What Is Plaster | Types of Plaster As Per Material | Defects In Plastering

Table of Contents

What Is Plaster?

This is the process of covering rough walls, uneven surfaces in the construction house, and other structures with a plastic material, called plaster or mortar.

Sometimes, the term ‘rendering’ is used instead of plastering when the plaster or cement is applied to the external surface of the wall either to improve the appearance or to protect them from wether agencies, such as rain heat, etc.

Requirement of a Good Plaster

To turn out to be a good plaster, the plastering material must possess to satisfy the following requirement

- It should adhere to the background and should remain adhered to during all variations of climate changes. Also, it should be possible to apply it during all weather conditions.

- It should not contract in volume while drying and setting. Otherwise, it will crack and give an unsightly appearance.

- It should be cheap and economical.

- It should be hard and durable, providing a smooth, non-absorbent, and washable surface with the required decorative effect and durability.

- It should offer good insulation against sound and high resistance against fire.

- It should effectively check the entry or penetration of moisture from the surface.

- It should possess good workability.

Types of Plaster As Per Material

There are various types of plasters used according to the requirements. To name some are as below:

- Lime Plaster

- Mud Plaster

- Cement Plaster

- Water Proof Plaster

Also Read: Plasticizer Vs Superplasticizer | What Is Plasticizer In Civil | What Is Superplasticizer In Civil

1. Lime Plaster

Lime used in plastering may be fat lime or hydraulic lime. Fat lime makes the best plaster as they yield good putty after slaking.

Hydraulic lime, on the other hand, yields harder and stronger plaster. But it may contain some unslaked particles which may slake slowly (maybe in 8 to 12 months) on absorbing moisture from the atmosphere and damage the plastering by forming blisters.

As a precaution, the hydraulic lime, if used, should be ground dry with sand; lift for about 2 or 3 weeks and then reground before use.

Mortar for lime plaster is usually prepared by mixing sand and lime in equal proportions. Cement in small quantities is sometimes added to the mixture to improve its strength.

Gugal (a kind of fragrant gum) and chopped hemp are sometimes added at the rate of 4.5 kg and 2.7 kg, respectively, to every 2.85 cu.m. of plaster. This treatment prevents the formation of cracks in the plaster on drying.

2. Mud Plaster

The mud plaster is prepared from equal volumes of well-tempered clay or brick earth and of chopped straw, hay, loose soil, or hemp and cow dung.

All these ingredients are thoroughly mixed and lifted for about 7 days with a large quantity of water.

This is mixed again thoroughly till it comes to the desired consistency of plaster sometimes mud plaster made of clay and sand is also used.

3. Cement Plaster

The cement plaster consists of one part of cement to four parts of clean, coarse, and angular river sand by volume the materials are thoroughly mixed in a dry condition before water is added to them.

The mixing of materials is done, or a watertight platform and plaster of one cement bag only are prepared at a time, and this quantity of plaster is consumed within 30 minutes after adding water.

4. Water Proof Plaster

The water-proof plaster is prepared by mixing one part of cement two parts of sand and pulverized alum at the rate of 120 N per m3 of sand.

In the water to be used. 0.75 N of soft soap is dissolved per one lite water, and this soap water is then added to the dry mix.

Also Read:Difference Between Lime and Cement | What Is Lime (Hydraulic) | What Is Cement

Defects In Plastering

Usual defects that are found in plastering wor. Below types of defects Plastering.

- Blowing or Blistering of Plaster

- Cracks

- Falling Out of Plaster

- Efflorescence

- Flaking

- Peeling

- Popping

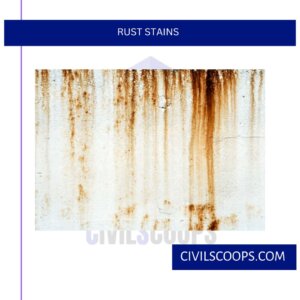

- Rust Stains

- Uneven Surface

- Softness

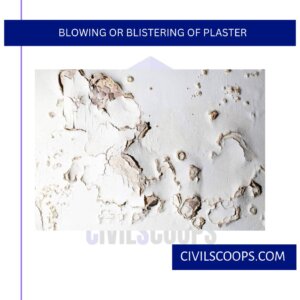

1. Blowing or Blistering of Plaster

This consists of the formation of small patches of plaster swelling out beyond the plastered surface and are chiefly due to improper slaking of lime particles in the plaster.

After the application of plaster, the unslacked particles in the lime start slaking and thus the defect takes place. Properly slaked lime should, therefore, be used to prevent blistering.

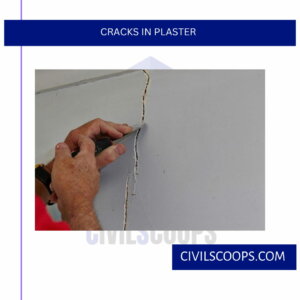

2. Cracks in Plaster

These are formed on the plastered surface and maybe hair cracks or cracks that may be easily seen.

