Unlock the magic of small spaces with innovative garden designs that transform limited square footage into enchanting … [Read more...]

200+ Garden Design Ideas to Make the Best of Your Outdoor Space

The article titled "200+ Garden Design Ideas to Make the Best of Your Outdoor Space" serves as an expansive resource for … [Read more...]

135+ Best Garden Design Ideas

Dive into a world where creativity meets nature, and practicality embraces beauty. Civil Scoops presents an eclectic … [Read more...]

195+ Best Garden Layout Ideas

In the realm of outdoor aesthetics, your garden is not just an extension of your home but a canvas where nature’s … [Read more...]

200 Best Garden Layout Ideas for Every Size Garden

Creating the perfect garden layout is both an art and a science. Whether you have a sprawling backyard or a tiny … [Read more...]

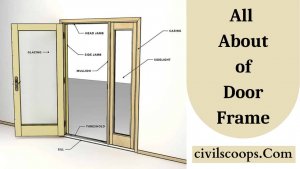

What is Door Frame? | 8 Main Parts of Door Frame | Types of Door Frame used in House

Information of Door Frame Doors are an important part of the building which allows occupants for horizontal movement in … [Read more...]

Soil Hydrometer | How Does a Soil Hydrometer Work | How to Read Hydrometer | What Does a Hydrometer Measure | Advantage, Disadvantages & Uses of Hydromete

Introduction Soil Hydrometer A hydrometer is a type of instrument which is used to gauge the general thickness of a … [Read more...]

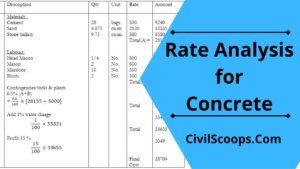

Rate Analysis for Concrete

Introduction of Rate Analysis for Concrete 1st Step - estimation of labour, materials, equipments & … [Read more...]

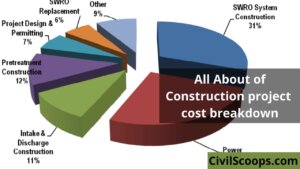

Construction Project Cost Breakdown

Introduction of Construction Project Cost Breakdown In any circumstance, the transparency and rational structure … [Read more...]

Estimate Cost of Construction Per Sq Ft

Introduction of Estimate Cost of Construction Per Sq Ft First, we must understand the asked price of every material … [Read more...]

Types of Crawl Space Insulation | Fiber glass Batt Insulation | Closed Cell Spray Foam Insulation | Open-Cell Foam Spray Insulation | Rigid Foam Insulation and Use|

Information of crawl space insulation There are two types of crawl space insulation that are majorly used. The first … [Read more...]

All About of Mezzanine Floor

Information of Mezzanine Floor The mezzanine floor is an intermediate floor of a building, below the open floor. At … [Read more...]

Reinforced Concrete Frame | Concrete Frame Construction Details | Concrete Building Construction

Reinforced Concrete Frame Reinforced concrete frames comprise of flat components (beams) and vertical components … [Read more...]

Road Gradient | Type of Gradient | All Gradient Advantages and Disadvantages

What Is Road Gradient? The rate of rise and fall with respect to the length of the road is termed as gradient of the … [Read more...]

OPC vs PPC | Difference between OPC and PPC Cement

OPC vs PPC Some Advantages that we get while using OPC in construction sites are. Ordinary Portland cement … [Read more...]

All About of Portland Cement Uses

What Is Portland Cement Uses? Portland cement is the most widely used form of cement in the world. It has been utilised … [Read more...]

Properties of Concrete | What Is the Grade of Concrete

Properties of Concrete There have many properties of concrete that are below- Grades of concrete (M20, M25, M30, … [Read more...]

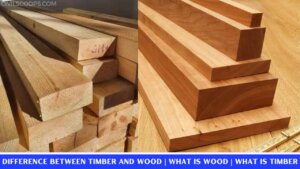

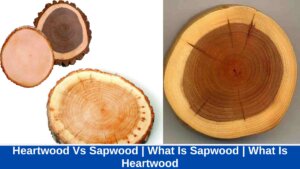

Types of Wood

Introduction of Wood Wood is one of several renewable natural coffers. It's an important product used in our day-to-day … [Read more...]

What Is Veneer | What Is Laminate | Veneer VS Laminate | Difference Between Veneer and Laminate

What is Veneer? In woodworking, veneer refers to small pieces of wood and sometimes bark, usually less than 3 mm … [Read more...]

What Is Concrete Blocks | Types of Concrete Blocks | Types of Hollow Concrete Block | Advantages & Disadvantages of Using Hollow Concrete Blocks

What Is Concrete Blocks? Concrete blocks are commonly used in the design of buildings. It is less expensive than the … [Read more...]

Steel Is Stronger Than Concrete?

Introduction of Steel Is Stronger Than Concrete Because concrete has a greater compressive strength than steel, steel … [Read more...]

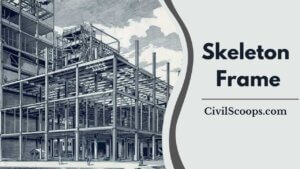

Skeleton Frame | Building Skeleton | Steel Structural Building

What Is Skeleton Frame? A skeleton frame is a framed design regularly utilized for the development of multi-story … [Read more...]

Information About Contractor

Introduction of Contractors Three major parties are committed to each construction design: the holder, the contractor, … [Read more...]

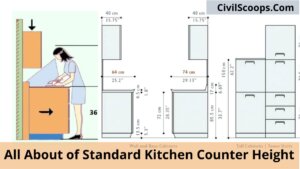

Standard Kitchen Counter Height

Standard Kitchen Counter Height The measurement from the floor to the surface of the counter is called kitchen counter … [Read more...]

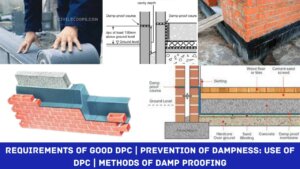

What Is Dampness | Causes of Dampness | Effects of Dampness | Damp Proofing Materials | Methods of Damp Proofing

What Is Dampness ? Dampness is a property of a building when the water or moisture is absorbed by the building … [Read more...]

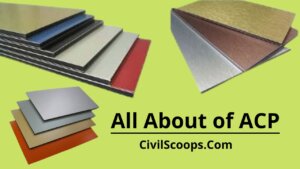

What Is ACP | Applications of ACP Sheet | Advantage of ACP Sheet | Disadvantages of ACP Sheet

What Is ACP Sheet? The ACP is a short form of Aluminum composite panel, it is also known as the sandwich panel. The … [Read more...]

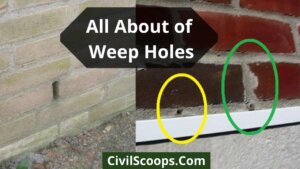

What Is Weep Holes | Function of Weep Holes | Types of Weep Holes

What Is Weep Holes? A weep hole, also known as a weep brick, is a small opening that allows water to drain from a … [Read more...]

Types of Tests on Bricks

Types of Tests on Bricks For construction works to determine the suitability of bricks the following test is … [Read more...]

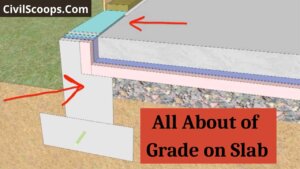

What Is Grade on Slab

What Is Grade on Slab? Grade on the slab is a special type of slab which is constructed on the earth soil. This type of … [Read more...]

Steel Is Stronger Than Concrete | Steel Vs Concrete

Steel Is Stronger Than Concrete? Because concrete has greater compressive strength than steel, steel bars are utilized … [Read more...]

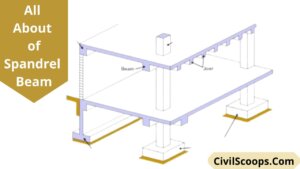

Spandrel Beam | What Is Spandrel | Spandrel Beam Definition | Advantages, Disadvantages, Uses Properties & of Spandrel Beam

Introduction of Spandrel Beam In concrete construction and steel construction spandrel beam is used. Spandrel beams are … [Read more...]

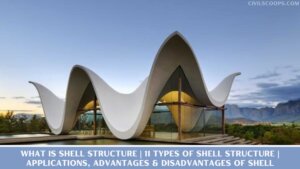

What Is Shell Structure | Types of Shell Structure | Applications of Shell Structure | Advantages & Disadvantages of Shell Structures

What Is Shell Structure? The structure that retains their size and support load, even without frame or solid mass … [Read more...]

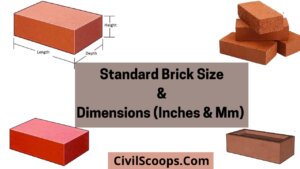

Standard Brick Size & Dimensions (Inches & MM)

Standard Brick Size & Dimensions (Inches & Mm) Standard Brick Sizes in England The majority of bricks in … [Read more...]

What is FerroCement| Properties| Materials required| Uses| Advantages| Disadvantages

What is Ferrocement? Ferrocement is a substance of wire meshes & cement mortar. It was 1st developed by P.L.Nervi, … [Read more...]

What Are Washers Used for ?

What Are Washers Used for ? The washer seems to be a thin plate with just a concentration hole which is then used to … [Read more...]

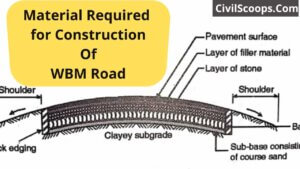

Material Required for Construction of WBM Road

Material Required for Construction Of WBM Road The term macadam at the present time means road surfaces and bases that … [Read more...]

What Is Slip Form? | Slip Form Construction | Slip Form Technique| Types of Slip Form System

What Is Slip Formwork? Formwork is a temporary moulid that is used for the pouring of concrete. The Traditional … [Read more...]

What Is Scaffolding | Types of Scaffolding

What Is Scaffolding? Scaffolding is a temporary platform used to lift, support, and supply materials during a … [Read more...]

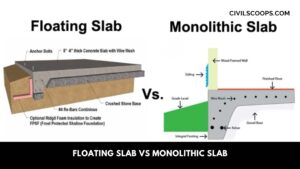

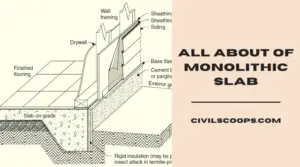

Floating Slab Vs Monolithic Slab | What Is Monolithic Slab | What Is Floating Slab

What Is a Monolithic Slab? The word Monolithic means “all in a single pour” so in construction where Monolithic … [Read more...]

EPDM Flat Roof Installation | Cost of EPDM Flat Roof | How to Install EPDM Rubber Roof | EPDM Flat Roof Installation

What Is EPDM? EPDM, known for its epdm rubber roofing cost effectiveness, is an extremely durable synthetic rubber … [Read more...]

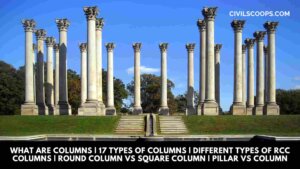

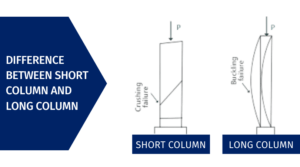

What Are Columns | Types of Rcc Column | Round Column Vs Square Column | Pillar Vs Column

Introduction of Columns The whole structure of a building is comprised of different types of components. The column is … [Read more...]

