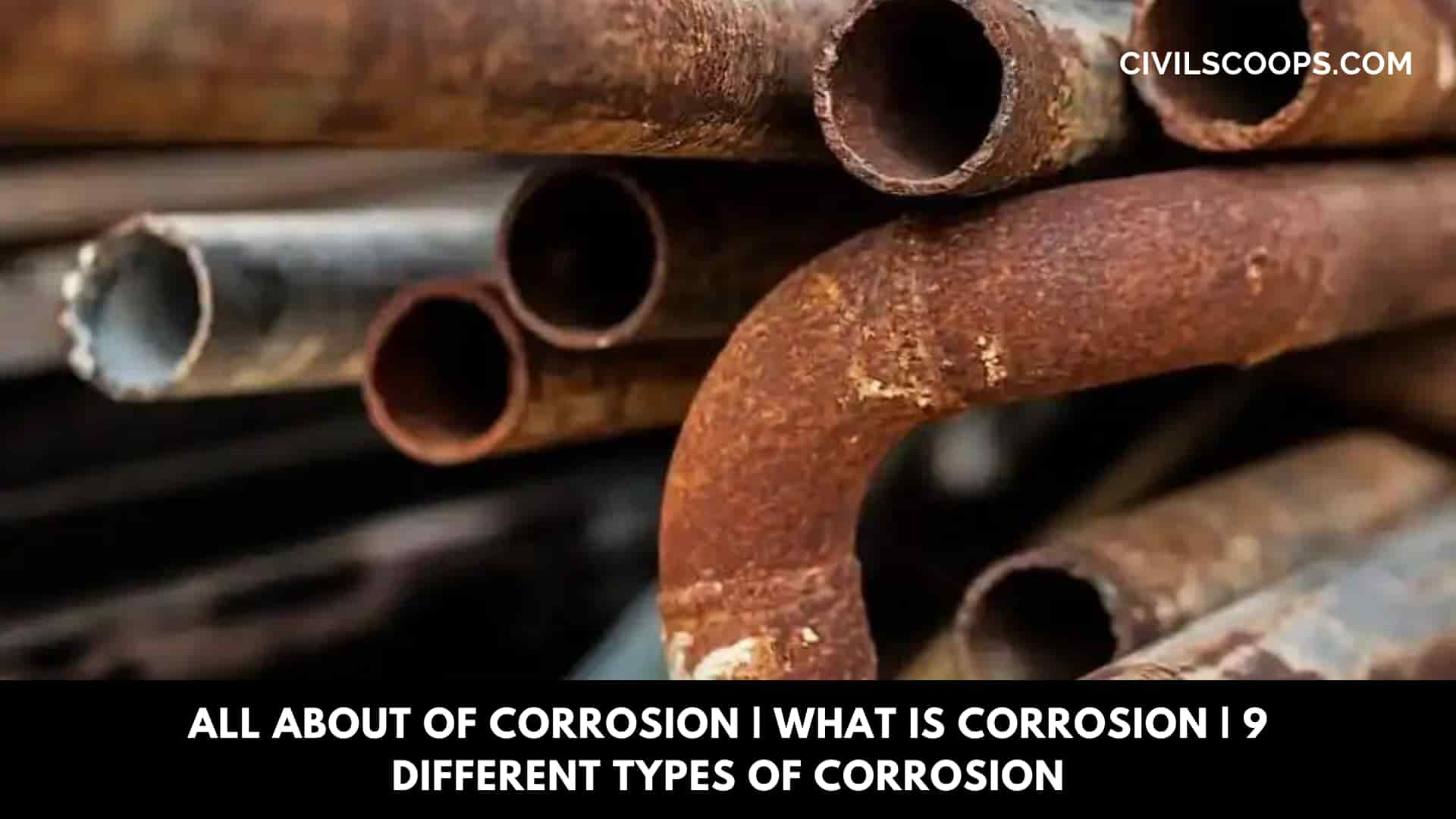

All About of Corrosion | What Is Corrosion | 9 Different Types of Corrosion

Table of Contents

What Is Corrosion?

Corrosion is a native method that transforms pure metals into a robust synthetic form like oxide or hydroxide. It is the constant of metal because of artificial action with their enclosing.

It degrades and erodes the metals by listless their power, looks, and long-lasting factors. Materials will generally part into two sections which are chemical and physical factors.

Types of Corrosion

1. Uniform Corrosion

A uniform coat of corruption will produce on the floor in uniform corrosion. The material and unroll over the whole bottom of the materials and this kind of corrosion is abroad spot on materials which are not safe by floor layer such as AL, Zn, and margin will include little materials generally damage by uniform corrosion.

