Rate Analysis for Concrete

Table of Contents

Introduction of Rate Analysis for Concrete

- 1st Step – estimation of labour, materials, equipments & miscellaneous items

- 2nd Step– check the component of structure to which the RCC rate analysis is needed,

Data required for RCC Rate Analysis

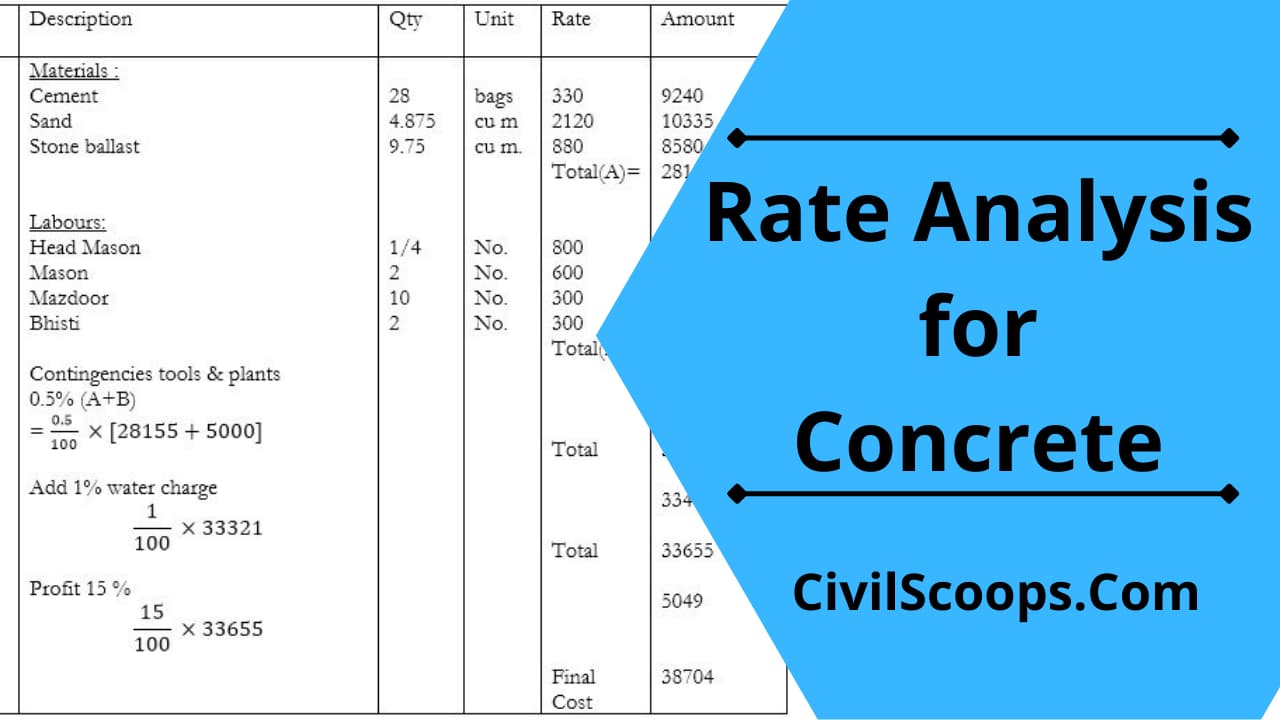

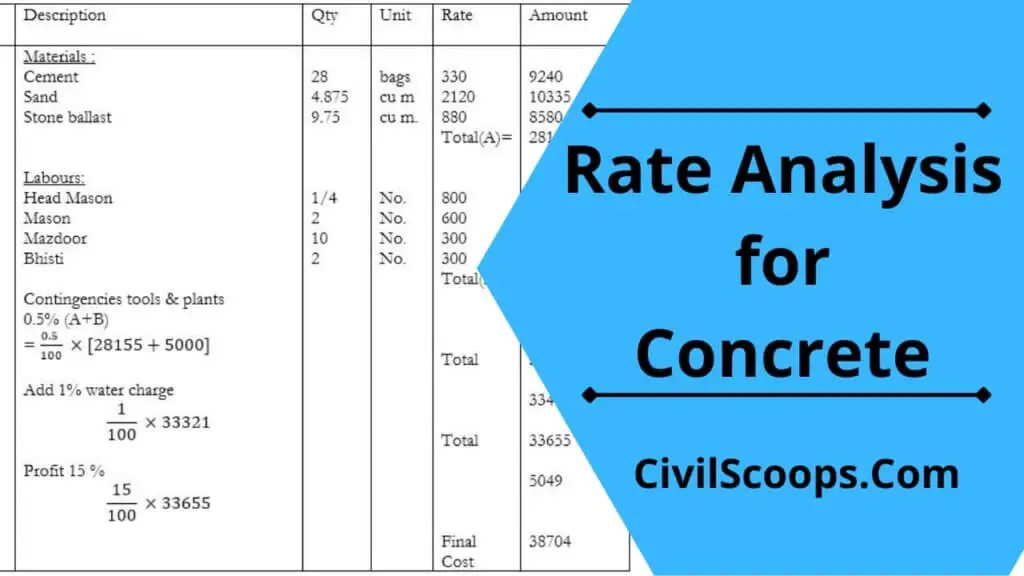

Step 1: Estimation of Materials

Principal Components are: cement, sand, coarse aggregate & steel. Let mix design is M20 (1:1.5:3). Total volume of substances required is 1.54 m3 for 1 m3 of wet concrete.

- For 1 m3 of m15 (1:2:4) grade

- Sub total cost = cement + sand + aggregate = Rs. (2520 +775 + 1860) = Rs. 5155.

- For 1 m3 of m7.5 (1:4:8) grade

- Sub total cost = cement + sand + aggregate = Rs. (1360 +837 + 2008 )= Rs. 4205.

- For 1 m3 of m10 (1:3:6) grade

- Sub total cost = cement + sand + aggregate = Rs. (1776 +815 + 1956) = Rs. 4547.

1.1 Bags of cement required:

- Cement density = 1440 kg/m3

- 1 bag cement weight = 50 kg

- For 1 m3of Concrete, Cement needed =0.28 m3

- Therefore, number of bags of cement required (volume of 1 bag of cement = 0.0347 m3= 8.07 bags of cement.

- For 1m3 of M15 (1:2:4) grade

- Amount of cement = 1/7 × 1.54 m3 × 1440 kg/m3 = 316.8 kg,

- For 1m3 m15 concrete, number of cement bags needed = 316.8/50 = 6.3.

