What Is Pneumatic Structures | Types of Pneumatic Structures | Advantages & Disadvantages of Pneumatic Structures | Uses of the Pneumatic Structures

Table of Contents

What Is Pneumatic Structures?

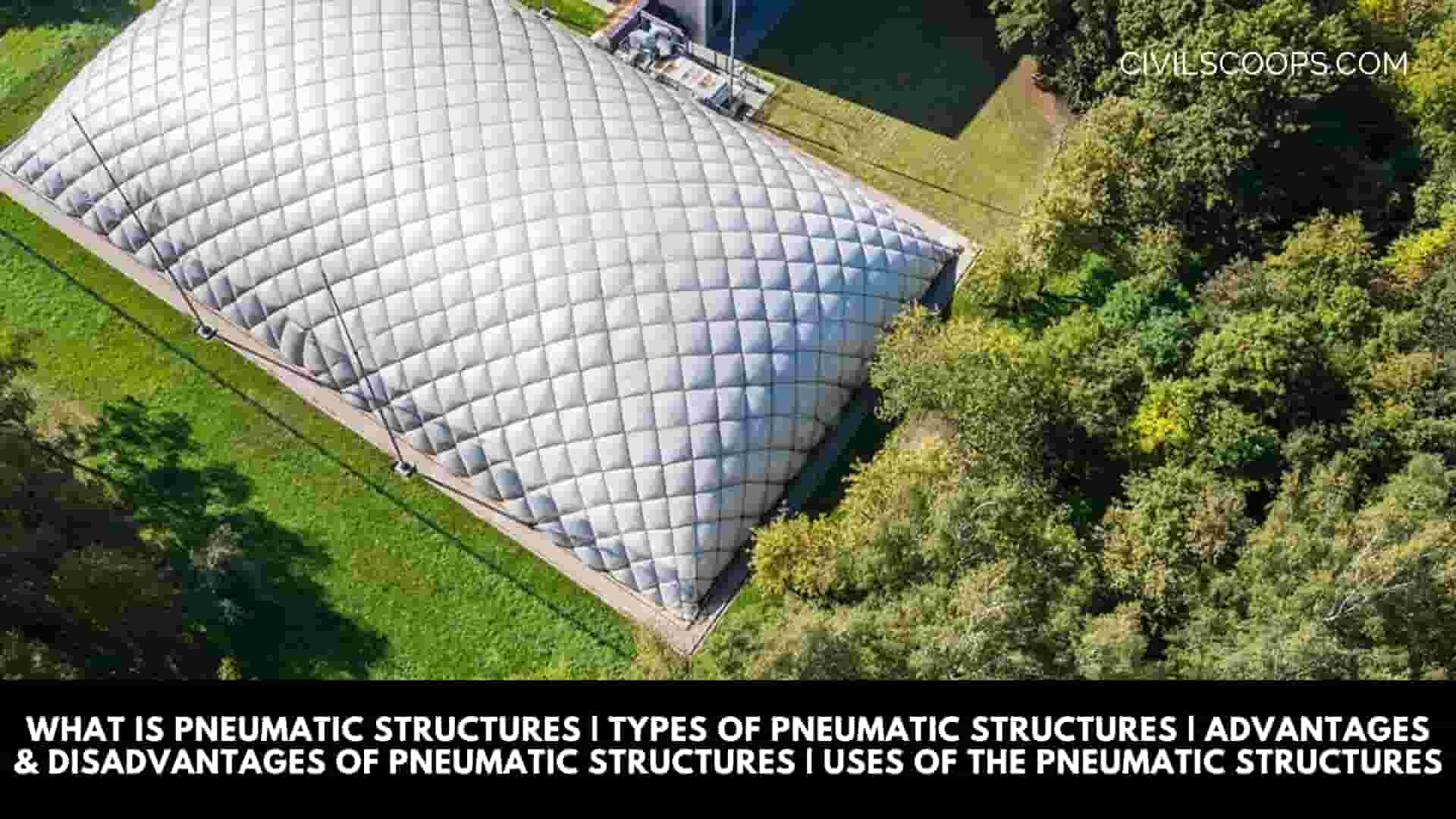

Pneumatic Structures are a special type of structure that is generally characterized by the slightly higher air pressure of internal surroundings.

