What Is a Concrete Vibrator | 6 Types of Concrete Vibrator | Concrete Vibrator Alternatives | Advantages of Concrete Vibrator | Disadvantage of Concrete Vibrator

Table of Contents

What Is a Concrete Vibrator?

A concrete vibrator is a machine used for construction purposes in civil projects. concrete vibrators come in a variety of shapes and sizes.

Some concrete vibrators are smaller, more efficient, and at battery power, while others are much larger with a primary power source based on electric power lines.

Choosing the right concrete vibrator can help resolve your concrete stability and long-term maintenance.

Using a concrete vibrator to help the concrete during the settling period shows a beneficial method that helps the long-term durability of the concrete.

When wet concrete is poured, air bubbles become trapped inside the mixture forming cavities or spaces that look like honeycombs.

If the air bubble is left untouched, “honeycombing” can jeopardize the longevity and strength of the concrete.

The concrete vibrators force the trapped air out of the mixture leaving the concrete to be more compact and level slab.

It is not uncommon to see small air bubbles coming from the wet part of the concrete where the concrete vibrator is used properly.

Also Read: What Is Rebar | Why use Reinforcement in Concrete | Types of Steel Reinforcement Bars

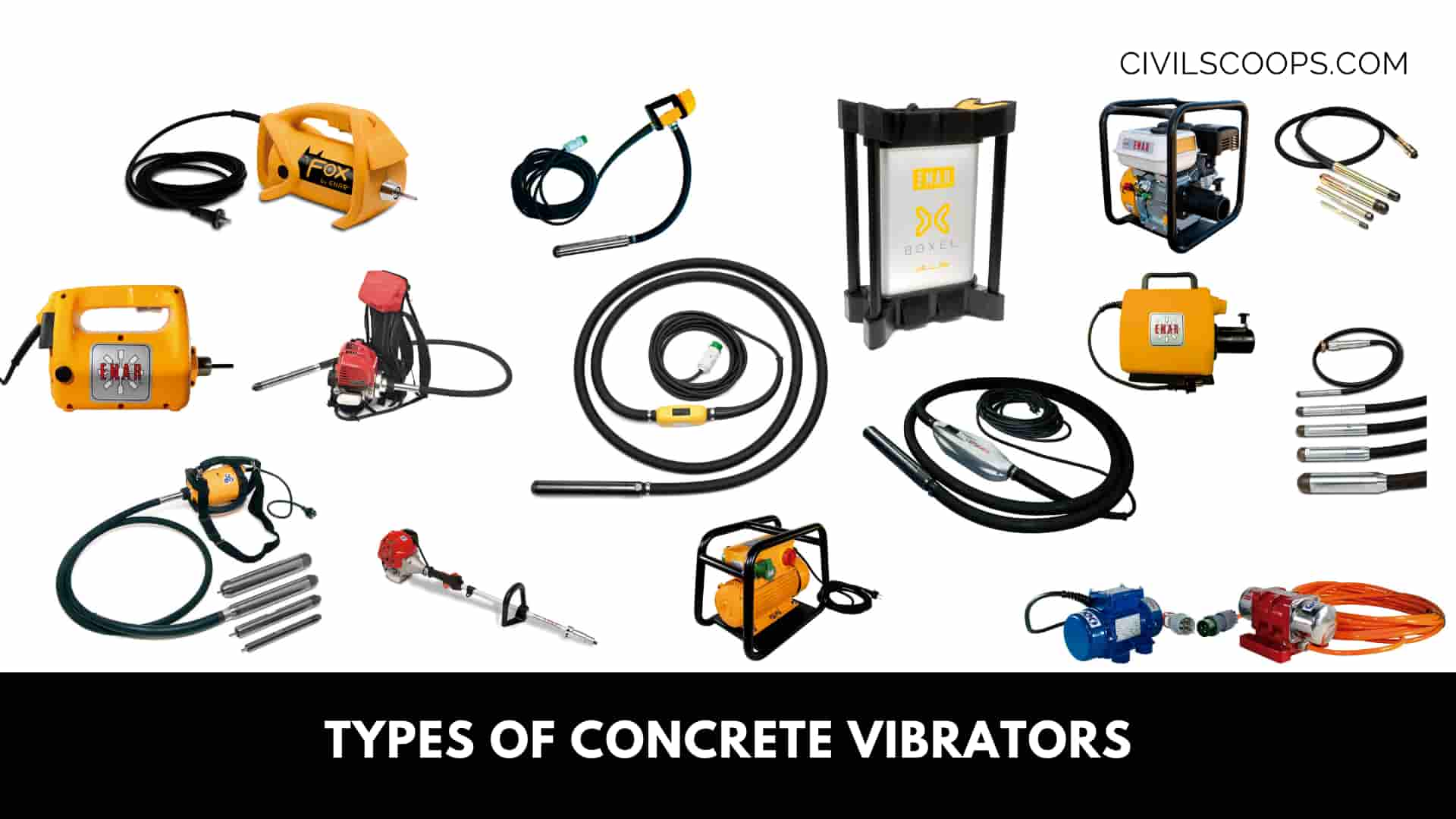

Types of Concrete vibrators

The length and depth of the civil project determine which type of concrete vibrator is right for use. There are many types of concrete vibrators, each with its own head size.

The usefulness of internal concrete vibrators makes them the most widely used option available. Internal concrete vibrators are commonly used for commercial areas and projects undertaken by the Department of Transportation.

Different types of concrete vibrators are as follows.

