All About Mix Design of Concrete | What Is Mix Design of Concrete | Nominal Mix | Design Mix

Table of Contents

What Is Mix Design of Concrete?

Concrete mix design involves a process of preparation in which a mix of ingredients creates the required strength and durability for the concrete structure.

The ingredients to be tested: are water, fine aggregate (sand), coarse aggregate, cement, chemicals, reinforcement, and soil.

Nominal Mix

The nominal mix specifies the fixed proportion of the cement, sand, and aggregates. Ingredients of concrete are mixed on the basis of volume.

It is a site-level mixing of ingredients to prepare a concrete mix. Such What Is Concrete | 31 Plush Different Types of Concrete mix is generally used in small quantities or where the load is not high.

Nominal Mix Concrete

Nominal mixes offer simplicity and under normal circumstances, have a margin of strength above that specified.

However, due to the variability of mixed ingredients the nominal concrete for given workability varies widely in strength. Nominal mix ratios for concrete are 1:2:4 for M15, 1:1.5:3 for M20 etc.

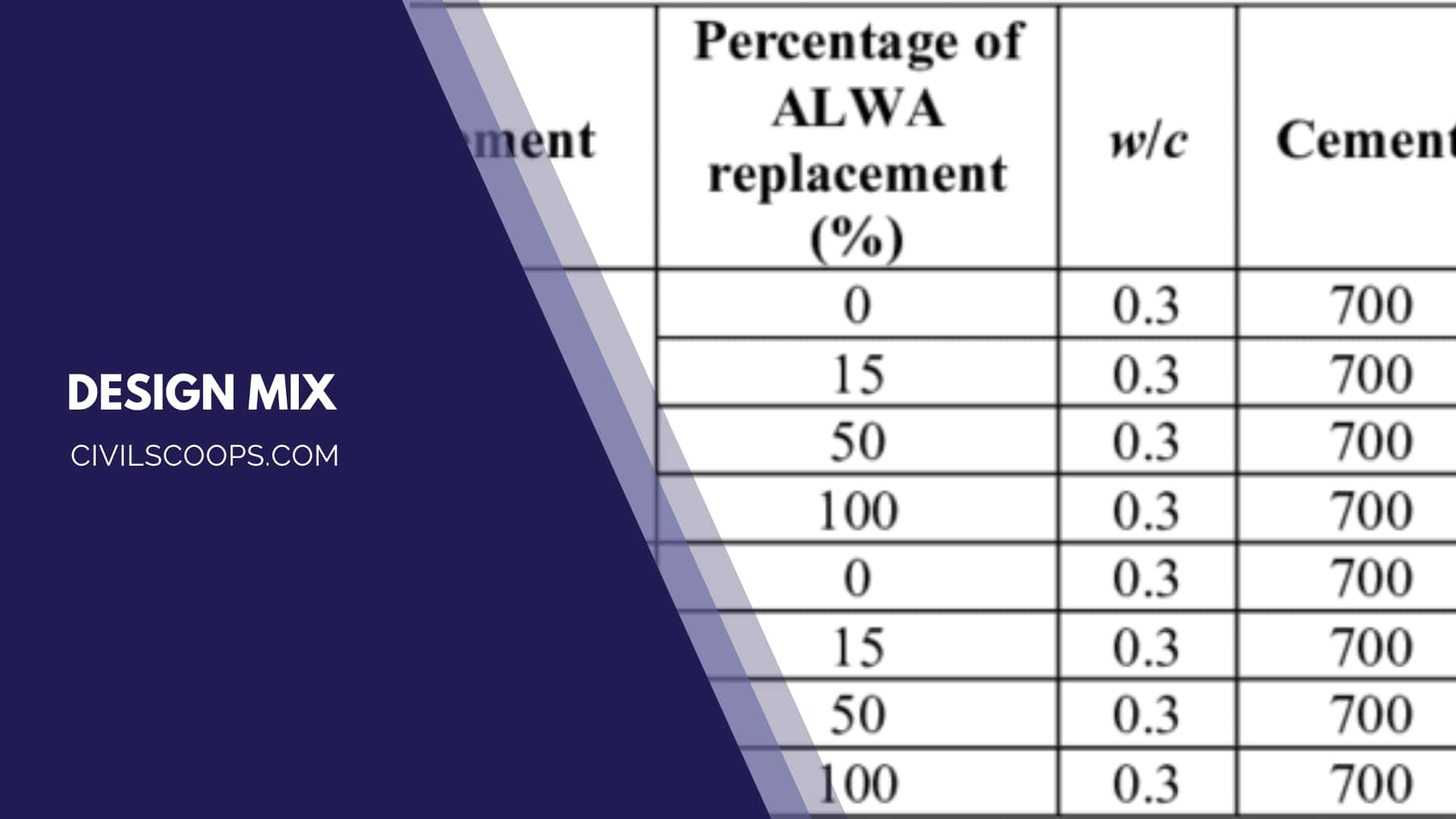

Design Mix

Design mix is a process to prepare the concrete by testing all necessary properties (like properties of cement, fine aggregate, and coarse aggregate) of concrete ingredients.

Ingredients of concrete are mixed on the basis of weight. It is generally designed from ready Mix Concrete (RMC) plant.

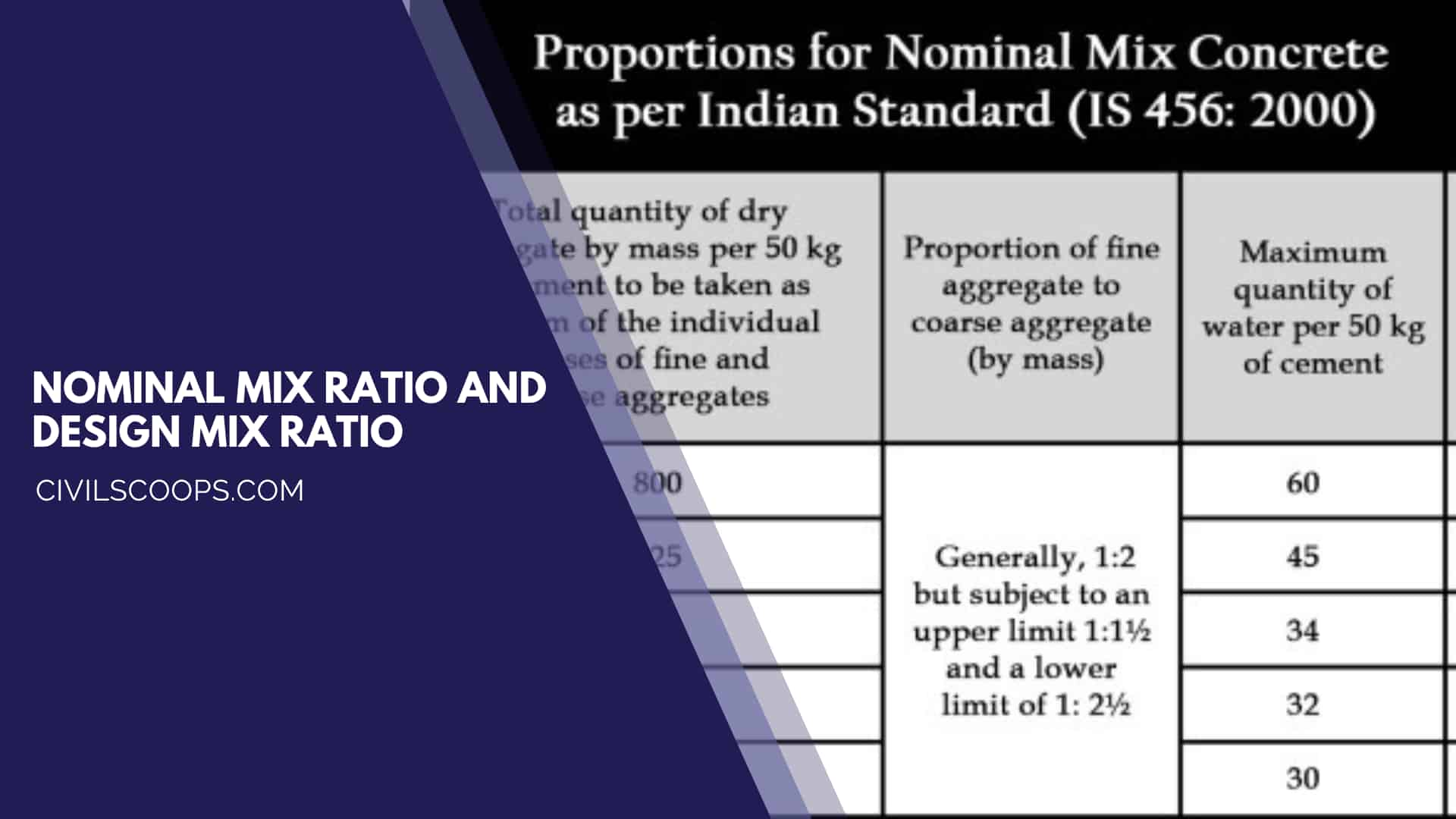

Nominal Mix Ratio and Design Mix Ratio

[su_table responsive=”yes” alternate=”no”]

