All About Grillage Foundation | Types of Grillage Foundation | Features of Grillage Foundation

Table of Contents

Grillage Foundation

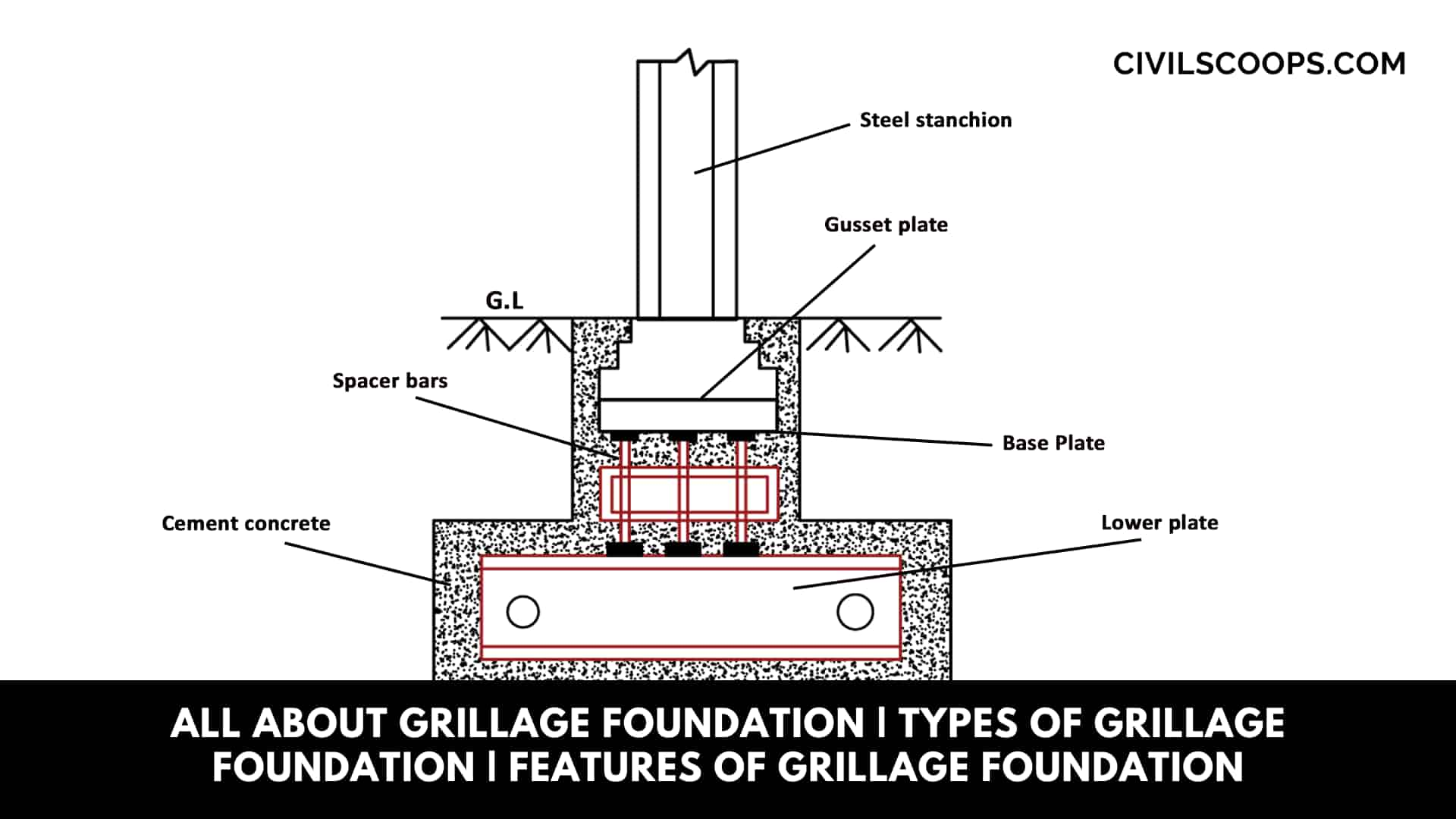

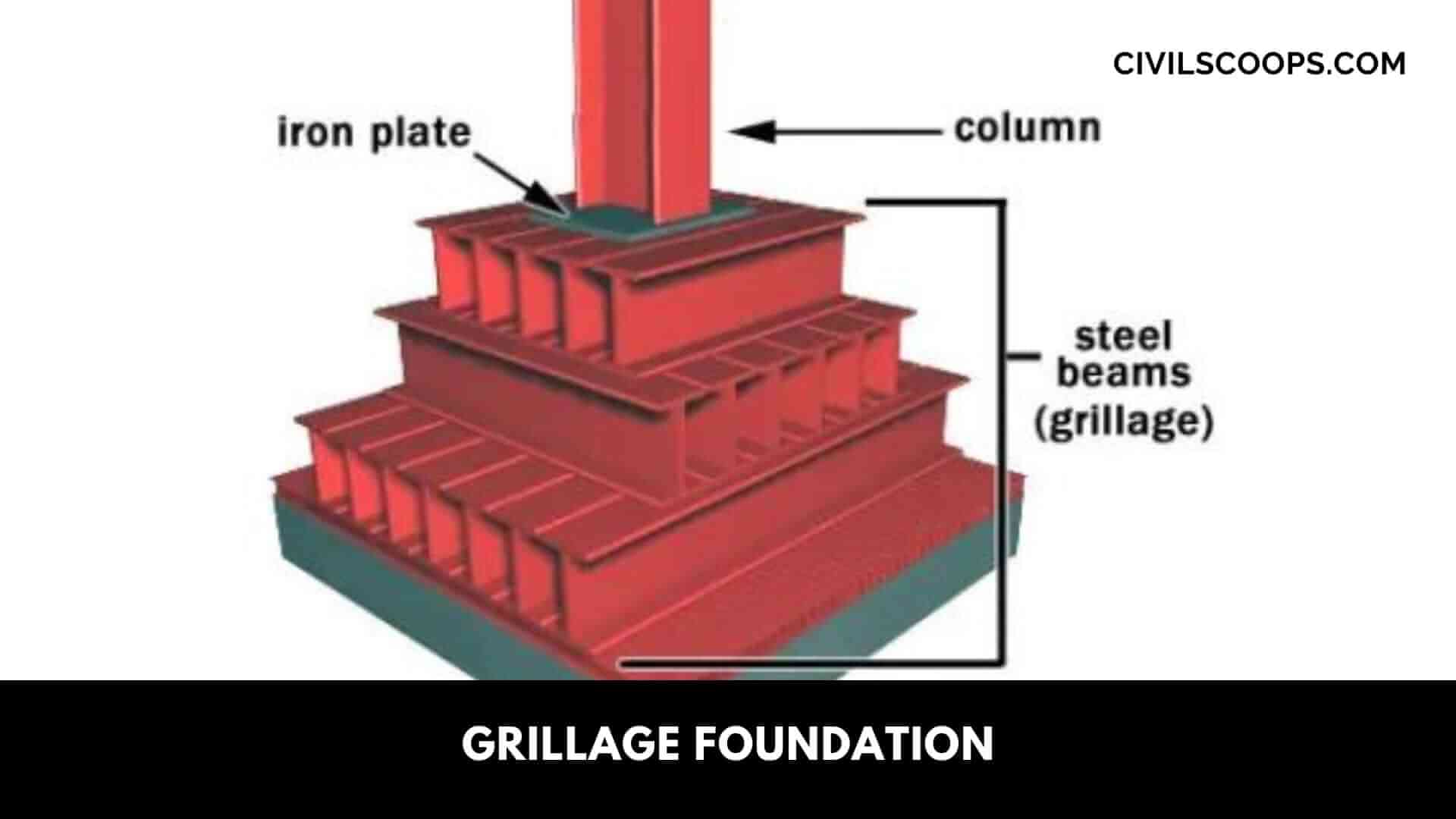

A foundation consisting of one, two or more layers of beams (typically steel) superimposed on a concrete layer to disperse the load over a large area is a foundation for grilling.

It is used at the base of the columns. These layers are wrapped in concrete and are at right angles to each other. This type of foundation is generally used for pillars and column scaffolds with a heavy structure.

Although the foundation and the grid look the same, they are different. Where the foundation transfers the load from the structure to the ground, the grid disperses heavy loads over large areas.

