Types of Concrete Construction Joints | Tips on Placing Joints in Concrete | Tips on Placing Joints in Concrete

Concrete joints are used to compensate when concrete expands or shrinks with changes in temperature.

Concrete joints are normally used to prevent cracking when concrete contractions, creating training, tools, sawdust, and placement of joint builders.

Pre-planned cracks will provide a finishing product with a better finish and will be formed in specific locations where those cracks can be monitored.

Sometimes, due to the material and the width or extent of the concrete joints, they are necessary to improve the performance of the material and allow the materials to expand/contract or move without damaging other structures.

Table of Contents

Types of Concrete Construction Joints:

Contractors can install different types of joints based on their requirements. A single plate can have different types of joints to make it safer and more resistant.

Here is a brief explanation of all types of joints that contractors can install on their concrete surface:

- Isolation Joints.

- Construction Joints.

- Concrete Contraction Joints.

- Decorative Concrete Joints.

1. Isolation Joints–

As the name suggests, this joint exists to insulate the concrete slab from neighboring buildings.

When the concrete slab expands or contracts, the isolation joints will ensure that the slab does not crack or cause problems in the pipes, columns, walls, and columns nearby.

These joints are almost always placed in external installations because the concrete surface does not expand as much indoors and with air conditioning.

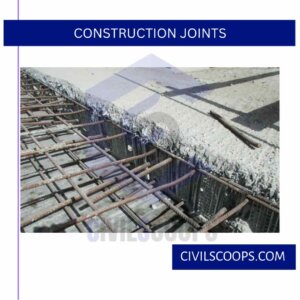

2. Construction Joints–

These joints are placed to keep the new concrete in place. They are essentially table rails made of wood, metal, or plastic and are placed during the pouring and finishing of concrete.

The construction joints will allow you to pour the concrete in stages and control the positioning of the slab according to your needs. You can also use construction joints as contraction joints if you plan placement well.

3. Concrete Contraction Joints–

It intends to create a weakened area in the concrete and regular where the cracks will occur, normally in a straight line.

The contraction joints should be placed to produce panels as square as possible and never exceed a length/width ratio of 1 1/2 to 1. The joints are usually spaced at distances equal to 24 to 30 times the thickness of the slab.

Joint spacing greater than 15 feet requires the use of load transfer devices. Contraction joints can be machined on the concrete surface at the time of laying.

Joints can also be sawn on the hardened concrete surface. It is important to understand that the more the saw is postponed, the greater the potential for cracks to be established before the saw is completed.

4. Decorative Concrete Joints –

Building decorative concrete joints require a little more planning and careful execution. The decorative stamping on the concrete does not sink enough to provide the necessary stability to the slab.

The joint must penetrate at least 1/4 of the surface to ensure that cracks are carefully controlled. You only need to cut the stamped design pattern to ensure that the joints are not visible from the surface.

Also Read: Properties of Stones | Requirements of Good Building Stones

Why Do We Need Placing Joints in Concrete?

Construction joints are used in circumstances where two consecutive concrete layers meet. Construction joints are usually placed at the end of the day or when concrete pouring is interrupted for longer than the initial concrete laying time.

Construction joints must be designed and specified by a structural engineer. You can also join and continue reinforcement through a construction joint.

If sufficient PCC is available at the end of the day, the construction joint can be placed on a planned transverse joint.

Tips on Placing Joints in Concrete

The following recommended tips should be observed:

- The maximum spacing of the joint should be 24 to 36 times the thickness of the slab.

- Joints should be 10 feet apart and a maximum of 15 feet apart.

- When using the joint groove for contraction joints, the joint must have a minimum depth of 1/4 the thickness of the slab.

- Saw joints must be made within 4 to 12 hours after finishing the concrete.

- Keyed joints are not recommended for industrial floors.

- Dry cutting joints should be made between 1 and 4 hours after finishing.

- The filling of the precast joint must be used to separate the slabs from the walls or feet of the building.

- Put 2 inches of sand in motion to prevent attachment to the foot.

- If the slab contains wire mesh, it is recommended to discontinue it through the contraction joints.

- The joint spacing must also be chosen so that the concrete sections are approximately

- It is recommended to have concrete joints along the lines of the column, sawn, or keyed.

- Metal dowels should be used on slabs that carry heavy loads.

- Plan the exact locations of all joints, including when to cut the saw.

- Use Isolation joints between slabs and columns, walls, and sidewalks and where sidewalks or sidewalks meet other concrete structures.

- The materials used in the concrete joints must be flexible enough to absorb or deform as needed and then be able to restore the original state.

- Always look for materials that are permeable, and that can adhere to the concrete.

Tools Use Placing in Concrete

The following tools are typically used to create concrete joints, although these tools may vary depending on the size and scope of the project.

Here Are The Most Used Tools:

- Manual Grover or Walking Grover:

- Depending on the size of the slab, it is advisable to choose one of these two.

- Tools for Wireless Control Joints:

- Ideal for use in small and medium-sized projects.

- Concrete Saw:

- Ideal for cutting saws in concrete, but be sure to know the depth of this. Otherwise, you may be creating other problems.

[su_box title=”FAQ” style=”default” box_color=”#333333″ title_color=”#FFFFFF” radius=”3″ class=”” id=””]

Construction Joint

A construction joint is a type of concrete joint that is used when a new section of concrete is poured adjacent to another concrete section that has already set. The purpose of a construction joint is to allow for some horizontal movement, while being rigid against rotational and vertical movement.

Concrete Joint

Concrete joints are used to compensate when concrete expands or shrinks with changes in temperature. Concrete joints are normally used to prevent cracks when the concrete shrinks by creating forming, tooling, sawing, and placing joint formers.

Construction Joint in Slab

Joints are commonly spaced at distances equal to 24 to 30 times the slab thickness. Joint spacing that is greater than 15 feet require the use of load transfer devices (dowels or diamond plates). Contraction joints may be tooled into the concrete surface at the time of placement.

Types of Construction Joints

There are three different types of concrete construction joints: Butt-Type, Keyway, & Dowel.

What Is a Construction Joint in Concrete?

A construction joint is the interface between concrete placements intentionally created to facilitate construction. A cold joint is a joint or discontinuity resulting from a delay in placement of sufficient duration to preclude intermingling and bonding of the material, or where mortar or plaster rejoin or meet.

Concrete Joint Types

There are three types of joints: Contraction Joints, Construction Joints and Isolation joints. The most common are contraction joints which control cracks which are caused by restrained shrinkage, loads and other stresses.

Control Joints in Concrete

Contraction/Control Joints. Contraction/control joints are placed in concrete slabs to control random cracking. A fresh concrete mixture is a fluid, plastic mass that can be molded into virtually any shape, but as the material hardens there is a reduction in volume or shrinkage.

Concrete Expansion Joint Material

Polyvinyl, Polyethylene and Steel are among the most common materials for Concrete Expansion Joints. While common, customers also consider Cellulose, Rubber and Polyolefin as options.

[/su_box]

[su_note note_color=”#F2F2F2 ” text_color=”#333333″ radius=”3″ class=”” id=””]

Like this post? Share it with your friends!

Suggested Read –

- 23 Different Types of Doors

- How to Get Rid of Paint Smell

- Best Concrete Mix for Driveway Repair

- What Is an Arch | 21 Different Parts of an Arch

- What Is Building Construction | Steps & Processes of Building Construction | Application of Building Construction | How to Do Planning of Building Construction

[/su_note]

Originally posted 2023-04-10 11:01:46.