2. Crevice Corrosion

Crevice corrosion happens because little space and interval favor producing liquid and not having a suitable body process. When crevice corrosion occurs, the chance for crevice corrosion adds with many connected fronts. Crevice corrosion will damage by mechanical injury because of the connective sign among the metallic floor and corrosive fluid.

3. Fretting Corrosion

Fretting corrosion happens at the two exposure zone of metals which will connect jointly, and this usually looks when the exposure space will pacify to fall and difference. This corrosion can be straightforward in fastening and engaging, secure floor, etc.

Also Read: What Is Granolithic Floors | Construction Method | Advantages аnd Disadvantage

4. Corrosion Fatigue

Fatigue matter will explain as the defeat of matter being replay apply of pressure, and the fatigue of ore will grow in the corrosive climate, then it will call as corrosion fatigue. It can develop by stopping the fatigue refusal of the metal.

5. Intergranular Corrosion

Intergranular corrosion is the corrosion that looks on the granular field, and the seed will not damage in this situation. It seems when there is a notable variation in a reaction opposite pollutant among sources and seed margins.

6. Galvanic Corrosion

Galvanic corrosion happens when two varieties of materials situate and connect in corrosive potassium, and the galvanic pair produced among the two matters are anode and cathode. Galvanic corrosion occurs the materials must be in electrical touch and bare to an electrolyte.

7. Environmental Cracking

Environmental cracking is a corrosion method resulting from a mixture of ecological states damaging the material, and synthetic, pressure, and the strain-connected outcome can combine.

In the below kinds of environment corrosion: corrosion fatigue, hydrogen-induced cracking, stress corrosion cracking, and liquid metal and embrittlement.

8. Erosion Corrosion

Erosion corrosion is an automatic convince crash of a matter floor, and in a corrosive environment, it will damage the joint motion of liquid matters and durable floors. Be on fire at the gash line finishes of the plumber line.

Example of Corrosion

Several corrosion examples removed from the daily living hood are;

Rust on metals bare to water like the layered metal of the mechanical washer-dryer where the saline environment momentum the erosion backlash and instantly there are crevice and the classic brown mark of oxidation.

It happens while iron rust in the existence of water and oxygen and oxidation is a different material with the chemical formula Fe2O3.XH2O, which will moisten the form of metal.

Corrosion of water pipeline mostly metallic which favor shatter add time, if not to pollute the water with a little dose of rust, afford it a brown color.

The paint of the statue of liberty, because its natural color should not be fresh but copper, the object from which it will create.

But around in the water, the velocity of wind rust it and coats it with new copper rust, the corrosion solution. Below is the chemical formula for copper corrosion

Cu + H2O + CO2 + O2 – Cu (OH) 2 + CuCO3

Corrosion of canning can like that have been in the store everlasting, and brown marks appear in several zones, an unmistakable impact which air corrosion has to start to damage him.

Tarnishing of silver- chemical reaction among the silver and Sulphur carry elements in the air because the silver to tarnish and silver supplied will build while silver material becoming dark because of a coating of silver sulfide. The below chemical formula of metal is

2Ag + H2S – Ag2S + H2

Main Causes of Corrosion

Pollutant in metals- commonly, impurity in metals momentum corrosion because their pollutants function as an invisible electrochemical layer which causes pollution.

In the situation of metals in electrochemical cell- in corrosion, the electrochemical series will be essential and active metals lose electrons sooner and corrode earlier.

The concentration of oxygen- corrosion will mention by developing in oxygen, and an anode will place with a small oxygen concentration, whereas a cathode is a zone with more oxygen concentration. Breakdown occurs as a solution.

Presence of electrolytes- they conduct ions, dilute the salt in waterworks an electrolyte and corrosion will movement while electrolytes will make existence in water.

Moisture in climate- while the water is moist, the existence of humidity with high-pressure movement corrosion because ions get power and start shifting earlier in more pressure, causing them to collide regularly.

[su_box title=”FAQ” style=”default” box_color=”#333333″ title_color=”#FFFFFF” radius=”3″ class=”” id=””]

Corrosion

Corrosion is a natural process that converts a refined metal into a more chemically stable oxide. It is the gradual deterioration of materials (usually a metal) by chemical or electrochemical reaction with their environment.

What Are the Types of Corrosion?

- Uniform corrosion.

- Galvanic corrosion.

- Concentration cells.

- Crevice corrosion.

- Pitting corrosion.

How to Prevent Corrosion?

- Use non-corrosive metals, such as stainless steel or aluminium.

- Make sure the metal surface stays clean and dry.

- Use drying agents.

- Use a coating or barrier product such as grease, oil, paint or carbon fibre coating.

- Lay a layer of backfill, for example limestone, with underground piping.

How to Prevent Corrosion of Metals?

- Use non-corrosive metals, such as stainless steel or aluminium.

- Make sure the metal surface stays clean and dry.

- Use drying agents.