Types of Grillage Foundation

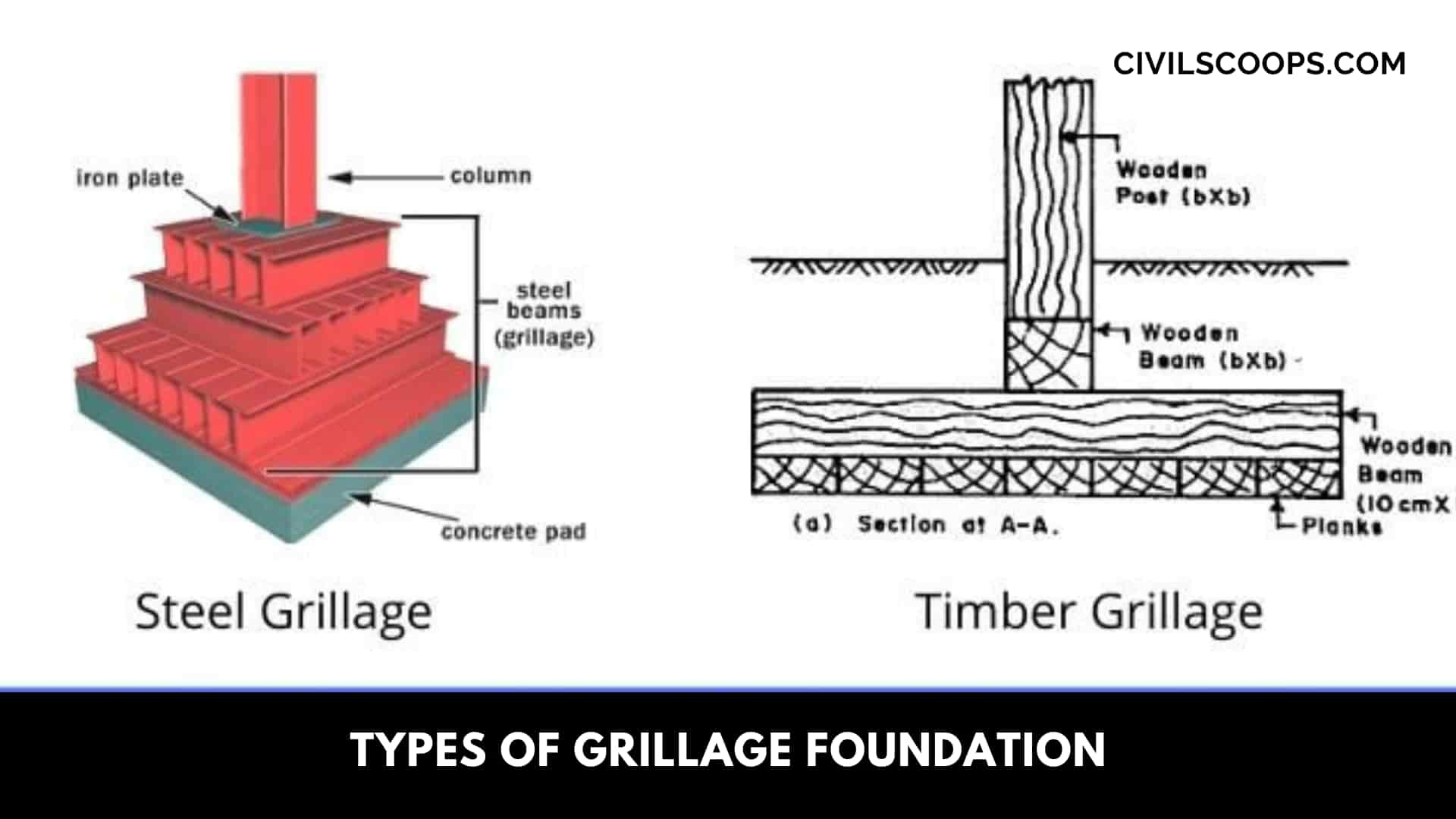

Here, two different types of grillage foundations are as follows.

- Steel Grillage Foundation.

- Timber grill foundation.