The word ‘Pneumatic’ means structures that are constructed with the support of Air Pneumatic structures were introduced in Building Technology about 40 years ago.

The pneumatic structure is a membrane structure that is stabilized with the help of compressed air. Pneumatic structures are a very cost-effective type of building for a longer span.

The roof of the pneumatic structures is made from rubber or enforced film with the help of polymers. The weight of the roofing membrane is balanced and maintained with the help of air compressors or blowers.

Pneumatic structures are environment-friendly structures. In the construction of Pneumatic structures, the pressure difference between the enclosed space and the exterior is responsible for the building for its shape and stability.

Pneumatic structures are the combination of two components with different properties which is an airtight membrane and compressed air.

One of the Disadvantages of pure pneumatic structures is that they required high air pressure to maintain their shape. The pneumatic structures are generally made from laminated membranes such as nylon, fiberglass polyester, silicon rubber, etc.

The shape of the Pneumatic structure is round because it creates a larger volume for less amount of material. The pneumatic structure is a membrane that can carry the total load developed from the tensile stresses.

The stabilization of the Pneumatic structure is done with the help of pre-stressing of the membrane. The pre-stressing of the membrane is done by applying an external force to put the membrane.

Pneumatic architecture structures are used widely for the construction of permanent as well as temporary structures. Pneumatic structures can develop an artificial environment that is adaptable to humans. The foundation required for the Pneumatic structure is secured to the ground using Heavyweights.

The material which is used for the envelope is as follows.

- Fibreglass which has high tensile strength and durability

- Polyester or PVC-coated polyester which is flexible.

- Nylon or vinyl-coated nylon has more strength and durability.

Principle of Pneumatic Structures

- The principle of the Pneumatic structure is the use of a very thin membrane that is supported by a pressure difference.

- The Dead weight of the space available in the envelope is balanced by increasing the inside air pressure.

- The thin membrane gets stressed to the point where it cannot be indented by the asymmetrical loading.

Types of Pneumatic Structures

There are mainly two types of Pneumatic structures

- Air-supported pneumatic structures

- Air-inflated pneumatic structures

1. Air Supported Pneumatic Structures

Air-supported structures have Air higher than the atmospheric pressure supporting the envelope. Air-supported inverter structures are supported by internal air pressure and the use of a network of cable stiffen the fabric.

The lifespan of the Air supported structures is 20 to 25 years. The Air supported Pneumatic structures have a relatively low cost. The Internal pressure in the air-supported structures is maintained above the Normal atmospheric pressure with the help of compressors or fans.

It should be provided with Airlocks which are required to prevent the loss of internal air pressure.

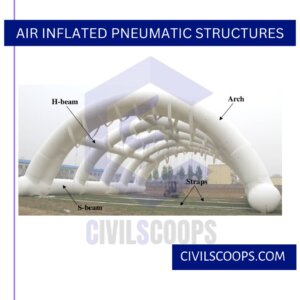

2. Air Inflated Pneumatic Structures

Air-inflated structures are supported by pressurized air which is contained with an inflated building element. Air-inflated structures are supported with the help of pressurized air within inflated building elements in the different shapes that will carry the loads.

In air-inflated structures, the air under high pressure fills only the supporting elements of the pneumatic structure. The internal pressure of the air Inflated structures remains at the atmospheric pressure.

Characteristics of the Pneumatic Structures

Pneumatic structure, Membrane structure that is stabilized by the pressure of compressed air.

Air-supported structures are supported by internal air pressure. A network of cables stiffens the fabric, and the assembly is supported by a rigid ring at the edge.

List of Characteristics of the Pneumatic Structures

- Weight of the Pneumatic Structures

- The Span of the Cinematic Structures

- Safety of the Parametric Structures

- The Time Required for Construction of Pneumatic Structures

Also Read: Steel Is Most Trusted TMT Bar in India?

Weight of the Pneumatic Structures

- The Pneumatic structures are lightweight.

- The weight of the Pneumatic structures as compared to the area on which it is constructed is very less.

- The lower pressure is sufficient to balance it.

The Span of the Cinematic Structures

- There is no theoretical maximum span for the Pneumatic structure. It varies as per the need and the design.