100 Ways to Save Energy at Home: Energy Saving Tips

100 Ways to Save Energy at Home: Energy Saving Tips There are several ways to save energy at your home. Here are some … [Read more...]

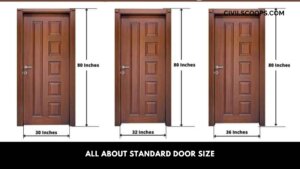

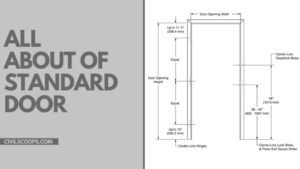

What Is Standard Door Size | Standard Door Height | Standard Door Width | Standard Door Frame Size

What Is Door? The door is the internal part of our house; without the door, we can not access our house or room. A … [Read more...]

How to Spot Hail Damage on Roof | Metal Roof Hail Damage | What Does Hail Damage Do to a Roof | 6 Signs of Hail Damage on a Roof

How to Spot Hail Damage on Roof? Generally, when assessing hail damage metal roof vulnerabilities, it’s evident that … [Read more...]

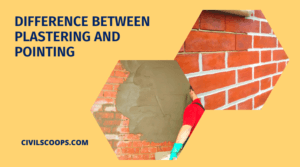

16 Definition Related for Plastering Work | Tools For Plastering | Preparation of Background for Plastering

Definition Related for Plastering Work Plasterwork is construction or ornamentation done with plaster, such as a layer … [Read more...]

All About Construction Contract

What Is Construction Contract? Contract, especially when we talk about types of contract in construction and types … [Read more...]

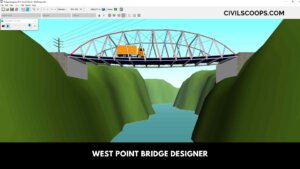

West Point Bridge Designer

What Is West Point Bridge Designer? West point bridge designer software for designing of the bridge. Bridge … [Read more...]

Civil Engineering Software | List of Civil Engineering Software | List of Engineering Software

Introduction of Civil Engineer Software There is a comprehensive civil engineering software list accessible which are … [Read more...]

What Is Staircase | Location of Staircase| Riser and Tread Calculation | How to Calculate Riser and Tread Dimensions

What Is Staircase? The Staircase, or staircase meaning, is basically a structure that is used for the vertical … [Read more...]

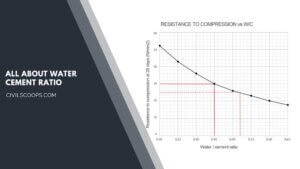

What Is Water Cement Ratio | Water-Cement Ratio and Concrete Strength | Role of Water in Concrete

What Is Water Cement Ratio? It is the ratio of cement and water utilized in the preparation of concrete. The … [Read more...]

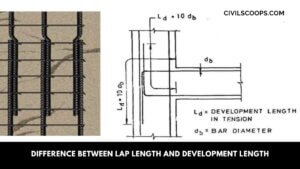

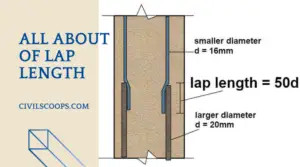

Difference Between Lap Length and Development Length

What is Lap Length? Lap Length is required when bars placed short of their required length (due to nonavailability … [Read more...]

Rotten Egg Smell In Car | Car Smells Like Rotten Eggs

Introduction of Rotten Egg Smell In Car Your senses are always essential when you’re driving your car. It would help if … [Read more...]

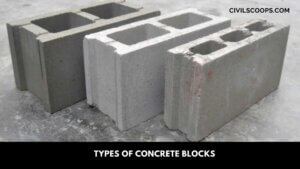

Types of Concrete Blocks

Introduction of Concrete Blocks Concrete blocks, widely known as Concrete Masonry Unit (CMU), encompass various types … [Read more...]

Basic Plumbing System | Drainage System | Supply and Drainage Subsystems

Basic Plumbing System Plumbing follows the basic laws of nature – gravity-pressure, water seeking its own … [Read more...]

Construction Risk Management | Contractor Risk Management | Construction Risk Register | What Is Construction Management at Risk

Information of Construction Risk Management Construction risk management is a long steep process, in which we have to … [Read more...]

Properties of Sand | Physical Properties of Sand | Chemical Properties of Sand

Properties of Sand It can be used as soon as it is obtained from the source. Contains binding content (5-20 per cent), … [Read more...]

What Is Recycled Concrete Aggregate | Importance of Recycled Concrete Aggregate | Crushed Concrete Driveway Pros and Cons

What Is Recycled Concrete Aggregate? Recycled concrete aggregates ( RACs ) are an alternative to the use in … [Read more...]

H-Beam vs I-Beam | What Is H-Beam | What Is I-Beam

H-Beam vs I-Beam H Beam Vs I Beam, Structural steel has been used extensively in the construction of commercial … [Read more...]

What Is Lightweight Concrete | Properties of Lightweight Concrete | Uses of Lightweight Concrete | Advantages & Disadvantages of Lightweight Concrete

What Is Lightweight Concrete? Lightweight concrete can be defined as a type of concrete that includes an expanding … [Read more...]

Specific Gravity Test of Bitumen | Procedure of Specific Gravity Test of Bitumen | Result of Specific Gravity Test of Bitumen

Specific Gravity Test of Bitumen By the specific gravity test on bitumen, we are determining the bitumen specific … [Read more...]

Water Damage in Bathroom | How to Fix a Water Damage Bathroom | Signs of Water Damage in Bathroom

Introduction of Water Damage in the Bathroom In the construction of the foundation of a structure, especially when … [Read more...]

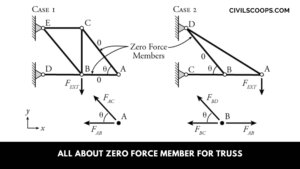

What Is Zero Force Member for Truss | How to Identification of Zero Force Members in Truss

What Is Zero Force Member? In a truss system, some members are not carrying any force. This called a zero-force … [Read more...]

What Is Bridge Abutment | 5 Types of Abutments

Bridge Abutment Means As a component of a bridge, the abutment provides the vertical support to the bridge … [Read more...]

Difference Between Flexible Pavement and Rigid Pavement | What is Pavement | Types of Pavement

What is Pavement? Pavement or carriageway, often referred to as pavement meaning, is that part of the road or … [Read more...]

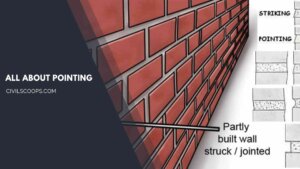

What Is Pointing | 7 Types of Pointing | Keyed Pointing

What Is Pointing? Pointing is the term given to the “finish” that sits between the bricks or stone used to build … [Read more...]

Introduction of Gantry Girder | Load on Gantry Girder | Types of Load on Gantry Girder

Introduction of Gantry Girder The gantry girders are girders which supports the loads that are transmitted through the … [Read more...]

What Is Scrap Value and Salvage Value | Types of Value in Civil Engineering

What Is Scrap Value and Salvage Value in Civil Engineering? Scrap Value in Civil Engineering The value of … [Read more...]

Corian Countertops | What Are Corian Countertops | How to Maintain Corian Countertops | How to Clean Corian Countertop

What Are Corian Countertops? Corian is the trade name of a complex plane countertop made by DuPont. This countertop … [Read more...]

All About Repointing Brick | What Is Repointing Brick | When You Need Brick Repointing | Types of Repointing Brick

What Is Repointing Brick? Repointing brick is generally known as repointing of brick or repointing of brickwork. … [Read more...]

All About Prismatic Compass Surveying

What Is Prismatic Compass Surveying? What is prismatic compass surveying? It is the kind of prismatic compass … [Read more...]

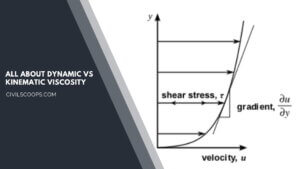

Dynamic Vs Kinematic Viscosity (Difference & Definition)

What Is Viscosity? Viscosity is a basic characteristic property of all liquids. When a liquid flows, it’s an inner … [Read more...]

All About Mix Design

What Is Mix Design? Concrete mix design is a procedure of manufacture of concrete with an ideal proportion of … [Read more...]

Different Types of Stucco | Information of Stucco | Types of Stucco Finishes | Stucco Maintenance

Introduction of Stucco Stucco has been a viral decorative coating for the building. In ancient times, Stucco originated … [Read more...]

All About Wall Putty | What Is Wall Putty | What Is Wall Putty Used For | Disadvantages of Wall Putty | Types of Wall Putty

What Is Wall Putty? Wall putty is basically a substance that is applied to the internal wall of any house to … [Read more...]

Definition Efflorescence | Efflorescence in Concrete

How to Define Efflorescence? Effloresces, often referred to as the efflorescence meaning, is a crystalline set down … [Read more...]

What Is Micro Concrete | How to Apply Micro Concrete | What Are the Benefits of Micro Concrete | How Is Micro Concrete Used

What Is Micro Concrete? Micro concrete is a cement-based coating that is used as a thin layer on different surfaces … [Read more...]

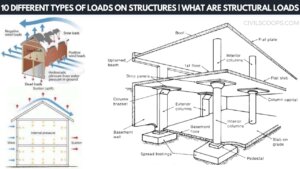

Live Load Vs Dead Load | What Is Load in Civil

What Is Load in Civil? There are different types of load than working on a structure, the design, location, and … [Read more...]

Different Types of Couches for Home

What Are the Couches? Couches are generally known as sofas. It is used for peaceful sleep, relaxing, and sitting … [Read more...]

Concrete Material Calculation / Concrete Quantity

What is Material Calculation In Civil? In civil material calculation, especially when it comes to concrete material … [Read more...]

All About Turbidity of Water | What Is Turbidity of Water | Procedure of Turbidity of Water Test

What Is Turbidity of Water? Turbidity of water is a property of water or liquid by which we can measure the … [Read more...]

What Is Moment Frame | Types of Moment Frames

Introduction of Moment Frame The Moment Frames are the fundamentals structure which consists of two-dimensional series … [Read more...]

What Is a Flight of Stairs | Types of Stairs | How Many Stairs in a Flight | Some Facts About Stairwells

What Is a Flight of Stairs? A flight of stairs is a set of steps between two floors or two landings. Flight of … [Read more...]

What Is Concrete Forms | Types of Concrete Forms, Uses, Advantage, Disadvantages and Applications

What Is Concrete Form? A concrete form is a system of formwork for reinforced cement concrete which is made with … [Read more...]

New Civil Engineering Technology 2023

New Technology Civil Engineering Here, list of construction inventions are as follows. Self-Healing Concrete … [Read more...]

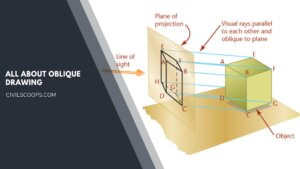

Understanding Oblique Drawing: Techniques, Examples, and Applications

What Is Oblique Drawing? Oblique Drawing is a type of projective drawing in which the frontal lines are given in … [Read more...]

All About No Hot Water in The House

Introduction of No Hot Water in House Dealing with no hot water causes in the house presents several challenges, but … [Read more...]

Repairing a Burst Pipe | Burst Pipe Repair Cost | Fixing a Busted Water Pipe | How to Fix a Burst Pipe | Pipes Burst Under House

Introduction of Repairing a Burst Pipe Burst pipe means bursting of pipe in different circumstances as well as in … [Read more...]