1. Steel Grillage Foundation

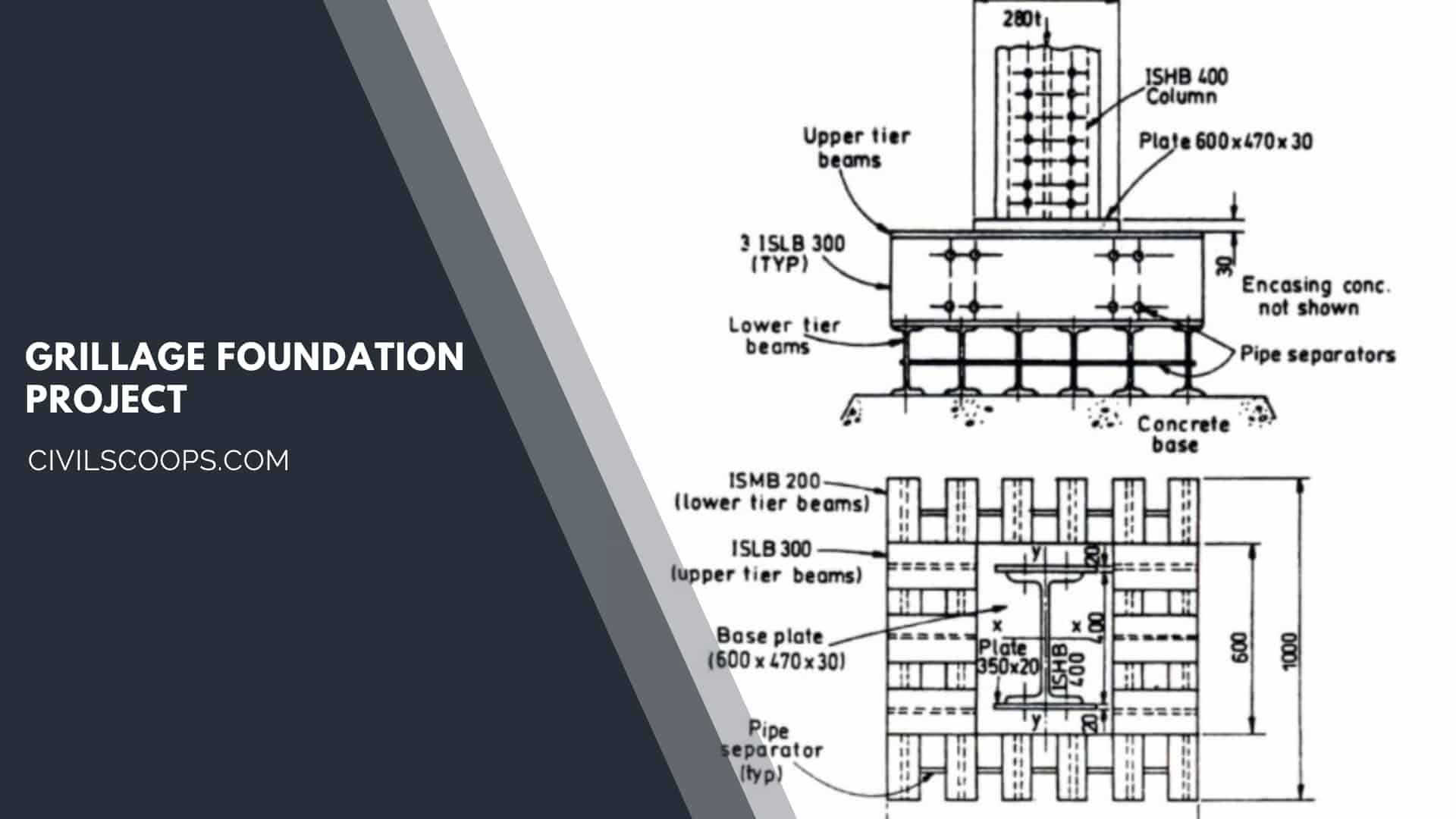

The Steel Grillage foundation consists of joints or steel beams supplied in single or double layers. Its name defines its function and structure, as it is composed of steel beams, structurally known as rolled steel beams.

A minimum coverage of 10 cm is maintained on the outer sides of the outer beams, as well as above the upper flanges of the upper layer.