- If rate of cement = Rs. 430/bag,

- Hence, cost of 5 bags cement = 5 ×430 = Rs. 2150.

- For 1 m3 of M7.5 (1:4:8) grade

- Amount of cement = 1/13 × 1.54 m3 × 1440 kg/m3 = 170 kg,

- For 1m35 concrete, number of cement bags needed = 170/50 = 3.4.

- If rate of cement = Rs. 440/bag,

- Hence, cost of 4 bags cement = 4 ×440 = Rs. 1760.

- For 1 m3 of M10 (1:3:6) grade

- Amount of cement = 1/10 × 1.54 m3 × 1440 kg/m3 = 222 kg,

- For 1m3 m10 concrete, number of cement bags needed = 222/50 = 4.44.

- If rate of cement = Rs. 450 per bag,

- Hence, cost of 5 bags cement = 5 ×450 = Rs. 2250.

1.2 Volume of Sand required:

- Volume of sand required for 1m3 of concrete = 0.42 m3 of sand.

- Conventionally sand is measured in CFT & Sand Density = 35.3147

- For 1 m3 of M15 (1:2:4) grade

- Amount of sand = 2/7 ×1.54 × 35.3147 = 15.5 cft,

- If rate of sand is Rs. 50/cft,

- Hence, cost of 15 cft sand = 15 × 50 = Rs. 750,

- For 1 m3 of M7.5 (1:4:8) grade

- Amount of sand = 4/13 ×1.54 × 35.3147 = 16.73 cft,

- If rate of sand is Rs. 55/cft,

- Hence, cost of 17 cft sand = 17 × 55 = Rs. 935,

- For 1 m3 of M10 (1:3:6) grade

- Amount of sand = 3/10 ×1.54 × 35.3147 = 16.3 cft,

- If rate of sand is Rs. 60/cft,

- Hence, cost of 19 cft sand = 19 × 60 = Rs. 1140,

1.3 Volume of Coarse Aggregate Required

For 1 m3 of concrete = 0.84 m3 of coarse aggregates.

