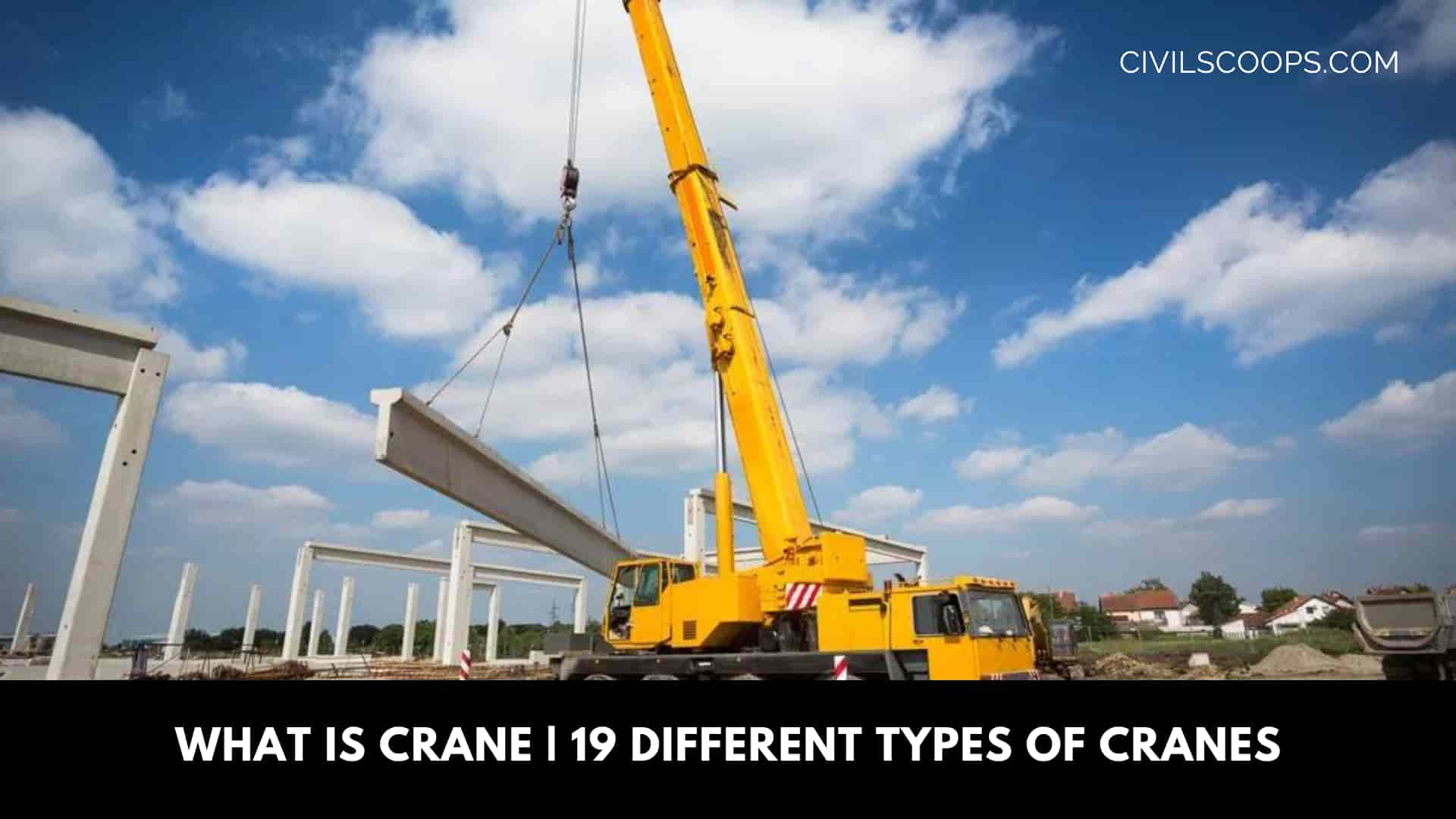

What Is Crane | 19 Different Types of Cranes

Table of Contents

What Is Crane?

