Reinforced Concrete Frame | Concrete Frame Construction Details | Concrete Building Construction

Table of Contents

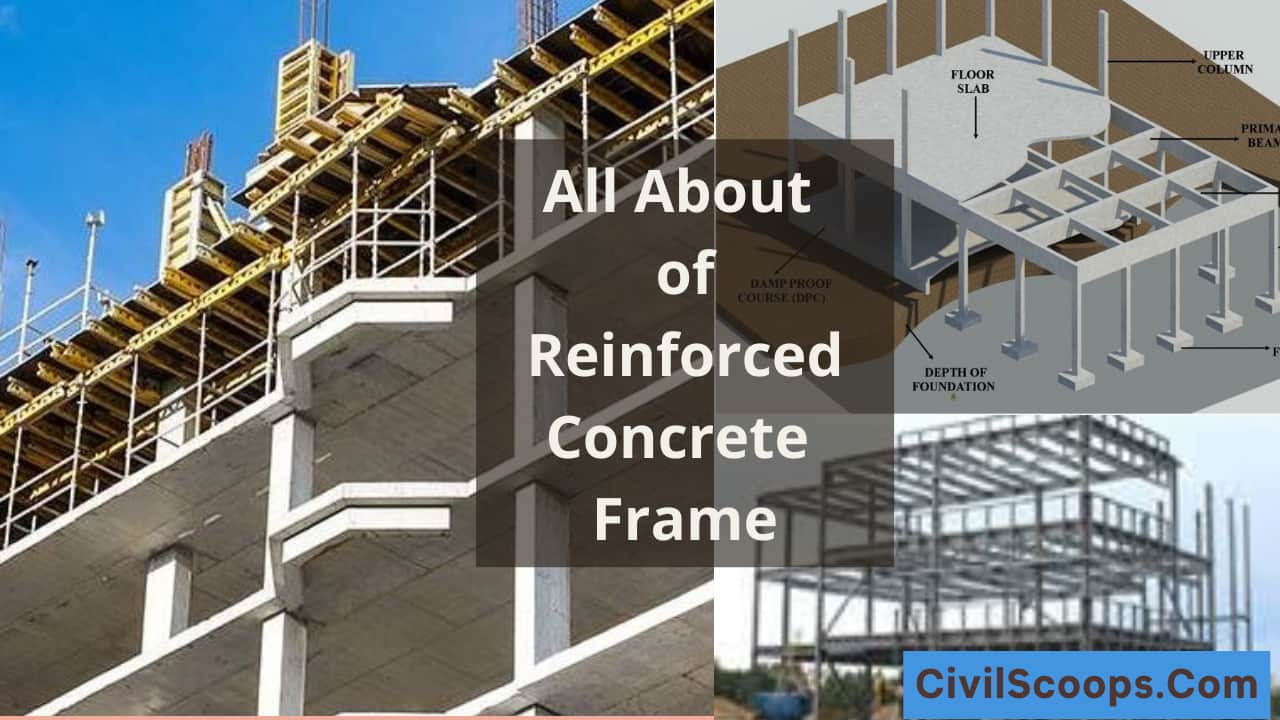

Reinforced Concrete Frame

Reinforced concrete frames comprise of flat components (beams) and vertical components (columns) associated by rigid joints. These designs are projected solidly that is, beams and columns are projected in a solitary activity to act as one.

RC frames give protection from both gravity and horizontal burdens through bowing in beams and columns.

Concrete Frame Construction

Concrete frame construction is a construction strategy which contains an organization of columns and beams to move the heaps going onto the design to the establishment effectively. Wholistically, it shapes a structural skeleton for the structure which is utilized to help different individuals like Floors, Roof, Walls, and Claddings.

