How Cement is Made | Cement Ingredients | History of Cement

Table of Contents

How Cement Is Made?

This Portland cement is a fundamental component of concrete. Concrete is produced when portland cement makes a paste with water that joint with rock and sand to harden.

Cement is manufactured through a closely controlled chemical combination of calcium, silicon, aluminium, iron and other ingredients.

Common materials used to manufacture cement include limestone, shells, and chalk or marl combined with shale, clay, slate, blast furnace slag, silica sand, and iron ore.

When These ingredients, heated at high heat, form a rock-like substance that is floor into the fine powder that we usually consider as cement.

Also Read: Difference Between Formwork, Shuttering, Centering, Staging & Scaffolding

[su_box title=”Note” style=”default” box_color=”#333333″ title_color=”#FFFFFF” radius=”3″ class=”” id=””]

Cement Ingredient

Cement is manufactured through a closely controlled chemical combination of calcium, silicon, aluminium, iron and other ingredients. Common materials used to manufacture cement include limestone, shells, and chalk or marl combined with shale, clay, slate, blast furnace slag, silica sand, and iron ore.

[/su_box]

Cement Ingredients

Various Types of cement ingredients and their work areas are given below,

- Silicon Dioxide (Silica)

- Calcium Oxide (Lime)

- Calcium Sulphate

- Aluminum Oxide (Alumina)

- Alkalis

- Iron Oxide

- Magnesium Oxide

- Sulfate

1. Silicon Dioxide (Silica):

![]()

- It is also a major vital ingredient of cement.

- It is familiar to silica.

- It clutches 19-23% of cement mass.

- It is chemically articulated by SiO2.

- Function: The purpose of silica is also to give strength to cement.

2. Calcium Oxide (Lime):

This is the main content of the cement manufacturing process or at the top of the list of the main ingredient of cement.

Calcium Oxide has 61% to 67% of the mass of cement, which is holding the highest percentage among all others.

Shortly it has known CaO. Generally, the calcium Oxide familiars as lime.

The function of this: It gave cement sound and provided inner boding strength to cement.

3. Calcium Sulphate:

CaSO4 is chemically composed of it. This Fixing is in the form of gypsum, and its function is to increase the initial setting time of cement.

Function: It assists in raising the initial setting time of cement.

4. Aluminium Oxide (Alumina):

- It is a known alumina. The chemical name is AI2O3.

- Cement contains its 2% – 6% alumina of its mass.

- This ingredient imparts quick functioning correctly to cement.

- Express alumina weakens the cement.

- Function: It works on a quick-setting property to cement.

5. Alkalis:

The majority of the alkalies within raw material are carried away from the flue gases through heating, and only a small quantity will be abandoned.

If they’re in excess in cement, efflorescence is caused.

A very little quantity of it may present in the cement.

6. Iron Oxide:

- It is also known as Ferric Oxide.

- Cement has 0.5%-6% iron oxide of its mass.

- Iron Oxide’s chemical name is Fe2O3.

- Function: It has to prove color and hardness to cement.

- It also gave enough strength to cement.

7. Magnesium Oxide:

Magnesium Oxide is articulated by MgO. It provides color and hardness to cement.

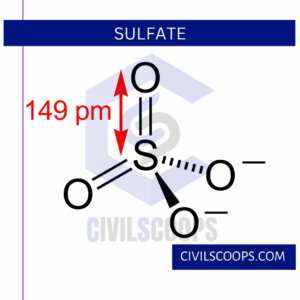

8. Sulfate:

- It is familiar to Sulphur.

- It clutches 1.5%-4% of the mass of cement.

- The chemical name of Sulphur is S.

- Function: A very little quantity of Sulphur in the cement makes it (Cement) sound.

History of Cement

Bricklayer of cement Mr.Joseph Aspdin of Leeds from England first made portland cement near the beginning in the 19th century by burning powdered limestone and clay in his personal kitchen stove.