The depth of the concrete must be at least 15 cm. After leveling the base and pouring the concrete, we must check that the compaction is done properly and that an impermeable layer of a thickness of not less than 15 cm is formed.

It protects steel beams from groundwater, which can lead to corrosion. Then, we place the first layer of beams on the concrete bed at a distance of 100 to 300 mm, with the help of tube separators.

Then, we pour concrete between and around the beams of the first layer. After that, we place the second beam level at right angles to the first levels with the help of the separator.

Then again, we pour concrete between and around the steel beams. In doing so, we connect the steel supports to the top layer with the help of a base plate, side angles, and a reinforcement plate.

These connecting elements are also embedded in the concrete to make the joint rigid.

Also Read: Quality Testing of Sand for Concrete | Quality Testing of Sand for Construction | Types of Sand Test

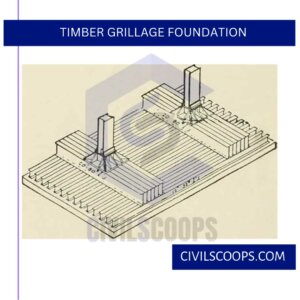

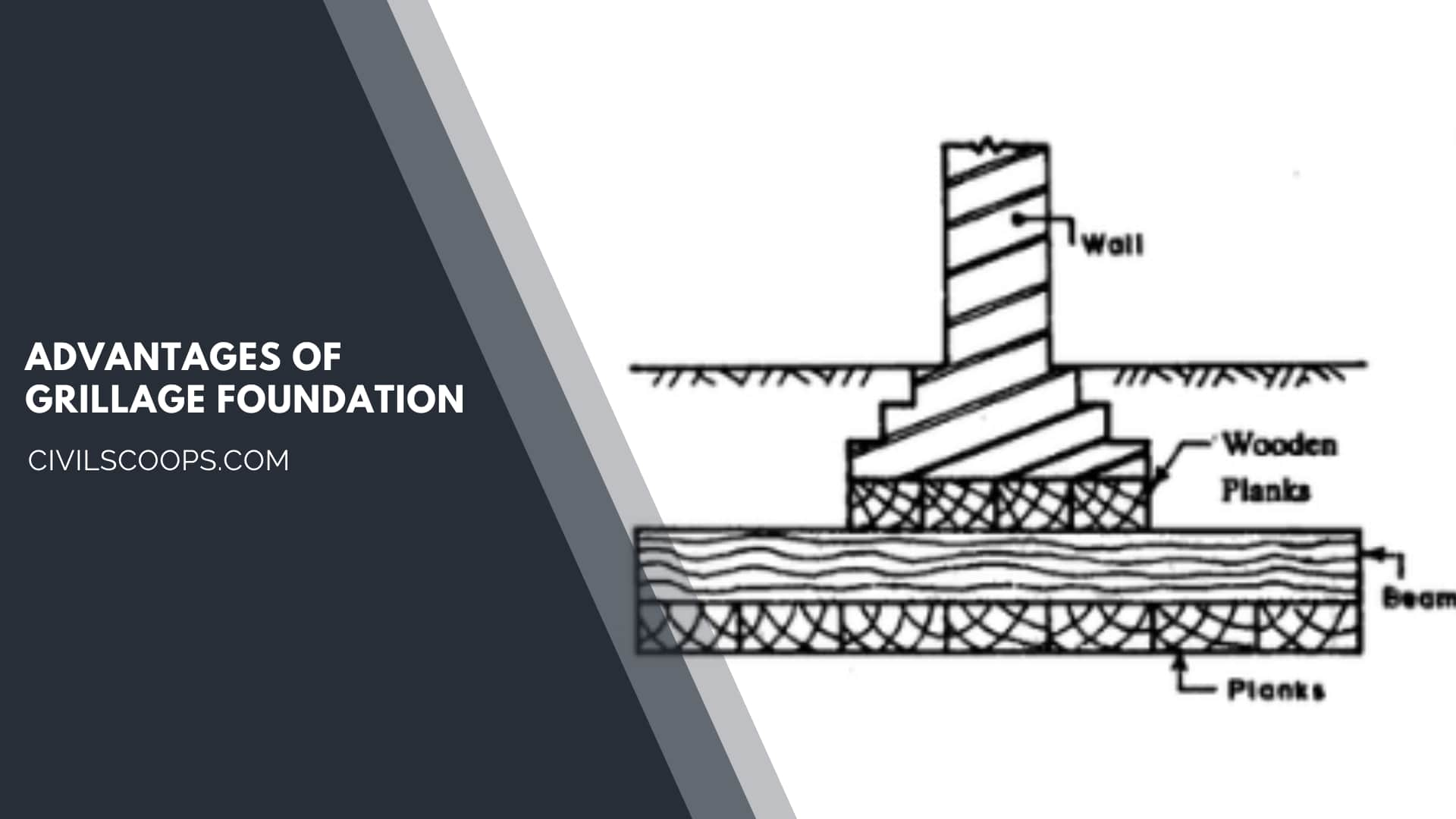

2. Timber Grillage Foundation

The timber-type foundation is provided for masonry walls heavily loaded with Timber columns. This foundation is especially useful in flooded areas, where the carrying capacity of the soil is very low and where the load on the soil is limited to 50-60 KN/M2.

Timber planks and Timber beams are used instead of steel beams. there is no concrete enclosed between the Timber joints. However, the lower concrete supplied in the steel grid is replaced by a Timber platform built with Timber planks.

The excavation of the base is level. The bottom layer of Timber boards of size 20 to 30 cm and width of 5 to 7.5 cm thick is placed side by side, with no space between them.

Above this layer, a Timber beam of the same section as that of the Timber post is placed at a right angle.

Then, another layer of planks is placed again at right angles to the direction of the beams. The top layer of boards maybe 7.5-10 cm. Thick, extending the entire width of the base of the wall, on which the masonry wall is built.

Grillage Foundation Project

For the grating foundation project, it is necessary to calculate the loads and moments of the superstructure.

From this, we need to determine the base area required for an adequate allowable ground bearing pressure of the condition.

Dividing this area, we will find the numbers and the size of each grid layer. Next, we have to design the layer so that it slopes from the edge of the layer above.

It will determine the beam sizes needed to withstand bending moments and shear forces.

