Cement Pdf

The initial setting time for OPC, SRC, PPC, RHPC and PSC is 30 minutes. The final setting time for OPC, SRC, PPC, RHPC and PSC is 600 minutes.

Initial Setting Time and Final Setting Time of Cement

3.2 Workability and setting time. High alumina cement is slow setting cement. Its initial setting time is 4–5 h and final setting time is about 30 min later after initial setting.

What Is Initial Setting Time of Cement?

The time available for mixing the cement and placing it in position is an Initial setting time of cement. If delayed further, cement loses its strength. For Ordinary Portland Cement, The initial Setting Time is 30 minutes.

Normal Consistency of Cement Pdf

The normal consistency of a cement paste is defined as that consistency (% of water) which will permit the vicat plunger to penetrate to a point 10 mm from the top of the vicatmould. The usual range of values being between 22 to 30 percent by weight of dry cement. Normal consistency is also called standard consistency.

Like this post? Share it with your friends!

Suggested Read –

- 15 Different Types of Cement and Their Uses

- What Are the Components of Stairs | 19 Different Types of Stairs Components

- What Is Sealing Brick Work| Advantages of Brick Sealer | Types of Brick Sealer

- 10 Different Between Mortar And Concrete | What Is Mortar & Concrete | Types of Mortar & Concrete

- What Is Weirs | Types of Weirs | Advantages & Disadvantages of Weirs | Operation & Limitations For Weir | Limitations of Weirs | Location of Weirs