How to Calculate Steel in RCC Slab

Table of Contents

Introduction of Calculate Steel in Rcc Slab

The slab is one of the most important structural elements in the construction of buildings. Many of us are confused that how to calculate steel in RCC slab. In this article, we will get to know about the step-by-step procedure to calculate steel in RCC slab.

A slab is a structural member which enables to move from one place is floor to another floor in the structure. The slabs are basically categorized into two types, one-way slabs and two-way slabs. In one way slab, the main bars are provided in the shorter direction, and the distribution bars are provided in the longer direction.

In case of the two-way slab, the main bars are provided in both directions, and a two-way slab is generally adopted for construction when the length and the breadth of the slab are more than 4 meters. The distribution bar are straight bars, and the Main bars are the crank bars at an angle of 45 degrees with a length of 0.42D

The extra bars are also provided at the bottom of the current bus, which is used to maintain the framework of the slab and the length of the extra bar is L/4.

Example of Calculate Steel in Rcc Slab

Let us understand it by taking one example of a one-way slab having 5m length and 2m width. Take main bars of 12mm diameter with a spacing of 100 mm c/c. The length of the distribution bars will be 8 mm in diameter and the spacing between the two bars is 125 mm c/c. The overall thickness of the slab is 150 mm with a clear cover of 25 mm on both sides top and bottom.

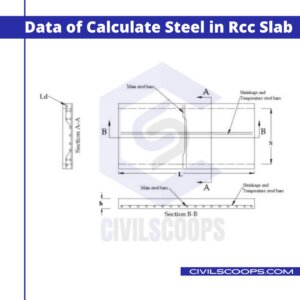

Data of Calculate Steel in Rcc Slab

- Length of the Slab = 5 m = 5000 mm

- Width of the Slab = 2 m = 2000 mm

- Thickenss of Slab = 0.150m = 150 mm

Step 1. Number of Main Bars & Distribution Bars

First upon we have to calculate the number of bars required for the slabs. Here we have to calculate the number of main bars and distribution bars.

Number of Main Bars

Formula for calculating a number of bars is as follows.

- Number of Bars = ( Total length of the slab – 2 x clear cover)/ centre to centre spacing of the bars + 1

- Number of Bars = (5000- 2 x 25 ) 100 +1

- Number of Bars = 50.5 = 51 nos

- There are 51 nos of main bars are required for the slab.

Distribution of Main Bars

Calculation of number of distribution bars

- Distribution Bars= (Total length of the slab – 2 x clear cover)/center to center spacing of the bars + 1

- Distribution Bars = (2000- 2 x 25) /125 +1

- Distribution Bars = 16.6 = 17 bars

- The number of distribution bars are 17 no.

Step 2. Calculate the Cutting Length of Bars

Calculate the cutting length of bars

For the main bars

- L= Clear span of the slab

- Ld = Development length which is 40 d where d is the diameter of the bar

- Calculate the value of D

- Development Length = Thickness of slab – 2 x clear cover – diameters bar

- Development Length = 150 – 2 x 25 -12

- Development Length = 88 mm

Main Bar Cutting Length

Formula for calculating the cutting length of Main Bars are as follows

- Main Bar Cutting Length = Length – 2 x Ld + ( 1 x 0.42 D ) – (2 x 1 d)

- Main Bar Cutting Length = 2000 + ( 2 x 40 x 12) + (1 X 0.42 X 88)- ( 2 x 1 x 12)

- Cutting Length = 2972.96 mm

- Cutting Length = 2973 mm

- Cutting Length = 2.973 m

Distribution Bar Cutting Length

Calculating the cutting length of distribution bars

- Distribution Bar Cutting Length = clear span + 2 x Ld

- Distribution Bar Cutting Length = 5000 + (2 x 40 x 8 )

- Distribution Bar Cutting Length = 5640 mm

- Distribution Bar Cutting Length = 5.64 m

Step 3. Total Weight of Slab Steel

Main Bars Steel Quantity Calculation

- The number of main bars required are 51 nos ( as per step 1)

- The length of one main bar = 2.973 m ( as per step 2)

- Weight of Steel = Total Length of Steel x Length of 1 m Steel as per dia of steel (D2/ 162)

- Total Length of the Main Bars = ( 51 X 2.973)

- Total Length of the Main Bars = 151.623m

- Weight of the Main Bars = Total Length x ( D2/ 162)

