What Is Falsework | Types of Falsework | Causes of Falsework Failures

Table of Contents

Falsework Means

The temporary structure is used to support a permanent structure, material, plant, equipment, and people until the construction of the permanent structure has advanced to the stage where it is self-supporting.

Falsework includes the foundations, footings, and all structural members supporting the permanent structural elements.

Falsework can be used to support formwork for in-situ concrete, prefabricated concrete elements, steel sections0, or stone arches, for example, during bridge construction.

What Is Falsework?

- Falsework is defined as a temporary structure used to support a permanent structure during its construction and until it becomes self-supporting.

- Falsework may be required to support steel and timber frameworks and masonry arches as well as in situ and precast concrete construction.

- The design and construction of falsework are covered by BS 5975: 1982 Code of Practice for Falsework.

- Falsework is often constructed from conventional loose steel scaffold tubes and fittings together with adjustable telescopic props and fork heads (sometimes flatheads), which carry the main timber bearers on which the formwork or deck is built.

- Secondary beams may be interposed between the main bearers and the formwork.

- Prefabricated steel frames, military trestles, towers, steel girders, and standard steel sections are employed for more specialized work, and generally, where the load to be supported is particularly heavy.

- The total or even partial collapse of falsework may lead to serious accidents for those on the structure who are thrown from or fall from their place of work.

- More often than not, collapse occurs when the structure is being loaded, e.g., during the placing of concrete when the number of workers involved in the operations is high.

- Where other work is being undertaken below the loading level, the people involved are also at considerable risk from falling materials, i.e., both from the falsework and from the supported permanent works.

- Accidents also occur without the falsework collapsing. These are the result of people slipping or falling or both from the structure.

- In addition to their major supporting roles, the falsework and the formwork provide a place of work, and normal edge protection requirements are necessary at all open sides and holes in the decking, as well as properly constructed access to all places where work is to be carried out (see above – Fig.).

- The collapse of falsework can be attributed to inadequate design, poor construction, or a combination of the two.

Also Read: 19 Different Types of Slabs in Construction | What Is a Slab | Types of Slabs

Types of Falsework

1. Shorbrace System

2. Cup-Lock Supporting System

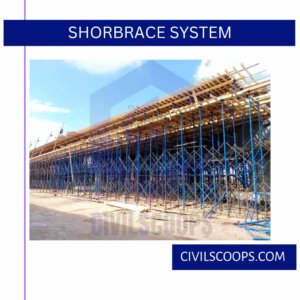

Shorbrace System

The short race support system is used widely to support the bridge deck. This system possesses many merits.

One of these merits is the simple and quick erection and dismantling of falsework. Also, it can be used to support heavy structures safely.

This system consists of many components as per below:

- Shorbrace Frame

- Shorebrace Telescopic Frame

- Vertical Frame Connector

- U Head Jack

- Cross Bracing

- Shorbrace Frame

Shorebrace Telescopic Frame

These frames are the main component of falsework. It is connected with each other to form a tower of the desired height to support formwork, as shown in the figure above.

Vertical Frame Connector

The function of this frame is to assist in maintaining the required height of falsework. This frame is inserted inside the short brace frame and then connected by a load pin with the mainframe

U Head Jack

The soldier of formwork will place inside the U-head jack. This u-head is adjustable and will contribute to providing an accurate profile of the casted slab.

Cross Bracing

This will brace adjacent shore brace frames. The figure above shows the different components of falsework.

Cup-Lock Supporting System

Cup-lock supporting system is used widely in bridge and building construction. This system required a small space for storage.

The erection and dismantling of this system are simple and quick compared to other supporting systems.

This system consists of many components as per below:

- Post-Head Jack

- U and Post Head Jack

- Spigot Connector

- Ledgers

Post-Head Jack

Standard height can vary from one to three-meter.

U and Post Head Jack

These items are used similarly as in shorbrace supporting system

Spigot Connector

A Spigot connector is used to connect two standards in the event the height of the standard is not enough

Ledgers

Ledgers are connected to standards to increase stiffness and minimize deformation.

Causes of Falsework Failures

In general, the primary causes of formwork disasters are

1. Excessive loads,

2. Premature removal of forms or shores, and

3. Inadequate lateral support for the shoring members.

Hadipriono and Wang (1986) examined the causes that resulted in 85 major falsework failures over the past 23 years.

[su_table responsive=”yes” alternate=”no”]

| Number of Occurrences | Symbol | Causes of failure |

| a. Triggering causes of failure | ||

| 3 | a | Heavy rain causing falsework foundation slippage |

| 1 | b | Strong river current causing falsework foundation slippage |

| 1 | c | Strong winds |

| 4 | d | Fire |

| 5 | e | Failure of equipment for moving formwork |

| 4 | f | Effects of formwork component failure |

| 1 | g | Concentrated load due to improper prestressing operation |

| 2 | h | Concentrated load due to construction material |

| 2 | i | Other imposed loads |

| 27 | j | Impact loads from concrete debris and other effects during concreting |