|

Concrete Grade

|

Design

|

Mix Ratio

|

Compressive Strength | |

| MPa (N/mm2) | psi | |||

| M5 | Nominal Mix | 1:05:10 | 5 MPa | 725 psi |

| M7.5 | Nominal Mix | 1:04:08 | 7.5 MPa | 1087 psi |

| M10 | Nominal Mix | 1:03:06 | 10 MPa | 1450 psi |

| M15 | Nominal Mix | 1:02:04 | 15 MPa | 2175 psi |

| M20 | Nominal Mix | 1:1.5:3 | 20 MPa | 2900 psi |

| M25 | Nominal Mix | 1:01:02 | 25 MPa | 3625 psi |

| M30 | Design Mix | NA | 30 MPa | 4350 psi |

| M35 | Design Mix | NA | 35 MPa | 5075 psi |

| M40 | Design Mix | NA | 40 MPa | 5800 psi |

| M45 | Design Mix | NA | 45 MPa | 6525 psi |

| M50 | Design Mix | NA | 50 MPa | 7250 psi |

| M55 | Design Mix | NA | 55 MPa | 7975 psi |

| M60 | Design Mix | NA | 60 MPa | 8700 psi |

| M65 | Design Mix | NA | 65 MPa | 9425 psi |

| M70 | Design Mix | NA | 70 MPa | 10150 psi |

[/su_table]

Difference Between Nominal Mix and Design Mix

1. Nominal Mix and Design Mix: Mixing

Nominal Mix: The nominal mix is site-level mixing small concrete mixer can be used to mix the ingredients.

Design Mix: The design mix is designed from a ready-mix concrete plant which is the RMC plant.

2. Nominal Mix and Design Mix: Mix Design

Nominal Mix: There are many grades of nominal mix concrete like M-5, M-7.5, M-10, M-15, and M-20.

Design Mix: A design mix is a process to prepare the concrete by testing all necessary properties (like properties of cement, fine aggregate, and coarse aggregate) of concrete ingredients.

3. Nominal Mix and Design Mix: Tests

Nominal Mix: For a nominal mix, no laboratory tests are conducted.

Design Mix: The design mix is based on the laboratory trial-and-error experiment method.

4. Nominal Mix and Design Mix: Time

Nominal Mix: The nominal mix is easy to make at the construction site. It does not take more time to decide the proportion because proportions are already given in IS456:2000.

Design Mix: Whereas the design mix is very difficult and its process takes more than 30 days, time to find out the most suitable mix for the project for design mix IS-20262 shall be followed.

Also Read: What Is Cantilever | What Is Cantilever Footing | Design of the Cantilever Footing

5. Nominal Mix and Design Mix: Skilled Persons

Nominal Mix: For a nominal mix, there is no need for skilled persons.

Design Mix: Whereas for design mix skilled person shall be required to prepare the mix design.

6. Nominal Mix and Design Mix: Basis

Nominal Mix: The nominal mix is based on past experience and has no scientific approach.

Design Mix: The design mix is more scientific than the nominal mix.

7. Nominal Mix and Design Mix: Strength

Nominal Mix: The nominal mix may or may not give exactly design strength unless all other factors like compaction and water-cement ratio curing of concrete are strictly followed.

Design Mix: Design mix not only makes concrete of design strength but also makes it economical too.

8. Nominal Mix and Design Mix: Accuracy

Nominal Mix: In the case of nominal mix water-cement ratio is considered by the assumption so if we do not take care of it sometimes it leads to bleeding segregation and may make concrete of poor strength and durability.

Design Mix: Whereas in the case of design mix, there is no such problem slump and strength can be related that is for strength. We can use different slumps by changing the water-cement ratio with or without admixtures.

