What Is Well Foundation | Component of Well Foundation

Table of Contents

What Is Well Foundation?

Well Foundation is a type of deep foundation that is generally provided below the water level for bridges. Cassions or well have been in use for foundations of bridges and other structures since the Roman and Mughal periods. The term ‘ cassions ’ is derived from the French word Caisse which means box or chest.

Well, foundations are used in India for centuries because of providing deep foundations below water for monuments, bridges, and aqueducts. For example, the famous Taj Mahal of Agra stands on well foundations.

Well foundations are similar to open caissons and are generally used to support bridge piers and abutments since they offer a number of advantages over other types of deep foundations for such large jobs.

The construction of a well foundation is, in principle, similar to the conventional wells sunk for obtaining underground water; in fact, it derives its name owing to this construction procedure.

It’s a monolithic and massive foundation and is relatively rigid in its engineering behavior. The plan shape of a well foundation is similar to that of a caisson.

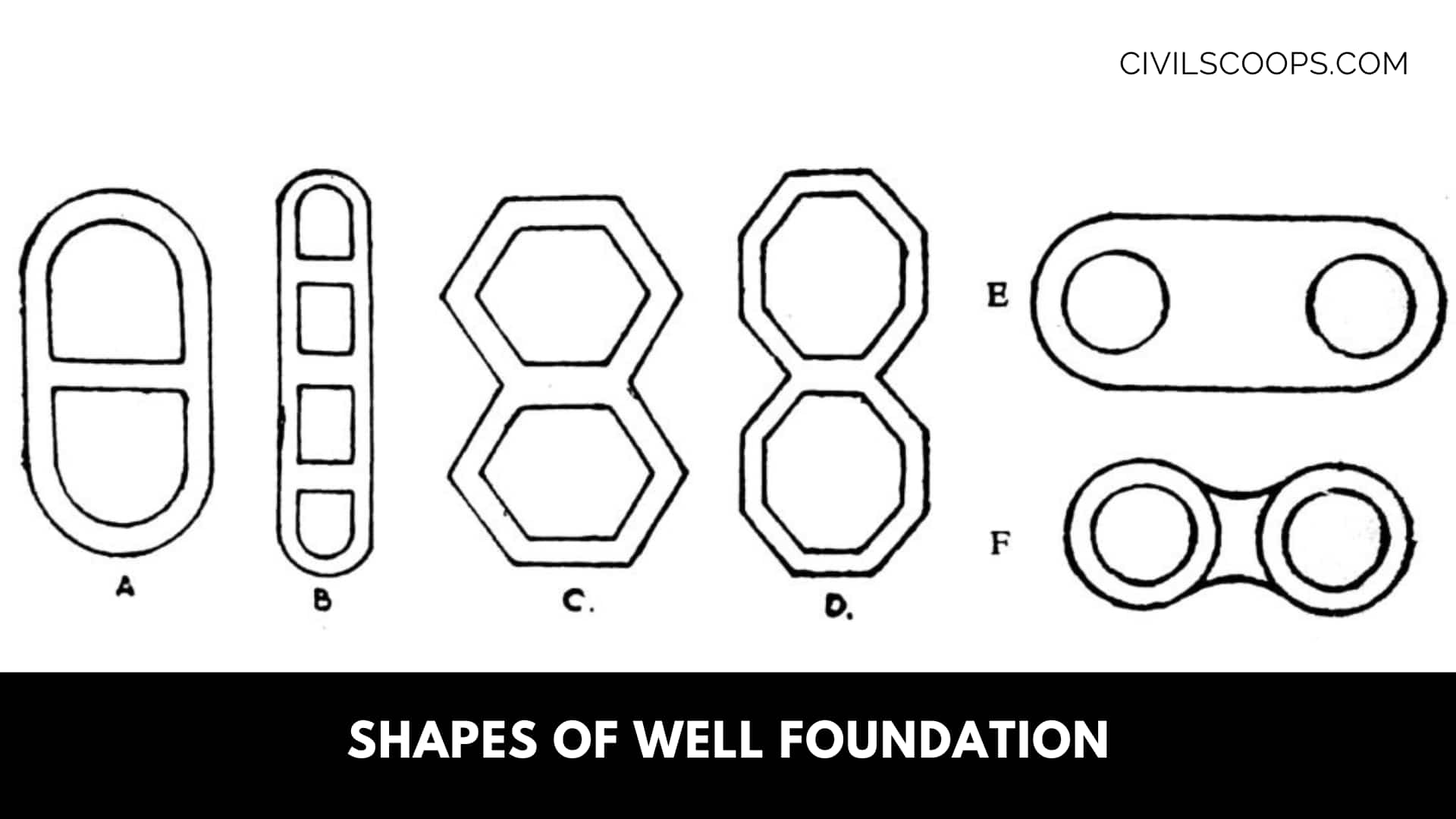

A single circular well becomes uneconomical to support a bridge pier since it must encircle the pier. In these cases, rectangular, twin-circular, twin-octagonal, or double-D sections might be used to advantage.

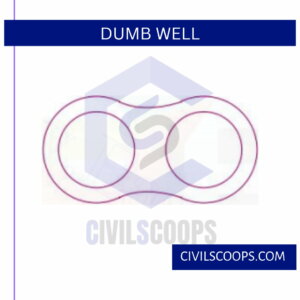

Dumb-bell and rectangular wells with multiple dredge holes arc two other types used for heavy bridge piers and abutments.

