All About of Underwater Concrete | What Is Underwater Concrete | Advantages & Disadvantages of Underwater Concrete

Table of Contents

What Is Underwater Concrete?

Underwater concrete is a special type of construction material which in used certain type of construction projects. Underwater concrete is used in those building substructure where those parts are rests in the underwater. In those area underwater concrete are widely used.

Advantages of Underwater Concrete

Here, the pros of underwater concrete are as follows.

- Underwater concrete are used in the difficult place and challenging atmosphere like also in excavation work.

- It is used in a innocuous environment workplace.

- Sheet pile construction is very simple and then it is easy to uninstall.

- In underwater concrete the materials, which are used, are utilized on certain programms.

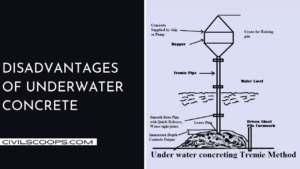

Disadvantages of Underwater Concrete

Here, the cons of underwater concrete are as follows.

- The main disadvantages of underwater concrete is in the quick rising water place there is a scour gap obtained and this the primary reason for bridge collapse.

- In the underwater concrete scaling, cracking and crazing are common thing, this is also a major disadvantage of this concrete.

- Another disadvantage of this concrete is the reinforcements, which is used in the underwater concrete construction, are getting corroded.

- In this type of concrete; concrete bend, flattened, stacked are common thing due to improper environmental condition.

Also, Read: What Is Weep Holes | Function of Weep Holes | Types of Weep Holes

Application of Underwater Condition

Underwater concrete are used in various places, those are-

- Marine development projects

- Hydro projects

- Underwater concrete structure repairs ( tank, dam, etc)

The milestone projects of underwater concrete in India are-

- Pamban Bridge, Rameswaram

- Bandra Worli Sea Link, Mumbai

- Salem Hydro Project, Andhra Pradesh

- Sardar Sarovar Dam

How Do They Pour Concrete Underwater?

- When we install the concrete in the underwater positioning in between design segments are very important and it ensures the consistency.