The development of fine hair cracks is known as crazing. The major causes are:

- Old surface not being properly prepared.

- Movements in the backing either on account of thermal expansion or due to shrinkage caused by the drying of the backing material. To avoid this the backing surface should be allowed to dry before applying the plaster.

- Movement in the plaster itself on account of the expansion (in case of gypsum plaster) or shrinkage of the plaster coat (in case of lime-sand plaster) during drying.

- Excessive shrinkage of plaster due to the application of mortar in thick coats.

- Workmanship and the method of application of the plaster. Rough textured finishes are generally less likely to show cracking than smooth finishes.

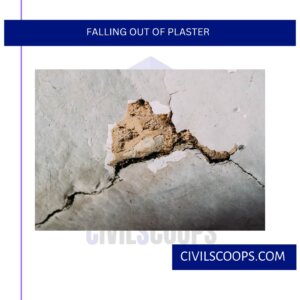

3. Falling Out of Plaster

The following are the reasons for this defect.

- The adhesion of the plaster to the background may not be perfect.

- The suction of the backing material may not be uniform. At places where the backing material absorbs an excessive amount of water, the plaster loses its strength as well as the mechanical bond between the two surfaces.

- Excessive thermal changes in plaster or backing.

- The bond between the successive cost of plaster may not be perfect.

- Inadequate curing of the plaster.

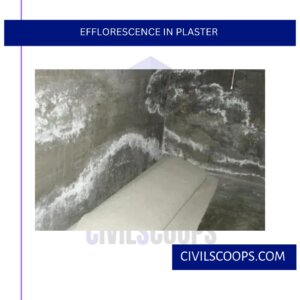

4. Efflorescence in Plaster

The soluble salts are present in plaster-making materials as well as building materials such as bricks, sand, cement, etc.

Even water used in construction work may contain soluble salts. When a newly constructed wall dries out, the soluble salts are brought to the surface and they appear in the form of a whitish crystalline substance.

Such growth is referred to as the efflorescence and it seriously affects the adhesion of paint with a wall surface.

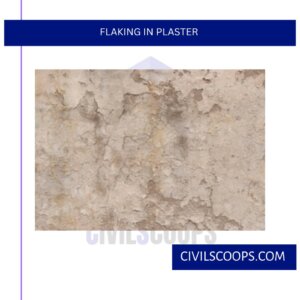

5. Flaking in Plaster

The formation of a very small loss mass on the plastered surface is known as flaking and it is mainly due to bond failure between successive coats of plaster.

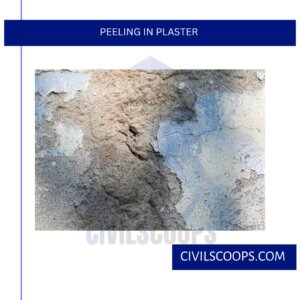

6. Peeling in Plaster

The plaster from some portion of the surface comes off and a patch is formed. Such formation is termed as peeling and it is also mainly due to bond failure between successive coats of plaster.

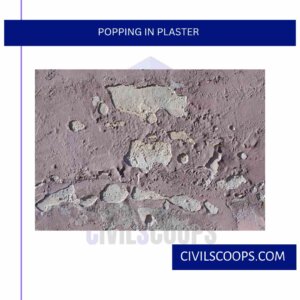

7. Popping in Plaster

Sometimes the plaster mix contains particles that expand on being set. A conical hole in the plastered surface is formed in front of the particle. This conical hole is known as the blow or pop.

8. Rust Stains

Seen sometimes on the plastered surface, especially when plaster is applied on metal lath.

9. Uneven Surface

This defect becomes prominent only due to poor workmanship of the work.

10. Softness in Plaster

The excessive dampness at certain points on the plastered surface makes that portion soft. The chief reasons for such softness are the undue thinness of the finishing coat.

Presence of deliquescent salts, excessive suction of the undercoat, etc.

[su_box title=”FAQ” style=”default” box_color=”#333333″ title_color=”#FFFFFF” radius=”3″ class=”” id=””]

What Is Plaster?

Plaster is a building material used for the protective or decorative coating of walls and ceilings and for molding and casting decorative elements. In English, “plaster” usually means a material used for the interiors of buildings, while “render” commonly refers to external applications.

Types of Plaster

- Clay plaster.

- Gypsum plaster (plaster of Paris)

- Lime plaster.

- Cement plaster.

- Heat-resistant plaster.

Defects in Plastering

- Blistering of Plastered Surface.

- Cracks in Plastering.

- Efflorescence on Plastered Surface.

- Flaking.

- Peeling.

- Popping.

- Uneven Plaster Surface.

- The softness of the Plaster.