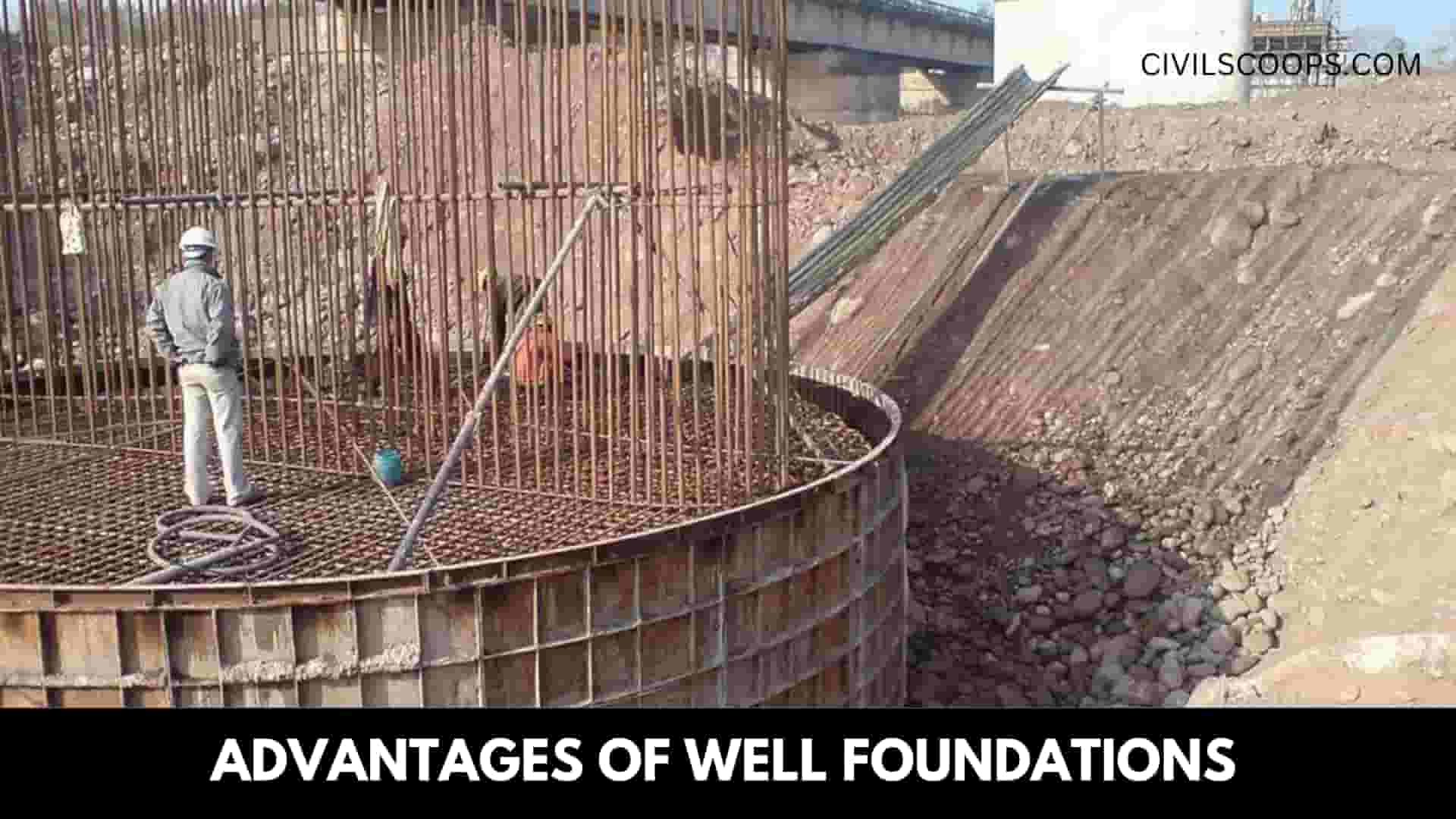

Advantages of Well Foundations

The advantages of well foundations over pile foundations are:

- A well foundation, because of its large cross-sectional area and rigidity, can withstand the effect of scouring better.

- The depth can be decided as sinking progresses, since the nature of the strata can be inspected and tested, if necessary, at any desired stage.

- Thus, it is possible to ensure that it rests upon a suitable bearing stratum of uniform nature and bearing power.

- A well foundation can withstand large lateral loads and moments that occur in the case of bridge piers, tall chimneys, and towers.

- There is no danger of damage to adjacent structures since the sinking of a well does not cause any vibrations.

Shapes Of Well Foundation

7 Different types of shapes of well foundation.

1. Single Circular well

They require only one dredger for sinking. As every point on the cutting edge is at a constant distance from the center of the dredge hole, the chances of tilting wells during the sinking are less. Circular wells can be used for piers of single-line railway or road bridges

2. Twin Circular Well

Twin Circular well