Safety of the Parametric Structures

- Pneumatic structures are safer as compared to conventional building structures.

- Cinematic structures are fire-resistant.

The Time Required for Construction of Pneumatic Structures

- Pneumatic structures can be quickly erected and dismantled.

- Pneumatic structures are suitable for the construction of temporary buildings.

- Good Natural lighting and ventilation can be provided in the Pneumatic Structures.

- The pressure of the Pneumatic structures ranges from 80-100 mm.

Advantages of Pneumatic Structures

The Advantages of the Pneumatic structures are as follows.

- Pneumatic structures are lightweight

- Pneumatic structures can cover a larger area of span without any type of internal support.

- Pneumatic structures are economical as compared to other structures.

- The construction and assembly of the Pneumatic structures are very fast.

- Pneumatic structures can be used to construct a whole structure as an entity.

- Pneumatic structures can be used for both temporary as well as permanent structures for various purposes.

- The initial cost of construction of Pneumatic structures is less as compared to a conventional building.

- The operation cost of periodic structures is also less than compared of a conventional building.

Disadvantages of Pneumatic Structures

The Disadvantages of Pneumatic structures are as follows

- Pneumatic structures are less durable and have a short service life.

- Pneumatic structures are poor resistance to fire and acoustic insulation.

- The enclosed membrane of the Pneumatic structures required maintenance of excess pressure.

Uses of the Pneumatic Structures

The various uses of pneumatic structures are as follows

- Pneumatic structures can be used for mobile buildings such as maintenance stations, camps medical aid stations, etc.

- Pneumatic structures can be used for permanent as well as temporary buildings for various purposes like seminar halls, production areas and Godowns, stadiums, etc.

- Pneumatic Structures are examples the Military structures which are used for storage and other emergency medical operations.

- Structures for Botanical gardens or zoological gardens.

Also Read: WPC Board Vs Plywood | Which Should Be a Better Choice | What Is WPC Board | What Is Plywood