Concrete Frame Construction Details

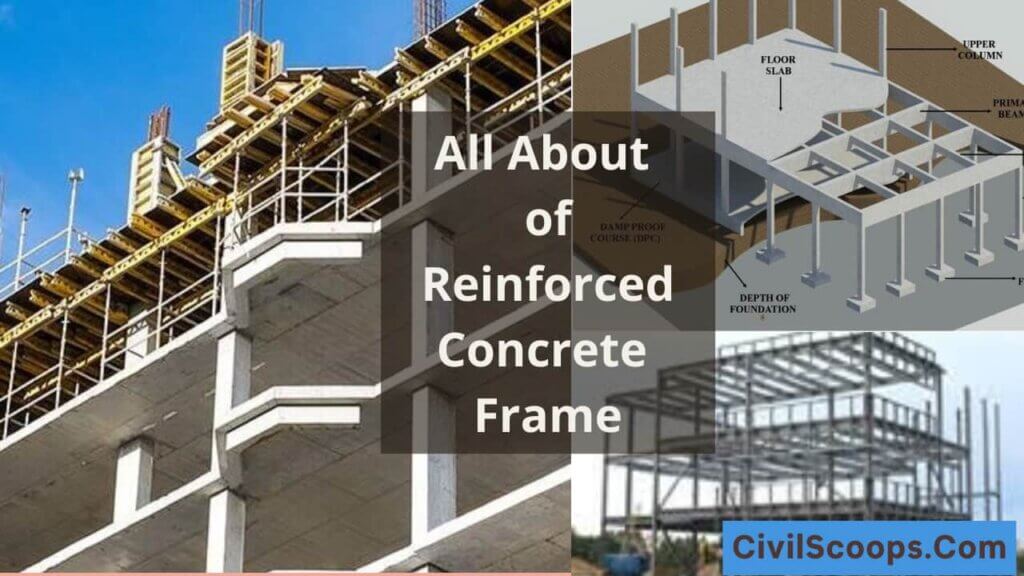

1. Columns in Framed Structure

Columns are an important primary individual from a frame building. They are the upward members which convey the loads from the shaft and upper columns and move it to the footings.

The loads conveyed might be axial or eccentric. Plan of columns is more important than the plan of beams and pieces. This is on the grounds that, in the event that one shaft comes up short, it’ll be a nearby disappointment of one floor, yet in the event that one segment falls flat, it can prompt the breakdown of the entire structure.

2. Beams in Framed Structure

Beams are the horizontal burden bearing members of the framed structure. They convey the loads from sections and furthermore the immediate loads of brick work dividers and their self-loads.

The beams might be supported on different beams or might be supported by columns forming an integral piece of the frame. These are basically the flexural members. They are ordered into 2 kinds :

- Main Beams – Transmitting floor and secondary bar loads to the columns.

- Secondary Beams – Transmitting floor loads to the main beams.

3. Slab in Framed Structure

A slab is a horizontal flat surface used to protect a building from the elements and provide shelter for its occupants. These are the plate elements, which flexure to carry the loads. They are usually used to transport vertical loads.

Because of their huge moment of inertia, horizontal loads can carry huge wind and earthquake forces and then transfer them to the beam.

4. Foundation in Framed Structure

The foundation’s main purpose is to transfer the load from the above-mentioned columns and beams to the solid ground.

5. Shear Walls in Framed Structure

In high-rise buildings, those were crucial structural features. Shear walls are really very massive columns that appear to be walls instead of columns due to their size. They are responsible for horizontal loads such as wind and earthquakes.

Vertical loads are also carried by shear walls. It’s critical to realise that they only operate for horizontal loads with one orientation, which would be the axis of the wall’s long dimension.

6. Elevator Shaft in Framed Structure

The elevator shaft is a vertical concrete box that allows the elevator to travel vertically and horizontally. Such shafts assist in the resistance of horizontal loads as well as the carrying of vertical loads.

Also Read:What Is Plastering | What Is Pointing | Difference Between Plastering and Pointing |

Concrete Building Construction

1. Estimation of Materials

Estimating materials is the process of measuring the quantity or proportion of materials such as cement, aggregates, water, and other ingredients in a concrete mix by weight or volume.

2. Preparing the Site

The most critical aspect of laying concrete is soil preparation. The earth must be well-drained and compacted before the concrete can be poured. Preparing the subsoil properly reduces the likelihood of cracks in the finished concrete construction.

3. Building Formwork

In building, formwork is being used to support structures and serve as moulds for the creation of structures so out concrete placed into the moulds. Molds constructed of steel, wood, aluminium, or prefabricated forms can be used to create formwork.

The building of formwork takes some time and can able to price to 20% to 25% of the structure’s total cost, if not more. Stripping refers to the process of eliminating the formwork. Panel forms are reused forms, while stationary forms are non-reusable.