- Weight of the Main Bars = 151.623 x (122/162)

- Weight of the Main Bars = 134.776 kg

Distribution Bars Steel Quantity Calculation

- The number of distribution bars required are 17 nos ( as per step 1)

- The length of one distribution bar = 5.64 m ( as per step 2)

- Total Length of the Distribution Bars = ( 17 X 5.64 )

- Total Length of the Distribution Bars = 95.88 m

- Weight of the Distribution Bars = Total Length x ( D2/ 162)

- Weight of the Distribution Bars = 95.88 x (102/162) = 37.87 kg

Total Weight of Steel

- Total Quantity of Steel Required For Slab = Weight of the Main Bars +Weight of the Distribution Bars

- Total Quantity of Steel Required For Slab = 134.776 kg + 37.87 kg

- Total Quantity of Steel Required For Slab = 172.646 kg

[su_box title=”FAQ” style=”default” box_color=”#333333″ title_color=”#FFFFFF” radius=”3″ class=”” id=””]

BBS for Slab

Bar bending schedule or bbs plays a significant role in estimating the quantity of steel for beams, columns, and slab. It helps to find out bar shape, size, length, weight, bending dimension, etc. In two way slab, the slab is supported by four sides and loads are carried along with both directions.

How to Calculate Steel Quantity for Slab

- Number of Main Bars & Distribution Bars.

- Calculate the Cutting Length of Bars.

- Total Weight of Slab Steel.

Steel Quantity

This can be done by multiplying cross-section area of steel by its total length by density of steel which 7850 kg/m3. Total steel quantity of column equal to the sum of both main and stirrup steels.

Steel Required Per Square Feet

If we take last thumb rule point, thumb rule for steel in RCC structure is 3.5 Kg to 4 kg/ sq.ft. of built-up area. 3500 Kg to 4000 Kg of Steel quantity is required for construction of 1000 square feet house.

Reinforcement in Slab

Structural reinforcement is typically placed in the bottom portion of the slab thickness to increase the slab’s load capacity. Most structural slabs-on-ground have both top and bottom layers of reinforcement for controlling crack widths and increasing load capacities.

How to Calculate Steel in RCC Slab?

Calculate Steel quantity in slab as 1% of volume of concrete = 0.01× 7850× 3= 236kg:- according to using Thumb Rule Steel quantity required for RCC slab should be 1% of total volume of concrete, here steel density = 7850 kg/m3, so quantity of steel in slab = 0.01× 7850× 3= 236kg.

Steel Quantity Calculation Formula

(Cutting length) main bar: formula = (l) + (2 x ld) + (1 x 0.42d) – (2 x 1d), where l = clear span of the slab, ld = development length which is 40 d (where d is diameter of bar), 0.42d = inclined length (bend length), 1d = 45° bends (d is diameter of bar) first calculate the length of “d“.

Steel Calculation Formula in Construction

Generally, weight of Steel is equal to multiplication of volume and their density, such as mass = volume × density, density of steel is around 7850 kg/m3, regarding this, “how calculate weight of Steel”, you can do weight of Steel calculation by using the various formula – D2/162 in kg/m, D2/533 in kg/ft or mass = volume × 7850 kg/m3 to determine and estimating the required quantity or weight of Steel.

How to Calculate Steel Weight?

Width * Length * Thickness * Density = Weight

Steel Calculation Formula for Column Beam and Slab

Formula for Steel Calculation for Columns, Beam, and Slabs in Construction. In steel calculation, L x D2 /162 is L x diameter x 162, where D is the diameter of metal and L is the length of steel.

[/su_box]

[su_note note_color=”#F2F2F2 ” text_color=”#333333″ radius=”3″ class=”” id=””]

Like this post? Share it with your friends!

Suggested Read –

- 10 Different Types of Loads on Structures | What Are Structural Loads

- What Is Composite Masonry | 6 Different Types of Composite Masonry

- What Is a Concrete Surface Retarder | Types of Retarders | Advantages & Disadvantages of Retarder in Concrete

- What Is Kelly Ball Test | Test Procedure of Kelly Ball Test | Use of the Kelly Ball | Advantages & Disadvantages of Kelly Ball Test

- What Is Inverted Arch Footing | Where Are Uses Inverted Arch Footing | Advantages of Inverted Arch Footing | Disadvantages of Inverted Arch Footing

[/su_note]