What Is Plaster Made Of?

plaster, a pasty composition (as of lime or gypsum, water, and sand) that hardens on drying and is used for coating walls, ceilings, and partitions. Plastering is one of the most ancient building techniques.

Which Lime Is Used for Plastering?

Hydraulic Lime

Thick lime or poor lime is often preferred for plastering operations because of the slow, tedious process of hydraulic lime. For external plastering, cement is occasionally used with lime mortar to increase its strength and characteristics.

Why Is My Plaster Cracking?

Cracking plaster is a common problem in older homes. There are several reasons why this happens. Cracks can be the result of thermal movement, the settling of a foundation or sill work, or even exposure to moisture for an extended period of time.

How Is Plaster Made?

It is produced by heating gypsum to around 150°C (300 °F). When mixed with water, the dry plaster powder re-forms into gypsum. Unmodified plaster starts to set about 10 minutes after mixing, but it will not be fully set until 72 hours have elapsed. Gypsum plaster has good fire-resistant qualities.

What Is Lime Plaster Made Of?

Lime plaster is a type of plaster that is made from marble dust, water, and non-hydraulic hydrated lime, which is also called slaked lime, high calcium lime, or air lime. Plasters made with ancient lime often included horse hair for reinforcement and pozzolanic chemicals to speed up the process.

Why Does New Plaster Crack?

Dry-shrinkage cracks occur when the liquid in a plaster or stucco material evaporates. They happen because plant-based materials—like cement and lime—shrink when they dry out. These cracks are stable but should be filled with filler before you paint.

Is Lime Plaster Dangerous?

While the high pH level offers fungicidal benefits to the building’s owners, it also makes lime plaster potentially dangerous during application. The caustic properties mean it can cause burns if it isn’t used with appropriate PPE.

Is Lime Plaster Waterproof?

Lime plasters are waterproof in the sense that they do not get soft when soaked, but they are also very breathable. They are traditionally maintained by periodic applications of limewash.

Is Plastering Expensive?

Plasterwork usually costs between $2 and $10 per square foot. The cost depends on whether you want resurfacing work or not. Expect to pay at least $10 per square foot with resurfacing; otherwise, plastering a wall usually costs between $2 and $5 per square foot.

What Is Lime Plaster Used For?

Lime plaster is a traditional type of mortar used to cover the surface of internal walls and ceilings before painting. Records of it being used date back 140 centuries to northern Jordan.

What Is Clay Plaster?

Clay plaster is a mixture of clay and sand that makes a beautiful, environmentally friendly alternative to conventional plaster and paint. It is natural, non-toxic, durable, and beautiful. Unlike most paint, it does not contain VOCs (harmful chemicals that are released during and after application).

How Is Gypsum Plaster Made?

Gypsum rock is converted into gypsum plaster by driving off some of the chemically combined water. Heating gypsum at 120°C for one-hour results in a hemi-hydrate (CaSO4. 1⁄2H2O) – with three-quarters of the water removed. Gypsum hemi-hydrate is also known as Plaster of Paris.

Cement Plaster Is Used For?

Cement plaster is used to plaster the interior as well as the exterior walls of the house. The best quality of cement plastering is needed in order to do a great job. Cement plaster is a mixture of water, fine aggregates, and Portland cement. Cement and sand are mixed in different amounts to obtain the cement plaster.

What Is Cement Plaster?

A mortar consisting of portland cement, sand, and water is used for plastering the interior surfaces of a building.

Is Plaster Waterproof?

Polished or Venetian plaster in its natural form is not waterproof, you can apply wax or some sealants to make it water resistant but it will never be totally waterproof.

Why Does Plaster Crack?

Cracks can be the result of thermal movement, the settling of a foundation or sill work, or even exposure to moisture for an extended period of time. The extent of the crack can also vary across different plastering types.

Why Does Plaster Crack in Old Houses?

Old lath and plaster walls are prone to cracking. Over time the plaster separates from the lath, creating structural cracks. Plaster is also prone to thinner spider-web cracks, which occur when the topcoat of the plaster degrades. It’s common to have both kinds of cracking — and both types can be repaired.

[/su_box]

[su_note note_color=”#F2F2F2 ” text_color=”#333333″ radius=”3″ class=”” id=””]

Like this post? Share it with your friends!

Suggested Read –

- What Is Bamboo Flooring | Bamboo Flooring Pros and Cons

- What Is Hardened Concrete | Properties of Hardened Concrete

- All About Retrofitting | What Is Retrofitting | Why Need Retrofitting | Advantages And Disadvantages of Retrofitting of Building

- What Are Hollow Bricks | Advantage of Hollow Bricks | Disadvantage of Hollow Bricks | Sizes of Bricks Blocks | How to Make Hollow Bricks

- What Is Fire Escape Staircases | Types of Fire Escaping Stairs | What Is the Importance of Fire Escape in the Building | What Are the Fire Staircase Requirements

[/su_note]

Originally posted 2023-03-13 10:48:13.