In this case, two independent circular wells are placed very close to each other and have a common well cap. The wells are sunk simultaneously. Twin-circular wells are commonly used where the length of the pier is considerable, which can not be accommodated on a double-D or double-octagonal well.

Also Read: 14 Difference Between CPM and PERT | What Is CPM | What Is PERT

3. Dumb Well

Dumb Well

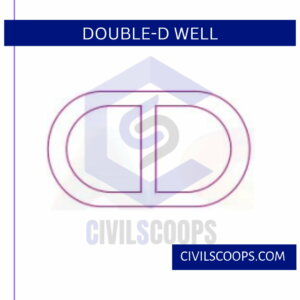

4. Double-D Well

Double – D Well

Double-D shape wells are an improvement over twin rectangular and twin circular wells and have two dredge holes each in the shape of the letter D, as shown above in fig.

The main advantage of double-D wells is their high lateral stability. When the size of the pier or abutment is large and cannot be accommodated on a single circular well economically, double-D wells will become the most economical and commonly used alternative shape.

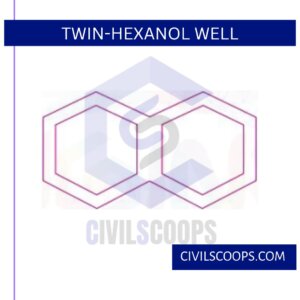

5. Twin-Hexanol Well

Twin – Hexanol Well

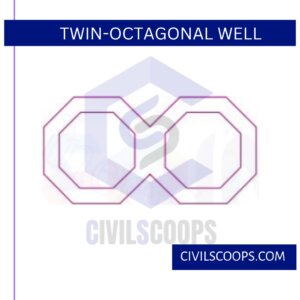

6. Twin-Octagonal Well

Twin–Octagonal Well

These wells are considered to be better than Double-D wells in numerous aspects. Most preferably the square corners are eliminated such that bending stresses are reduced considerably.

Additionally, these wells provide higher resistance against sinking than double-D wells because of increased area.