9. Nominal Mix and Design Mix: Use

Nominal Mix: The nominal mix is preferred for simpler relatively unimportant and small concrete works, in other words, the nominal mixes adopted for ordinary concrete work nominal mix may be used for concrete of M 20 grade or lower grade.

Design Mix: Whereas design mixed is used for more extensive and important concrete works design mix can be used for all the grades but it is generally used for M 25 and above grades.

[su_box title=”FAQ” style=”default” box_color=”#333333″ title_color=”#FFFFFF” radius=”3″ class=”” id=””]

Mix Design of Concrete

A concrete mix is a combination of five major elements in various proportions: cement, water, coarse aggregates, fine aggregates (i.e. sand), and air. Additional elements such as pozzolanic materials and chemical admixtures can also be incorporated into the mix to give it certain desirable properties.

Concrete Mix Ratio Table

[su_table responsive=”yes” alternate=”no”]

| Concrete Grade | Mix Ratio | Compressive Strength |

| M7.5 | 01:04:08 | 7.5 MPa |

| M10 | 01:03:06 | 10 MPa |

| M15 | 01:02:04 | 15 MPa |

| M20 | 01:05.5 | 20 MPa |

[/su_table]

Concrete Mix Design Ratio

The safest bet for any concrete mix is four-two-one: four parts crushed rock; two parts sand; and one part cement. The four-two-one mix, obviously, has seven parts. Conveniently, when mixing concrete, the ratio can be mixed on any range of scales.

Mix Design Ratio

[su_table responsive=”yes” alternate=”no”]

| Concrete Grade | Mix Ratio | Compressive Strength |

| M15 | 01:02:04 | 2175 psi |

| M20 | 01:05.5 | 2900 psi |

| Standard Grade of Concrete | ||

| M25 | 01:01:02 | 3625 psi |

[/su_table]

M50 Concrete Mix Ratio

Mix Proportion by weight of M50 grade of concrete without fly ash is 1:2.28:3.12 and its water-cement ratio was found to be 0.44.

Scc Concrete Mix Design

SCC mixtures typically have a higher paste volume, less coarse aggregate, and higher sand-to-coarse aggregate ratio than typical concrete mixtures. SCC mixtures can be designed to provide the required hardened concrete properties for an application, similar to regular concrete.

Shotcrete Mix Design

Shotcrete typically consists of one part cement and four parts sand by weight with approximately 7% water by mass of dry ingredients.

What Is Mix Design and Types of Mix Design?

[su_table responsive=”yes” alternate=”no”]

| Concrete Grade | Mix Ratio (Cement : Sand : Aggregates) | Compressive Strength |

| M7.5 | 01:04:08 | 7.5 MPa |

| M10 | 01:03:06 | 10 MPa |

| M15 | 01:02:04 | 15 MPa |

| M20 | 01:05.5 | 20 MPa |

[/su_table]

What Is a Mix Design?

What Is Mix Design? Mix design can be defined as the process of selecting suitable ingredients of concrete and determining their relative proportions with the object of producing concrete of certain minimum strength and durability as economically as possible.

What Is Modern Rustic Decor?

Modern rustic style trends toward whites, warm neutrals, and earth tones. Fabric choices lean toward solids rather than prints, with materials emphasizing natural textures. A modern rustic palette doesn’t have to imply boring, but it should radiate a relaxing and welcoming vibe.

What Is Traditional Contemporary Decor?

What Is Contemporary Style? Fundamentally, a contemporary style of decorating is defined by simplicity, subtle sophistication, deliberate use of texture, and clean lines. Interiors tend to showcase space rather than things. Things that are modern and current with the styles of the moment are contemporary style.

What Is a 1 2 3 Mix for Concrete?

In making concrete strong, these ingredients should usually be mixed in a ratio of 1:2:3:0.5 to achieve maximum strength. That is 1 part cement, 2 parts sand, 3 parts gravel, and 0.5 part water.

What Are the 4 Types of Concrete?

- Reinforced Concrete.

- Lightweight Concrete.

- High-Strength Concrete.

- High-Performance Concrete.

- Precast Concrete.

Nominal Mix

The nominal mix is the process in which all the ingredients are prescribed as per specifications and their proportions are specified in the ratio of cement to aggregates for a certain strength achievement. The proportions of ingredients in the nominal mix are the same for all the projects.

Standard Mix Concrete

The safest bet for any concrete mix is four-two-one: four parts crushed rock; two parts sand; and one part cement.

What Is Design Mix?