A crane is a significant type of construction machine that’s utilized to move loads horizontally. Equipped with a hoist rope, cable ropes, and sheaves, it may be used to lift heavy loads or transport them to other places.

The mechanical benefits created by several elements on the crane may produce powerful strength.

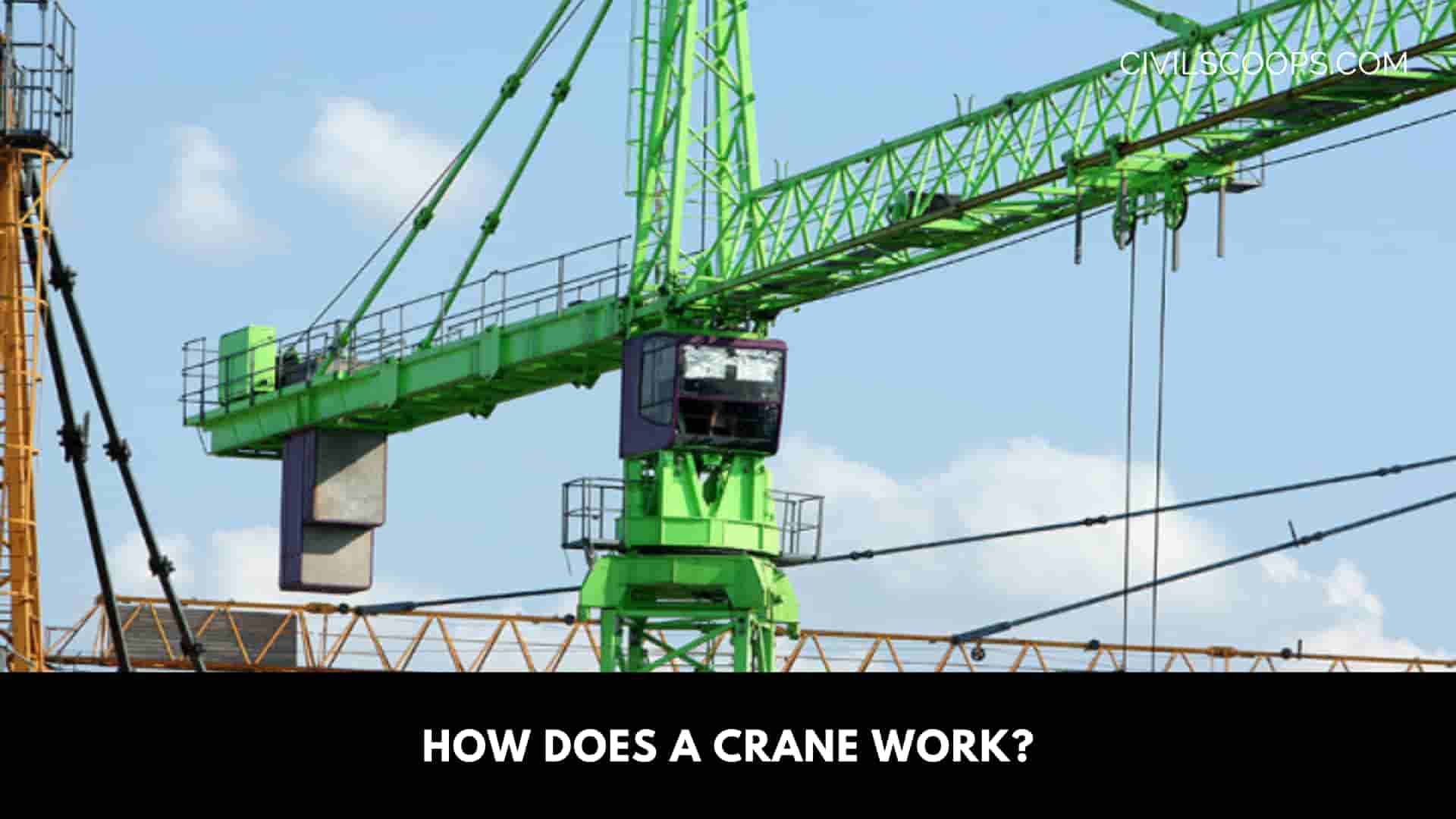

How Does a Crane Work?