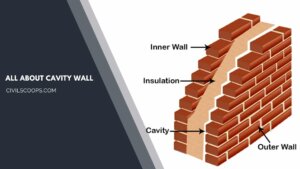

What Is a Cavity Wall | How to Build a Cavity Wall | Cavity Wall Detail | Cavity Wall Thickness | Cavity Wall Insulation Pros and Cons | Brick Cavity Wall

What Is a Cavity Wall? A cavity wall consists of a hollow space between them. The cavity walls normally consist of … [Read more...]

What Is the Best Foundation for a House | Types of House Foundations | How to Build a House Foundation | What Is the Strongest Foundation for a House

Introduction of Foundation for House Foundation, often referred to as house foundation types, is one of the most … [Read more...]

How to Get Wet Blood Out of Carpet?

How to Get Wet Blood Out of Carpet? Wet blood on the carpet is a very problematic thing and blood is type of stain … [Read more...]

What Is Timber | Types of Timber | What Is Mass Timber Products | Type of Mass Timber in Construction

What Is Timber? Timber is a simply wooden structure which is converted into the shape of beams and planks. Another … [Read more...]

All About of Tiles | What Are Tiles | How to Calculate Number of Tiles Needed for a Room

Purpose of Tile Flooring in the House There are some essential purposes behind fitting tiles in the home, It is … [Read more...]

All About Chalk Paint | What Is Chalk Paint | How to Fix the Chalking Paint Problem

What Is Chalk Paint? Initially founded by the common paint variety Annie Sloan, ”chalk paint” is politically an … [Read more...]

How to Remove Paint from Concrete Without Chemicals | Procedure to Remove Paint from the Concrete Surface | How to Get Spray Paint Off Concrete

Instruction of Remove Paint from Concrete Concrete is a widely used building material in the construction industry. … [Read more...]

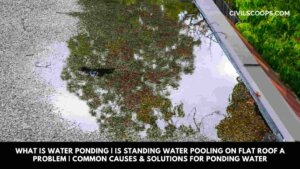

What Is Water Ponding | Is Standing Water Pooling on Flat Roof a Problem | Common Causes & Solutions for Ponding Water

What Is Water Ponding? As in Construction Industry, National Roofing Contractors Association(NRCA) described Water … [Read more...]

Water Leakage from Ceiling | Water Leakage from Ceiling | How to Stop Water Leakage from Ceiling

Information of Water Leakage from Ceiling Water is one of the most important resource but it is also the biggest enemy … [Read more...]

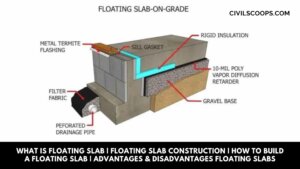

What Is Floating Slab | Floating Slab Construction | How to Build a Floating Slab | Advantages & Disadvantages Floating Slabs

What Is a Floating Slab? These slabs are constructed in two stages. At the first stage, the footings are poured … [Read more...]

Introduction to Stair Landing | What Is Stair Landing | Stair Landing Dimensions

Introduction to Stair Landing Flight of stairs landing is a significant part of a structure giving admittance to … [Read more...]

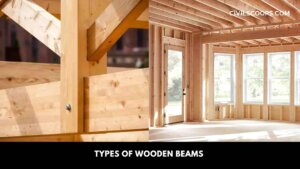

Types of Wooden Beams

What is Wooden Beam? A wood beam is structural support made from wood. They are most commonly used in wood frame … [Read more...]

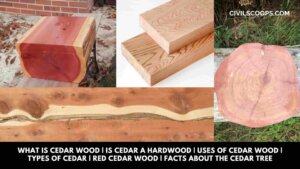

What Is Cedar Wood | Is Cedar a Hardwood | Uses of Cedar Wood | Types of Cedar | Red Cedar Wood | Facts About the Cedar Tree

What Is Cedar Wood? Cedar is a very durable wood. It lasts long for decades. Cedar woods have a natural resistance … [Read more...]

What Is Skillion Roof | Types of Skillion Roof | Uses of Skillion Roof | How to Build a Skillion Roof

What Is Skillion Roof? The Skillion roof is a unique type of roof which has just one unvarying isolated surface. … [Read more...]

What Is Gypsum Boards? | Properties of Gypsum Board | Types of Gypsum Board | Advantages & Disadvantages of Gypsum Board

Information of Gypsum Boards There are various new innovative materials are available in the market which enhances the … [Read more...]

What Is Louvered Door? | 10 Different Types of Louvered Doors Available in Market

Induction of Louvered Door Doors are one of the important parts of our home which provides the horizontal movements of … [Read more...]

15 Types of Porch Used for Home | What Is Porch | How to Infer What Porch You Need

Information of Porch The porch is the most important section and front part of the structure whenever we enter the … [Read more...]

What Is an Ice Dam | How to Remove Ice Dam From Roof | What Causes Ice Dams on Roof | How to Remove Ice Dams

What Is an Ice Dam? Generally, ices are very beautiful in nature, but they can also cause many problems like … [Read more...]

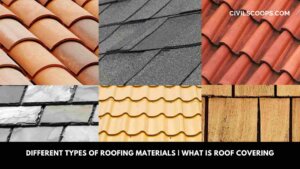

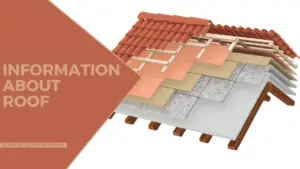

Different Types of Roofing Materials | What is Roof Covering

Introduction of Roof Covering Material A roof may be defined as the upmost part of the structure. A roof is a top … [Read more...]

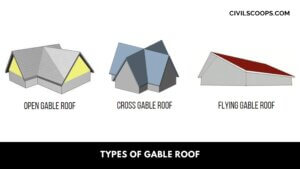

Types of Gable Roof

Types of Gable Roof Here, the different types of gable roof are as follows Box Gable Roofs Front Gables … [Read more...]

What Is Salt Concrete Finish | How to Create a Salt Finish | Rock Salt Concrete Finish Installation Procedure

What is Salt Concrete Finish? As one of the older, more conventional decorative concrete finishes, salt finish … [Read more...]

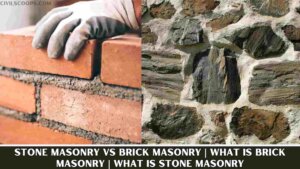

What Is Stone Masonry | Types of Stone Masonry

Masonry means construction of buildings utilizing building blocks such as stone, bricks, and concrete blocks, etc.. … [Read more...]

What Does Hail Damage Look Like on a Roof | Identifying Hail Damage to Your Roof | Wood Shingles Hail Damage

What Does Hail Damage Look Like on a Roof? Generally, shingles of the roof react differently when they are struck … [Read more...]

All About Marble Flooring | What Is Marble Flooring | Types of Marble Flooring

Information Marble Flooring For thousands of years to create elegant floors Marble has been used widely. And today it … [Read more...]

What Is Asphalt Paving | Types of Asphalt Paving | What Does Asphalt Cost | Hot Mix, Warm Mix, and Cold Mix Asphalt

Introduction of Asphalt Paving Asphalt is also known as bitumen. Asphalt is a sticky, black, largely thick liquid or … [Read more...]

What Is Roof Replacement | What Is Roof Repair | Difference Between Roofing Repair and Replacement

Introduction of Roof Repair Vs Roof Replacement When your roof became older and the water enters the house then you … [Read more...]

Concrete Construction Tools for Construction Sites

Introduction of Concrete Construction Tools for Construction Sites Concrete is one of the most widely used building … [Read more...]

Construction Technology | Types of Construction Technology You Will Use in the Future

Information Of Construction Technology The use of Technology and Digitalization is increasing rapidly in almost every … [Read more...]

What Is Mansard Roof | Mansard Roof Replacement Cost | Advantages and Disadvantages of Mansard Roof

What Is Mansard Roof? Generally, this mansard roof is also known as a French roof or curb roof, which is a combined … [Read more...]

What Is Concrete Screed | Concrete Screed Specifications | Characteristics of Concrete Screed | Advantages & Disadvantages of Concrete Screed

Introduction of Concrete Screed A construction element which is available in a range of thickness to bring forth the … [Read more...]

Fly Ash in Concrete | Advantages & Disadvantages of Fly Ash Concrete | Use of Fly Ash in Concrete | Applications for Fly Ash Concrete | Benefits of Fly Ash Concrete

What Is Fly Ash? Fly ash is a fine powder that would be a by-product of the combustion of pulverized coal in power … [Read more...]

What Is Hail Damage | How to Inspect a Wooden Roof for Hail Damage | Roof Types and Hail Affects on Roof

What Is Hail Damage? In simple words, Hail can be defined as a crystallized piece of snow. Many a time hail is … [Read more...]

Hail Damage to Asphalt Shingles | Introduction of Hail Damage to Asphalt Shingles | What Is Hail and How Does It Damage the Asphalt Shingles

Introduction of Hail Damage to Asphalt Shingles As humans came into this world, at first, they started living in caves … [Read more...]

Built Up Roof with Gravel | Why Do They Put Gravel on Flat Roofs | Purpose of Gravel on a Flat Roof | Added Benefits of Bur Flat-Roof Gravel

Introduction of Built-Up Roof with Gravel BURs (also known as tar and gravel roofs) are a well-known and popular form … [Read more...]

Water Damage from Water Heater | How to Repair Water Damage from a Leaking Water Heater

Water Damage from Water Heater Water damage from a water heater is now a common problem in all residential, … [Read more...]

Roof Leak Detection | What Can a Leaking Roof Due to My Home | What Are the Symptoms of a Leaking Roof | What Causes a Roof to Leak

Roof Leak Detection Here, some sins of 11 different types of roof leak sections are as follows. At first, we … [Read more...]

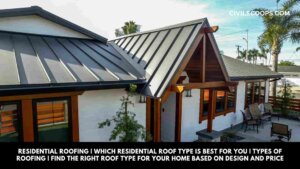

Residential Roofing | Which Residential Roof Type Is Best for You | Types of Roofing | Find the Right Roof Type for Your Home Based on Design and Price

Introduction of Residential Roofing Residential roofing is different from commercial roofing in the terms of materials, … [Read more...]

Repairing Water Damaged Wall | How to Repairing Water Damaged Wall | How to Fix Water Damaged Wall

Introduction of Water Damaged Wall Sometimes water can be highly destructive to the building materials. At the meeting … [Read more...]

History of Dutch Gable Roof | What Is Dutch Gable Roof | How to Build Dutch Gable Roof | Advantages & Disadvantages of Dutch Gable Roof

Introduction of Dutch Gable Roof The Dutch gable roof is also called a gablet that consists at the top of a roof of a … [Read more...]

All About Exterior Paint | What Is Exterior Paint | Top 10 Exterior Paint Companies in India 2022

What Is Exterior Paint? Exterior paints state that paint is used outdoors in buildings, offices, and other … [Read more...]

How to Fix Damaged Roof Shingles | How Often Should You Replace Your Roof Shingles | Replacing Roof Shingles

How to Fix Damaged Roof Shingles? There are have many steps for the fix to damaged roof shingles that’s are … [Read more...]

How to Reduce Construction Cost (Tips)

How to Reduce Construction Cost ( Tips) By flowing some steps we can reduce the cost of the construction that is … [Read more...]