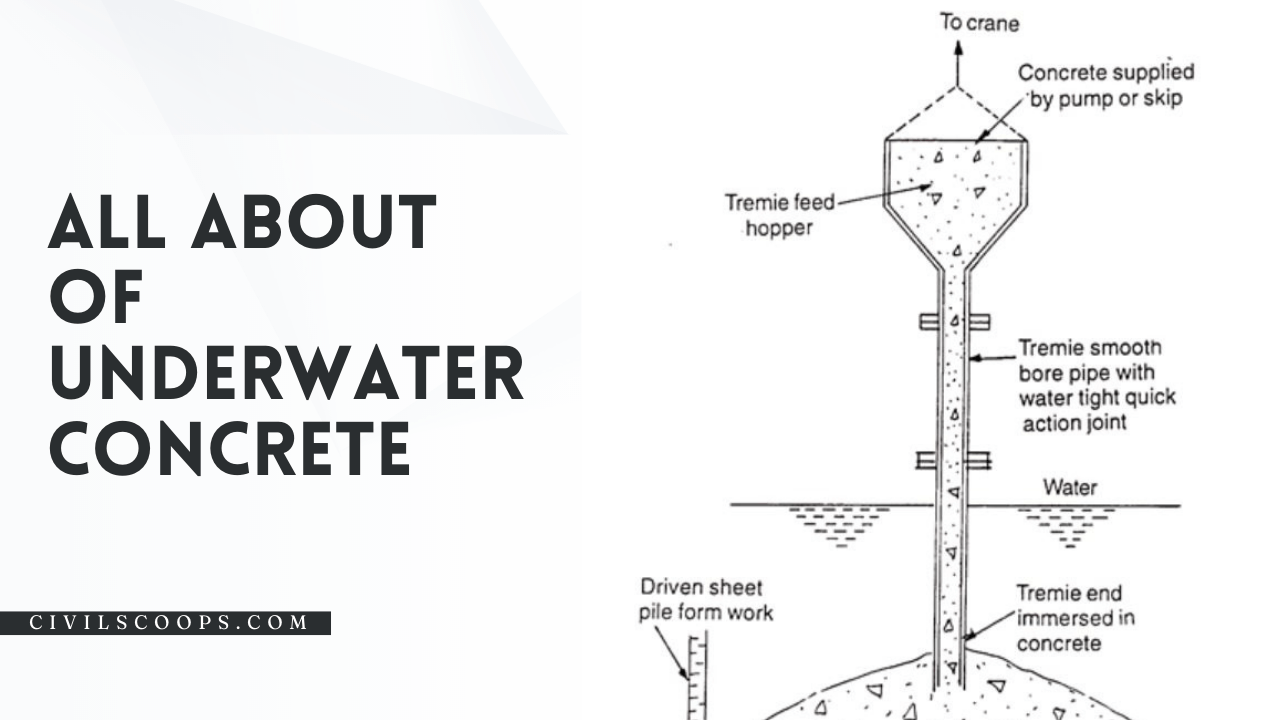

- To eliminate the segregation process puddling and any type of physical disruption is stopped during the concrete placements. In underwater concrete treatment, Tremie is the most popular process which is used. Tremie is generally comprised with a vertical steel shaft which is covered by hopper, enough wide space to enter the underwater excavation work above the water surface.

- In the steel tubing method watertight sealing is a the top and steel tubing is at the base of the excavation. Pipe is partly filled or fully packed by concrete according to the level.

- After that process the pipe is gently elevated near about six inches to create a path of concrete coming up across the tube. After proper positioning of Tremie, to close the pipe a sealing material is used until the concrete is properly placed.

- Next the Tremie is dropped at the base of the mould and maintains the water pressure.

- The retention wire is then released individually or extracted if there is multiple numbers. After that the Tremie is lifted around 4 to 6 inches from the bottom, it enables the concrete to flood into position.

- By pressing an inflatable rubber ball, in any appropriate plug, is placed to the top of the container. To increase the pressure on the concrete the ball is driven back. The advantage of using a ball is it rise the surface after removing the shaft.

- It will create a huge difficulties if there is a stoppage through tremie placement so we must predict and stop them.

- The main reason of the stoppage in the pipe is the pipe diameter is too short, so the concrete materials create a bridge across the pipe and the transporting time through the pipe is more so the materials become stiffens.

- The smooth pipe surface is destroyed due to the rough and solid mixture, poor aggregate grading, etc and binding is happens.

Also, Read: What Are Washers Used for ?

Pouring Concrete Underwater

There are mainly two different methods which are generally follows-

- Caissons

- Cofferdam

1. Caisson

- Caissons is a watertight member, which is used as a supporting framework and durable also. It is generally used in dam construction, ship maintenance, bridge pier construction, etc.

- It drains out the water from that place and create a place for underwater concrete for safe work place.

2. Cofferdam:

- Cofferdam is a temporary structure which is installed in a water body or in a dock. The area inside the cofferdam which is filled with water; pumping operation is done to remove the water and make a dry workplace.

- Cofferdams are naturally steel structures which is surrounded by sheet piles. Generally two cofferdams are constructed in a dam construction on of them is for upstream side and another one is for downstream side.

Concrete Placing Methods

- Underwater concrete methods are used for preventing the concrete from being washed

- Some modern techniques which are used for placing concrete, those are-

- Pumping Technique

- Tremie Method

- Hydro valve Method

- Skip Method

- Pneumatic valve Method

- Tilting pallet barge Method

- Toggle bags Method

- Bagged Concrete Method

- Preplaced aggregate concrete

Tremie Concrete Placement

- Using Tremie process in underwater concrete is ideal for the vast volume of high flowing concrete pouring.

- Then the concrete is placed by the conveyor belt, pumpin, skips, etc.

- The Tremie tubing is only used in the exact condition when the top range is attached with the tremie and the bottom range is immersed in the concrete.

- When the lower part of the Tremie pipe is immersed then we must avoid the intermixing the both concrete and water.

Underwater Concrete Method Using the Tremie Process

Underwater tremie process have several steps and considerations, those are-

1. Tremie Equipment

- The tremie pipe has three different ways, one is constant length which is raised during concreting, second one is different cross section pipe which is sued fro the dismantle of the concrete and the final one is the telescopic pipe.

- Those pipes which are made of aluminium alloy creates detrimental effects on the concrete and starts reaction with them. The pipe must have required diameter to avoid the blockage in the pipe due to the overall size of the concrete materials.