Cranes are part of the construction process since their invention in Greece. The cranes are basically for heavy construction work and for all types of lifting tasks.

Equipped with pulleys and cables and based on the use of fundamental mechanical principles, a crane could lift and lower loads that no human working capacity could.

Crane design has evolved to meet the requirements of a wide variety of industrial needs, and modern cranes often coordinate simple systems to do complex lifting jobs – sometimes in environments that could be dangerous for human workers.

Also Read: 15 Difference Between Bridge and Culvert | What Is Bridge | What Is Culvert

19 Types of Cranes

Different types of cranes are as follows.

- Telescopic Crane.

- Mobile Cranes.

- Truck Mounted Crane.

- Tower Crane.

- Rough Terrain Crane.

- Overhead Crane.

- Bridge Crane.

- Jib Crane

- Crawler Crane.

- Aerial Crane.

- Hydraulic Crane.

- Carry Deck Crane.

- Floating Crane.

- Bulk-handling Crane.

- Hammerhead Crane.

- Stacker Crane.

- Railroad Crane.

- Harbor Cranes.

- Level Luffing Crane.

1. Telescopic Crane

The telescopic crane consists of a large boom where some numbers of tubes have been fitted inside with each other.

It increases their height with the help of tubes throughout the hydraulic system. They are specially used to transport goods from one place to another.

When it comes to transferring the object to a high place, Telescopic cranes would be the best. Since they could adjust their heights in line with the place. They may also be used in rescue operations.

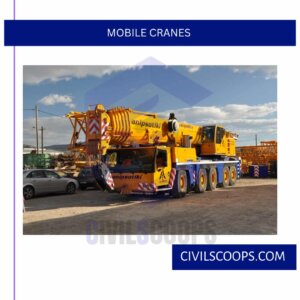

2. Mobile Cranes

Mobile cranes are generally found on vehicles, but cranes used for construction work are adapted to move on the tractor, and several cranes may be attached to barges when used for construction work on waterway bridges.

The lifting arm is usually articulated to allow lifting and reduction as required. generally, this is achieved through a system of cables or hydraulic mechanisms, and the whole mobile structure may be coupled to a support to provide more stability during its operation.

3. Truck Mounted Crane

Truck-mounted cranes are made up of both parts of the carrier, along with the boom (arm). Due to their unique build, they are ready to travel easily on the road without a unique setup or transportation equipment.

Truck-mounted cranes are outfitted with counterweights and outriggers for insertion, allowing them to move slowly while carrying a large load.

Different versions of this truck-mounted crane exist; for example, special truck-mounted cranes are used for the inspection, maintenance, and building of bridges.

4. Tower Crane / Construction Crane

Commonly utilized in the construction of tall buildings, tower cranes offer you amazing lifting capabilities. |Because of their size, tower cranes are equipped with an operating cab that controls the whole crane.

Tower cranes have their jib extending horizontally from the mast (tower part), which itself rests on a concrete base. A luffing jib can move up and down, while the fixed jib has an operating dolly that moves materials horizontally.

The engine (known as a slewing unit) that controls the rotation of the crane sits on the top of the mast. As a result of their size, tower cranes are built together with the building, growing alongside it; once the building is done, the process is reversed.

Using its height, ability to lift heavy materials, and various features, tower cranes are an essential tool when constructing a tall building.

5. Rough Terrain Crane

A rough terrain crane is a crane that’s mounted in an undercarriage with four rubber wheels, designed for operations off-road.

The outriggers extend vertically and horizontally to level and stabilize the crane when hoisting. These types of cranes are single-engine machines in which the same engine can be used for powering the undercarriage as it is for powering the crane.

These cranes are ideal for construction sites that have uneven, dirt, and rocky terrain. The mobility and ability of this crane to travel around the site make it an effective support crane for lighter hoists on the highway, infrastructure, and construction projects.

6. Overhead Crane

These types of cranes can also be known as suspended cranes. They are usually used at a factory, and some are able to lift very heavy loads.

The hoist of the crane is set onto a trolley that can move in one direction along a beam, sometimes both beams.