How to Improve Your Indoor Air Quality at Home?

How to Improve Your Indoor Air Quality at Home? When outside air corruption offers a treat, it must be simple to ignore … [Read more...]

All About Green Concrete | What Is Environmentally Friendly Concrete

Introduction of Green Concrete In the history of the concrete world, green concrete is a revolution topic in Denmark; … [Read more...]

Earthmoving Equipment With Picture

What is Earthmoving Equipment? As the name might suggest, earth-moving equipment generally refers to any piece of … [Read more...]

How to Prevent Home Theft (Tips)

How to Prevent Home Theft (Tips) Home theft is a common problem in recent times, so there are some easy & common … [Read more...]

10 Different Types of Kitchen Sinks | Kitchen Sinks

What Is a Sink? A sink is known by many names like washing basin, washing bowl, and hand basin. Some people just … [Read more...]

Land Moving Equipment

Land Moving Equipment For excavation purposes, earthwork, grading of soil, rock etc. Land-moving equipment are commonly … [Read more...]

Types of Renewable Energy Resources

Types of Renewable Energy Resources In all over the world, scientists have found six number of renewable energy … [Read more...]

All About Site Preparation | What Is Site Preparation | Types of Site Preparation

What Is Site Preparation? Site preparation affects many works such as destruction of old alive design, the gap of … [Read more...]

How to Remove Stains from Wood?

How to Remove Stains from Wood? If you’re renewing your wood products or apparatus, you must remove old wood product … [Read more...]

What Is Pipe Fittings | Types of Pipe Fittings

What Is Pipe Fittings? Pipe fittings are the process where we divert the flow of the water by using piping … [Read more...]

How to Kill Tree Roots?

How to Kill Tree Roots? If it is not necessary then you do not kill the tree roots, because after cutting the tree … [Read more...]

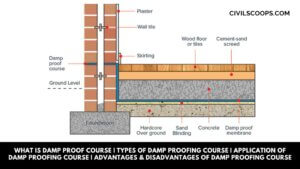

What Is Damp Proof Course | Types of Damp Proofing Course | Application of Damp Proofing Course | Advantages & Disadvantages of Damp Proofing Course

What Is Damp Proof Course? The damp proof course is an important layer for all walls of the building that is … [Read more...]

What Is GIS In Surveying | Definitions of GIS | Parts & Work Flow of GIS | Advantages of GIS

What Is GIS In Surveying? GIS stands for a geographic information system. An information system is a computer … [Read more...]

Waterproof a Concrete Roof | Old Concrete Roof Waterproofing | Concrete Roof Sealant Flat Concrete Roof Waterproofing

Waterproof a Concrete Roof At a first, the concrete roof is only used for commercial buildings, but nowadays to … [Read more...]

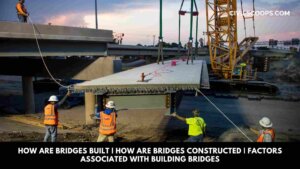

How Are Bridges Built | How Are Bridges Constructed | Factors Associated with Building Bridges

How Are Bridges Built? As human beings started to expand across lands and territories, we had a structure to … [Read more...]

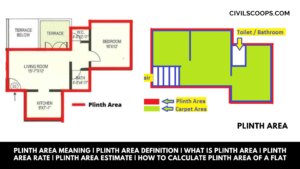

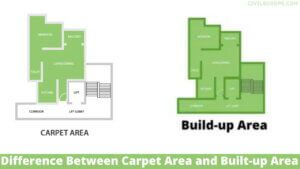

Plinth Area Meaning | Plinth Area Definition | What Is Plinth Area | Plinth Area Rate | Plinth Area Estimate | How to Calculate Plinth Area of a Flat

Plinth Area Meaning: The plinth area means we know the built-up covered area at the floor level of the basement or of … [Read more...]

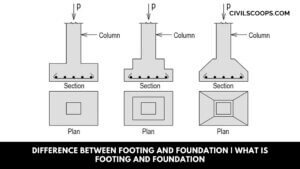

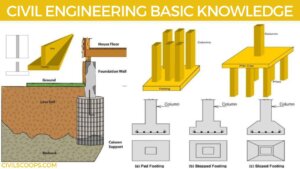

Difference Between Footing and Foundation | What is Footing and Foundation

What is Footing? Foundation Definition: The footing is generally supporting columns and may be round, square, or … [Read more...]

8 Different Methods of Concrete Crack Repair | How to Select Suitable Method of Concrete Crack Repair

Introduction of Concrete Repair Method Concrete is one of the most widely used building materials in the construction … [Read more...]

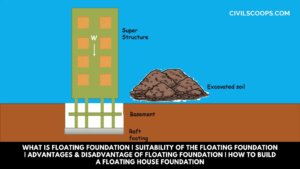

What is Floating Foundation | Suitability of the Floating Foundation | Advantages & Disadvantage of Floating Foundation | How to Build a Floating House Foundation

Introduction of Floating Foundation Foundation is one of the most important parts of the structure which carries the … [Read more...]

All About Wood | Types of Wood | What Is Wood | Advantages of Wood

What Is Wood? Wood is a natural product and one of the most beautiful materials, providing a long-term sustainable … [Read more...]

Top 45 Greatest Constructions of Gothic Architecture in World | What Is Gothic Architecture | Unique Features Of Gothic Architecture

Introduction of Gothic Architecture Since the day the human left caves and started living in houses, the birth of … [Read more...]

What Is Spalling Concrete | Causes of Spalling in Concrete | Repairing Concrete Spalding

What Is Spalling of Concrete? Spalling of concrete at fires is the breaking-off of layers of a concrete surface in … [Read more...]

What Are Curb and Gutter | Types of Curb and Gutter| Advantages & Disadvantages of Curb and Gutter

Introduction of Curb and Gutter There are various types of Curbs and gutters are used in the construction of light and … [Read more...]

9 Curing of Concrete Methods | What Is Curing of Concrete | Why Curing Is Important | Minimum Curing Period for Concrete Cement | How Long Does It Take for Concrete to Dry

What Is Curing of Concrete? Curing performs a crucial role in the growth as well as the resilience of concrete … [Read more...]

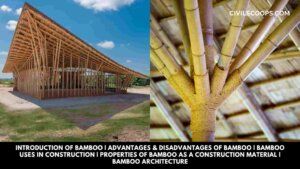

Introduction of Bamboo | Advantages & Disadvantages of Bamboo | Bamboo Uses in Construction | Properties of Bamboo as a Construction Material | Bamboo Architecture

Introduction of Bamboo Bamboo is one of the oldest and traditional construction materials used in different … [Read more...]

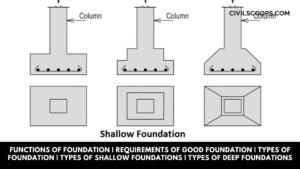

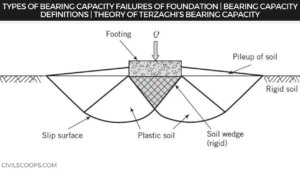

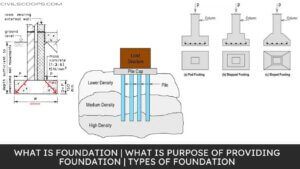

Functions of Foundation | Requirements of Good Foundation | Types of Foundation | Types of Shallow Foundations | Types of Deep Foundations

Introduction of Foundation: Foundation is one of the most important parts of the building. The foundation plays a … [Read more...]

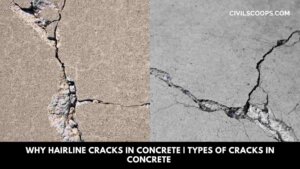

Why Hairline Cracks in Concrete | Types of Cracks in Concrete

Why Hairline Cracks in Concrete? Hairline Cracks in concrete are extremely common but often misunderstood. Once an … [Read more...]

What Is Brutalist Architecture | Brutalist Design | Brutalism Architects Buildings & Houses | What Is Neo-Brutalism

History of Brutalist Architecture: The history of brutalist architecture goes back three years the 1940s to the … [Read more...]

Difference Between Marble and Granite | What Is Marble and How Is It Made | What Is Granite and How Is It Made

Introduction of Marble and Granite Someone busy planning the interior of their home, let me tell you research is very … [Read more...]

What Is Paint Finishes for Walls | Types of Paint Finishes | Types of Paint Finishing

What Is Paint Finishes for Walls? If you have selected a fresh paint color for your home makeover design, you may … [Read more...]

10 Principles of Architecture | What Is Architecture | Why Need Design Principles in Architecture

What Is Architecture? The techniques and art of making the layout of buildings and constructing the building are … [Read more...]

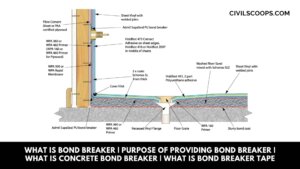

What Is Bond Breaker | Purpose of Providing Bond Breaker | What Is Concrete Bond Breaker | What is Bond Breaker Tape

What Is Bond Breaker? In the modern construction industry, the term “prefabrication” or “precast” holds a significant … [Read more...]

Concrete Batching | Concrete Batching Plant | Types of Batching of Concrete | Various Factors Affecting the Choice of Batching System

All About of Concrete Batching Generally, concrete is a multipurpose, eco-friendly construction material that is … [Read more...]

What Is Superstructures | Difference Between Load-Bearing and Framed Structures

What Is Superstructures? The portion above the ground level and below the ground floor level is known as a plinth. … [Read more...]

What Color Helps You Fall Asleep | Best Bedroom Colors for Sleep 2022

What Color Helps You Fall Asleep? You may apply soft pillows, a glossy blanket, a solid cushion, and slow music … [Read more...]

Difference Between Fat Lime and Hydraulic Lime | What Is Fat Lime | What Is Hydraulic Lime

What Is Fat Lime? Fat lime is also known as Rich lime, High calcium lime, Pure lime, White lime. It is obtained by … [Read more...]

All About Waffle Slab Foundation | What is Waffle Slab Foundation | Waffle Slab Foundation Pros and Cons | Features of Waffle Slab Foundation

What is Waffle Slab Foundation? The waffle slab foundation system is also called a waffle mat foundation. The … [Read more...]

What Is Transportation Engineering | Major Disciplines of Transportation Engineering | What Do Transportation Engineers Do

What Is Transportation Engineering? Transportation plays an important role in the development of the country. … [Read more...]

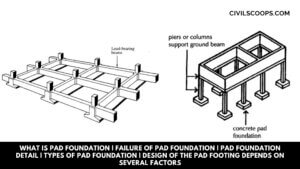

What Is Pad Foundation | Failure of Pad Foundation | Pad Foundation Detail | Types of Pad Foundation | Design of the Pad Footing Depends on Several Factors

What Is Pad Foundation? Pad footing is the type of shallow footing used to spread a concentrated load through … [Read more...]

Types of Roof Tiles | Tile Roof Replacement | Tile Installation Cost | Roofing Tile Price | Ceramic Tile Price Per Square Foot | Tile Installation Factors

Types of Roof Tiles There are various types of tiles that are available in the market. There are mainly twelve … [Read more...]