Conventionally aggregate measured in CFT & 1m3 = 35.3147

- For 1 m3 of M15 (1:2:4) grade

- Amount of aggregate = 4/7 ×1.54 × 35.3147 = 31 cft,

- If rate of aggregate is Rs. 60/cft,

- Hence, cost of 30 cft aggregate = 30 × 60 = Rs. 1800,

- For 1 m3 of M7.5 (1:4:8) grade

- Amount of aggregate = 8/13 ×1.54 × 35.3147 = 33.47 cft,

- If rate of aggregate is Rs. 65/cft,

- Hence cost of 32 cft aggregate = 32 × 65 = Rs. 2080,

- For 1 m3 of M10 (1:3:6) grade

- Amount of aggregate = 6/10 ×1.54 × 35.3147 = 32.6 cft,

- If rate of aggregate is Rs. 70/cft,

- Hence, cost of 34 cft aggregate = 34 × 70 = Rs. 2380 ,

1.4 Estimation of Reinforced Steel:

- Entire weight of steel required / total volume of concrete for various components.

- Assuming the proportion of reinforcement for different components.

- For slabs = 1 % of concrete

- For Beam = 2 % concrete

- For column = 2.5 % of concrete

- For RCC Roads, 0.6% concrete

Step2: Labor Requirement for 1m3 of RCC

- Mason: 1 mason required for 0.37 days.

- Labors: 1 Unskilled labor required for 3.5 days.

- Water carrier: 1 water-carrier required for 1.39 days.

- Bar Bender: 1 bar-bender required for 100 kg steel for 1 day.

- Mixer Operator: 1 mixer-operator required for 0.0714 days.

- Vibrator Operator: 1 vibrator-operator required for 0.0714 days.

- Other charges 7% (approx)

Let 1 mason & a pair of helpers completed 1 m3 of work in 8 hour,

Mason rate Rs. 550

Helper Rate 450,

Hence, cost of labour in concreting work = Rs. 550 +(2×450) = Rs. 1450.

- For 1m3 of M15 (1:2:4) grade

- Sub total cost = Rs. (5155 + 1450) = Rs. 6605

- For 1m3 of M7.5 (1:4:8) grade

- Sub total cost = Rs. (4205 + 1450) = Rs. 5655

- For 1m3 of M10 (1:3:6) grade

- Sub total cost = Rs. (4547 + 1450) = Rs. 5997

Step 3: Equipments and sundries

Let it be 7.5%.

- For 1m3 of M15 (1:2:4) grade

- Let cost of apparatus is 1.5 %,then 1.5% of 6605 = Rs. 99.075

- Sub total cost = Rs. (6605 + 99.075) = Rs. 6704.07

- For 1m3 of M7.5 (1:4:8) grade

- Let cost of apparatus is 1.5 %,then 1.5% of 5655 = Rs. 84.825

- Sub total cost = Rs. (5655 + 84.825) = Rs. 5739.82

- For 1m3 of M10 (1:3:6) grade

- Let cost of apparatus is 1.5 %,then 1.5% of 5997 = Rs. 89.955

- Sub total cost = Rs. (5997 + 89.955) = Rs. 6086.95

Step 4: Contractor’s Profit

It ranges from 10 – 20%. Let it be 15% of total cost of materials, labours & equipments.

- For 1m3 of M15 (1:2:4) grade

- Let contractor’s profit is 10%, then 10% of 6605 = Rs. 660.5

- Total cost = Rs. (6605 + 660.5) = Rs. 7265.50.

- For 1m3 of M7.5 (1:4:8) grade

- Let contractor’s profit is 10%, then 10% of 5655 = Rs. 565.5

- Total cost = Rs. (5655 + 565.5) = Rs. 6220.50.

- For 1m3 of M10 (1:3:6) grade

- Let contractor’s profit is 10%, then 10% of 5997 = Rs. 599.7

- Total cost = Rs. (5997 + 599.7) = Rs. 6596.70.

Step 5: Rate Analysis for Floors

A floor has the subsequent modules.