| 3 | k | Impact load from construction equipment/vehicles |

| 5 | l | Vibration from nearby equipment/vehicles or excavation work |

| 6 | m | Effect of improper/premature falsework or formwork removal |

| 20 | n | Other causes or not available |

| b. Enabling causes of failure | ||

| 17 | A | Inadequate falsework cross-bracing/lacing |

| 14 | B | Inadequate falsework component |

| 9 | C | Inadequate falsework connection |

| 7 | D | Inadequate falsework foundation |

| 8 | E | Inadequate falsework design |

| 4 | F | Insufficient number of shoring |

| 1 | G | Inadequate reshoring |

| 4 | H | Failure of movable falsework/formwork components |

| 2 | I | Improper installation/maintenance of construction equipment |

| 1 | J | Failure of permanent structure component |

| 4 | K | Inadequate soil foundation |

| 2 | L | Inadequate design/construction of a permanent structure |

| 30 | S | Other causes or not available |

| C. Procedural causes of failure | ||

| 23 | M | Inadequate review of falsework design/construction |

| 22 | N | Lack of inspection of falsework/formwork during concreting |

| 2 | O | Improper concrete test prior to removing falsework /formwork |

| 4 | P | Employment of inexperienced/inadequately trained workmen |

| 1 | Q | Inadequate communication between the parties involved |

| 5 | R | Change of falsework design concept during construction |

| 38 | T | Other causes or not available |

[/su_table]

Table – 1. Causes of falsework failure (Hadipriono and Wang, 1986)

Three causes of failure were identified: triggering, enabling, and procedural causes (above table).

In many cases, an excessive rate of concrete pouring and the use of powered equipment, such as motor buggies, imposed lateral forces on the falsework; several of the that were not adequately braced have come down.

Inadequate falsework cross bracing or lacings were the primary source of several falsework accidents (see table, Section b), such as the collapses of the Arroyo Seco Bridge in CA, the Skyline Center Complex in VA, the highway ramp in East Chicago, and the Coliseum in New York.

[su_box title=”FAQ” style=”default” box_color=”#333333″ title_color=”#FFFFFF” radius=”3″ class=”” id=””]

Falsework

Falsework is any temporary structure used to support the forms of concrete. Falsework supports the forms until the concrete can support itself. It is essential that falsework be strong enough to support the weight of three things: the forms, the fresh concrete, and any construction equipment and workers

Falsework and Formwork

FALSEWORK: This is typically a temporary horizontal system onto which you cast concrete. FORMWORK: This is typically a temporary vertical structure into which you pour concrete.

Falsework in Construction

Falsework is any temporary structure used to support the forms of concrete

Bridge Falsework

Falsework includes steel or timber beams, girders, posts, foundations, and any. proprietary equipment including modular shoring frames, post shores, and horizontal. shoring. The term “falsework” is typically associated with the construction of cast-in-place. concrete structures, particularly bridge structures

Concrete Falsework

Falsework is any temporary structure used to support the forms of concrete. Falsework supports the forms until the concrete can support itself. It is essential that falsework be strong enough to support the weight of three things: the forms, the fresh concrete, and any construction equipment and workers

Falsework and Scaffolding

Falsework supports the formwork with the RC structure of a building. Scaffolding is a temporary structure for building operations

Falsework and Shoring

Falsework – or shoring, in some regions – is a temporary structure that is used to support formwork in a horizontal position, using elements such as props and scaffolding

Types of Falsework

Falsework includes steel or timber beams, girders, posts, foundations, and any proprietary equipment including modular shoring frames, post shores, and horizontal shoring. The term “falsework” is typically associated with the construction of cast-in-place concrete structures, particularly bridge structures

Steel Falsework

Falsework consists of temporary structures used in construction to support a permanent structure until its construction is sufficiently advanced to support itself. For arches, this is specifically called centering.

Cross Bracing Buildings

Cross bracing is used to keep buildings stable when the wind blows and during seismic events, such as an earthquake. It also limits the building’s lateral movement, reducing the likelihood of damage to the structure’s components and cladding

Ledgers in Construction

In construction, a “ledger” can refer to a horizontal support installed under the end of a joist or other structural component — but that’s not what we’re talking about here. In construction accounting, a general ledger does act as a sort of support — a support to the financial health of a construction business

Falsework Construction

Falsework is any temporary structure used to support the forms of concrete. Falsework supports the forms until the concrete can support itself.

Types of Falsework in Construction

Falsework includes steel or timber beams, girders, posts, foundations, and any proprietary equipment including modular shoring frames, post shores, and horizontal shoring. The term “falsework” is typically associated with the construction of cast-in-place concrete structures, particularly bridge structures

What Is Falsework

Temporary framework structures are used to support a building during its construction.

Falsework for Construction Purposes

Any temporary structure used to support the forms of concrete.

Falsework Components

Falsework includes steel or timber beams, girders, posts, foundations, and any proprietary equipment including modular shoring frames, post shores, and horizontal shoring. The term “falsework” is typically associated with the construction of cast-in-place concrete structures, particularly bridge structures.

Falsework Concrete

It is essential that falsework be strong enough to support the weight of three things: the forms, the fresh concrete, and any construction equipment and workers.

[/su_box]

[su_note note_color=”#F2F2F2 ” text_color=”#333333″ radius=”3″ class=”” id=””]

Like this post? Share it with your friends!

Suggested Read –

- All About Sand | What Is Sand | 29 Types of Sand | Composition of Sand

- 19 Different Types of Slabs in Construction | What Is a Slab | Types of Slabs

- All About Gypsum Plaster | What Is Gypsum Plaster | 15 Advantage of Gypsum Plaster | Disadvantages of Gypsum Plaster

- All About M Sand | What Is M Sand | Properties of Manufactured Sand | Advantages & Disadvantages of Manufactured Sand

- All About Uscs | Which Test Gives a Better Estimation of the Friction Angle | Introduction of USCS ( Unified Soil Classification System )

[/su_note]

Originally posted 2023-02-25 13:13:23.