7. Rectangular Well

Rectangular Well

Rectangular wells are principally employed on bridge foundations with depths up to 7m-8m. In the case of larger foundations, double-rectangular wells can be used. The loading stresses at the steining are very high in rectangular wells.

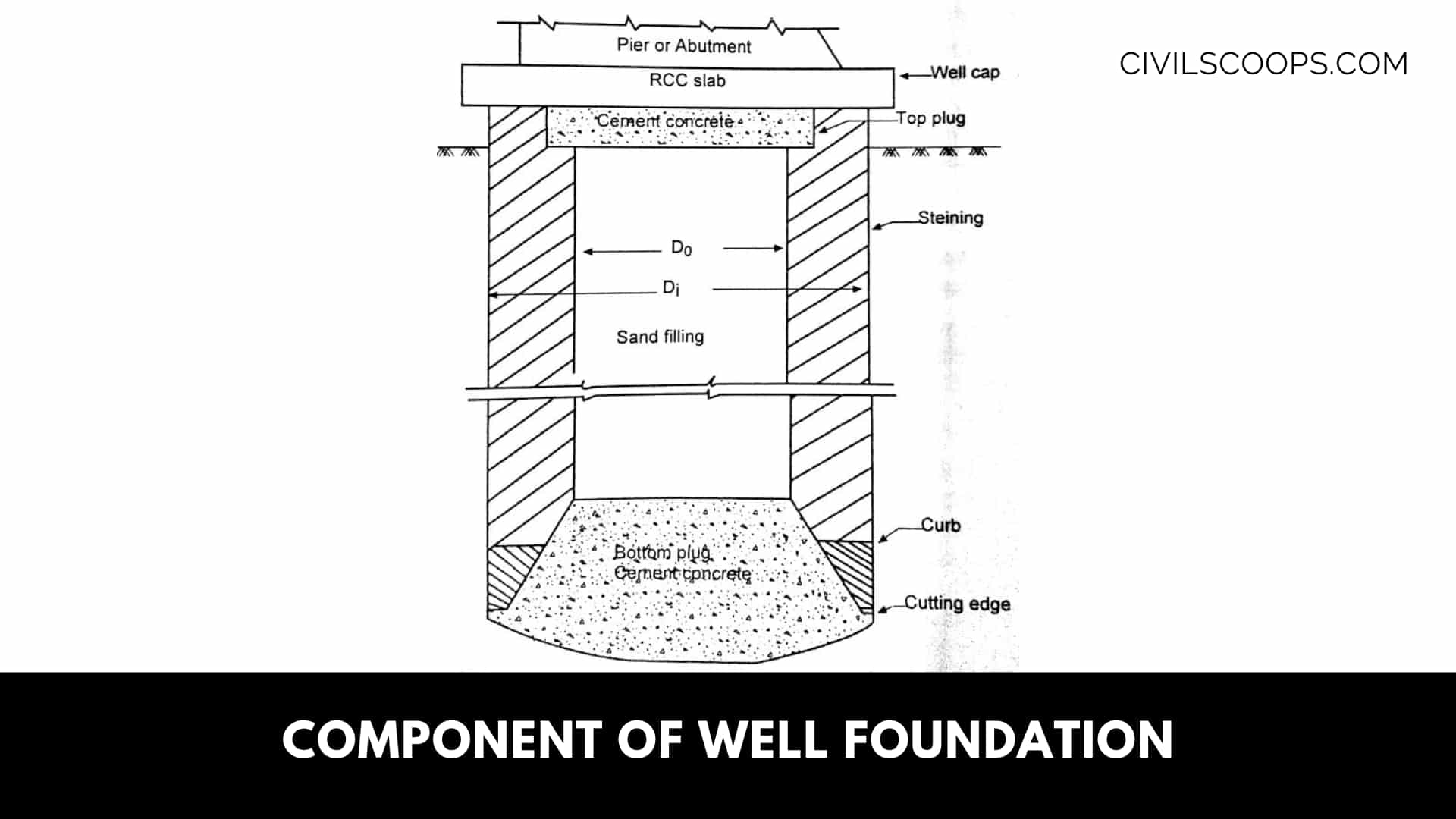

Component of Well Foundation

1. Well Curb

The well curb is designed for supporting the weight of the well with partial support at the bottom of the cutting edge, i.e. when only part of the cutting edge is in contact with soil and the remaining portion is only held by skin friction.

