What Is Lap Length? | Lap Length in Beam | Why Lapping Is Provided? | How to Calculate Lap Length? | Lap Length as Per Is Code 456 | What Are the General Rules for Lap Length? | Lapping Zone

Table of Contents

What Is Lap Length?

- Lap length is specified as the length given to enable the overlapping of two reinforcement bars, enabling secure and efficient load transfer through one bar to another.

- Once the reinforcement bars are mounted, the length of a single reinforcement bar will not be adequate. Throughout this scenario, the required design length is obtained by overlapping two bars. The lap length is thus given to facilitate such side-by-side lapping of the reinforcement bars. In these other terms, the lap length is the length of overlap between the two reinforcing bars.

- Lap length can also be given where the width of the reinforcement bar may be changed along its length, such as when reinforcing columns. Lapping is the act of overlapping the reinforcing bars side by side to achieve the desired design duration.

- The lap’s purpose is to ensure that axial force is transferred efficiently from the terminating bar to the new attached bar in the same line of action in the junction.

Lap Length in Beam

- Generally, 24d is used for the compression zone and 45d for the tensile zone in a beam.

- Lapping should not be done at the midpoint of the beam, but either at the intersection of the column and the beam, or L/4 length from the casting face of the column.

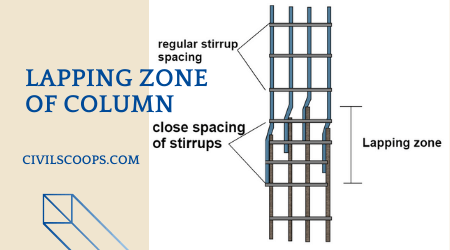

- The stirrups should be mounted closely to the lapping zone.

- The overlapping of bars can be done alternately.

Why Lapping Is Provided?

Assume we need to construct a 40 meter high column, but there is no 40 meter long single reinforcement available to consumers; instead, the reinforcement available from various steel manufacturers is 12 metres (40 feet) long. So, in order to securely pass tension load from one rebar to the next, you must join three rebars to achieve the desired height. Overlapping should be achieved between two rebars.

What Will Happen If We Don’t Provide Lap Length?

Although we all learn, lapping can be offered between two rebars in order to safely move shear forces through one bar to another. If you do not provide lap length between two rebars, the load is not safely shifted from one bar to the next, allowing the system to collapse, and if not failed, it causes splitting and irreversible collapsing of a structure. Lapping should be given in steel as we put steel in RCC structure to avoid breaking, structure collapse, and irreversible collapsing.

How to Calculate Lap Length?

- Compression and stress are experienced by various RCC structures such as column beams and slabs. When a load is applied to a beam or a slab, it can feel both compression and stress, which is why it is referred to as a flexural member of a concrete frame.

- When a load is applied to a column, it just feels compression, indicating that the column is a compressive part of a concrete RCC structure.

- When a load is added to a beam, it faces both negative and positive bending times. The top concrete fibre of the beam and slab will undergo compressive tension, with maximal bending at both support ends and minimum bending in the centre of a span in the compression field.

- The bottom concrete fibre of the beam and slab will feel strain stress, with bending stress being highest in the centre of the stretch and lowest at both support ends in the tension region. As a result, more steel is given near the two reinforcement ends of the top concrete fibre in the compression zone and the centre span of the bottom concrete fibre in the stress zone.

Lap Length as Per Is Code 456

- Compression and stress can arise in RCC systems such as column beams and slabs, according to IS code 456 tension has two case: –

- With one flexural stress lap length, it should be equal to the construction length of the rcc structure or 30d, whichever is greater.

- In general, the lap length should be calculated as 41d, where d is the diameter of the rebar.

- For direct stress, the lap length should be twice the production length (2Ld or 30d).

- For compression, the lap length should be equal to the production length and should not be less than 24d.

What Are the General Rules for Lap Length?

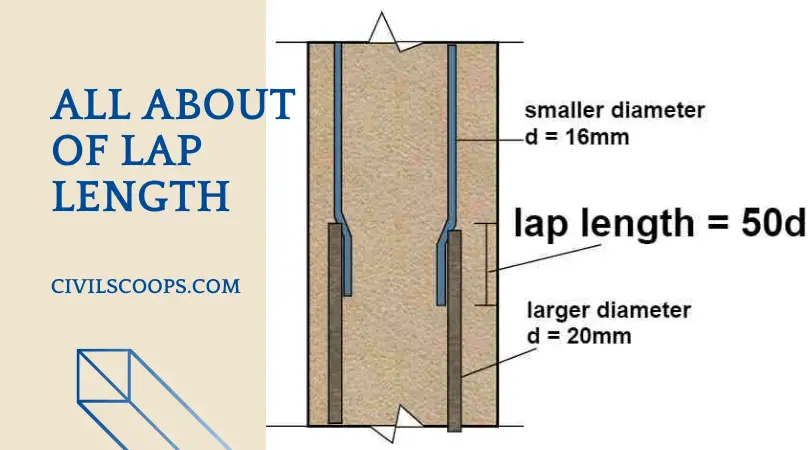

- When splicing bars with varying diameters, the lap length is measured using the smaller diameter bars.

