All About Soak Pit Design | Health Aspects | Operation and Maintenance of Soak Pit | Applicability of Soak Pit Design

Table of Contents

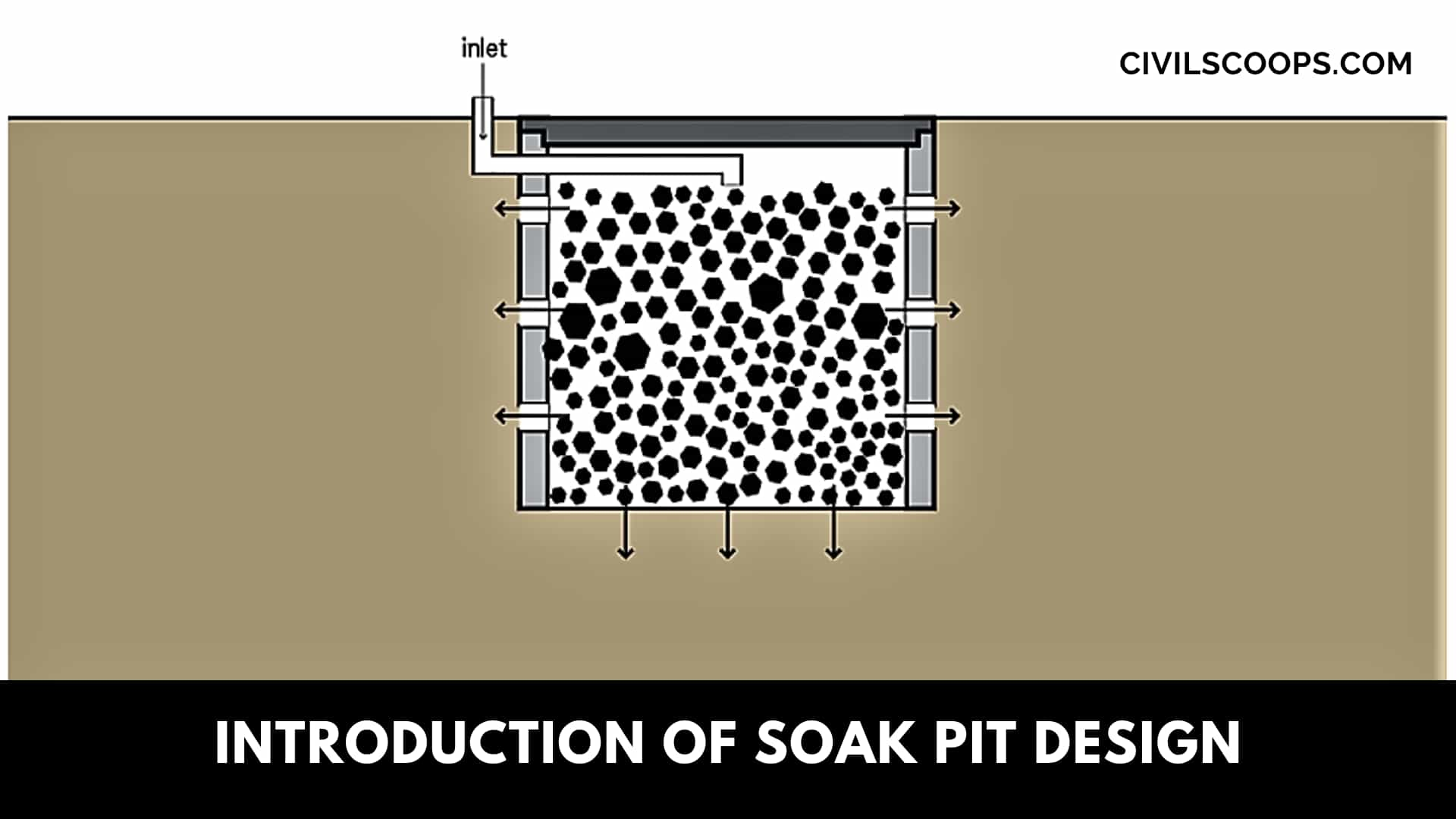

Introduction of Soak Pit Design

If there is no intention or need to reuse wastewater, collected rainwater or gray water, immersion pits can offer an economic opportunity for partial treatment of waste-water or ash from a primary treatment (eg septic tank, double pits for flush toilets, biogas collector, deflector anaerobic reactor, etc.) and a relatively safe way to discharge it into the environment and thus recharge groundwater bodies.