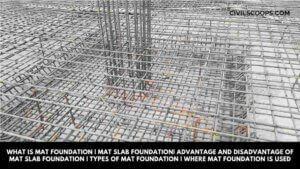

What Is Mat Foundation | Mat Slab Foundation| Advantage and Disadvantage of Mat Slab Foundation | Types of Mat Foundation | Where Mat Foundation Is Used

What Is Mat Foundation? Mat foundation is also called a raft foundation. Generally, it is a continuous slab laying … [Read more...]

What Is Soil Vent Pipe | How Does Soil Stack Pipe Works | Soil Vent Pipe Material | Types of Plumbing System

Introduction of Soil Vent Pipe The plumbing system and the Drainage of the important aspect of the building because … [Read more...]

Shotcrete Vs Gunite | What Is Gunite | Advantage & Disadvantage of Guniting Process | What Is Shotcrete | Advantage & Disadvantage of Shotcreting

Introduction of Shotcrete Vs Gunite Shotcreting and Guniting are one of the most important and widely used … [Read more...]

What Is Hydraulic Cement | Hydraulic Cement Uses | How to Apply Hydraulic Cement | Advantages & Disadvantages of Hydraulic Cement

Introduction of Hydraulic Cement Water is the biggest enemy of the Civil Engineering Structures. Water can cause great … [Read more...]

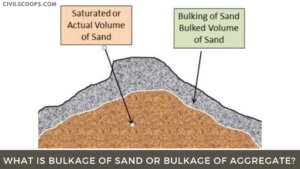

What Is Bulking of Sand | Bulking of Sand Is Caused Due to | Bulking of Sand Graph | Bulking of Sand Formula | Test Procedure to Determine the Bulking of Sand

What Is Bulking of Sand? The free moisture content in the fine aggregate or sand results in bulking of its … [Read more...]

All About Sandbag Cofferdam | What Is Sandbag Cofferdam | Advantages of Sandbag Cofferdam

What Is Sandbag Cofferdam? The cofferdam is a short-term design that supports the building activity behind the … [Read more...]

Top 20 AAC Block Company in India

Introduction Top 20 AAC Block Company in India Best AAC Block Company in India or which AAC Block brand company should … [Read more...]

Detail of Beam Connection | Simple Framing Connection | Semi-Rigid Framing Connection | Rigid Frame Connection

Detail of Beam Connection Beams are connected to the main beams or into the columns. The design of these … [Read more...]

All About Transom Window | What Is a Transom Window | Types of Transom Window

What is a Transom? The transom is blank of the window, but it is one kind of beam which divide the upper of the … [Read more...]

What Is Plumbing Joint | 11 Types of Plumber Joint | Different Types of Pipe Joints and Where Are Use

What Is Plumbing Joint? Pipes are connected with the help of joints. A variety of joints are used in an assembly of … [Read more...]

20 Vastu Tips Before House Construction | Vastu Tips for Different Locations of House | Scientific Facts of Vastu Location of Rooms

Introduction of Vastu Tips for Home If you live in India then you must know about the word ‘Vastu‘. But if you do not … [Read more...]

All About Tile Popping | What Is Tile Popping | Reason for Tile Popping | How to Fix Popped-Up Tiles

What Is Tile Popping? Tile popping is a phenomenon in which the floor tiles pop out, crack, or flex, causing … [Read more...]

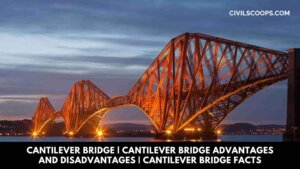

Cantilever Bridge | Cantilever Bridge Advantages and Disadvantages | Cantilever Bridge Facts

Introduction of Cantilever Bridge Cantilever Bridge is a special type of bridge which is constructed by using … [Read more...]

What Are Plastic Roads | How to Make Plastic Roads | Who Invented Plastic Roads | First Man Made Plastic Road | Advantages & Disadvantages of Plastic Roads

What Are Plastic Roads? Plastic Roads are roads that are made completely of plastic or composites of plastic made … [Read more...]

20 Types of Construction Materials | What Is Building Materials List | Construction Materials List | Different Materials Used in Building Construction

Introduction of Different Materials Used in Building Construction Building Materials are an essential element in the … [Read more...]

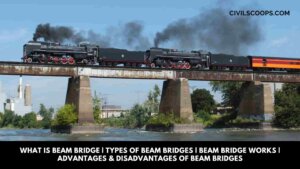

What Is Beam Bridge | Types of Beam Bridges | Beam Bridge Works | Advantages & Disadvantages of Beam Bridges

Introduction of Beam Bridge Bridges are one of the most important parts of the Infrastructure of the country which … [Read more...]

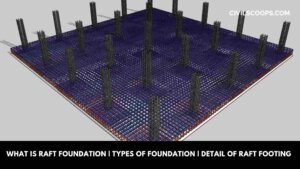

What Is Raft Foundation | Types of Foundation | Detail of Raft Footing

What is a Raft Foundation? A raft foundation, also called a raft foundation, is essentially a continuous slab … [Read more...]

All About Marble Price | What Is Marble | Types of Marble Available in India

Introduction of Marble Price Marble is an easily available material in the market. It is used on floors and tables, … [Read more...]

What Is Inverted Beam | Advantages of Inverted Beam | Purpose of Inverted Beam

What Is Inverted Beam? The Inverted beam is a reinforced concrete beam, different types shape of beam-like I beam, … [Read more...]

All About Door Hinges | 13 Different Types of Door Hinges | What Is Door Hinges | Types of Door Hinges

Introduction of Door Hinges Hinge recreates a vital role in keeping your door in its right position. Hinges are … [Read more...]

All About Load Bearing Wall Construction | How to Tell If a Wall Is Load Bearing | Load Bearing Beam | Non-Load Bearing Wall | Non-Load Bearing Wall Framing

Load Bearing Wall Construction: Load Bearing Wall Construction was most widely used form of construction for large … [Read more...]

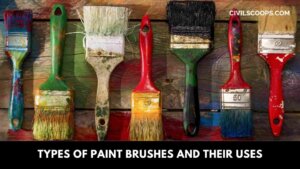

Types of Paint Brushes and Their Uses

Types of Paint Brushes and Their Uses Selecting current paint for your house is a great dramatic actor. We can expand … [Read more...]

What Is Guniting | How to Set Guniting Systems | Advantage of Guniting | Disadvantage of Guniting

What Is Guniting? The process was applicable in construction work, where it applied in the stabilization of prone … [Read more...]

All About Floating Houses | What Are Floating Houses | Type of Floating Houses | What Is Floating Building | Floating Architecture Examples

What Are Floating Houses? Floating house is generally a modern type of technology which is very popular in recent … [Read more...]

What Is Calacatta Quartz | 12 Types of Calacatta Quartz

What Is Calacatta Quartz? Calacatta quartz is hardware that features calacatta marmoreal, a model of marmoreal. The … [Read more...]

What Is Pitched Roof | 8 Types of Pitched Roof | Advantages of Pitched Roof

Instruction of Pitched Roof From the beginning of civilization, roofs are one of the essential structural components, … [Read more...]

What Is Bitumen and Bitumens Types?

What is Bitumen? Bitumen is a viscous, solid, or nonvolatile liquid. Bitumen is a complex and complected colloid … [Read more...]

36 Different Types of Plumbing Valve

Plumbing Valve A plumbing valve is a system that is installed in the plumbing system. Plumbing is generally defined … [Read more...]

What Is Sewage Pump | Types of Sewage Pump | Advantages and Disadvantages of Sewage Pump

What Is a Sewage Pump? A sewage pump will apply to move sewage liquids and stability from one place to other. The … [Read more...]

All About Bathroom Accessories | 28 Different Types of Bathroom Accessories

What Are Bathroom Accessories? The bathroom needs every section of the house. Now, bathrooms are essential for us. … [Read more...]

All About Energy-Efficient Homes

Why Are Energy-Efficient Homes Necessary? We are staying in a production where regular energy root will apply at a … [Read more...]

Commercial Building Roof Types | What is Commercial Building Roof

What is Commercial Building Roof? Commercial roofs are available in the marketplace in different types and … [Read more...]

All About Roof Overhangs | 10 Various Types of Roof Overhangs | Standard Roof Overhangs | Overhang Roof Design | Roof Overhangs on Houses

What Is Roof Overhangs? The distance between the house’s siding and the roof determines how much of an overhang … [Read more...]

What Is Canal | Classification of Canals | What Is Perennial Canal | Advantages & Disadvantages of Canal Irrigation

Introduction of Canal Canal plays one of the most important roles in transportation and global commerce. The … [Read more...]

All About Transportation of Concrete | What Is Transportation of Concrete | Methods for Transportation of Concrete

What Is Transportation of Concrete? Transportation of concrete is a process where we move freshly prepared concrete … [Read more...]

Bolt Vs Screw | What Is Bolt | What Is Screws

What Is Bolt? A bolt is an externally threaded fastener created for the insertion through holes in the assembled … [Read more...]

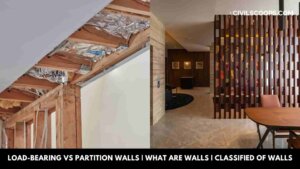

Load-Bearing Vs Partition Walls | What Are Walls | Classified of Walls

What Are Walls? Wall is a structural element that divides the space (room) into two spaces (rooms) and also … [Read more...]

All About Gabion Wall | What Is the Purpose of the Gabion Wall | Gabion Wall Construction

What Is the Purpose of the Gabion Wall? A gabion wall is an arresting division designed by mountain rock covered … [Read more...]

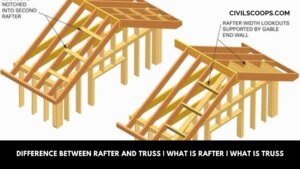

Difference Between Rafter and Truss | What Is Rafter | What Is Truss

Introduction of Difference Between Rafter and Truss. The Roof Framing system has undergone a huge revolution over the … [Read more...]

Fineness Modulus of Fine Aggregate | Fineness Modulus of Coarse Aggregate | Sieve Analysis of Fine Aggregate | Sand Zone Classification

Fineness Modulus of Fine Aggregate: The sand fineness module (fine aggregate) is an index number describing the … [Read more...]

What Is Skirting | Types of Skirting | Skirting Replacement Cost | Purpose of Skirting Boards | What Is Skirting Roof | Skirting on Bathroom

What Is Skirting? In civil engineering, skirting is one of the most important part. Skirting is constructed in … [Read more...]

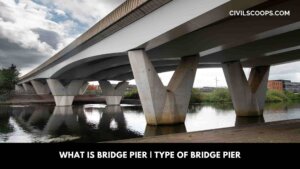

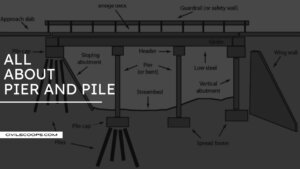

What Is Bridge Pier | Type of Bridge Pier

Introduction of Bridge Human beings have been constructing bridges for about four thousand years. The oldest and … [Read more...]

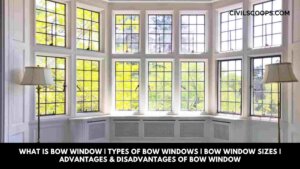

What Is Bow Window | Types of Bow Windows | Bow Window Sizes | Advantages & Disadvantages of Bow Window

What Is Bow Window? Bow window a type of window which is used to provide extra space to the homeowner. It creates … [Read more...]