- Use a coating or barrier product such as grease, oil, paint or carbon fibre coating.

How to Stop Corrosion?

Protective Coating

Rubber paints are the most effective because they act as a barrier that prevents the metal’s chemical structure from interacting with environmental compounds like water and oxygen that result in corrosion. Applying a powder coat is another effective method of corrosion prevention.

How to Treat Aluminum Corrosion?

By combining distilled water with either pure lemon juice or white vinegar, and then gently agitating the corroded area with a mild scrubbing pad, most mild cases of aluminum corrosion can be removed.

How Corrosion Can Be Prevented?

One of the easiest and cheapest ways to prevent corrosion is to use barrier coatings like paint, plastic, or powder. Powders, including epoxy, nylon, and urethane, adhere to the metal surface to create a thin film. Plastic and waxes are often sprayed onto metal surfaces.

How Can We Prevent Corrosion of Iron?

Two ways to prevent the rusting of iron are: Oiling, greasing, or painting: By applying oil, grease, or paint, the surface gets a waterproof coating and the moisture and oxygen cannot come into direct contact with the iron article. Hence, rusting is prevented.

How Does Alloying Prevent Corrosion?

Alloying prevents rusting by combining several metals or elements that interact with each other to form a protective layer over the top of the surface of the metal. This barrier limits oxygen and air getting past the surface of the metal and penetrating the inner structure.

Why Corrosion of Iron Is a Serious Problem?

When iron is exposed to oxygen and water, it corrodes, resulting in the formation of an iron oxide known as rust. Corrosion of iron is a severe problem since it reduces the beneficial characteristics of iron, causing it to lose strength and eventually become unsuitable for use.

Why Corrosion Occurs?

General corrosion occurs when most or all of the atoms on the same metal surface are oxidized, damaging the entire surface. Most metals are easily oxidized: they tend to lose electrons to oxygen (and other substances) in the air or in water. As oxygen is reduced (gains electrons), it forms an oxide with the metal.

What Is the Difference Between Corrosion and Erosion?

Corrosion generally refers to the destruction of materials through chemical reactions. As for erosion, it is basically the physical phenomenon involving the movement of small fragments of rocks or the topsoil due to the influence of natural forces like gravity, water, wind, etc.

How to Prevent Erosion Corrosion?

- Reduce the turbulence of the fluid in the tube by streamlining the piping.

- Control the velocity of the fluid to reduce high-flow velocities.

- Use corrosion-resistant materials.

- Use corrosion inhibitors and cathodic protection.

How to Prevent Galvanic Corrosion?

- Selecting materials with similar corrosion potentials.

- Breaking the electrical connection by insulating the two metals from each other.

- Applying coatings to both materials. …

- Separating the two materials by inserting a suitably sized spacer.

How to Stop Galvanic Corrosion?

Galvanic corrosion can be prevented by: Selecting materials with similar corrosion potentials. Breaking the electrical connection by insulating the two metals from each other. Applying coatings to both materials.

How to Prevent Fretting Corrosion?

- lubrication with oils or greases, to reduce friction and exclude oxygen from the interface.

- Increase in the hardness of one or both materials in contact. …

- Use of seals to absorb vibrations and exclude oxygen and/or moisture.

What Causes Fretting Corrosion?

Fretting corrosion is a special type of erosion-corrosion which occurs in the atmosphere rather in aqueous solutions. Fretting corrosion occurs due to vibration and slip in contact areas between materials under load.

How to Prevent Crevice Corrosion?

Eliminating gaps, such as those found in welds and joints, can help to reduce crevice corrosion risk. Ensuring complete drainage of vessels and removing electrolytes from surfaces can further reduce risk. Utilizing solid, non-absorbent gaskets can reduce risk at connections and equipment.

How to Prevent Uniform Corrosion?

- Use thicker materials for corrosion allowance.

- Use paints or metallic coatings such as plating, galvanizing or anodizing.

- Use Corrosion inhibitors or modifying the environment.

[/su_box]

[su_note note_color=”#F2F2F2 ” text_color=”#333333″ radius=”3″ class=”” id=””]

Like this post? Share it with your friends!

Suggested Read –

- What Is Stone | Types of Stone | Uses of Stones

- How Cement is Made | Cement Ingredients | History of Cement

- All About Soak Pit Design | Health Aspects | Operation and Maintenance of Soak Pit | Applicability of Soak Pit Design

- What Is Hard Hat | Hard Hat Colour Definition | Different Hard Hat Colour Codes | Types of Safety Helmets | Classification of Hard Hats

- What Is Pier and Beam Foundation | Advantages & Disadvantages of Pier and Beam Foundations | Pier and Beam Foundation Design | How to Build a Post and Pier Foundation

[/su_note]

Originally posted 2023-03-29 11:12:47.