By this crude technique, he had laid the groundwork for an industry that annually processes mountains of limestone, cement rock, clay, and other materials factually into a powder so fine it will go by a sieve able of holding water.

The cement plant laboratories check each move in the manufacture of portland cement by frequent chemical and physical tests.

The labs also analyze and test the completed product to ensure that it complies with all industry stipulation on all weather conditions.

Manufacturer of Cement

The most familiar way to manufacture portland cement is through a dry process. The primary step is to dig up the principal raw materials, chiefly limestone, clay, and extra materials.

After digging up the rock is crushed. This involves various stages. In the initial first stage, crushing reduces the rock to a maximum size of about 6 inches.

The rock then moves toward secondary crushers machine or hammer mills for a decrease to about 3 inches or lesser.

The crushed rock is amalgamated with other ingredients such as iron ore, fly ash, and ground, mixed, and fed to the cement kiln.

The cement kiln gave heats to all the ingredients around about 2,700 degrees Fahrenheit in enormous cylindrical steel rotary kilns lined with special firebrick.

Kilns are normally as much as 12 feet in diameter—large enough to put up an automobile and longer in many instances than the top height of a 40-story building. The large kilns are mounted with the axis inclined from the horizontal.

The finely grinded raw material or slurry is fed into the higher end. On the other hand,the lower end is a roaring blast of flame, produced by specifically controlled burning of the contains like powdered coal, oil, alternative fuels, gas under forced draft.

When the material moves through the kiln, certain elements are driven off in the form of gases. The remaining elements after burning bond to form a new substance known as clinker.

The Clinker comes out of the kiln as grey balls, its size about of marbles.

The Clinker is released red-hot from the lower base end of the kiln, and usually, it is brought down to managing temperature in diverse types of coolers.

The heated air from the coolers comes back to the kilns, a method that saves fuel and increases burning efficiency.

Afterward, the clinker is cooled, and cement plants grind it where it mixes with small amounts of limestone and gypsum. Cement is too fine, for example,1 pound of cement contains 150 billion grains.

Finally, the cement is ready for transport to ready-mix concrete companies to be habitual in a multiplicity of construction projects.

At the end of this process, the dry process is the most contemporary and prominent way to produce cement, some kilns in the United States apply a wet process.

These two methods are basically alike except in the wet process. The basic materials are ground with water before being fed into the kiln.

[su_box title=”FAQ” style=”default” box_color=”#333333″ title_color=”#FFFFFF” radius=”3″ class=”” id=””]

What Is Cement Made Of?

Cement is a fine, soft powder used as a binder because it hardens after contact with water. It is produced from a mixture of limestone and clay that’s charred and then ground up.

What Is Cement Used For?

Cement is mainly used as a binder in concrete, which is a basic material for all types of construction, including housing, roads, schools, hospitals, dams and ports, as well as for decorative applications (for patios, floors, staircases, driveways, pool decks) and items like tables, sculptures or bookcases.

What Is Portland Cement Used For?

Basic use. Use Portland Cement in concrete for bridges, walls, culverts, floors, pavements, sidewalks, pipe, railway structures, reinforced concrete buildings, tanks and reservoirs, as well as for masonry units and other precast products.

Ingredients in Cement

Cement is manufactured through a closely controlled chemical combination of calcium, silicon, aluminum, iron and other ingredients. Common materials used to manufacture cement include limestone, shells, and chalk or marl combined with shale, clay, slate, blast furnace slag, silica sand, and iron ore.

Silica in Portland Cement

Portland cement refers to a class of hydraulic cements that are odorless gray powders containing less than 1 percent crystalline silica.

Lime in Cement

Incorporating an appropriate proportion of hydrated lime into a cement-based mixture improves plasticity and workability, making the product easier to handle on the trowel. Hydrated lime also increases water retention which helps to improve the contact and bond with the substrate.