Types of Kitchen Faucets

Types of Kitchen Faucets The below kinds of kitchen faucets will checklist. Touchless Kitchen Faucets Pull Out … [Read more...]

Difference Between Beam and Column | What Is Beam | What Is Column

What Is Beam? The beam is a structural element that stands against the bending. Mainly beam carries vertical … [Read more...]

What Is Drywall | Drywall Water Damage | Drywall Water Damage Repair | Cost to Repair Drywall Ceiling Water Damage

What Is Drywall? Drywall is basically a gypsum board which is installed on the interior wall of the house. Drywall … [Read more...]

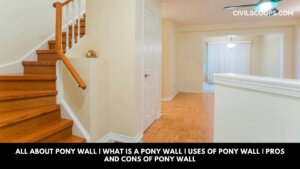

All About Pony Wall | What Is a Pony Wall | Uses of Pony Wall | Pros and Cons of Pony Wall

What Is a Pony Wall? The pony wall is small. Also, it is known as the ”knee wall,” and this wall is a short design … [Read more...]

Polysulfide Sealant Vs Polyurethane Sealant | Functions of Sealants | What Is Polysulphide Sealant | What Is Polyurethane Sealant

What Is Sealant? The term “Sealant” can be simplified as “sealing elements”. Sealants are the materials, which are … [Read more...]

What Is Mass Concrete | Properties of Mass Concrete | Advantage of Mass Concrete | Disadvantage of Mass Concrete |How Much Mass Density of Concrete

Mass Concrete: Large bridge piers, foundation, and such as dams like the massive structure, the mass concreting … [Read more...]

Nail Vs Screw | What Are Nail | What Is Screw

What Is a Nail? Nail is the most common fasteners used in construction. Up to the end of the Colonial period, all … [Read more...]

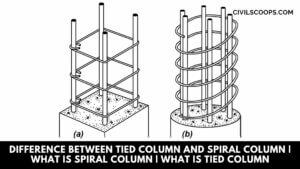

Difference Between Tied Column and Spiral Column | What Is Spiral Column | What Is Tied Column

Introduction of Column The column is one of the most important component parts of the structure. The main … [Read more...]

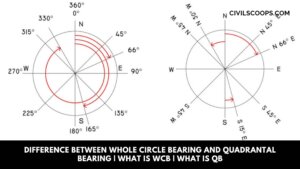

Difference Between Whole Circle Bearing and Quadrantal Bearing | What Is WCB | What Is QB

Introduction of WCB Vs. QB Whole circle bearing(WCB) and Quadrantal bearing(QB) are the two types of bearing which is … [Read more...]

What Is Mezzanine Floor | Types of Mezzanine Floor Construction | Features of Mezzanine Floors | Advantages & Disadvantages of Mezzanine Floors | Uses of Mezzanine Floors | Application of Mezzanine Floors

Mezzanine Floor The mezzanine floor is an intermediate floor of a building, below the open floor. At least twice as … [Read more...]

Types of Concrete Construction Joints | Tips on Placing Joints in Concrete | Tips on Placing Joints in Concrete

Concrete joints are used to compensate when concrete expands or shrinks with changes in temperature. Concrete joints … [Read more...]

13 Types of Houses With Pictures And Advantages and Disadvantages

Types of Houses The types of houses vary from old to new times. Due to turn of people live hood. Now a day’s sum of … [Read more...]

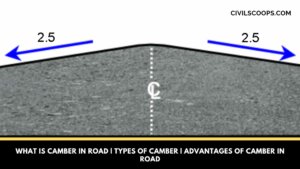

What Is Camber in Road | Types of Camber | Advantages of Camber in Road

What Is Camber in Road? It’s mostly found in the highways the median part of the road surface is elevated with … [Read more...]

What Are Columns | 17 Types of Columns | Different Types of Rcc Columns | Round Column Vs Square Column | Pillar Vs Column

Introduction of RCC Column The whole structure of a building is comprised of different types of components. The … [Read more...]

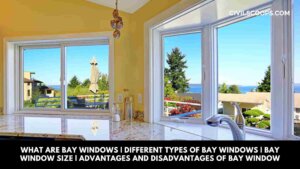

What are Bay Windows | Different Types of Bay Windows | Bay Window Size | Advantages and Disadvantages of Bay Window

Introduction of Bay Window Bay windows are generally a set of three or more windows that creates an outer angle beyond … [Read more...]

All About Driveways | What Are Driveways | Types of Driveways

What Are Driveways? When there is no offering their knowing factors, driveways can and must will express to be … [Read more...]

Luminous Flux Vs Lumens | What Is Luminous Flux | What Are Lumens | How Bright Is 1000 Lumens

What Is Luminous Flux? Luminous flux, or luminous power, is the measure of the perceived power of light. It … [Read more...]

23 Different Types of Cement Available in India and as Per Is Standards

23 Types of cement that are available and used in India. Ordinary Portland Cement 33 Grade Ordinary Portland … [Read more...]

Best Concrete Mix for Driveway Repair

Best Concrete Mix for Driveway Repair Concrete is the universally applied building object in the universe, and it’s … [Read more...]

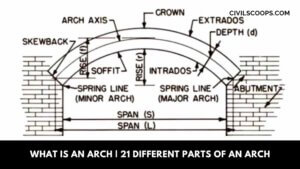

What Is an Arch | 21 Different Parts of an Arch

What Is an Arch? An arch is a design built up in a curved arc with a block arch system, which will connect with … [Read more...]

What Is Building Construction | Steps & Processes of Building Construction | Application of Building Construction | How to Do Planning of Building Construction

Definition of Construction Construction is the methodology of developing a building or infrastructure. … [Read more...]

How to Get Rid of Paint Smell

How to Get Rid of Paint Smell? The paint smell is one of the very annoying things in our house or room. We are … [Read more...]

23 Different Types of Doors

Introduction of Doors Doors are an important part of the buildings which provide entrance and exit in the building. The … [Read more...]

6 Different Types of Concrete Finishes | 7 Types of Wall Finishes | How to Finish Concrete | 3 Types of Concrete Finish Machines | 14 Types of Concrete Finishes for Driveways

Introduction of Concrete Finishing Concrete is a versatile building material which is widely used in the … [Read more...]

What Is Concrete | 31 Different Types of Concrete

What Is Concrete? Concrete is the final product resulting from mixing cement, aggregates (including sand), water, … [Read more...]

17 Types of Properties of Cement | Physical Properties of Cement | Chemical Properties of Cement

Introduction of Properties of Cement Cement is one of the most widely used building materials in the … [Read more...]

What Is Classification of Bricks | Classification of Bricks Different Base

What Is Classification of Bricks? Many types of brick available in the market. All bricks are a different purpose … [Read more...]

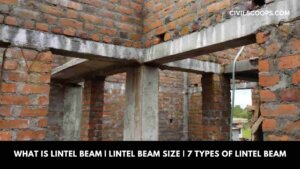

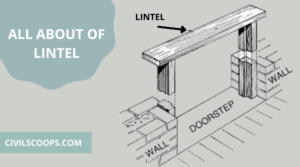

What Is Lintel Beam | Lintel Beam Size | 7 Types of Lintel Beam

What Is Lintel Beam? The lintel is a horizontal flexural member that spans over the openings in the walls for … [Read more...]

What Is Sunken Slab | Advantages & Disadvantages Sunken Slab

What Is Sunken Slab (Sunk Slab)? The sunken slab is one of the familiar and adaptable ways to maintain … [Read more...]

What Is a Concrete Mixer | Types of Concrete Mixer | Specifications of the Concrete Mixer | How to Mix Concrete in a Mixer

Introduction of Concrete Mixer Concrete is one of the main and widely used building materials in construction. Concrete … [Read more...]

What Is Bracing | Types of Bracing | What Does Brace Mean | Advantages & Disadvantages of Bracing Systems

Selection of the right lateral force resisting system has a significant effect on the performance of the structure in … [Read more...]

What Is Caisson Foundation | Types of Caisson Foundation | Advantage, Disadvantage, Application, & Construction of Caisson

What Is Caisson Foundation? Caisson is a watertight structure which it is generally made up of timber, steel, and … [Read more...]

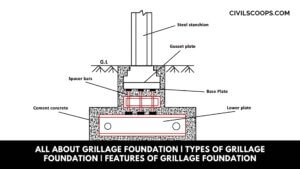

All About Grillage Foundation | Types of Grillage Foundation | Features of Grillage Foundation

Grillage Foundation A foundation consisting of one, two or more layers of beams (typically steel) superimposed on a … [Read more...]

What Is Pier Foundation | Types of Drilled Piers | Advantages and Disadvantages of Drilled Pier Foundations

What Is Pier Foundation? A pier foundation is a collection of large diameter cylindrical columns to support the … [Read more...]

What Is Plaster | Methods of Plastering

What Is Plaster? This id the process of covering rough walls, uneven surfaces in the construction house and other … [Read more...]

All About Asphalt Flooring | What is Asphalt Flooring | Asphalt Flooring Used | Asphalt Flooring Advantages and Disadvantages

What is Asphalt Flooring? This floor is water-resistance, unclean, junction, acid-resistance and charming in look … [Read more...]

All About Drywall Water Damage Repair

Drywall Water Damage Repair What is drywall? A question often asked by many people. So before knowing how to fix … [Read more...]

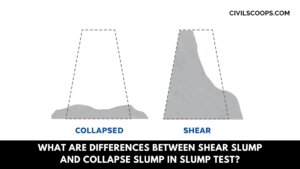

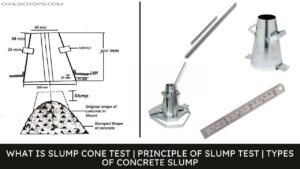

What Are the Differences Between Shear Slump and Collapse Slump in Slump Test?

What Are Differences Between Shear Slump and Collapse Slump in Slump Test? The differences that can be seen between … [Read more...]

What Is Glass | Types of Glass Used in Construction | Qualities of Glass | Advantages & Disadvantages of Glass

What Is Glass? Glass is generally the oldest material and fancy material which is used in the building industry and … [Read more...]

What Is Hempcrete | Hempcrete Blocks | Advantages & Disadvantages of Hempcrete Blocks | Applications of Hempcrete

What Is Hempcrete? Hempcrete is a bio-composite that is made from the inner wood core of the hemp plant and mixed … [Read more...]

Quality Testing of Sand for Concrete | Quality Testing of Sand for Construction | Types of Sand Test

Quality Testing of Sand at The Construction Site for The Concrete There are different methods for testing the … [Read more...]

All About of Corrosion | What Is Corrosion | 9 Different Types of Corrosion

What Is Corrosion? Corrosion is a native method that transforms pure metals into a robust synthetic form like oxide … [Read more...]

What Is Hard Hat | Hard Hat Colour Definition | Different Hard Hat Colour Codes | Types of Safety Helmets | Classification of Hard Hats

What Is Hard Hat? Hard hats are one of the most important and essential accessories which are widely used on … [Read more...]

How Cement is Made | Cement Ingredients | History of Cement

How Cement Is Made? This Portland cement is a fundamental component of concrete. Concrete is produced when portland … [Read more...]

What Is Pier and Beam Foundation | Advantages & Disadvantages of Pier and Beam Foundations | Pier and Beam Foundation Design | How to Build a Post and Pier Foundation

Introduction of Pier and Beam Foundation The foundation plays important role in the construction of the building. … [Read more...]