- If you are building a column and a 20 mm diameter bar comes from the bottom and a 16 mm diameter bar needs to be spliced, the 16 mm diameter can be used to calculate lap length rather than the 20 mm diameter.

- Lapping should not be performed on steel bars larger than 36 mm in diameter; instead, welding should be given on the rebar for continuity and length increase in order to safely pass load from one rebar to the next rebar.

- lapping should not be given where full shear force occurs in concrete fiber, it should be provided where shear forces is minimal.

- real design of lapping length measured on the basis of design arrangement of column, beam, and slab according to the grade of Steel, grade of concrete, and a number of stress forces occur.

Lapping Zone

-

Lapping Zone of Column

- The bending moment is equivalent to 0 at the middle region of the column, implying that the middle section of the column is under the least tension. As a result, it is preferable to have the lapping at this part of the column. As a result, stresses can be quickly and smoothly moved from one reinforcing bar to the other in the column’s mid-section.

- Lap zone= L/2.

-

Lapping Zone of Beam

- In the context of a beam, the upper part of the beam is compressed, while the lower portion is compressed and tensioned. As a result, the uppermost reinforcing bar in the beam should be established on the left side of the beam’s mid span. Because the beam is not exposed to a negative moment at the midsection, lapping in the beam is ideal.

- It is preferable to provide lapping at the beam’s end parts for bottom reinforcement. The lapping can also be given at a distance of L / 4 from the face of the shaft, but this is not the midsection of the beam.

- Compression Zone = L / 3 (center).

- Tension Zone=L/4 (Beam column Junction).

Lap Splices for Columns

The essential considerations for lap splice length, location, and position as per IS 456-2000, clause.26.2.5.1 are discussed below.

- Lapping is not used with bars larger than 36 mm in diameter. Welding, couplers, or welding with helical reinforcing may be used to attach wider bars.

- Lapping is not available in the tension zones (Zone-A).

- The general lap length for column reinforcement is greater of the development length Ld and 30d, where ‘d’ is the reinforcement bar’s diameter. If the structural builder does not have a lap length estimate, this value is used.

- The lateral reinforcement or ties are placed close together in the lap length area. Closely spaced special constrained reinforcement is often given at a distance lo from the top and bottom of the column, according to the ductile reinforcement principle. According to IS 13920-1993, clause.7.4.1, ‘lo’ equals hc/6 or 450 mm (minimum value is taken).

- When lapping two bars of varying diameters, the lap length is measured for the bar with the smaller diameter.

- Lapping can not be done at the column-beam junction because it is subject to the most tension.

- The lapping must be given alternately so that the lapping of adjacent rebars does not occur in sequential order.

- The rebars are spaced and lapped properly to retain the column’s transparent cover.

- The provided lapping length cannot be less than 75 mm.

Lapping Zone of Columns as Per Is 13920: 1983

- The columns are divided into three zones according to Indian standard codes, as seen below. The zones are created by taking the moment diagram of the column under lateral load into account.

- The column is exposed to a maximum moment at the ends and a zero moment in the middle due to the action of load. As a result, the top and bottom portions of the column subjected to maximal moment are classified as Zone-A, while the section where the moment is decreasing to zero is classified as Zone-B. As a result, the less important area of the column, Zone-B, forms the column’s lapping zone.

- Zone-A has a length of hc/4 if the clear width of the column is hc. The height of Zone-B is then calculated as (hc– (h/4 + hc/4)) = hc/2.

- These areas are designated to have special confining reinforcement as part of the ductile detailing of R.C.C columns.

[note note_color=”#F2F2F2 ” text_color=”#333333″ radius=”3″ class=”” id=””]

Like this post? Share it with your friends!

Suggested Read –

- Hollow Block | Hollow Concrete Block | Hollow Concrete Block Size |Hollow Concrete Block Advantage | Hollow Concrete Block Disadvantage | Hollow Concrete Wall | Hollow Block Construction | Size of Hollow Blocks | How to Make Hollow Blocks

- Hand Level Surveying | What Is Site Level? | What Is Hand Level? | How to Use a Hand Sight Level | Estimating Distances with a Sight Level

- Types of Cement Grades | Difference Between 33, 43 &53 Grade Cement

- What Is Panelled Window? | What Is Glazed Window? | Difference Between Paneled Window and Glazed Window

- What Is Fresh Concrete? | Properties of Fresh Concrete | Factors Affecting Workability

[/note]

Originally posted 2021-09-04 08:16:07.