4. Placing of Reinforcement

Reinforcement will be precisely positioned and sufficiently upheld before concrete is put, and will be gotten against dislodging. Reinforcement ought to be set as demonstrated on the putting drawings which shows the quantity of bars, bar lengths, twists, and positions. The cover is likewise important to guarantee that the steel bonds to the concrete alright to foster its solidarity.

5. Mixing of Concrete

Appropriate mixing of concrete fixing is a lot of essential as it influences the nature of concrete in its new state just as in the solidified state. A concrete is supposed to be very much blended in the event that it satisfies the accompanying necessities.

The concrete blend ought to be uniform in shading. Concrete ought to accomplish legitimate consistency for which it is planned. The complete mixing of every single concrete fixing. Cement glue should cover all the outside of the total.

6. Pouring of Concrete

The blended concrete is shipped to the site of cementing inside the underlying set time. The poring of concrete can be different strategies, for example, siphoning and manual moving. the poured concrete is compacted utilizing a vibrator for guaranteeing appropriate compaction. Care should be taken to forestall air pockets and guarantee an even surface.

7. Finishing of Concrete

The most fundamental kind of concrete completion is a smooth surface made using tirades and scoops. Following the concrete has been set in structures, the tirade is utilized to even out the concrete surface. Tirades often comprise of long bits of metal or wood that are pulled and pushed across the concrete surface to eliminate overabundance of concrete and fill in holes in the concrete surface.

8. Curing of Concrete

Curing of concrete is the last and quite possibly the main exercises needed to be taken during the time spent concrete development. Curing of concrete is the way toward keeping the concrete soggy to empower it to acquire original capacity. This last advance assumes an extremely critical part in concrete exhibition and needs full and moment consideration.

Also Read: Building Layout | How to Building Layout | Construction Layout Techniques

Frame Construction

Frame construction is a structure procedure which includes building a steady framework of studs, joists, and rafters, and joining all the other things to this framework. This structure style can be cultivated rapidly with a gifted team, and it is incredibly regular everywhere on the world.

The cycle of frame construction begins with developing a ledge on the ground, with the ledge being appended to an establishment. Long studs are joined to the ledge at set stretches to make an organization which can be connected to the joists and rafters which make up the rooftop or extra stories. The frame might be furthermore upheld with cross propping and different procedures. Basically, frame-style construction makes a skeleton, and a quick group can frame a house in a couple of days.

When the frame is finished, dividers and different highlights can be added. The construction develops dynamically more steady as hardened ground surface and dividers are added, making extra help and protection from the components. Inside the construction, the developers can separate from basic primary dividers, which offer help to protect the structure, and segments which can be utilized to gap and change the state of different spaces inside the design for utility.

Platform frame construction, in which a design is assembled floor by floor, is the most well-known sort of this construction style. Some more seasoned structures use balloon frame construction, in which long joists run right from the ledge to the top plate, which meets the rooftop, regardless of how tall the structure is. For functional reasons, balloon frame construction is generally restricted to a few stories, and it is extraordinary to see in new designs, due to timber accessibility issues.

Traditionally, frame construction is cultivated with wood, which should be painstakingly sliced and handled to guarantee that the uprightness of the frame is kept up. Wood which has not been restored as expected, for instance, will foster warping and twisting which could haul the design crooked. Metal shafts can likewise be utilized in outlining, and they can reduce expenses essentially in regions where timber is costly.

Types of Frame

Here, the different types of frames are as follows.

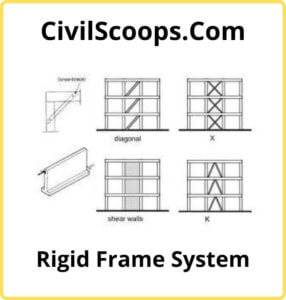

1. Rigid Frame System

Rigid frame systems, also known as moment frame systems, are made up of linear elements such as beams and columns. The term rigid refers to a person’s capacity to resist deformation. It can be found in steel and reinforced concrete structures. The absence of pinned joints within the frame distinguishes rigid frames, which are often statically indeterminate.

The bending of beams and columns in a rigid frame can resist both vertical and lateral loads. The rigid frame’s stiffness is primarily provided by the bending rigidity of rigidly connected beams and columns. The joints must be constructed to have enough strength and stiffness while exhibiting minimal deformation.

Internal forces and moments, as well as support responses, can be solved using structural analysis methods such as the portal method (approximate), the method of virtual work, Castigliano’s theorem, the force method, the slope-displacement method, the stiffness method, and matrix analysis.