Calcium Oxide in Cement

Lime, or calcium oxide, is a principle ingredient in the production of Portland cement, the basis for most mortars and concrete. Hydrated or ‘slaked’ lime is the chemical calcium hydroxide. This chemical is also used in mortars.

Free Lime in Cement

Clinker, which is an intermediate material for cement, is produced by mixing and calcinating cement raw materials such as limestone, clay and silica in a rotary kiln at a high temperature. The unreacted calcium oxide remaining after calcination of the clinker is called free lime (f. CaO).

Cement and Lime

Lime hardens slowly when mixed in producing mortar. The cement hardens quickly when mixed in a mortar. It cannot be used for important and heavy engineering structures. It can be used for important and heavy engineering structures.

High Alumina Cement Uses

Generally, this refractory product is widely used in sewer infrastructure and marine construction. Besides, it is also used in refractory concretes for furnaces, boilers, kilns, and chimneys. This is due to its strength to withstand very high temperatures with proven durability.

Alkalis in Cement

The alkali content refers to the content of Na2O and K2O in cement. The condition for concrete to conduct the alkali-aggregate reaction is that the cement must contain alkali. When the active aggregate material is used, the cement with low alkali content should be used.

Low Alkali Cement

Low-alkali cements are portland cements with a total content of alkalies not above 0.6 percent. These are used in concrete made with certain types of aggregates that contain a form of silica that reacts with alkalies to cause an expansion that can disrupt a concrete.

Iron Oxide in Concrete

Iron oxide pigments can drastically improve the value of concrete. By adding color, concrete is more attractive and provides color-related properties such as solar reflectiveness. Solomon Colors uses only the highest quality synthetic iron oxide to blend dry, liquid, and granular pigment for concrete and mortar colors.

MgO in Cement

When the content of MgO in the clinker is in a range from 2.0% to 5.0%, the strengths development of the cement is improved and the setting time is shortened. If the MgO content reaches about 8.0%, strength of the cement decreases slightly and the setting time is extended.

Sulphate Resisting Cement

SRPC is a type of Portland cement in which Tricalcium Aluminate (C3A) amount is less than 5% and the amount of C3A and calcium aluminoferrite (C4AF) together is less than 25%. Use it where there the concrete structure faces the risk of being damaged by high amount of sulphates found in its immediate environment.

Invention of Cement

Cement as we know it was first developed by Joseph Aspdin, an enterprising 19th-century British stonemason, who heated a mix of ground limestone and clay in his kitchen stove, then pulverized the concoction into a fine powder. The result was the world’s first hydraulic cement: one that hardens when water is added.

Cement Invention Date

The invention of portland cement usually is attributed to Joseph Aspdin of Leeds, Yorkshire, England, who in 1824 took out a patent for a material that was produced from a synthetic mixture of limestone and clay.

History of Cement Industry

Cement as we know it was first developed by Joseph Aspdin, an enterprising 19th-century British stonemason, who heated a mix of ground limestone and clay in his kitchen stove, then pulverized the concoction into a fine powder. The result was the world’s first hydraulic cement: one that hardens when water is added.

[/su_box]

[su_note note_color=”#F2F2F2 ” text_color=”#333333″ radius=”3″ class=”” id=””]

Like this post? Share it with your friends!

Suggested Read –

- What Is Stone | Types of Stone | Uses of Stones

- What Is Septic Tank | How Does A Septic Tank Work | Septic Tank Design based Per User Consumption

- All About Soak Pit Design | Health Aspects | Operation and Maintenance of Soak Pit | Applicability of Soak Pit Design

- All About Undercoat | What Is Undercoat | What Does Undercoat Paint Do | Why Use Undercoat | Difference Between Primer and Undercoat

- What Is Pier and Beam Foundation | Advantages & Disadvantages of Pier and Beam Foundations | Pier and Beam Foundation Design | How to Build a Post and Pier Foundation

[/su_note]

Originally posted 2023-03-27 12:23:54.