Pile Cap Design | Pile Cap Construction | Piles Structure | Pile Cap Foundations | Square Piling Caps | Pile Cap Reinforcement

Table of Contents

Introduction of Pile Cap

The pile cap is a type of thick concrete mat-like structure which rests on the pile (timber or concrete) which gives a stable foundation to the whole system. This concrete pile cap transfers the entire load of the superstructure to the into the piles, which gives you a stable bearing capacity. The similar structure of the pile cap is a raft foundation, where there is also a concrete block-like structure is constructed.

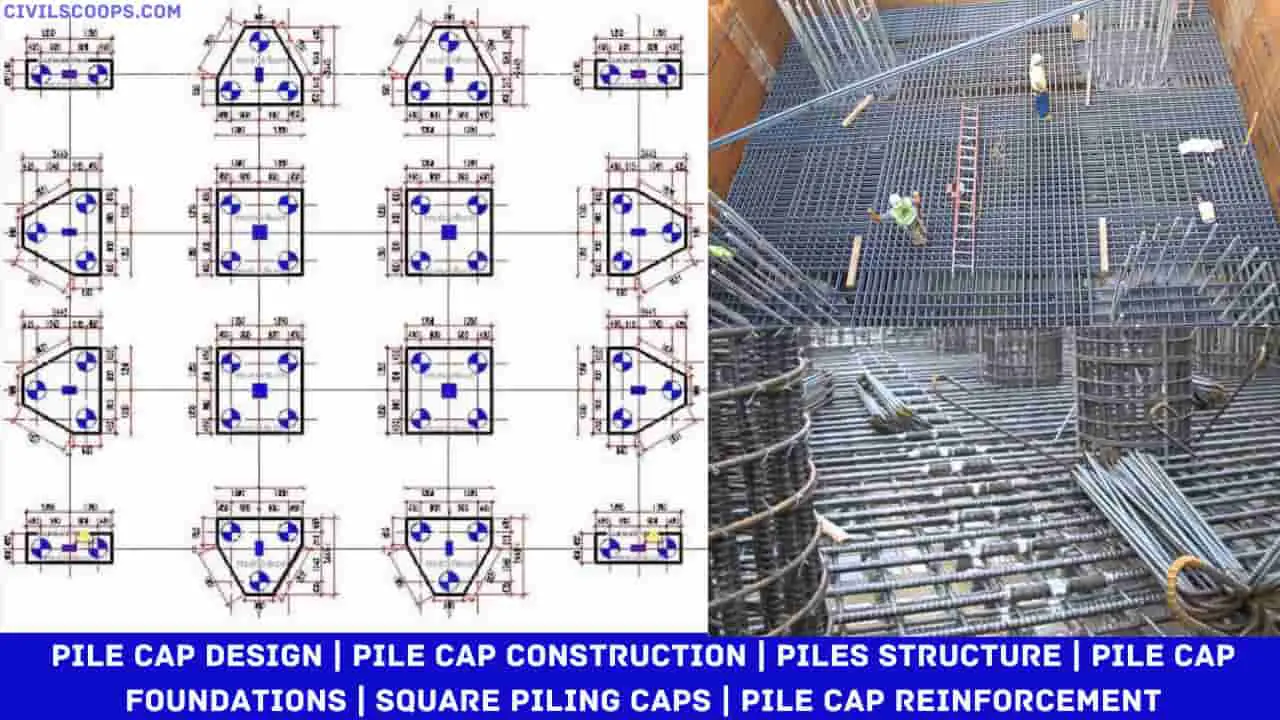

Pile Caps – Design

The pile cap is a mat-like structure which rests on a group of piles to transfer loads from the superstructure. By IS 2911-2010, the pile cap could be arranged so that the column’s load is spread at 45° out of the top of the cap.

1. Suppositions in the Pile Cap Design

The pile cap is must be rigidly set to the structure. Though piles are slight elastic column, that’s why some distortions will be found, and we need to measure those in the plan. The heads of the pile are pivoted to the pile cap to provide safety from the bending moment occur in a pile.

2. Limitations of Pile Cap Designing

- Shape and form of the pile cap.

- Quantity of steel is used in the pile cap.

- Reinforcement placing in the pile cap.

- Depth of pile.

3. Characteristics of Pile Cap Designing

The dimension of the pile is considered by the overhanging portion of the pile cap is not less than 100 mm, it would be highly preferable if you provide 150 mm.

The thickness of the pile cap is needed to be higher because the reinforcements of columns may come out and overlay to the reinforcement of the pile cap. In pile cap construction, the clear cover must be more than 40 mm.

The pile cap’s span to thickness ratio must be not in excess than 5. The pile cap must be relatively rigid to transfer the load to the pile section to downwards. The thickness must not be below 500 mm, and it’s decreased to 300 mm on the peripheries. The pile must not less than 50 mm into the pile cap. The upper coarse of pile cap is not less than 75 mm thick concrete.