The grid cannot be enclosed in concrete and in order, as the composite action of the beam and concrete will be demoralized. The method of construction and loading must be compatible with the needs of the project

Features of Grillage Foundation

- The grill connects the entire foundation to the single structure and thus contributes to an even distribution of the weight of the house and all the piles.

- Most of the time, this foundation is organized as a monolithic reinforced concrete structure. The resistance is provided by the metallic structure (steel foundation for grilling).

- Minimum clearance of around 800 mm (8cm) is provided between the grillage beams so the concrete will be easily poured and properly compacted.

- As the concrete filling doesn’t carry a load, it functions to keep the beams in position and prevents them from getting corroded.

- The depth of concrete below the lower tier is kept at a minimum of 150mm (15cm).

Installation of the Grillage Foundation

The steps for installing the foundation for grilling are shown below:

- First, for the solid monolithic grid, we need to produce and install the structure. We prefer this barbecue because it is more reliable.

- The formwork is made of edge boards in the form of rectangular gutters. Its height is 1 foot and width is equal to the minimum thickness of the house wall. A space of about 15 to 30 cm should be defined between each grid.

- Within the formwork, we have to define a reinforcement connection structure using the connecting wire. The shortest distance from the structure next to the formwork must be the same.

- Then, the reinforcement is connected to the same connecting wire used previously.

- Then, the concrete must be prepared with the cement mixer. It is poured into the formwork in a continuous cycle. The connections must be placed at a height of about 25 to 30 mm so that they are completely immersed in the concrete. Concrete must be poured with care to avoid unwanted cavities. 6. After filling the surface, it should be leveled and left to dry. When dry, the formwork can be removed. The foundation is ready now.

Advantages of Grillage Foundation

- It requires less time and materials for installation.

- It reduces the evocation of heat from the house with the help of the foundation, since it is not applied to frozen soil.

- It reduces the vibration level of the house (it is very real if the house is built close to highways).

- The installation process of Grillage Beam requires less time and materials.

- This type of foundation can be used for significant structures such as column piers, and scaffolds.

- It is capable of transforming load over a larger area.