What Is Stone | Types of Stone | Uses of Stones

What Is Stone? Stone is a naturally available building material that has been used in the early age of … [Read more...]

All About Soak Pit Design | Health Aspects | Operation and Maintenance of Soak Pit | Applicability of Soak Pit Design

Introduction of Soak Pit Design If there is no intention or need to reuse wastewater, collected rainwater or gray … [Read more...]

All About Undercoat | What Is Undercoat | What Does Undercoat Paint Do | Why Use Undercoat | Difference Between Primer and Undercoat

Introduction of Undercoat Paint plays a crucial role in the appearance of the structure. Paint also protects the … [Read more...]

What Is Septic Tank | How Does A Septic Tank Work | Septic Tank Design based Per User Consumption

What Is Septic Tank? A septic tank collects and treats wastewater in a property that isn’t linked to the mains … [Read more...]

What Is Folded Plate | Folded Plate Structure | Folded Plate Roof Construction Details | Folded Plate Staircase | What Are Folded Plate Roofs

What Is Folded Plate? When assemblies of flat plates are rigidly connected together with each other along their … [Read more...]

What Is Window Glazing | Types of Window Glazing

What Is Window Glazing? Window glazing is one of the best innovations that help to maximize the energy of the … [Read more...]

What Is Shotcrete | Shotcrete & Concrete | Shotcrete Technology | Types of Shotcrete Technology | Advantages of Shotcrete | Disadvantages of Shotcrete

What Is Shotcrete? Shotcrete is a kind of refined concrete drizzled by a gas hose-pipe nozzle at high pressure … [Read more...]

All About Brick Bat Coba | What Is a Brick Bat Coba | Procedure of Brick Bat Coba Waterproofing | Advantages & Disadvantage of Brick Bat Coba Waterproofing

Introduction of Brick Bat Coba We spent a lot of money on the interior and exterior view of our home. But many people … [Read more...]

What Is Linear Measurement Surveying | Types of Linear Measurement Surveying

Introduction of Measuring Distance Distance measurement is usually regarded as the most fundamental of surveying … [Read more...]

What Is DLC (Dry Lean Concrete) | Advantage of DLC (Dry Lean Concrete)

Dry Lean Concrete: Everything You Need to Know About Dry Lean Concrete Dry Lean Concrete is a mixture in which the … [Read more...]

Carbon Steel vs. Stainless Steel | What Is Carbon Steel | What Is Stainless Steel

What Is Carbon Steel? One of the trendy and widely used construction materials in the world contains steel. Steel … [Read more...]

All About Soffit | What Is Soffit | Different Types of Soffit | What Is Fascia | Advantages & Disadvantages of Fascia and Soffits |

Instruction of Soffits and Fascia The Soffits and fascia play a vital role in the exterior of the structure. Many … [Read more...]

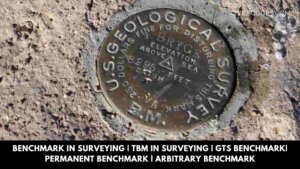

Benchmark in Surveying | TBM in Surveying | GTS Benchmark| Permanent Benchmark | Arbitrary Benchmark

What Is a Benchmark in Surveying? Benchmark is a permanent and temporary reference point in surveying. The term is … [Read more...]

All About FSI and FAR | What Is FSI | What Is FAR | What Is Premium FSI | FSI Full Form | FAR Full Form

What Is FSI? FSI Full-Form Floor Space Index FSI (Floor Space Index) means Floor space index- the ratio of the … [Read more...]

What Are Walls | What Is Interior Walls | 25 Types of Wall | Types of Interior Wall Materials | Types of Wall Construction | Types of Load Bearing Wall

What Are Walls? A wall is a structure and a surface that defines an area, carries a load, provides security, … [Read more...]

All About PPC Cement | What Is PPC Cement | Types of Pozzolana Materials | Manufacture of Portland Pozzolana Cement | Uses of Portland Pozzolana Cement

What Is PPC Cement? Portland Pozzolana cement is an incorporated cement produced in that certain ratio by the … [Read more...]

What Is Admixture | 26 Types of Admixtures | Advantages & Disadvantages of Admixture

What Is Admixture? Admixture is artificial or natural materials added to concrete, in addition to cement, water, … [Read more...]

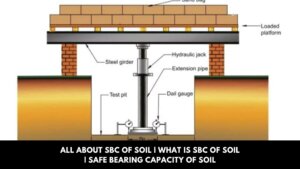

All About SBC of Soil | What Is SBC of Soil | Safe Bearing Capacity of Soil

Introduction of SBC of Soil The first test to be carried out before construction is the soil’s safe bearing capacity. … [Read more...]

14 Types of Plaster Finishes (List of Plaster Finishing)

What is Plaster Finishes? Having your walls up is not the end of the building construction process. If you want to … [Read more...]

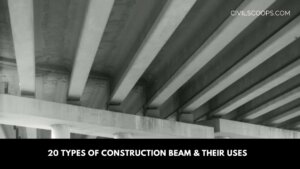

20 Types of Construction Beam & Their Uses

Introduction of Construction Beams There are various types of construction beams are used in buildings depending upon … [Read more...]

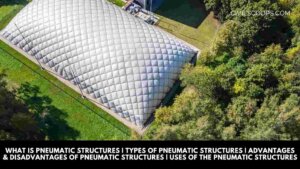

What Is Pneumatic Structures | Types of Pneumatic Structures | Advantages & Disadvantages of Pneumatic Structures | Uses of the Pneumatic Structures

What Is Pneumatic Structures? Pneumatic Structures are a special type of structure that is generally characterized … [Read more...]

What Is a Concrete Vibrator | 6 Types of Concrete Vibrator | Concrete Vibrator Alternatives | Advantages of Concrete Vibrator | Disadvantage of Concrete Vibrator

What Is a Concrete Vibrator? A concrete vibrator is a machine used for construction purposes in civil projects. … [Read more...]

What Is RQD | Advantages of Rock Quality Designation | Limitations of Rock Quality Designation (RQD)

Introduction of RQD In Civil engineering, different parameters are used to characterize the Quality of the rocks. … [Read more...]

Extra Rapid Hardening Cement | Advantages & Disadvantages of Extra Rapid Hardening cement | Applications, Properties & Uses of Extra Rapid Hardening cement

Introduction to Extra Rapid Hardening Cement Time is one of the most important factors in construction projects. Time … [Read more...]

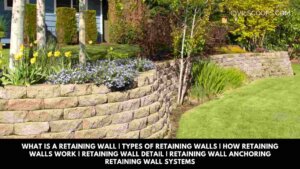

What Is a Retaining Wall | Types of Retaining Walls | How Retaining Walls Work | Retaining Wall Detail | Retaining Wall Anchoring Retaining Wall Systems

What Is a Retaining Wall? A retaining wall is a design of a structure; it is built when there is a desired change … [Read more...]

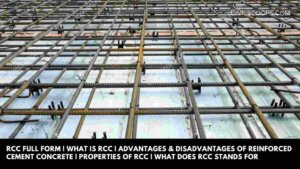

RCC Full Form | What Is RCC | Advantages & Disadvantages of Reinforced Cement Concrete | Properties of RCC | What Does RCC Stands for

Introduction of RCC ( Reinforced Cement Concrete) Concrete is a versatile material that is widely used for the … [Read more...]

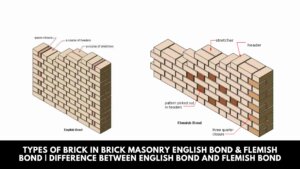

Types of Brick in Brick Masonry English Bond & Flemish Bond | Difference Between English Bond and Flemish Bond

Introduction of English Bond & Flemish Bond Various types of bonds in brick masonry used for wall construction … [Read more...]

Difference Between Formwork, Shuttering, Centering, Staging & Scaffolding

What Is Formwork? The construction of a concrete building requires formwork to support the slabs (horizontal … [Read more...]

What Is Under-Reamed Pile Foundation | Uses of Under-Reamed Piles | Advantages & Disadvantages of Under-Reamed Piles

Reamed Meaning Reamed is a cutting procedure for which a cutting process creates a very precise hole size. What Is … [Read more...]

What Is Chicken Mesh for Plaster | Type of Chicken Mesh for Plaster | Why Use Chicken Mesh for Plaster

What Is Chicken Mesh for Plaster? Chicken wire has specific properties for plastering use. Chicken wire mesh is … [Read more...]

What Is Crane | 19 Different Types of Cranes

What Is Crane? A crane is a significant type of construction machine that’s utilized to move loads horizontally. … [Read more...]

What Is Well Foundation | Component of Well Foundation

What Is Well Foundation? Well Foundation is a type of deep foundation that is generally provided below the water … [Read more...]

What Is Plaster | Types of Plaster As Per Material | Defects In Plastering

What Is Plaster? This is the process of covering rough walls, uneven surfaces in the construction house, and other … [Read more...]

10 Construction Certifications and Where to Get Them

Introduction of Construction Certifications Certification can be a huge addition to a construction worker’s resume, as … [Read more...]

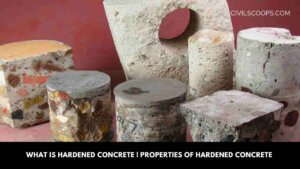

What Is Hardened Concrete | Properties of Hardened Concrete

What Is Hardened Concrete? Hardened concrete is a type of concrete that is strong and have the capacity to bear the … [Read more...]

What Is Fire Escape Staircases | Types of Fire Escaping Stairs | What Is the Importance of Fire Escape in the Building | What Are the Fire Staircase Requirements

Introduction of Fire Escape Staircase Urbanization leads to the Construction of the High Rise building. It is also … [Read more...]

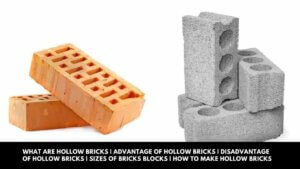

What Are Hollow Bricks | Advantage of Hollow Bricks | Disadvantage of Hollow Bricks | Sizes of Bricks Blocks | How to Make Hollow Bricks

Introduction of Hollow Bricks Bricks are one of the most essential and commonly used Building units in the construction … [Read more...]

What Is Bamboo Flooring | Bamboo Flooring Pros and Cons

What Is Bamboo Flooring? Bamboo flooring is evolving as a popular choice to standard hardwood flooring as it has … [Read more...]

All About Retrofitting | What Is Retrofitting | Why Need Retrofitting | Advantages And Disadvantages of Retrofitting of Building

What Is Retrofitting? Retrofitting is the modern technique or methodology used to increase the structure’s … [Read more...]

Types of Coffered Ceiling | What Is Coffered Ceiling | Coffered Ceiling Cost

What Is Coffered Ceiling? The coffered ceiling is like the baroque style which is invented in the early era of the … [Read more...]

Automation in Construction | Advantages of Automation | Applications of Automation | Where Are Use Automation in Construction Sector

Introduction of Automation in Construction Construction is one of the largest industries all over the world. … [Read more...]

What Is Building | Types of Building

What Is Building? A building is a structure that consists of a roof, floor, walls, foundations, door, windows, etc. The … [Read more...]

Top-Down Construction | What Is a Top-Down Construction | Advantages & Disadvantages of Top-Down Construction

Top-Down Construction The easy description of the top-down construction method will help the storeroom surface of the … [Read more...]