As the waste-water (gray water or black water after primary treatment) penetrates the soil from the immersion well, small particles are filtered through the soil matrix and organics are digested by microorganisms.

The waste-water effluent is absorbed by the soil particles and moves horizontally and vertically through the soil pores.

The subsoil layers must, therefore, be permeable to water in order to avoid rapid saturation. High daily volumes of discharged effluents must be avoided (HEEB et al. 2008).

Thus, immersion wells are more suitable for soil with good absorption properties; clay, hard or rocky soil is not appropriate.

Immersion wells are used in the same way as leach fields but require less space, as well as less operation and maintenance.

But they can also generally receive less influence, and groundwater pollution can be greater than in leach fields.

Also Read: What Is RQD | Advantages of Rock Quality Designation | Limitations of Rock Quality Designation (RQD)

Design Considerations of Soak Pit Design

The immersion well, basically consisting of a single well (usually approximately 1 m3), should be between 1.5 and 4 m deep, but, as a general rule, never less than 2 m above the water table.

It must be located at a safe distance from a source of drinking water (preferably more than 30 m).

The immersion well must be kept away from areas of heavy traffic, so that the soil above and around it is not compacted.

It can be left empty and lined with a porous material to provide support and prevent collapse, or left unfinished and filled with thick stones and gravel.

The rocks and gravel will prevent the walls from collapsing, but will still provide adequate space for wastewater.

In both cases, a layer of sand and fine gravel should be spread over the bottom to help disperse the flow.

To allow future access, a removable cover (preferably concrete) must be used to seal the well until it needs to be maintained.

Health Aspects / Acceptance of Soak Pit

As long as the immersion well is not used for raw sewage, and as long as the previous collection and storage/treatment technology is working well, health concerns will be minimal.

The technology is located underground and, therefore, humans and animals should not have contact with the effluent.

It is important, however, that the immersion well is located at a safe distance from a source of drinking water (preferably at least 30 m).

As the immersion well is odorless and is not visible, it must be accepted by even the most sensitive communities.

Operation and Maintenance of Soak Pit

A good-sized immersion well should last between 3 and 5 years without maintenance.

To prolong the life of immersion well, care must be taken to ensure that the effluent has been clarified and/or filtered to avoid excessive accumulation of solids.

The immersion well must be kept away from areas of heavy traffic, so that the soil above and around it is not compacted.

Particles and biomass will eventually clog the well and will need to be cleaned or moved. When the performance of the immersion well deteriorates, the material inside the immersion well can be excavated and replenished.

To allow for future access, a removable (preferably concrete) lid should be used to seal the pit until it needs to be maintained.

Applicability of Soak Pit

A soak pit does not provide adequate treatment for raw wastewater and the pit will quickly clog. It should be used for discharging pre-settled blackwater or greywater.

Soak pits are appropriate for rural and peri-urban settlements. They depend on soil with sufficient absorptive capacity, whereas clay soils, as well as hard-packed or rocky soils, are not appropriate.

They can be used in almost every temperature, although there may be problems with pooling effluent in areas where the ground freezes.

They are not appropriate for areas prone to flooding or that have high groundwater tables and should be constructed at a distance of at least 30 m from drinking water wells in order to prevent cross-contamination.

Soak Pit: Need and Functions

A soak pit or a soakaway is a closed porous chamber that is directly connected to a primary treatment unit of a residential or commercial building.

It serves the function of letting the wastewater coming from the septic tank to slowly soak into the underlying ground.

Need for Soak Pit of Soak Pit Design

The water coming out from a primary treatment chamber is not pure. The primary treatment unit can be a septic tank, a biogas settler, anaerobic baffled reactor, twin-pits, etc.

The effluent water coming out of these units are called greywater, which must be subjected to a partial treatment before letting it into the ground soil.

For this partial treatment, most of the wastewater management system needs a soak pit.

There is no intention to reuse the wastewater that is coming from the primary treatment unit.

But the partial treatment of effluent water through a soak pit is a safer way of discharging the water into the environment.

The Function of Soak Pit

The greywater passing through the soak pit is subjected to filtration. This results in the settlement of smaller particles of effluents at the bottom of the soak pit.

These smaller particles are digested by the microorganisms which are a sustainable process of degradation. The filtered water is then discharged out through the porous wall of the soak pit.