Three-point support of the cutting edge resting on a log may be assumed for design purposes. The load coming on the cutting edge is uncertain as a considerable part of it is borne by skin friction.

Another factor of uncertainty is in regard to the effective depth of the well curb since the entire well acts as a deep girder to resist torsion and bending.

Since the load is occasional, working stress up to 99% of yield stress may be permitted. The well curb has also to withstand stress due to sand blows, as well as due to light blasting required when a boulder obstructs the sinking of the well.

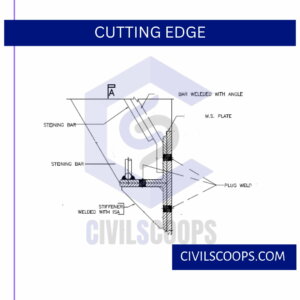

2. Cutting Edge

The cutting edge should have as sharp an angle as practicable for knifing into the soil without making it too weak to resist the various stresses induced by boulders, blows, blasting, etc.

An angle to the vertical of 30° or a slope of I horizontal to 2 verticals has been found satisfactory in practice. In concrete caissons, the lower portion of the cutting edge is wrapped with 12 mm steel plates which are anchored to the concrete by means of steel straps.

A sharp vertical edge is generally provided along the outside face of the caisson. Such an edge facilitates the rate of sinking and prevents air leakage in the case of pneumatic caissons.

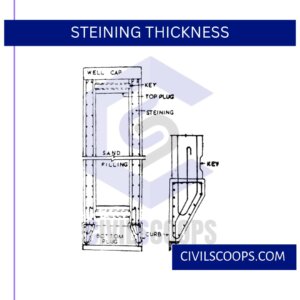

3. Steining Thickness

The thickness of steining is designed in such a way that at all stages the well can be sunk under its own weight, as the need for weighting with kentledge takes time and retards progress considerably.

For a circular well with outer diameter D and thickness I of the steining, we have

Self-weight per unit height = π ( D – t ) t ρ

Skin friction forces per unit weight = π D r ƒ

Where

ρ = unit weight of concrete or masonry of the steining

r ƒ = Unit Skin Friction

Equating the two, we get π ( D – t ) t ρ = π D r ƒ

From Which

t = D/2 * [1 – sqrt(1 – (4r_{f})/(rho*D))]

It will be seen from this equation that for a given value of skin friction, the steining thickness comes out to be less with increasing value of the diameter of the well.

This is, however, contrary to the usual practice of providing a greater thickness of steining with increasing diameter of the well as given in the following table:

[su_table responsive=”yes” alternate=”no”]

| D (Outside Dia of Wall) | t (steining thickness) |

| 3m | 0.75m |

| 5m | 1.20m |

| 7m | 2.00m |

[/su_table]

This is so because of large diameter well is taken deeper and the skin friction increases with depth. Moreover, for deeper wells, water is invariably met and the effective self-weight is reduced by buoyancy in the well below the water level, hence larger steining thickness is required.

4. Skin Friction

The unit skin friction increases with depth, and at a given depth, the skin friction is equal to the coefficient of friction which is times the lateral earth pressure.

However, it is not possible to evaluate the skin friction from laboratory tests as the lateral earth pressure depends upon a state of stress.

It is also not possible to accurately determine the value of i.t. For the purpose of design, the values of skin friction given in the following table (Terazaghi and Peck, 1948) may be used:

[su_table responsive=”yes” alternate=”no”]

| Type of Soil | Skin Friction (t/m2) |

| Silt and Soft Clay | 0.73 – 2.93 |

| Very Stiff Clay | 4.9 – 19.5 |

| Loose Sand | 1.22 – 3.42 |

| Dense Sand | 3.42 – 6.84 |

| Dense Gravel | 4.9 – 9.4 |

[/su_table]

Greater skin friction requires greater sinking efforts, and hence retards the sinking of the well. Hence, methods should be used to reduce skin friction while sinking the well.