They move at angles to the direction across the ground or elevated level tracks. The tracks are usually mounted across the side of an assembly area.

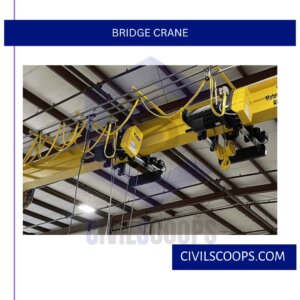

7. Bridge Crane

The bridge crane also called an overhead crane, is generally found in industrial environments. Its name comes from the fact that it resembles a bridge supported by both steel beams, which straddle the workload, together with the hoist traveling along the bridge part of the crane. There are both subtypes of overhead cranes: gantry and jib cranes.

Gantry

A variant of this overhead crane is the gantry crane, although sometimes both terms are used interchangeably.

The most critical difference between a bridge and gantry crane is that the gantry crane is supported by both a-frame steel legs and is normally built on a track.

Gantry cranes are generally seen at shipping docks and ports, lifting cargo off ships.

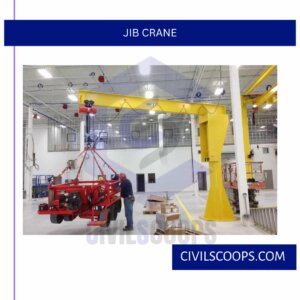

8. Jib Crane

Jib cranes are just another version of the bridge crane. These kinds of cranes are permanently installed within a workstation and usually utilized for repetitive tasks.

The jib, or arm, is usually mounted on either a wall or floor-mounted pillar using a moveable hoist and might have some additional movement.

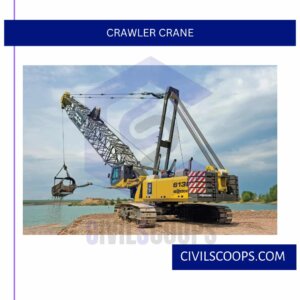

9. Crawler Crane

Crawler crane moves it self with the help of tracks that are also known as crawlers. It has many disadvantages and advantages depending on its use.

Their main advantage is that it may move mostly on any surface of the earth; it may even move on soft soils because of its crawlers.

Because it transfers its load to a great area. That is why it may be used at unprepared sites without worrying about anything.

And their main disadvantage is that it is very heavy and move on tracks. That is why it can’t be moved easily from one site to another and will cost more money.

However, it can be moved by trucks easily and without costing much money.

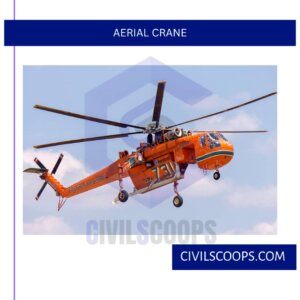

10. Aerial Crane

These types of cranes can also be known as Sky Cranes. They looked like helicopters and used to carry large loads.

They’re used mostly because places where reaching by land is difficult. And as all of you know that Helicopters fly, that means they’re capable of reaching any place.

They generally lift loads to high rise buildings. They could lift anything in their capacity from boats, cars to pre-made swimming pools. They may also be used for rescue purposes in disaster.

11. Hydraulic Crane

Hydraulic cranes could be simple in design but can perform difficult tasks that would otherwise seem impossible.

In a matter of minutes, these machines are capable of assembling beams on the roads, lifting heavy equipment in factories, as well as building houses.

12. Carry Deck Crane

Carry deck cranes are a relatively new type of crane which evolved from the older pick and carry model, which was first introduced in the 1980s.

They are small, four-wheeled, can rotate a full 360 degrees, and are more portable than other types of cranes.

Carry deck cranes are easy to set up, and their small size easily allows them to navigate around open and restricted spaces, making them a staple on many job sites.

Also Read: What Is Slump Cone Test | Principle of Slump Test | Types of Concrete Slump

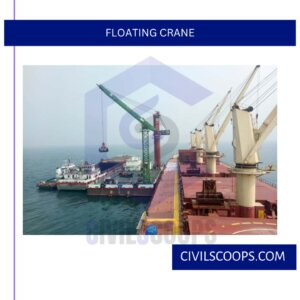

13. Floating Crane

Also called a crane vessel or crane boat, these floating cranes are used for projects in the sea, like ports or oil rigs.