- Sub Base

- Base.

- Topping

Sub Base

- Sub Base is the lower part of the floor.

- Sub Base is developed by Lime Concrete or Lean Cement Concrete.

- Concrete (1:4:8) or (1:3:6) is employed.

- Sub Base isn’t required if the bottom is solid & strong.

Base

- The base is developed directly over the sub-grade on the ground.

- This part is formed with concrete (1:2:4).

Topping

- The toppingis the topmost part of the ground.

- The topping is sometimes developed with Terrazzo, Mosaic, Cement Concrete, and Tiles.

Also Read: Building Layout | How to Building Layout | Construction Layout Techniques

Step6: Rate Analysis for White Washing and Painting

- Unit Area is chosen.

- 10 sq m & 100 sq ft are considered as Unit Area in meters & feet respectively.

- 2 kgs of white fat lime are going to be required.

- 06 kgs of adhesive are going to be required into the blend.

[su_box title=”FAQ” style=”default” box_color=”#333333″ title_color=”#FFFFFF” radius=”3″ class=”” id=””]

Petrographic Analysis of Concrete

Petrographic analysis (astm c856) – a microstructural examination by optical and scanning electron microscopy (sem) of the paste and aggregate on a prepared sample of concrete to look for features such as degree of cement hydration, microcracking, reaction products, breakdown of aggregate and evidence of poor freeze

Concrete Failure Analysis

Petrographic analysis is a diagnostic tool for examining failures in concrete. Once onsite, we can carry out an initial visual examination of the area in order to ascertain possible causes of the problem and to determine the best position for taking samples.

Petrographic Testing of Concrete

Petrographic testing (astm c856) is a method that uses microscopes to examine the mineralogical and chemical characteristics of concrete and minerals. Each of these characteristics gives the engineer a sense of what is going on with the concrete and its physical properties.

Concrete Analysis

Chemical analysis of hardened concrete can provide a wealth of information about the mix constituents and possible causes of deterioration. Standard methods can be used to find the cement content and original water/cement ratio, but many other properties can also be established.

Siding Estimate near Me

House siding costs $4,300 to $15,800 on average, or between $3 to $11 per square foot depending on the home’s size and materials used. The cost to reside a 2,000-square-foot home with vinyl is $7,100 on average. The cost to replace siding adds $1,000 to $3,000 for removing the old siding.

Building Construction Materials Estimate

It’s easy to figure out – simply take the total amount of square feet that were measured for the project, then divide the total amount of square feet by the coverage rate of the material.

Drywall Estimating Software

Let’s get started to start your drywall estimate you’re going to first need to upload your plans. And then set your scale correctly for those plans.

Windows and Siding Estimator

On the low-cost end of the spectrum, you can spend between $1,400 and $9,500 to re-side a 2,000 square foot home, or depending on the material you choose, siding costs start at 10k+.

Home Depot Roofing Estimate

Measure the length and width of each portion of the roof, multiply length by width for each plane, and then add the planes together for the total square footage. If you have a simple gable roof, you’ll only need to measure and sum up the 2 planes of the roof.

Lumber Takeoff

Framing takeoff means a basic count of the framing lumber. It is the first step in estimating construction materials for a new residential or construction building.

[/su_box]

[su_note note_color=”#F2F2F2 ” text_color=”#333333″ radius=”3″ class=”” id=””]

Like this post? Share it with your friends!

Suggested Read –

- What Is a Spillway | Types of Spillway | Definition Spillway | Spillway Design

- What Is Sheepsfoot Roller? | Characteristics of Sheepsfoot Rollers | Difference Between Padfoot and Sheepsfoot Rollers

- What Is Workability | What Is Workability of Concrete | Types of Workability of Concrete | Factors Affecting Workability of Concrete

- Monolithic Slab I Monolithic Definition I Monolithicfooting I Monolithic Slab Foundationl Monolithic Slab Foundation Design L What Is a Monolithic Slab L How to Form a Monolithic Slab

- Types of Curing | Concrete Curing Time | How to Cure a New Concrete Slab | What Is Curing of Concrete | How Long Does Concrete Take to Dry | How Long Does It Take for Cement to Dry

[/su_note]

Originally posted 2024-04-05 05:14:02.