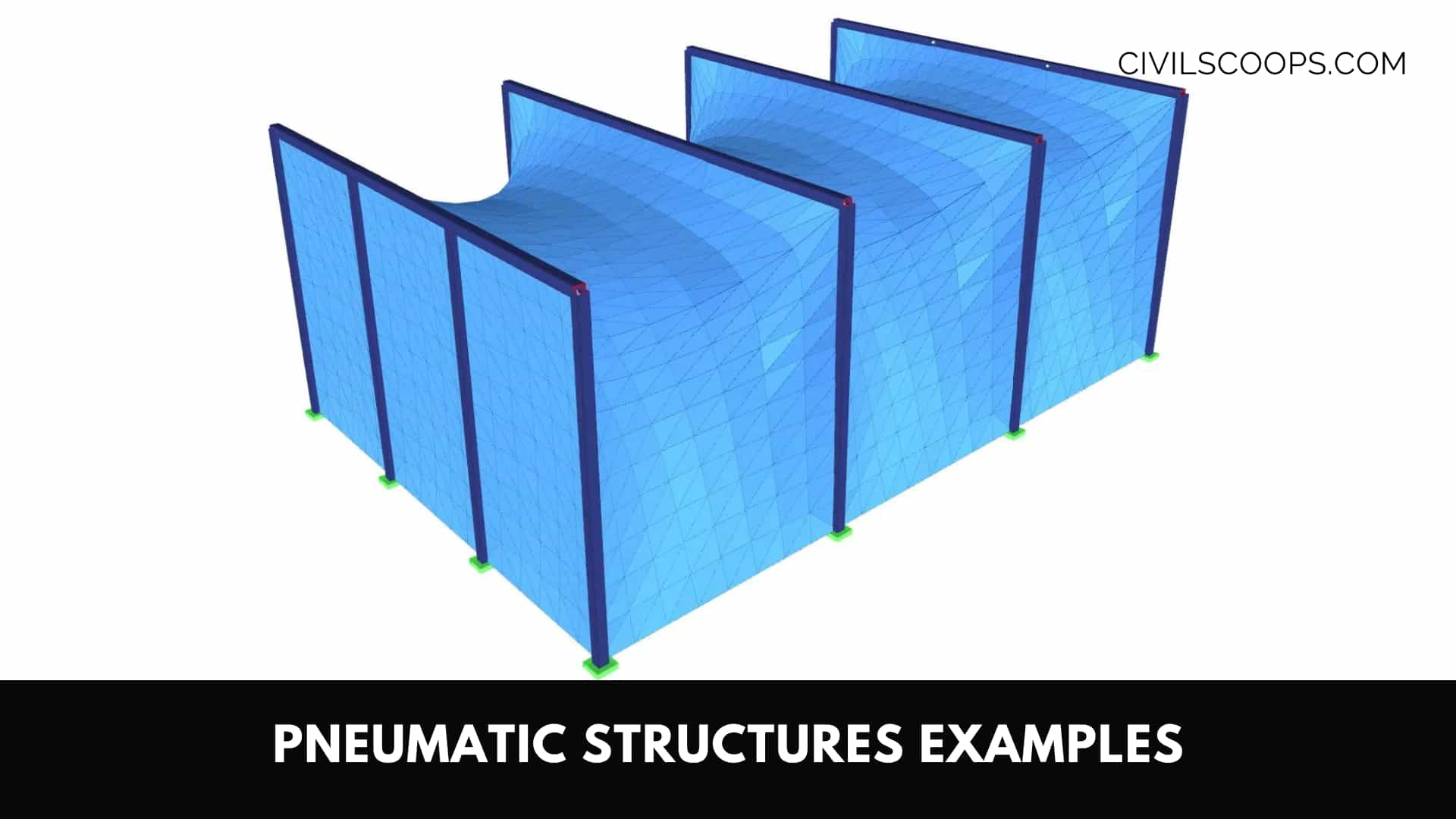

Pneumatic Structures Examples

There are various examples of pneumatic structures as follows

- The pneumatic roof is the roof with the largest span without the support of columns. This type of rule is very helpful for climate control.

- The Pneumatic structure example is the Syracuse Carrier Dome.

- The Allianz Arena stadium in Germany is the largest pneumatic structure

[su_box title=”FAQ” style=”default” box_color=”#333333″ title_color=”#FFFFFF” radius=”3″ class=”” id=””]

Pneumatic Structures Examples

- Pneumatic structure.

- Membrane structure.

- Pneumatic cushion.

- Pneumatic cushions.

- Air hall.

- ETFE.

- Low-pressure system.

- High-pressure system.

Air Supported Pneumatic Structures

Air-supported structures are supported by internal air pressure. A network of cables stiffens the fabric, and the assembly is supported by a rigid ring at the edge. The air pressure within this bubble is increased slightly above normal atmospheric pressure and maintained by compressors or fans.

Pneumatic Structures Architecture

pneumatic structure, Membrane structure that is stabilized by the pressure of compressed air. Air-supported structures are supported by internal air pressure. A network of cables stiffens the fabric, and the assembly is supported by a rigid ring at the edge.

Air-Supported Structures Examples

Air-supported structures are secured by heavy weights on the ground, ground anchors, attachment to a foundation, or a combination of these. Among its many uses are: sports and recreation facilities, warehousing, temporary shelters, and radomes.

Air-Inflated Pneumatic Structures

Air-inflated structures are supported by pressurized air within inflated building elements that are shaped to carry loads in a traditional manner. Pneumatic structures are perhaps the most cost-effective type of building for very long spans.

[/su_box]

[su_note note_color=”#F2F2F2 ” text_color=”#333333″ radius=”3″ class=”” id=””]

Like this post? Share it with your friends!

Suggested Read –

- 10 Construction Certifications and Where to Get Them

- What Is Hardened Concrete | Properties of Hardened Concrete

- What Is Plaster | Types of Plaster As Per Material | Defects In Plastering

- What Are Hollow Bricks | Advantage of Hollow Bricks | Disadvantage of Hollow Bricks | Sizes of Bricks Blocks | How to Make Hollow Bricks

- What Is Fire Escape Staircases | Types of Fire Escaping Stairs | What Is the Importance of Fire Escape in the Building | What Are the Fire Staircase Requirements

[/su_note]

Originally posted 2023-03-21 10:54:44.