Construction of Pile Cap

Here, the list of pile cap constriction are as follows.

- The pile cap is a mat-like structure which is made of cement, sand and small aggregates.

- This mixture is placed in the required place, and it is supported by the framework to resist the whole structure from sagging and

crack, this entire process is termed as shuttering and reinforcing. - In a pile, cap reinforcements are placed in the longitudinal section of the pile cap, and it creates a wire type of reinforcement.

- At first, the reinforcement cage is placed in the pointed place; then the framework is done by timber to hold the wet concrete.

- After the concrete has placed then the most vital job is to remove the air bubbles from the concrete; otherwise, the concrete gets

- porous, and it may be weaker.

- After concrete placing, compaction and finishing happen then the concrete starts its internal reaction and it generates a lot of

amount of heat that’s why we need to cure the concrete by the water curing process. - In the vast amount of concrete placing, there is a coolant that is used to reduce the heat, which is produced by hydration is called

refrigerant coolant.

So, these are those actions which are very useful during the construction of the pile cap.

Piles Structure

The pile is generally a strong cylinder structure which supports loads of superstructure and transfers it to the subsoil. The pile cap is constructed just above the pile. Pile foundation is used in some following situations, those are-

- Pile foundation is used when the subsoil is weaker, but the superstructure load is too heavy to carry that by shallow footing, then we use a pile foundation structure.

- When the structure load is too heavy like a bridge, water tank, high rise building, etc., we need to use a pile foundation.

Piles are mainly two types, those are.

- End-bearing Pile: In this type of pile, the end portion of this pile rests on the hard starts below the ground. In this type of pile is acting as a vertical column.

- Friction Pile: when the structural load is too heavy, but the subsoil is not too hard, and we can not find hard strata in a reasonable depth, then we need to use friction pile. This type of pile dia is too large because to increase the surface area for the friction.

Pile Cap Foundations

Foundation of the pile cap depends upon various points; those are-

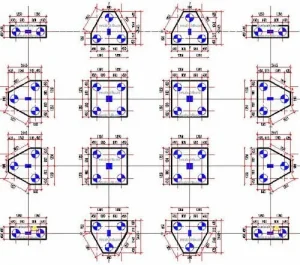

1. Shape and Size of Pile cap

The shape and dimensions depend upon the numbers of the pile and the spacing between two piles. Like- Triangular pile cap for three piles, hexagonal pile cap for 6-7 piles, rectangular pile cap for other numbers of the pile, etc.

This type of pile cap is used to reduce the pile cap area because it’s compact the position of the pile. The pile cap should not be overhanging more than 150 mm. This minimum area provides sufficient length to:

- Tension reinforcement has a large radius bend.

- Make sure that enough reinforcement cover.

- Must satisfy construction tolerance.

2. Depth of Pile Cap

Depth of pile cap is another section in the pile cap foundation works. The following criteria are considered-

- Shrinkage of clay

- Shear capacity of the pile cap

- Pile anchorage

- Natural condition like frost attack

- The water table of the ground surface

Naturally, the depth of the pile cap is much more than pad footing; that’s why it can carry more concentrated loads.

Pile cap depth for different diameters of the pile-

[su_table responsive=”yes” alternate=”no”]

| Pile Diameter (mm) | Depth of Pile (mm) |

| 300 | 700 |

| 350 | 800 |

| 400 | 900 |

| 450 | 1000 |

| 500 | 1100 |

| 550 | 1200 |

| 600 | 1400 |

| 750 | 1800 |

[/su_table]

Also Read: What Is Quick Setting Cement | Uses of Quick Setting Cement

Square Piling Caps

The square pile cap is one type of popular pile cap structure. In this pile cap structure, all the piles are situated in a combined and compacted way. The square pile cap is provided when the number of piles is even; it may be four, six, eight etc. The square pile cap is highly used in bridge structure, high rise building, etc.

Pile Cap Reinforcement.

Pile cap reinforcement and it’s calculation is one of the most essential things in the pile cap section. Before starting the main calculation, we need to find out the main volume of the pile cap that is (length x breadth x height). Bar bending schedule table for reinforcement:

[su_table responsive=”yes”]

| Spec | Dia of Rod (mm) | No. of Rods | Length of Rods. (M) |

Total Length |

| Vertical bar | 12 | 12 | 21.3 | 255.6 |

| Inner spacer ring | 16 |

11 |

1.59 | 17.49 |

| Outer spiral ring | 8 | 101 | 1.65 | 166.65 |

[/su_table]

In pile cap designing, we use reinforcement cage; it increases the strength of vertical concrete column when the soil condition is not good. In the case of the prefabricated pile, the piles are directly placed in the site, and then the pile cap reinforcement works are done.