Disadvantages of Grillage Foundation

- It requires the need to build piles at a sufficiently large depth.

- Space under the grid must be filled and heated.

- Excavation of a larger area is needed, which increases the excavation cost.

- It gets affected by a larger uplift force.

- Column alignment in this type of foundation might slightly change.

[su_box title=”Short Note” style=”default” box_color=”#333333″ title_color=”#FFFFFF” radius=”3″ class=”” id=””]

Grillage Foundation

A Grillage Foundation is a type of foundation often used at the base of a column. It consists of one, two or more tiers of steel beams superimposed on a layer of concrete, adjacent tiers being placed at right angles to each other, while all tiers are encased in concrete.

What Is a Grillage Foundation?

A foundation which consists of one, two or more tiers of beams (typically steel) superimposed on a layer of concrete to disperse load over an extensive area is grillage foundation . It is used at the base of columns. These tiers are encased in concrete and are at right angles to each other.

Is Grillage Foundation a Deep Foundation?

Grillage foundation is considered when the foundation depth is restricted to 1 to 1.5 m for reasons such as rocky earth. Moreover, the grillage foundation can sustain & transfer heavy loads from the structure to large areas.

Is Grillage a Code for Foundation?

Grillage foundation is the most economical foundation in case of transferring heavy loads from columns to soil of low bearing capacity. A type of foundation often used at the base of a column.

What Is Timber Grillage Foundation?

The foundation uses timber planks and timber beams in the place of steel joists. This foundation is specially useful in water logged areas where the bearing power of the soil is very low, and where the steel beams may get corroded due to subsoil water.

How do you make a Grillage foundation?

Construction Procedure of Grillage Foundation are as follows.

- First, a trench is excavated of depth 90 to 150 cm and levelled. A layer of concrete ratio 1:2:4 or 1:1.5:3 of thickness 23 to 30 cm is spread and compacted.

- Over this concrete base, steel I-beams are laid and placed at suitable intervals 45 to 90 cm. This I-beams length is equal to the foundation’s width.

- Then concrete is poured to fill the space between the I beams. Above these, the next layer of I-beams is installed perpendicular to the primary layer.

- Again concrete is poured into the internal space to fill it.

- Now fix steel stanchions by connecting with the base plate. A gusset plate and side angles are used for a secure connection. To make them monolithic, these connections are also secured in the concrete.

What is a Grillage beam?

Grillage foundations consist of a number of layers of beams usually laid at right angles to each other and used to disperse heavy point loads from the superstructure to an acceptable ground bearing pressure.

What is a steel Grillage?

Steel Grillage foundation consists of steel joints or beams which are provided in single or double tiers. Its name defines its function and structure as it is made up of steel beams, structurally known as rolled steel joist.

What is Grillage in engineering?

A footing that consists of two or more tiers of closely spaced structural steel beams resting on a concrete block, each tier being at right angles to the one below.

[su_box title=”FAQ” style=”default” box_color=”#333333″ title_color=”#FFFFFF” radius=”3″ class=”” id=””]

What Is Grillage Foundation?

A Grillage foundation consists of one or more tiers of beams (steel or timber) superimposed at right angles to each other on a concrete layer to disperse load over an extensive area.

Steel Grillage Foundation Details

The steel grillage foundation consists of steel beams placed in single or double tiers and enclosed concrete. The grillage beams of each tier are held in position by 25 mm-diameter pipe separators and 20 mm spacer bars. The beams are spaced appropriately to allow the placement and compacting of concrete between them.

[/su_box]

[su_note note_color=”#F2F2F2 ” text_color=”#333333″ radius=”3″ class=”” id=””]

Like this post? Share it with your friends!

Suggested Read –

- What Is Plaster | Methods of Plastering

- All About Drywall Water Damage Repair

- What Is Glass | Types of Glass Used in Construction | Qualities of Glass | Advantages & Disadvantages of Glass

- What Are the Differences Between Shear Slump and Collapse Slump in Slump Test?

- All About Asphalt Flooring | What is Asphalt Flooring | Asphalt Flooring Used | Asphalt Flooring Advantages and Disadvantages

[/su_note]

Originally posted 2023-04-05 10:33:33.