These cranes have a rich history they’ve been used since the Middle Ages as well as with the help of continuous technological advancements, have helped many generations of people.

As of today, there are several types of floating cranes as well, like the sheerleg and semi-submersible. Nevertheless, the only difference floating cranes have from another common type is that they’re used in the sea.

14. Bulk-handling Crane

Bulk-handling cranes are utilized to carry large volumes of heavy materials, such as coal or minerals.

Instead of a hook at the end, bulk-handling cranes have a specialized hook that uses a grabbing mechanism along with a bucket to grab, hold, and lift materials.

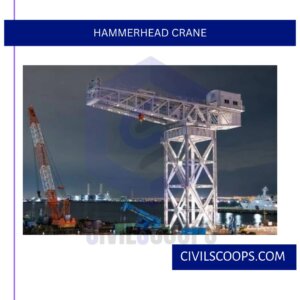

15. Hammerhead Crane

Hammerhead cranes are a few of the most commonly utilized in construction projects. This crane has a horizontal, swiveling lever resting on a fixed tower.

The trolley is held at the forward part of the arm and can be counterbalanced with the part of the arm, which extends backward.

Hammerhead cranes also offer a feature called racking, which allows the trolley to move forward and back horizontally along the crane arm. These cranes can be extremely heavy and are assembled on the job site.

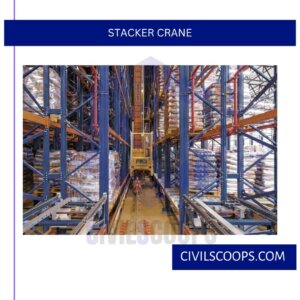

16. Stacker Crane

Stacker cranes are automated machines using a forklift-like mechanism and are primarily designed for warehouse storage.

Normally, stacker cranes are used in places with special working conditions, such as extremely cold temperatures, making it unnecessary for a human worker to endure extreme working conditions.

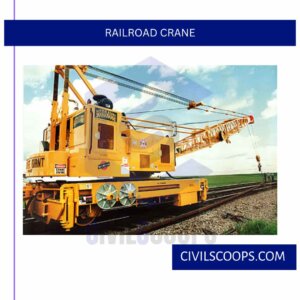

17. Railroad Crane

These kinds of cranes move on the railway track. Rail Road Cranes are utilized for the construction of railway lines, maintenance, and for their repairing.

They cannot travel on roads or other places except railway tracks because of the flanged wheels.

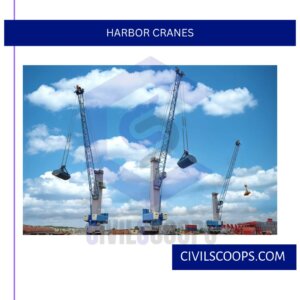

18. Harbor Cranes

Thie crane uses for the harbor area. So, called Harbor cranes, this crane use loading and unloading of ships.

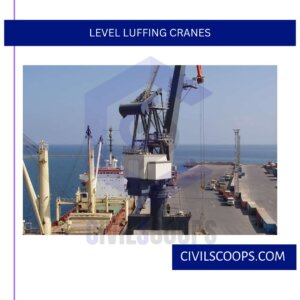

19. Level Luffing Cranes

This crane features a special mechanism where the crane hook was made to stay at a constant level. Because of this, the up and down motions of the jib arm are only going to move the hook toward, or away from, the base of the crane.

The advantage of this type of motion is that the crane could be set to operate at a fixed level relative to the ground, where such action is required to handle load materials with precision as may be often required, for instance, during shipbuilding.