In General, the Important Functions of a Soak Pit Are Enlisted Below:

- Soak pit serves the purpose of receiving the effluent water from the primary treatment

- Soak pit undergoes the partial treatment of the effluent water coming out of the primary treatment unit.

- The soak pit discharges clear and non-harmful water to the ground.

- The soak pit is designed in such a way that the treated water comes out of the porous walls of the soak pit.

- The soak pit helps to recharge the groundwater bodies.

Advantages

- It can be built and repaired with locally available materials.

- Technique simple to apply for all users.

- A small land area is required.

- Low capital costs; low operating costs.

- Recharging groundwater bodies.

Disadvantages

- Primary treatment is required to prevent clogging.

- May negatively affect soil and groundwater properties.

- Applicable only were soil conditions allow infiltration, the groundwater table is at least 5 m below the soak pit, there is no risk for flooding and any water well is in a distance of at least 30m.

- Difficult to realize in cold climate.

- Should be avoided for high daily volumes of discharged effluents.

Summary

A soak pit, also known as a soakaway or leach pit, is a covered, porous-walled chamber that allows water to slowly soak into the ground.Pre-settled effluent from a collection and storage/treatment or (semi-) centralized treatment technology is discharged to the underground chamber from which it infiltrates into the surrounding soil.

[su_box title=”FAQ” style=”default” box_color=”#333333″ title_color=”#FFFFFF” radius=”3″ class=”” id=””]

What Is a Soakaway Pit?

A soak pit, also known as a soakaway or leach pit, is a covered, porous-walled chamber that allows water to slowly soak into the ground.

Soak Pit Construction

Soak pit bottom should never be less than 2 m above the groundwater table. It is either lined with porous material or left empty to prevent wall collapse and provide support. It must be constructed away from the high traffic areas, to avoid soil compaction and it should be located away (30 m) from a drinking source.

Soak Pit Dimensions

The soak pit should be covered by the precast slab. Soak pit shall not be less than 90 cm (Approx 3 feet) in diameter and not less than 1.5 m ( Approx 5 feet) in depth below the invert level of the inlet pipe.

Soak Pit in Clay Soil

Thus, soak pits are best suited for soil with good absorptive properties; clay, hard packed or rocky soil is not appropriate. Soak pits are used the same way as leach fields, but require less space as well as less operation and maintenance.

How Deep Should a Soak Pit Be?

The soak pit , consisting basically of a simple pit (generally approximately 1 m3), should be between 1.5 and 4 m deep, but as a rule of thumb, never less than 2 m above the groundwater table. It should be located at a safe distance from a drinking water source (ideally more than 30 m).

How Does a Soak Pit Work?

A soak pit is a covered, porous-walled chamber that allows water to slowly soak into the ground. Soak pits, which can be lined with porous materials, which provide foundational support to prevent collapse of the underground chamber, may also be used for separate treatment of greywater.

Types of Soak Pit

Lined Soak Pit.

Unlined Soak Pit.

Distance Between Septic Tank and Soak Pit

Normally the soak pit and borewell should not be too near. The ideal distance between them should be 30 m i.e. 100 ft.

What Is Soak Pit for Septic Tank?

A soak pit or a soakaway is a closed porous chamber that is directly connected to a primary treatment unit of residential or commercial building. It serves the function of letting the wastewater coming from the septic tank to slowly soak into the underlying ground.

How to Clean Soak Pit?

To clean the soak pit, use a spade to remove any accumulated silt or debris from the bottom and around the edges of the tank. Carefully inspect all components, such as risers, manholes and outlets, for damage or blockages.

[/su_box]

[su_note note_color=”#F2F2F2 ” text_color=”#333333″ radius=”3″ class=”” id=””]

Like this post? Share it with your friends!

Suggested Read –

- What Is Window Glazing | Types of Window Glazing

- What Is Septic Tank | How Does A Septic Tank Work | Septic Tank Design based Per User Consumption

- What Is Folded Plate | Folded Plate Structure | Folded Plate Roof Construction Details | Folded Plate Staircase | What Are Folded Plate Roofs

- All About Undercoat | What Is Undercoat | What Does Undercoat Paint Do | Why Use Undercoat | Difference Between Primer and Undercoat

- What Is Shotcrete | Shotcrete & Concrete | Shotcrete Technology | Types of Shotcrete Technology | Advantages of Shotcrete | Disadvantages of Shotcrete

[/su_note]

Originally posted 2023-03-27 12:00:36.