All About Mastic Asphalt Flooring | What Is the Meaning of Mastic Floor | Mastic Asphalt Flooring Cost | Where Is Asphalt Flooring Used

Mastic Asphalt Flooring The surface of your house is another point, and there is no privacy. Its humidity and … [Read more...]

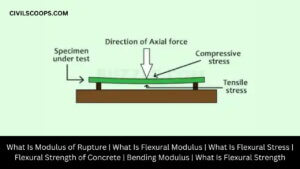

What Is Modulus of Rupture | What Is Flexural Modulus | What Is Flexural Stress | Flexural Strength of Concrete | Bending Modulus | What Is Flexural Strength

Modulus of Rupture of Concrete Beam: Modulus of rupture of Concrete beam indicates the amount of compression and … [Read more...]

Definition of Design Period | Why Design Period is Provided | Factors Affecting Design Period | Design Period Values

Definition of Design Period: The design period could be defined as the number of years in the near future in which … [Read more...]

How Much Does It Cost to Pump a Septic Tank | Why Septic Tanks Required Pumping | Typical Problems Leading to Septic Tank Pumping

Information of Septic Tanks System A septic tank is basically an underground structure that is made from concrete, … [Read more...]

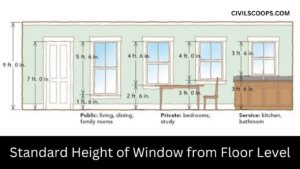

Standard Height of Window from Floor Level | Window Sill Height from Floor

Standard Height of Window from Floor Level To the base of the window from the floor level up, the height is known as … [Read more...]

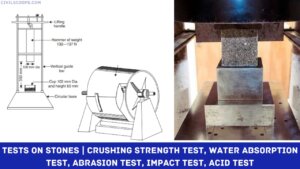

Properties of Stones | Requirements of Good Building Stones

Properties of Stones The following properties of the stones should be looked into before selecting them for … [Read more...]

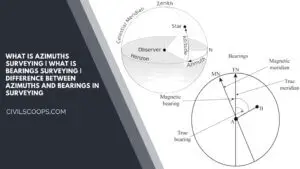

What Is Azimuths Surveying | What Is Bearings Surveying | Difference Between Azimuths and Bearings in Surveying

What Is Azimuths Surveying? Azimuths are defined as horizontal angles that are measured from the reference meridian … [Read more...]

What Is Falsework | Types of Falsework | Causes of Falsework Failures

Falsework Means The temporary structure is used to support a permanent structure, material, plant, equipment, and … [Read more...]

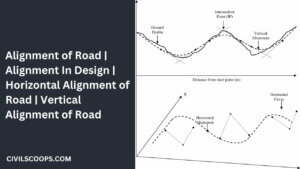

Alignment of Road | Alignment in Design | Horizontal Alignment of Road | Vertical Alignment of Road

Alignment of Road: Alignment is the center line position of the highway on the ground; it is also termed highway … [Read more...]

Mortar Vs Grout | What Is Mortar and Grout | Type of Mortar and Grout | Difference Between Mortar and Grout

What Is Mortar? The term mortar is used to indicate a paste prepared by adding the required quantity of water into … [Read more...]

What Is a Classified Road | Classification of Roads in India

Introduction of Indian Road India is a very vast country and where the economic development of the country mainly … [Read more...]

What Is Levelling in Surveying | Types of Levelling in Surveying | Advantages & Disadvantages of Levelling in Surveying

Introduction to Levelling Levelling is one of the most important parts of surveying before starting the construction of … [Read more...]

What Is Dressing of Stone | Types of Dressing of Stone

What Is Dressing of Stone? Dressing of stone is a process of providing a proper shape, size and smooth finish to the … [Read more...]

What Is Injection Grouting | Types of Injection Grouting | Different Types of Grouting Materials

What Is Injection Grouting? Injection Grouting is defined as the process of filling the cracks, and voids under … [Read more...]

15 Difference Between Bridge and Culvert | What Is Bridge | What Is Culvert

What is Bridge? A Bridge, a connecting structure, create bonding between different disconnected parts of a country, … [Read more...]

Skeleton Frame | What Is Building Skeleton | What Is Steel Structure Building | Use of Steel Frame Structures| Advantages & Disadvantage of Steel Frame

What Do You Mean by Skeleton Frame? A skeleton frame is a framed structure often used for the construction of … [Read more...]

Plasticizer Vs Superplasticizer | What Is Plasticizer In Civil | What Is Superplasticizer In Civil

What Is Plasticizer In Civil? Plasticizers us in concrete for the workability, Strength, and Durability of … [Read more...]

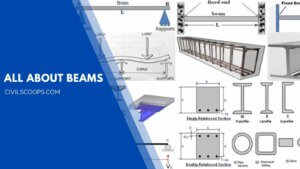

22 Types of Beams | Standard Size of Beams

Introduction of Beam The Beam is the horizontal structural member which is used to resist the loads which are … [Read more...]

What Is Bridge | Components of Bridge and Their Function

What Is Bridge? A bridge is a system for transporting road traffic and perhaps other moving loads across a deep … [Read more...]

What Is Honeycomb in Concrete | Cause of Honeycomb in Concrete| Cure of Honeycomb in Concrete | Types of Grouting

What Is Honeycomb In Concrete? This takes place when the mortar doesn’t fill the distance between the coarse aggregate … [Read more...]

What Is Dampness | Requirements of an Ideal Material for Damp-Proofing | Materials Used for Damp-Proofing

What Is Dampness? The most common source of dampness is due to the capillary attraction of sub-soil water in the … [Read more...]

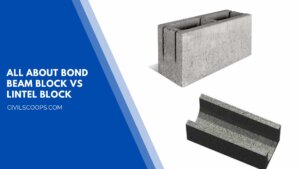

All About Bond Beam Block vs Lintel Block | What Is Bond Beam | What Is a Lintel Block | Bond Beam Detail | Advantages & Disadvantages of Bond Beam Blocks

Introduction of Bond Beam Block vs Lintel Block: Bond beam is a horizontal structural element that is generally … [Read more...]

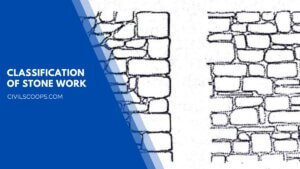

Classification of Stone Work | What Is Stone Masonry

What Is Stone Masonry? The construction of stones bonded together with mortar is termed stone masonry. Where the … [Read more...]

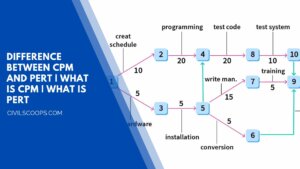

14 Difference Between CPM and PERT | What Is CPM | What Is PERT

The network technique is a major advance in management science. This technique is based on the basic characteristics … [Read more...]

All About Gypsum Plaster | What Is Gypsum Plaster | 15 Advantage of Gypsum Plaster | Disadvantage of Gypsum Plaster

History of Gypsum Plaster Gypsum plaster has been used as an interior wall and ceiling finish for thousands of … [Read more...]

All About M Sand | What Is M Sand | Properties of Manufactured Sand | Advantages & Disadvantages of Manufactured Sand

What Is M Sand? Manufactured sand (M-Sand) is an additional river sand for concrete structures. Manufactured sand … [Read more...]

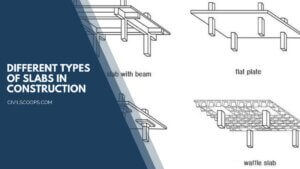

19 Different Types of Slabs in Construction | What Is a Slab | Types of Slabs

What Is a Slab? Slabs are structural elements manufactured from concrete constructed to produce flat surfaces, … [Read more...]

All About Sand | What Is Sand | 29 Types of Sand | Composition of Sand

What Is Sand? Sand could be a blend of bijou grains of rock & granular materials, which is distinctly defined … [Read more...]

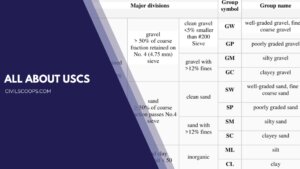

All About Uscs | Which Test Gives a Better Estimation of the Friction Angle | Introduction of USCS ( Unified Soil Classification System )

Which Test Gives a Better Estimation of the Friction Angle? Usually, the economics of the project dictates the type of … [Read more...]

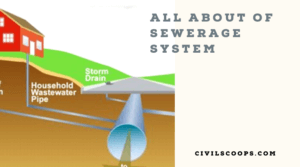

What Is Sewerage | What Is Storm Drain | Household Drain Systems | House Drainage Parts and Components | Types of Sewer Pipes | Sanitary Pipework

What Is Sewerage? A sewerage system, or waste product assortment system, maybe a mesh of pipes, pumping stations, … [Read more...]

What Are Defects in Painting | 18 Types of Defects in Painting | How to Prevent Defects in Painting

What Are Defects in Painting? Painting is one of the important finishing works used in structural construction in … [Read more...]

Top 10 Companies for Environmental Engineers to Work For

With climate change upon us, we are counting on engineers like you to help save the planet so no pressure. Environmental … [Read more...]

What Is Consistency of Cement | What Is Initial Setting Time of Cement | What Is Final Setting Time of Cement

What Is Consistency of Cement? Any Cement paste requirement of minimum water in cement paste to initiate the chemical … [Read more...]

All About Glass Block Floor | Glass Block Floor | Advantages of Glass Blocks | Disadvantages of Glass Blocks

Introduction of Glass Block Floor Glass blocks are one of the unique construction materials which were developed in … [Read more...]

All About Reinforced Brick Masonry | What Is Reinforced Brick Masonry | Construction of the Reinforced Brick wall

What Is Reinforced Brick Masonry? Reinforced brick masonry is totally different from the normal method of brick … [Read more...]

All About Slab Construction | What Is Slab Construction | Types of Slab Design

Introduction of Slab Construction The concrete slab is a horizontal surface of a residential building or commercial … [Read more...]

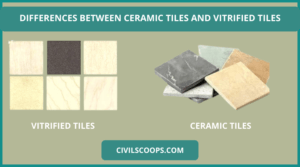

All About Vitrified Tiles | What Are Vitrified Tiles | Advantages of Vitrified Tiles

Introduction of Vitrified Tiles Tiles are one of the most important parts of the interior of the building. Tiles give a … [Read more...]

Steel Is Most Trusted TMT Bar in India?

Introduction of Shyam Steel Industries Ltd. Shyam Steel Industries Ltd started its journey in 1953 with a small factory … [Read more...]

All About Roller Compacted Concrete | What Is Roller Compacted Concrete | Roller Compacted Concrete Process

Roller Compacted Concrete Roller Compacted Concrete also known as RCC. Roller Compacted Concrete takes its name … [Read more...]

All About Plaster | What Is Plaster | Requirement of Good Plaster | Types of Plasters

What Is Plaster? This is the process of covering rough walls, uneven surfaces in the construction house, and other … [Read more...]

All About Aggregates | How do Shape and Size Matter in Aggregate | Fine Aggregate Vs Coarse Aggregate

Aggregates Aggregates are inert granular, substances like either sand gravel or crushed stone which are an important … [Read more...]

All About Mix Design of Concrete | What Is Mix Design of Concrete | Nominal Mix | Design Mix

What Is Mix Design of Concrete? Concrete mix design involves a process of preparation in which a mix of ingredients … [Read more...]