Types of Cranes and Uses of Carnes

[su_table responsive=”yes” alternate=”no”]

| Sr.No. | Types of Cranes | Use of Cranes |

| 1 | Telescopic Crane |

Highly adaptable for a variety of mobile situations

|

| 2 | Mobile Crane |

Lift heavy objects and move them short distances

|

| 3 | Truck Mounted Crane |

Mainly for loading and moving equipment on the job site

|

| 4 | Tower Crane |

Building large structures

|

| 5 | Rough Terrain Crane |

Pick and carry operations on rough terrain

|

| 6 | Overhead Crane |

Extremely heavy or bulky loads through the overhead space in a facility

|

| 7 | Bridge Crane |

Typically used for industrial environments

|

| 8 | Crawler Crane |

Jobs with soft/uneven terrain

|

| 9 | Aerial Crane |

Places where it’s hard to be reached by land cranes

|

| 10 | Hydraulic Crane |

A hydraulic crane is a type of heavy-duty equipment used for lifting and hoisting.

|

| 11 | Carry Deck Crane |

Loading and moving materials on job sites

|

| 12 | Floating Crane |

Projects on the sea, like ports or oil rigs

|

| 13 | Bulk-handling Crane |

Lifting and moving bulk cargo, like coal or scrap metal

|

| 14 | Hammerhead Crane |

One of the most commonly used crane types

|

| 15 | Stacker Crane |

Retrieval of cargo in warehouse storage

|

| 16 | Railroad Crane |

A railroad for one of three primary purposes: freight handling in goods yards, permanent way (PW) maintenance, and accident recovery work

|

| 17 | Harbor Crane |

Unloading small loads (balls, crates, etc.) from ships at the Port of Barcelona

|

| 18 | Level Luffing Crane |

Large project and industrial equipment installing fields where large lifting capacity, high perching accuracy, and high safety are required for lifting large members and equipment component

|

[/su_table]

[su_box title=”FAQ” style=”default” box_color=”#333333″ title_color=”#FFFFFF” radius=”3″ class=”” id=””]

How Does a Crane Work?

Cranes work by using pulley systems to change the direction of the force needed to lift a load and to distribute that force over a greater distance. At the far end of the boom rests the main boom tip sheave.

How Much Can a Crane Lift?

As a general rule of thumb, tower cranes can lift up to 20 tonnes, while mobile cranes could potentially lift anywhere from 10 to 60 tonnes, depending on their size and mobility.

Which Type of Crane Is Known as a Conventional Crane?

Mobile cranes are the most standard and versatile cranes used in construction today. They are the most basic of all cranes and consist of a steel truss or telescopic boom mounted on a mobile platform, which could be a rail, wheeled, or even on a cat track.

What Is a Tower Crane?

A Tower crane is a type of lifting structure that utilizes a vertical mast or tower to support a working boom in an elevated position. Loads are suspended from the working boom.

What Is the Biggest Mobile Crane in the World?

Liebherr 11200-9.1

The massive, yet still very mobile, Liebherr 11200-9.1 is the world’s tallest and strongest telescopic boom crane. Fully assembled, this impressive piece of equipment can lift up to 1,179 tons, and reach a height of 550 feet with extensions attached.

How Do Tower Cranes Work?

The jib, or working arm, is attached to the turntable and will extend horizontally. From there, a hoist & hook, which is a trolley mechanism, will be connected to the jib. This mechanism allows the jib to perform lifting. Located behind the cab and in coordination with the working jib is the counter-jib.

What Is a Tower Crane Used For?

More thoroughly explained, a tower crane is a type of machine equipped with a hoist rope, chains, or sheaves, and used to lower, lift, and move heavy or bulk construction materials around. The work of the tower crane is crucial.

How Does a Hydraulic Crane Work?

The crane’s hydraulic system uses pressurized fluids — typically oil — to generate all the lifting power it needs to pick up large loads. Hydraulic truck cranes use a fixed system of pipes, allowing for constant pressure to be maintained while the operator is performing the lifts.

How Does a Crawler Crane Work?

Crawler cranes are composed of a standard cab mounted on a crawler undercarriage. The undercarriage uses tracks instead of wheels to navigate the terrain at construction sites. Additionally, the upper deck rotates a full 360 degrees, and it features a box or lattice boom with an optional extension.

What Is a Rough Terrain Crane?

Rough-terrain cranes, also called off-road cranes, are mounted on a four-wheeled undercarriage. Both the wheels and the base are wider to boost the crane’s stability, and the wheels are taller to increase ground clearance over rugged terrain.