The design mix refers to three aspects of design that companies need to consider when developing a product. All three are functions, manufacturing costs, and aesthetics.

What Is Concrete Mix Design?

Concrete mix design involves a process of preparation in which a mix of ingredients creates the required strength and durability for the concrete structure. Because every ingredient in the mix consists of different properties, it’s not an easy task to create a great concrete mix.

Design Mix Concrete

Concrete mix design is the process of finding right proportions of cement, sand and aggregates for concrete to achieve target strength in structures. So, concrete mix design can be stated as Concrete Mix = Cement:Sand:Aggregates.

What Concrete to Use for Countertops?

Before all else, do not use regular Quickrete for concrete countertops. Instead, make sure to choose concrete with a PSI of at least 6000. The PSI indicates how hard the concrete will be once it’s been cured.

What Is the Price of Concrete Per Yard?

For installing and repairing driveways, sidewalks, stairs, or patios, concrete is a durable and cost effective option. Concrete cost per yard ranges from $100 to $200, with the national average at $128. Here’s everything you need to know about the cost of concrete.

What Is the Cost of Concrete Per Yard?

How much is a yard of concrete? When estimating the cost of concrete, use $125 per yard as a ballpark figure. However, concrete prices differ by region, and you’ll have to pay a ready mix delivery fee, plus factor in labor charges if hiring a contractor.

What Is the Best Concrete Mix for Fence Posts?

The best concrete mix for fence posts I’ve found is Quikrete Fast Setting Concrete Mix in a 50 lb bag. It’s 4000 psi, easy to work with, sets up fast, and doesn’t need to be mixed. Just pour it in the hole and soak with water.

What Is the Best Water Cement Ratio for Mixing Concrete?

Water–cement ratios in the range of 0.40 to 0.60 are typically used. For higher-strength concrete, lower w/c ratios are necessary, along with a plasticizer to increase flowability.

Concrete Mix Design Calculations

Procedure for Concrete Mix Design of M25 Concrete

- ftarget = fck + 1.65 x S.

- = 25 + 1.65 x 4.0 = 31.6 N/mm2

- Cement Content = (197.4/0.5) = 394.8 kg/m3

- Cement content = (197.4/0.55) = 358.9 kg/m3

Mix Design Calculation

- Mix Design (M) = Cement: Sand :Aggregate.

- i.e volume of dry Concrete = 1.54 to 1.57 times Volume of wet concrete.

- Summary: –

- 8 bags of cement required for 1 cu. …

- 672 kg of Sand required for 1 cu. …

- 1326 kg of 20mm Aggregate is required for 1 cu. …

- 200 litres of water is required for 1 cu.m of M20 grade concrete.

Concrete Mix Ratio by Volume

Another “old rule of thumb” for mixing concrete is 1 cement : 2 sand : 3 gravel by volume. Mix the dry ingredients and slowly add water until the concrete is workable. This mixture may need to be modified depending on the aggregate used to provide a concrete of the right workability.

Concrete Mix Ratio 1:2:4

For concrete of 1:2:4 mix proportion, first two boxes of sand and one bag of cement should be dry-mixed thoroughly. Then, a dry mix of cement and sand is placed over a stack of 4 boxes of stone aggregates and the whole mixture is dry-mixed, turning at least three times to have a uniform mix.

M30 Concrete Mix Ratio

cement = 360 x 0.045 = 16.2 kg. water = 140 x 0.045 = 6.3 kg. 20 mm = 645 x 0.045 = 29.03 kg. 12.5 mm = 639 x 0.045 = 28.76 kg.

[/su_box]

[su_note note_color=”#F2F2F2 ” text_color=”#333333″ radius=”3″ class=”” id=””]

Like this post? Share it with your friends!

Suggested Read –

- 7 Different Types of Bitumen | What is Bitumen

- Grey Water vs Black Water | What Is Grey Water | What Is Black Water

- Kani’s Method | Advantages of Kani’s Method | How to Use Kani’s Method for Analysis | Procedure of Kani’s Method

- Difference Between Prismatic Compass and Surveyors Compass | Least Count of Prismatic Compass & Surveyor Compass

- How to Build a Suspension Bridge | Suspension Bridge Facts | Suspension Bridge-Strength & Weaknesses | Advantages and Disadvantages of a Suspension Bridge

[/su_note]

Originally posted 2022-11-01 09:13:07.