Since the frictional resistance depends on the roughness of the surface of contact, a smoothly plastered well steining surface that is in a true plane without kinks or warps will considerably reduce skin friction.

Skin friction is also reduced by flaring the well. In order to reduce skin friction on the San Francisco Oakland Bay Bridge, a coating that gave a smooth oily surface and which was tough enough not to be rubbed off during the sinking process was used on the walls of the caissons and it was estimated that this reduced the friction between the concrete and fairly stiff clay by roughly 40%.

It has also been reported that bentonite solution injected on the external surface considerably reduces skin friction.

5. Bottom Plug

The bottom plug of concrete is to be designed for an upward load equal to the soil pressure (including the pore pressure) minus the self-weight of the bottom plug and filling.

The bottom plug is made bowl-shaped so as to have an inverted arch action. As generally under-water concreting has to be done for the bottom plug, and no reinforcement can be provided.

The bottom plug is generally designed as a thick plate subjected to a unit bearing pressure under the maximum vertical load which is transmitted from the vertical walls of the well.

Based on the theory of elasticity, the thickness of the bottom plug is as follows:

12= 3w -(3+)=1.18 R (For Circular Wells)

and

t ^ 2 = (3q * b ^ 2)/(4f_{c}(1 + 1.61alpha))

Where,

t = Thickness of the concrete or steel plug

W = Total bearing pressure on the base of the well

ƒc = Flexural strength of a concrete seal

μ = Poisson’s ratio = 0.15 for concrete

R = Radius of well base

q = Unit bearing pressure against the base of well

b = Width or short side of the well

∝ = Width/length or, Short side / long side of well.

[su_box title=”FAQ” style=”default” box_color=”#333333″ title_color=”#FFFFFF” radius=”3″ class=”” id=””]

What Is Bore Well?

A pipe that is put into a hole that has been bored in the ground, and used with a pump in order to get water from under the ground.

What Is a Shared Well?

By definition, a shared well is a well that services more than one home whether its for residential or irrigation purposes.

What Is a Domestic Well?

Domestic well means a groundwater well used to supply water for the domestic needs of an individual residence or a water system that is not a public water system and that has no more than four service connections.

What Is a Private Well?

Private wells are wells that are not part of a public water supply. Private wells have fewer than 15 connections and serve fewer than 25 people. They are usually wells that serve a single home or farmhouse.

What a Well?

A well is a hole drilled into the ground to access water contained in an aquifer. A pipe and a pump are used to pull water out of the ground, and a screen filters out unwanted particles that could clog the pipe.

What Is the Average Gallons Per Minute for a Well?

5 gpm (two fixtures running simultaneously at 2.5 gpm) is a good estimate of peak demand, for the typical household. Water wells that reliably yield 5 gpm should be able to meet peak and daily needs for most residences. Wells yielding less than 5 gpm, however, are sometimes the only water source available.

What Is a Cistern Well?

A cistern (from Middle English cisterne; from Latin cisterna, from cista ‘box’; from Ancient Greek κίστη (kístē) ‘basket’) is a waterproof receptacle for holding liquids, usually water. Cisterns are often built to catch and store rainwater. Cisterns are distinguished from wells by their waterproof linings.

What Causes Mud in Well Water?

Your well pump could have been installed incorrectly, sucking up mud and other particles instead of just water. It’s also possible that your pump is not adequately sized for your use case. Pumps that are too large or too small can both lead to additional contamination making its way into your well water.

What Does a Well Do?

Well is a hole drilled into the ground to access water contained in an aquifer. A pipe and a pump are used to pull water out of the ground, and a screen filters out unwanted particles that could clog the pipe.

What Causes a Well to Run Dry?

The pump may be broken or clogged, there may be a fault with the electrical system or a leak in a pipe may be preventing the well water from reaching the house. Minerals can also build up inside the well, decreasing the quality and quantity of the water that flows.

What Is the Purpose of a Well?

Wells are extremely important to all societies. In many places wells provide a reliable and ample supply of water for home uses, irrigation, and industries. Where surface water is scarce, such as in deserts, people couldn’t survive and thrive without groundwater, and people use wells to get at underground water.