How Does a Jib Crane Work?

Jib cranes often have a hand-powered rotation and traverse motion, while it is common to see either electric-powered or hand-powered lift motion. The hand-powered rotation and traverse motion are accomplished by push/pull, while the hand-powered lifting is accomplished by a chain similar to a non-powered garage door.

How Much Is a Tower Crane?

Tower Crane ($300,000 – $1,500,000+) – One of the largest cranes, this is a balance crane that usually has the highest and most powerful lifting capabilities due to its size and strength.

What Is Hydraulic Crane?

A hydraulic crane is a type of heavy-duty equipment used for lifting and hoisting. Unlike smaller cranes, which rely on electric or diesel-powered motors, hydraulic cranes include an internal hydraulic system that allows the crane to lift heavier loads.

What Is a Carry Deck Crane?

Carry deck cranes are versatile pick-and-carry cranes. They’re built for lifting material that needs a low-profile and compact crane. Because carry deck cranes are small, they’re ideal when it comes to operating in narrow spaces or around overhead obstacles.

What Type of Simple Machine Is a Crane?

Levers and fulcrums, the most basic simple machine, date back thousands of years. A claw hammer is a good example of a lever and fulcrum. When using the claw to extract a nail, the head of the hammer acts as a fulcrum and the handle acts as the lever.

What Is the Tallest Crane in the World?

The Liebherr LR 13000 is the most powerful crawler crane in the world. Designed for use in nuclear power station construction, the LR 13000’s main boom can reach a height of 473 feet, and the crane has a lifting capacity of 3,000 tons. The crane itself weighs 748 tons.

What Is a Crane Made Of?

Most crane producers use high-strength low-alloy steel (HSLA) to ensure durability and longevity. HSLA steel is lightweight and uses a vast amount of hardening and corrosion-resistant agents in its manufacture. Such qualities allow for heavy-duty cranes to be virtually indestructible and energy-efficient.

What Is Slewing in Crane?

In crane terminology, slewing is the angular movement of a crane boom or crane jib in a horizontal plane. The term is also used in the computer game Microsoft Flight Simulator wherein the user presses a key and he or she can rotate and move the virtual aircraft along all three spatial planes.

What Is Two Blocking a Crane?

This kind of crane accident is called ‘two-blocking. ‘ It occurs when a crane’s hook comes in contact with its boom tip, putting extra stress on the hoist line. This is a dangerous scenario that can cause the hoist to snap and the load to drop, wreaking havoc on the work site.

What Is a Gantry Crane Used For?

A gantry crane is a type of overhead crane that uses legs to support the bridge, trolley, and hoist. These legs travel along the ground on wheels or ride on rails implanted in the ground. A gantry crane is typically used for outdoor applications or for lifting capability below existing overhead bridge crane systems.

What Is a Conventional Crane?

Conventional Truck Cranes (also referred to as Lattice Boom Cranes) are the standard for construction for a few different reasons, but they ultimately boil down to adaptability and portability. Their design allows them to be easily transported down major highways without issue.

What Is a Monorail Crane?

A monorail crane system is a stationary, overhead track on which trolleys travel to carry loads from one place to another in a facility. Monorail cranes are an ideal solution for linear, overhead material handling due to the fact that they enhance production workflow and create a safe and secure work environment.

[/su_box]

[su_note note_color=”#F2F2F2 ” text_color=”#333333″ radius=”3″ class=”” id=””]

Like this post? Share it with your friends!

Suggested Read –

- 10 Construction Certifications and Where to Get Them

- What Is Hardened Concrete | Properties of Hardened Concrete

- What Is Plaster | Types of Plaster As Per Material | Defects In Plastering

- What Are Hollow Bricks | Advantage of Hollow Bricks | Disadvantage of Hollow Bricks | Sizes of Bricks Blocks | How to Make Hollow Bricks

- What Is Fire Escape Staircases | Types of Fire Escaping Stairs | What Is the Importance of Fire Escape in the Building | What Are the Fire Staircase Requirements

[/su_note]

Originally posted 2023-03-19 11:01:43.