[su_box title=”FAQ” style=”default” box_color=”#333333″ title_color=”#FFFFFF” radius=”3″ class=”” id=””]

Pile Cap Design

The pile cap has normal-weight concrete with a compressive strength of 4000 psi and Grade 60 reinforcement. And the piles are embedded 4 in. into the pile cap. The axial loads on the column are due to dead and live loads and are equal to 425 and 250 kips, respectively.

Piles Structure

A pile foundation is defined as a series of columns constructed or inserted into the ground to transmit loads to a lower level of subsoil. A pile is a long cylinder made up of a strong material, such as concrete. Piles are pushed into the ground to act as a steady support for structures built on top of them.

Pile Cap Design Example

Data for Pile Cap Design Example

- Pile Diameter 600mm

- Design Load 3000 kN

- Cover to the reinforcement 50mm

- Grade of concrete 30

- Characteristic strength of steel as 500 N/mm2

- Size of the column on the pile cap 500x500mm

- Calculate the dimensions of the pile cap

Consider 150mm offset from the pile and space between piles as 2.5 times pile diameter.

- Width = 500 + 150 + 150 = 800mm

- Length = 2.5 x 600 + 250 + 250+ 150 + 150 = 2150mm

- Consider depth of 1000mm and main bar diameter as 20mm

Effective depth, d = 1000-50-20/2 = 940 mm > 750mm; (2.5×600/2) Ok.

- Consider truss theory

- Tension Force, T = Nl / 2d

- T = 3000 x 0.75 / (2 x 0.94 ) = 1197 kN

- As = T / 0.87fy

- As = 1197 x 1000 / (0.87 x 500 ) = 2752 mm2

- Provide 7 T25 (As provided = 3430 mm2 )

- Check for Punching Shear

- V = 3000 x 103 / ( 4 x 500 x 940) = 1.596 N/mm2

- Vall = 0.8 (fcu)0.5 = 0.8 x (25)0.5 = 4 N/mm2 < 5 N/mm2

- Hence, punchig shear is Ok

Types of Pile Cap

The shapes of pile caps are typically either:

- Triangular (for 3 piles).

- Hexagonal (for 6-7 piles).

- Rectangular (for all other number of piles).

Pile Cap Function

Pile caps create a stable foundation and offer a larger area for the distribution of the building load onto the piles. They act in a similar way to piled raft foundations, where a concrete slab rests on soil which may be susceptible to movement, above a group of piles.

Pile Cap Size

The pile cap should overhang the outer piles by at least 150mm but should not be excessive, generally not more than the diameter of the pile diameter. This minimizes the plan area and thus the cost, while providing sufficient length to: Anchor the tension reinforcement with a large radius bend.

Importance of Pile Cap

Pile caps create a stable foundation and offer a larger area for the distribution of the building load onto the piles. They act in a similar way to piled raft foundations, where a concrete slab rests on soil which may be susceptible to movement, above a group of piles.

Pile Cap Thickness

The thickness of the pile cap t is a variable, which is between 0.5m and 3.0m. The diameter of piles is 0.5m, and the length is 8.5m. The center-to-center spacing of piles is 2.5 m. Both pile cap and piles are made of concrete.

Minimum Pile Cap Thickness

The span to thickness ratio of the cap should not be more than 5 so that pile cap is rigid enough to distribute the load uniformly to the piles. 5. Generally, its thickness should not be less than 500mm which may be reduced to 300mm at the free edges.

Pile Cap Depth Rule of Thumb

The overall depth of pile cap shall also be selected such that the effective depth of bottom reinforcement is at least 12 inches. Consider a uniform distribution of column load to the provided piles.

[/su_box]

[su_note note_color=”#F2F2F2 ” text_color=”#333333″ radius=”3″ class=”” id=””]

Like this post? Share it with your friends!

Suggested Read –

- What Is Bituminous Road? | Bituminous Road Construction | Bituminous Road Layers | Bituminous Macadam | Bituminous Road Construction Process | Advantages of Bitumen Road | Disadvantages of Bitumen Road | Application Road

- What Is Super Elevation? | Superelevation Definition | Purpose of Providing Superelevation in Roads | Calculation of Superelevation in Roads | Minimum and Maximum Superelevation in Roads | Method of Providing Superelevation to the Roads

- What Is Lintel? | Function of Lintel | Types of Lintel

- What Is Grouting | Type of Grouting | Experiment of Grouting | Characteristics of Grouting | Types of Grout for Ceramic Tile | Advantage of Grouting | Disadvantage of Grouting

- What Is Grade of Concrete | Concrete Mix Ratio | Type of Concrete Mix | Different Types of Concrete Grade with Concrete Mix Ratio and Compressive Strength | Uses of Different Grades of Concrete

[/su_note]

Originally posted 2022-07-17 08:03:47.