- The general diameter of the pipe is 200 to 300 mm and rarely used 150 mm & 450 mm, the aggregate size may vary from 19 mm to 40 mm and then the pipe diameter should be 150 mm and 200 mm respectively.

2. Tremie Seal

- The edge of the tremie pipe is capped with wooden plate because for stopping the water and asphalt in the pipe. It resists the water from entering the in the pipe and leaves it dry.

- The concrete mixture is placed and breaks the lock after reaching the pipe into the desired location.

3. Placing Concrete for Tremie

- The pipe is immersed into the concrete mix about 1 to 1.5 m to stop the moisture from penetrating the pipe. By dropping the rate of flow is regulated.

- Rising the concrete leakage and increasing the pipe, failure of the seal happens, so this way concrete can be controlled.

4. Flow Pattern for Tremie

- Generally two type of flow patterns are known those are layered and bulging. When concrete is pushed then it is bulging flow.

Can Concrete Cure Underwater?

- Concrete can cure in underwater but not like the atmosphere concrete curing. In the underwater concrete curing cement hydrates fragments are chemically reacts with water and make a bond with sand and gravel. This type of curing needs a few weeks of time and after that the cement gets patched.

- In the underwater concrete curing several components create al layer of water. This type of exterior cover protects the concrete moisture soaking, diluting of cement, etc.

- After that the next process will be going in a slower speed and the concrete will gain ultimate strength after 28 days.

- Water evaporation is not takes places in this type of concrete curing, here chemical reaction is the main reason of cement setting.

- In underwater concrete extra water interacts with cement substances to start fresh reactions.

- After the concrete settlement it does not dry, because the chemical reaction is ongoing and it shows submerged appearance.

Also, Read: Material Required for Construction of WBM Road

Steps Underwater Concrete Repair

There are few steps which are followed by the underwater concrete repair, those are-

- Surface spalling repair

- Underwater reinforced concrete reconstruction in large scale

- Pre-positioned aggregate concrete

- Underwater reconstruction of a concrete structure by injection procedure

- Grunting process for the restoration of underwater concrete structure

- Steel sleeve underwater concrete restoration procedure

Like this post? Share it with your friends!

Suggested Read –

- What Is Shell Structure | Types of Shell Structure | Applications of Shell Structure | Advantages & Disadvantages of Shell Structures

- Standard Brick Size & Dimensions (Inches & MM)

- Skeleton Frame | Building Skeleton | Steel Structural Building

- Soil Hydrometer | How Does a Soil Hydrometer Work | How to Read Hydrometer | What Does a Hydrometer Measure | Advantage, Disadvantages & Uses of Hydromete

- Rate Analysis for Concrete

Frequently Asked Questions (FAQ)

What Is Underwater Concrete?

Underwater concreting is a critical concreting process performed for offshore construction. It involves the process of carefully placing fresh concrete underwater. As construction in water results in many difficulties, the start to end of an underwater construction requires special care, supervision and planning. For example, the construction of the foundation and piles to support the bridge crossing a river, or a dock construction.

What Concrete To Use Underwater?

The type of cement used for most construction, including underwater construction, is Portland cement. Made from heated clay and lime, Portland cement is the secret to concrete’s ability to set underwater.

Pumping Concrete Under Water

Underwater concreting using pumping technique is a developed version of Tremie pipe and it is quicker method for concreting in areas that is difficult to access such as under piers.

Pumping provide several advantages that Tremie pipe is lacking for example, pouring concrete from mixer to formworks directly, solve blockages in the pipe because concreting is through pumping instead of using gravitational force, and risk of segregation is decreased. Figure 2 show typical pipeline configuration

What Happens When Water Sits on Concrete?

Concrete slabs are very porous. This means standing water can easily fill in pores on the surface and eventually break down the concrete. As a result, the concrete may crack, move, or even settle

What Type of Concrete Is Used for Underwater?

The type of cement used for most construction, including underwater construction, is Portland cement. Made from heated clay and lime, Portland cement is the secret to concrete’s ability to set underwater. But before we go underwater, we need to clear up a common misconception about how cement sets on land.

Originally posted 2022-05-27 06:13:25.