What Is Considered a Shallow Well?

A shallow well is a hole which has been dug, bored, driven or drilled into the ground for the purpose of extracting water is a well. A well is considered to be shallow if it is less than 50 feet deep. The source of a well is an aquifer.

What Is in Well Water?

Heavy metals include: arsenic, antimony, cadmium, chromium, copper, lead, selenium and many more. Heavy metals can contaminate private wells through groundwater movement and surface water seepage and run-off.

What Causes Well Water to Be Brown?

When water collects and remains in iron pipes too long, it can create what is known as iron water. A proliferation of iron causes water, sink, and clothing stains and impacts your water’s taste, smell, and appearance. One form of iron water is manganese, which causes brown or black tints to water and a bitter taste.

What Causes Green Stains from Well Water?

If you notice blue-green stains in your sinks, showers or other areas that heavily use water, your water likely has a low pH value which means your water is slightly acidic. When water is acidic, the water can cause water pipes made of copper and lead to corrode and leach metals into your water.

What to Do with an Old Water Well?

All abandoned wells should be properly closed to protect groundwater and community health and safety. In fact, landowners are required under the state well code to plug their abandoned wells. Common materials used to properly close wells include bentonite clay, neat cement or concrete grout.

What Does It Cost to Drill a Well?

On average, drilling a water well costs $3,500–$15,000, depending on several geological and technological factors. You may be able to dig a shallow well yourself, but it’s best to hire a professional contractor for a well that will provide water for an entire home.

Well Foundations

Well foundation is a type of deep foundation which is generally provided below the water level for bridges. Cassions or well have been in use for foundations of bridges and other structures since Roman and Mughal periods. The term ‘cassion’ is derived from the French word caisse which means box or chest.

Well Curb

A stone surround at the top of a well.

What Happens When Well Runs Dry?

Running the well pump when there isn’t water to pump can damage the pump itself which can cause it to burn out prematurely

How Does a Home Well Work?

Wells get drilled as far down as 1,000 feet into the rock to access the water. Pipe casing gets installed into the hole, and a concrete or clay sealant surrounds it to protect against contaminants. Water travels through this casing via a well pump. The well system gets capped off above ground.

How Deep Well Works?

Deep-well submersible pumps use pressure tanks to suction water via one pipe that connects the inside well to your house. These pumps can take in water from depths as low as 400 feet below ground, but one potential downside is that repairs require removal from the well casing.

How a Well Works?

Well is a hole drilled into the ground to access water contained in an aquifer. A pipe and a pump are used to pull water out of the ground, and a screen filters out unwanted particles that could clog the pipe.

How Does Well Water Work?

Well water is water that comes from a hole dug deep into the ground, which reaches groundwater from an aquifer (a layer of water-bearing rock or sediment) far below the surface. This groundwater is the well water’s supply, and it’s brought up to homes using a pump or bucket.

How Does a Well System Work?

Water travels through this casing via a well pump. The well system gets capped off above ground. The water then enters your home from a pipe connected between the casing and a pressure tank (generally located in your home’s basement). From there, it gets distributed to faucets throughout your home.

How Well Pumps Work?

Well pumps can work in one of two ways: by pushing water up a pipe or using suction to pull it from underground. Well pumps are activated by a well pressure switch, a device that sends a signal to the pump when water pressure inside a well pressure tank becomes too high or low.

[/su_box]

[su_note note_color=”#F2F2F2 ” text_color=”#333333″ radius=”3″ class=”” id=””]

Like this post? Share it with your friends!

Suggested Read –

- 10 Construction Certifications and Where to Get Them

- What Is Hardened Concrete | Properties of Hardened Concrete

- What Is Plaster | Types of Plaster As Per Material | Defects In Plastering

- What Are Hollow Bricks | Advantage of Hollow Bricks | Disadvantage of Hollow Bricks | Sizes of Bricks Blocks | How to Make Hollow Bricks

- What Is Fire Escape Staircases | Types of Fire Escaping Stairs | What Is the Importance of Fire Escape in the Building | What Are the Fire Staircase Requirements

[/su_note]

Originally posted 2023-03-19 10:49:21.