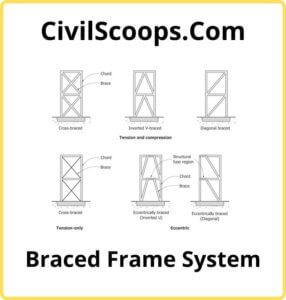

2. Braced Frame System

To resist lateral stresses, braced frames are made up of beams and columns that are “pin” connected by bracing. This style of frame is easy to evaluate and put together. Both horizontal and vertical bracing are used to provide resistance to lateral forces.

Knee bracing, diagonal bracing, X bracing, K or chevron bracing, and shear walls that resist lateral stresses in the plane of the wall are only a few examples. This frame technology is more effective in terms of earthquake and wind resistance. It performs better than a rigid frame system.

[su_box title=”FAQ” style=”default” box_color=”#333333″ title_color=”#FFFFFF” radius=”3″ class=”” id=””]

Reinforced Concrete Frame

Sadly the bike never went anywhere, but it struck me as wonderfully coincidental that i’m testing what’s claimed to be the world’s lightest production disc brake bike – the s-works aethos – and its weight? It’s 6.23kg, or 13lbs 12oz in old money.

Concrete Frames

Sadly the bike never went anywhere, but it struck me as wonderfully coincidental that i’m testing what’s claimed to be the world’s lightest production disc brake bike – the s-works aethos – and its weight? It’s 6.23kg, or 13lbs 12oz in old money.

Insulated Concrete Framing

Insulating concrete forms, or icfs, are forms used to hold fresh concrete that remain in place permanently to provide insulation for the structure they enclose. Their history dates back to after world war ii, when blocks of treated wood fibers held together by cement were used in switzerland.

Framing for Concrete

Prior to placing concrete forms: construct the form with 2×4 or 2×6 lumber and secure in place by wood stakes and deck screws. Excavate the slab area to a depth of about 7 inches, allowing 3 inches for a gravel base and 4 inches for concrete.

Tilt Wall Construction

Tilt-up construction features series of concrete panels tilted up into place to form a building’s exterior wall. These panels are created at the work site using wood forms, rebar and concrete. The forms are shaped and rebar cut to match final designs. Next, concrete is poured into the forms and finished.

World of Concrete 2022

World of Concrete 2022 Will Adhere to Informa Allsecure Health and Safety Standards, as Well as Guidance from Local Authorities, and Any Venue or Location-Specific Regulations.

Basement Foundation Repair

You can start to worry when you see, cracks that are wider than 1/10 inch. Cracks that are wider at one end. Cracks that are getting bigger over time.

Concrete Foundation Repair

Use about 5/8 cold chisel and just knock out some of it. Making the gap wider. Now a cold chisel designed to break out in masonry. So it works fine.

Foundation Crack Repair

Foundation crack repairs cost between $250 and $800. Some foundation cracks are minor and easy to fix. Cracks wider than ⅛ inch cause concern, and hairline cracks should be repaired to prevent water damage. If you discover large cracks, consult with a structural engineer about your options.

Mud Jacking near Me

Mudjacking costs $3 to $6 per square foot, and foam jacking is $5 to $25 per square foot. The average cost of slabjacking to raise a concrete slab is between $511 and $1,790, with most spending $830.

[/su_box]

[su_note note_color=”#F2F2F2 ” text_color=”#333333″ radius=”3″ class=”” id=””]

Like this post? Share it with your friends!

Suggested Read –

- Types of Curing | Concrete Curing Time | How to Cure a New Concrete Slab | What Is Curing of Concrete | How Long Does Concrete Take to Dry | How Long Does It Take for Cement to Dry

- What Is Sheepsfoot Roller? | Characteristics of Sheepsfoot Rollers | Difference Between Padfoot and Sheepsfoot Rollers

- Monolithic Slab I Monolithic Definition I Monolithicfooting I Monolithic Slab Foundationl Monolithic Slab Foundation Design L What Is a Monolithic Slab L How to Form a Monolithic Slab

- What Is a Spillway | Types of Spillway | Definition Spillway | Spillway Design

- What Is Workability | What Is Workability of Concrete | Types of Workability of Concrete | Factors Affecting Workability of Concrete

[/su_note]

Originally posted 2024-04-05 05:14:01.