What Is Lintel? | Function of Lintel | Types of Lintel

Table of Contents

What Is Lintel?

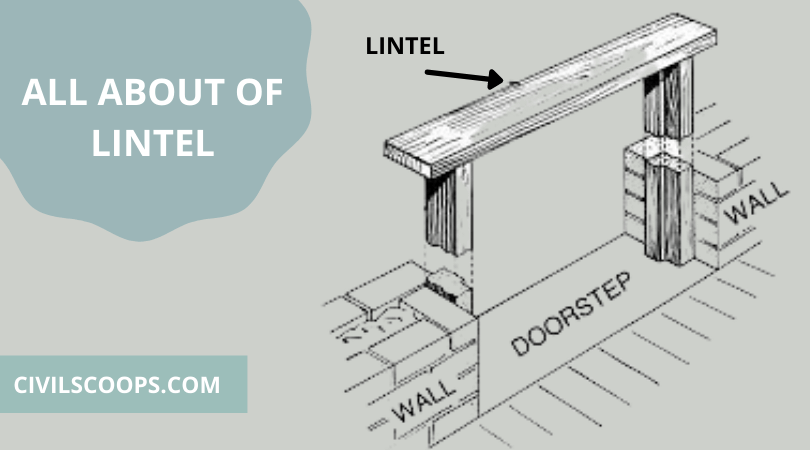

- To support the load from the structure above from the building, the lintel is a beam that is placed across the openings like windows, doors, etc.

- To the width of a wall, the width of the lintel beam is equal, and the lintel beam is end to the end of the walls.

- Based on their material of construction the lintels are classified.

- As compared to arches the horizontal lintels are easy to construct.

Function of Lintel

- The function of the lintel is, to support the load from the structure above from the building, the lintel is a beam that is placed across the openings like windows, doors, etc.

- The function of the lintel beam is, it is constructed to transfer the imposed load that’s coming from the superstructure to the side walls.

- The function of a lintel is sometimes it is used as a decorative purpose for the structure.

- The function of the lintel is, it provides a safeguard of the doors and windows.

- The lintel is provide the stability to the structure. It is another important function of the lintel.

Types of Lintel

Six types of lintel are below

1. Timber Lintel

- Timber lintels were mostly used, in the olden days of construction.

- But nowadays they are replaced by many modern techniques, but in the hilly areas, the timber lintel is mostly used.

- The advantage of timber lintel is, it is easy to use in construction and easy to make desired shape and size.

- Another advantage of timber lintel is; it is easily available near construction sites.

- The main disadvantages of timber lintels are it is less durable and vulnerable to fire and costlier.

- Another disadvantage of timber lintel is, with the help of steel bolts it is provided by joining the multiple numbers of wooden pieces, if the length of the opening is more.

- Sometimes, with the help of packing pieces made of wood, it is composed of two wooden pieces kept at a distance, in case of wider walls.

- Sometimes, by the provision of mild steel plates at their bottom and top, these are strengthened, that is called flitches lintels.

2. Brick Lintel

- The brick lintel is generally used when lesser loads are acting on the structure and the opening is less than 1m.

- depending upon the span the depth of the brick lintel is varies from 10 cm to 20 cm.

- From the normal bricks, the frogs’ bricks are more suitable because when the end joints of frogs are filled with mortar give more shear resistance which is known as a joggled brick lintel.

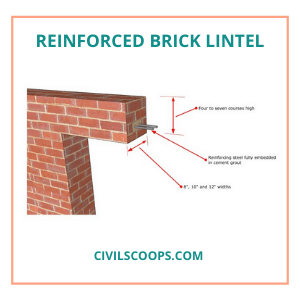

3. Reinforced Brick Lintel

- The reinforced brick lintel is generally used where the span is greater than 1m and heavy loads are acting on the structure.

- multiple of 10 cm or 10 cm to 15 cm, the depth of reinforced brick lintel should be equal.

- As reinforcement between adjacent bricks for the insertion of mild steel bars 2 to 3 cm wide space is left lengthwise the bricks are so arranged.

- To fill up the gaps in the bricks 1 : 3 cement mortar is used.

- In every 3 rd vertical joint, the vertical stirrups of 6 mm diameter are provided.

- From 8 to 10 mm diameter bars at the bottom consists of the main reinforcement is provided, at the ends which are cranked.

4. Stone Lintel

- Especially where the stone is mostly available, there the stone type of lintel is commonly used.

- In the stone lintel, the most important factor of its design is the thickness.

- On the openings of the brick walls, this type of lintels is providing.

- more than one piece or single piece the Stone lintel is provided in the walls.

- With a minimum value of 15 cm, the depth of stone lintels is kept equal to 10 cm per meter of span.

5. Reinforced Cement Concrete Lintel

- The reinforced cement concrete lintel is widely used to span the openings for windows, doors, etc.

- In a structure because of its rigidity, strength, economy, fire resistance, and ease in construction.

- The reinforced cement concrete lintel is suitable for any span or all the loads.

- The depth depends on the magnitude of loading and length of span and the width is equal to the width of the wall.

- In the reinforced cement concrete lintel half of these bars are cranked at the ends and the main reinforcement is provided at the bottom.

- To resist transverse shear in the structure, shear stirrups are provided.

6. Steel Lintel

- The steel lintel is used where the openings are large and the superimposed loads are heavy.

- The steel lintel is consisting of rolled steel joists or channel sections.

- Depending upon the requirement we can use it in combinations or one single section.

- To keep the width the same as the width of the wall the steel joist is either cladded with stone facing or embedded in concrete when we used the singly steel lintel.

- They are kept in position by tube separators when more than one unit is placed side by side.

[note note_color=”#F2F2F2 ” text_color=”#333333″ radius=”3″ class=”” id=””]

Like this post? Share it with your friends!

Suggested Read –

- What Is Grouting | Type of Grouting | Experiment of Grouting | Characteristics of Grouting | Types of Grout for Ceramic Tile | Advantage of Grouting | Disadvantage of Grouting

- What Is Grade of Concrete | Concrete Mix Ratio | Type of Concrete Mix | Different Types of Concrete Grade with Concrete Mix Ratio and Compressive Strength | Uses of Different Grades of Concrete

- What Is Hidden Beam | Why Is It Used | Where Is It Used in Buildings | How to Design a Hidden Beam | Purpose of Hidden Beam | Advantages of Hidden Beam | Disadvantages of Hidden Beam

- What Is Workability | What Is Workability of Concrete | Types of Workability of Concrete | Factors Affecting Workability of Concrete

- What Is Combined Footing | Types of Combined Footing | Advantage & Disadvantage of Combined Footing | Application of Combined Footing

[/note]

Originally posted 2021-07-23 18:53:27.