What Is Vacuum Concrete | Application of Vacuum Concrete | Advantages & Disdvantages of Vacuum Concrete

Table of Contents

What Is Vacuum Concrete?

Vacuum concrete is that type of concrete where the extra water is removed for increasing the strength of concrete. A small part of concreting part is constructing by vacuum concrete of slab and walls; then, we need to maintain the water-cement ratio 0.5-0.65.

If we remove the excess water and air from the vacuum concrete at the time of constructing, then we get a better strength. We use a vacuum pump, surface treatment for the treatment of vacuum concrete.

Application of Vacuum Concrete

- The main application of vacuum concrete is hydropower plants.

- Vacuum concrete application is a cooling tower.

- The another application of vacuum concrete is on the industrial floor, cold storages, etc.

- Vacuum concrete is widely used in bridges of ports and harbours.

Advantages of Vacuum Concrete

There are many advantages of vacuum concrete, those are:

- The one of the main advantages of vacuum concrete is the density of this concrete is higher than other concrete.

- The vacuum concrete has decreasing power of permeability; it is also one of the main advantage.

- The final strength of concrete is increased by 25% than any other concrete.

- The stiffness of this concrete is very high; that’s why the formwork is easily removed within 30 minutes and columns of the height of 20 feet.

- Vacuum concrete has a bond strength of 20% higher than other concrete.

- The one of the main advantages of this vacuum concrete is the cost of this is reasonable, so it’s economical. Vacuum concrete is mainly used in the precast factory.

- Vacuum concrete creates well bonds with older concrete; this is the main reason for using this concrete for repair purpose. This is mainly used in road slab repair.

Disadvantages of Vacuum Concrete

Here, the cons of vacuum concrete are as follows.

- One of the main disadvantages of vacuum concrete is it requires specific equipment than other concrete, so this is the main cause of the increase in the cost of concrete.

- Vacuum concrete needs more skillful labour; it’s another disadvantage.

- The initial cost of vacuum concrete is higher than the normal one.

- Vacuum concrete needs more power consumption for using special and specific equipment.

- The porosity of vacuum concrete is a little bit higher than normal concrete; for this reason, it allows to move the of substances like oil, water, grease, etc.