- Internal concrete vibrator.

- Exterior concrete vibrator.

- Internal Gas concrete vibrator.

- Screed concrete vibrator.

- Rebar Shaker.

- Vibrating Table.

1. Internal Concrete vibrator

Internal concrete vibrators have the best price and offer unparalleled mobility due to their size and weight. High-frequency concrete vibrators perform the power conversion of a single-phase into three-phase power, which is a beneficial feature due to the consistency of the power supply for large projects.

2. Exterior Concrete vibrator

Exterior concrete vibrators can be a good choice for any vertical project, such as walls or other areas that require high reinforcement.

Exterior concrete vibrators can also help reduce the mistakes that other types of internal vibrators can cause.

Also Read: What Is Hardened Concrete | Properties of Hardened Concrete

3. Internal Gas Concrete vibrator

Internal gas concrete vibrators are obviously the best option when electricity is not available or poses a safety risk on the construction site.

Internal gas concrete vibrators also work well in different areas such as curbing, gutters, and construction joints that require extra caution.

4. Screed Concrete vibrator

Concrete vibratory screeds are an ideal, easy-to-use method due to the operator’s ability to remain standing in an upright position.

Easy to use and reputation for lightweight makes concrete vibratory screed a great choice for large or small projects, indoor or outdoor, such as patios, driveways, and indoor or outdoor basketball courts.

5. Rebar Shaker

The Rebar Shaker simply slipped over the top of the rebar, vibrates, and consolidates grout in 5 to 7 seconds.

Tremendous savings in man-hours, from filling and refilling cells, clean-up, and lost time due to injury from slips and falls are realized through the use of the Rebar Shaker.

6. Vibrating Table

Concrete Vibrating Table is used for consolidating fresh concrete when forming cylinder and beam molds. The power cable to the vibrating table is user-supplied.

Also Read: Construction Project Cost Breakdown

Concrete Vibrator Alternatives

- A rebar shaker is another great concrete vibrator alternative to various traditional concrete vibrators.

- The technology is similar to a standard concrete vibrator, but in this case, the Rebar shaker is slipped over the reinforcement bar and “shakes” or transmits vibration to the concrete.

- Rebar shakers can be found in a wide range of sizes and can lead to significant savings in working hours and reduced cleanup activities. This tool will reduce the time it takes to pour concrete into a cell or a very tight space.

Advantages of Concrete Vibrator

The following are the Advantages of using a concrete vibrator.

- The honeycomb structure caused by air bubbles can be avoided when using a concrete vibrator.

- A structure with heavy reinforcement can be easily compacted by using a concrete vibrator.

- When a concrete vibrator is used while constructing a building, it becomes dense and waterproof.

- A low water-cement ratio can be used in construction when using a concrete vibrator.

- The pace of work is increased when using a concrete vibrator.

- A high aggregate cement ratio can be used when using a concrete vibrator.

- When a concrete vibrator is used while constructing a building, it improves the bond with reinforcement steel and gives greater strength to the building.

- When a concrete vibrator is used while constructing a building, it provides a greater bond on construction joints which gives great durability to the building.

- A concrete vibrator reduces the amount of cement required by using dry mixes and improves the building finish.

Disadvantage of Concrete Vibrator

The following are the disadvantages of using a concrete vibrator.

- When a concrete mix is built with low workability, excess substantial vibration causes more energy consumption, which leads to energy dissipation.

- If the concrete vibrator is left on the concrete for too long, a water film will be on the concrete floor and the cement will often sink, resulting in lower strength on the concrete surface.

[su_box title=”FAQ” style=”default” box_color=”#333333″ title_color=”#FFFFFF” radius=”3″ class=”” id=””]

What Is a Concrete Vibrator?

A concrete vibrator is a machine used for construction-based purposes. These machines can come in several different shapes and sizes. Some are small and run strictly on battery power, while others are much larger with a primary power source stemming from electric power cords.

Types of Concrete Vibrators

- Internal Vibrator.

- Form Vibrators.

- Surface Vibrators.

- Vibrating Tables.

- Rebar Shaker.

Concrete Vibrator Alternatives

A rebar shaker is one good alternative to traditional vibration techniques. The technology is very similar to a regular vibrator, but in this case, the device is slipped over the top of the reinforcing bar and “shakes” or transmits the vibration into the concrete.

Advantages of Concrete Vibrator

- Greater density of the concrete.

- Greater strength.

- Improved bond with reinforcement steel.

- Greater bond on construction joints.

- Greater durability.

- Improved product finish.

- Reduction in the amount of required cement through the use of drier mixes.

Disadvantages of Concrete Vibrator

If the concrete mixture is designed with low workability, the over-vibration causes additional power consumption, resulting in energy dissipation.

[/su_box]

[su_note note_color=”#F2F2F2 ” text_color=”#333333″ radius=”3″ class=”” id=””]

Like this post? Share it with your friends!

Suggested Read –

- 10 Construction Certifications and Where to Get Them

- What Is Plaster | Types of Plaster As Per Material | Defects In Plastering

- Difference Between Formwork, Shuttering, Centering, Staging & Scaffolding

- What Is Chicken Mesh for Plaster | Type of Chicken Mesh for Plaster | Why Use Chicken Mesh for Plaster

- What Is Under-Reamed Pile Foundation | Uses of Under-Reamed Piles | Advantages & Disadvantages of Under-Reamed Piles

[/su_note]

Originally posted 2023-03-21 10:38:14.