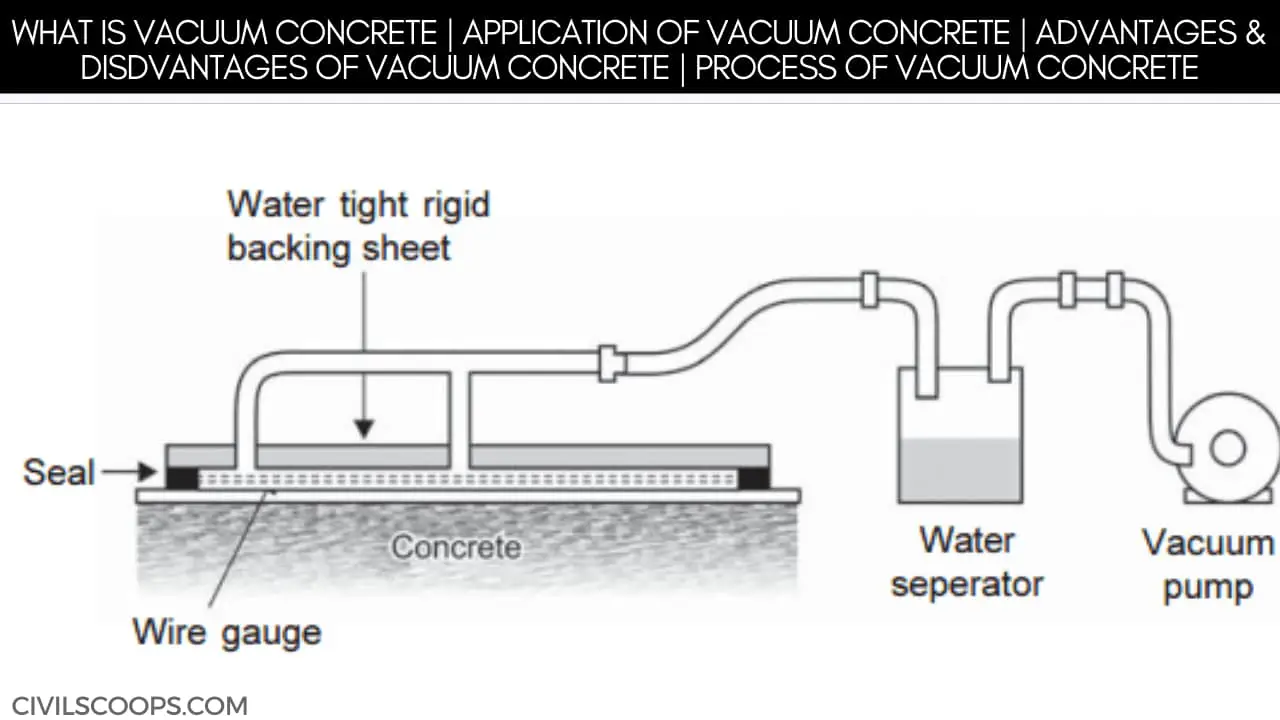

Process of Vacuum Concrete

Here, the process of vacuum concrete are as follows.

- In normal concrete, workability is the main factor to speed up the construction work, but we don’t think too much about the workability of vacuum concrete.

- In the vacuum concrete procedure, there is a huge amount of vacuum present on the top surface of the concrete.

- In vacuum concrete processing, there are a large amount of water is removed from a certain depth of the concrete.

- Vacuum concrete is constructed by laying porous mats which are connected by a vacuum pump.

- After that, the water-cement is reduced, and the concrete gains it is strength.

- Vacuum concrete has higher strength capacity, low permeability, and higher durability property, which make the concrete very effective to use.

[su_box title=”FAQ” style=”default” box_color=”#333333″ title_color=”#FFFFFF” radius=”3″ class=”” id=””]

What Is Vacuum Concrete?

Concrete that has had a vacuum applied through special mats, pads, or forms shortly after placement for the purpose of removing a portion of the mixing water not needed for the hydration of the cement.

Advantages of Vacuum Concrete

- Due to dewatering through a vacuum, both workability and high strength are achieved simultaneously.

- Reduction in water-cement ratio may increase the compressive strength by 10 to 50% and lowers the permeability.

- It enhances the wear resistance of concrete surfaces.

Application of Vacuum Concrete

- The main application of vacuum concrete is hydropower plants.

- Vacuum concrete application is a cooling tower.

- The another application of vacuum concrete is on the industrial floor, cold storages, etc.

- Vacuum concrete is widely used in bridges of ports and harbours.

Disadvantages of Vacuum Concrete

- High initial cost.

- Need trained labor.

- Need specific equipment.

- Need power consumption.

Process of Vacuum concrete

Vacuum concrete is the type of concrete in which the excess water is removed for improving concrete strength. The water is removed by the use of vacuum mats connected to a vacuum pump.

Vacuum Dewatering

Vacuum dewatering lowers the water content of a freshly placed concrete slab by 15-25 percent, increases the density, strength, and frost resistance of the slab, and decreases the slab’s absorption, abrasion, and shrinkage.

[/su_box]

[su_note note_color=”#F2F2F2 ” text_color=”#333333″ radius=”3″ class=”” id=””]

Like this post? Share it with your friends!

Suggested Read –

- Building Layout | How to Building Layout | Construction Layout Techniques

- What Is Ceramic Tiles? | Advantages & Disadvantages of Ceramic Tiles | What Is Vitrified Tiles? | Advantages & Disadvantages Vitrified Tiles | Differences Between Ceramic Tiles and Vitrified Tiles

- What Are Conceptual Sketches | Concept Sketch Definition | Use of Concept Sketches in Class | Using Concept Sketches in the Field | Architecture Concept Drawings | Difference Between Sketches and Drawings

- What Is Gable Roof | History of Gable Roofing | Gable Roof Design | Parts of Gable Roof | Types of Gable Roofs | How Long Can the Roof Last? | Gable Roof Advantages and Disadvantages | Cost of Gable Roof Construction

- Concrete Release Agent | Concrete Form Release Agent | Concrete Formwork Release Agent | Concrete Form Release Oil | Concrete Mold Release Agent | Homemade Concrete Release Agent | Concrete Release Agent for Wood | How to Keep Concrete from Sticking to Wood | Fiberglass Release Agent

[/su_note]

Originally posted 2022-07-19 14:03:02.